Solcon RVS-DN 8 User manual

R

RV

VS

S-

-D

DN

N

D

Di

ig

gi

it

ta

al

l

S

So

of

ft

t

S

St

ta

ar

rt

te

er

r

8

8-

-3

30

00

00

0A

A,

,

2

22

20

0-

-1

12

20

00

0V

V

I

In

ns

st

tr

ru

uc

ct

ti

io

on

n

M

Ma

an

nu

ua

al

l

Ver. 14/06/2009

2 • Table of content

__________________________________________________________________________________

RVS-DN Instruction Manual

1. TABLE OF CONTENT

1. Table of content........................................................................................................................2

2. Safety & Warnings....................................................................................................................5

2.1 Safety..........................................................................................................................................5

2.2 Attention......................................................................................................................................5

2.3 Warnings.....................................................................................................................................5

3. Technical Data ..........................................................................................................................6

3.1 Introduction .................................................................................................................................6

3.2 Rated Currents and Frame Sizes ...............................................................................................8

3.3 RVS-DN Selection ......................................................................................................................8

3.3.1 Motor Current and Starting Conditions............................................................................8

3.4 Mains and Control Description....................................................................................................9

3.5 Input/Output Indication..............................................................................................................13

3.5.1 Preparation for Bypass Contactor .................................................................................14

3.5.1.1 Maintaining Current Protection after Bypass Closes..............................................14

3.5.1.2 Maintaining Current Protection after Bypass Closes - RVS-DN 950-3000a...........15

3.5.2 Input Terminal 7 - Energy Save/Slow Speed/Reset......................................................16

3.5.3 Input Terminal 8 - Dual Adjust/Reverse/Reset..............................................................16

3.5.4 Output Terminals 10, 11 & 12 – Immediate/Shear Pin Relay .......................................16

3.6 Ordering Information.................................................................................................................18

4. Recommended Wiring diagrams...........................................................................................19

4.1 Terminal 21 Connections With Various Mains..........................................................................19

4.2 Control Supply, Control Input and Mains are From the Same Source, Neutral Connected to

Terminal 21......................................................................................................................................20

4.3 Control Supply and Control Input From the Same Source, Neutral not Connected to Terminal 21

20

4.4 Control Supply and Control Input from Separate Sources........................................................21

4.5 Soft Start, Soft Stop and Stop, Control Supply and Control Input from the Same Source .......21

4.6 Soft Start, Soft Stop and Stop, Control Supply and Control Input from Separate Sources ......21

4.7 Soft Start and Immediate Stop (no Soft Stop) ..........................................................................22

4.8 Soft Start and Soft Stop ............................................................................................................22

4.9 Soft Start, Soft Stop and Immediate Stop.................................................................................22

4.10Energy Save, Slow speed or Reset ..........................................................................................23

4.11Slow Speed and Slow Speed Reverse .....................................................................................23

4.12External Fault............................................................................................................................24

4.13Line Contactor ..........................................................................................................................24

4.14Bypass Contactor .....................................................................................................................25

4.15Reversing with Two Line Contactors ........................................................................................26

4.16Operating via Communication Links .........................................................................................27

4.17D.ADJ.:GENERATOR PARAMETERS Wiring..........................................................................28

4.18Short Circuit Protection.............................................................................................................29

4.19Transient Protection..................................................................................................................29

4.20UL, cUL Installation Instructions ...............................................................................................29

4.21LR Recommendations for Marine, Off-shore or Industrial Use.................................................30

4.22Inside Delta Mode.....................................................................................................................30

4.22.1 General Information ......................................................................................................30

4.22.2 Notes on Inside Delta Connection.................................................................................31

4.22.3 Motor Connection and Terminals ..................................................................................31

4.22.4 RVS-DN Connected Inside Delta w/Bypass Contactor and Inside Delta Contactor .....32

4.22.5 RVS-DN Connected Inside Delta - Reverse Speed ......................................................33

3•Table of content

__________________________________________________________________________________________

5. Dimensions .............................................................................................................................34

5.1 Standard Models.......................................................................................................................34

5.1.1 Control Module Dimensions ..........................................................................................45

5.2 RVS-DN 1000V and RVS-DN 1200V Models...........................................................................46

5.3 UL/cUL/Marine Models .............................................................................................................47

6. Installation...............................................................................................................................54

6.1 Prior to Installation ....................................................................................................................54

6.2 Mounting ...................................................................................................................................54

6.3 Temperature Range & Heat Dissipation ...................................................................................54

6.3.1 Forced Ventilation .........................................................................................................55

6.3.2 Calculating the Enclosure Size, for Non-Ventilated Metal Enclosure............................55

6.4 Main PCB and Optional PCBs ..................................................................................................55

6.5 Dip Switch Settings on the Main PCB.......................................................................................56

6.5.1 Switch # 1 – Display Modes ..........................................................................................56

6.5.2 Switch # 2 – Tacho Feedback (0-10VDC).....................................................................57

6.5.3 Switch # 3 – Main/D.ADJ.:GENERATOR PARAMETERS............................................57

6.5.4 Switches # 5, 6 – Language Selection ..........................................................................57

6.5.5 Switch # 7 – Expanded Settings ...................................................................................58

6.5.6 Switch # 8 – Software Lock...........................................................................................58

6.6 Internal Fan Control ..................................................................................................................58

6.7 Analog I/O (Option 5) (Terminals T1, T2, Gnd, Out (-), Out (+))..............................................59

6.8 Remote Key-Pad Installation ....................................................................................................60

7. Control Keypad.......................................................................................................................61

7.1 LCD Arrangement.....................................................................................................................61

7.2 Push-Buttons ............................................................................................................................61

7.3 Status LEDs..............................................................................................................................62

7.4 Reviewing and Modifying Parameters ......................................................................................62

7.5 Special Actions Performed in TEST/MAINTENANCE Mode ....................................................62

7.5.1 Run Self Test ................................................................................................................62

7.5.2 View Software Version ..................................................................................................63

7.5.3 Obtain Default Parameters............................................................................................63

7.5.4 Reset Statistical Data....................................................................................................63

7.5.5 Calibrate Voltage and Current (Factory Use Only!) ......................................................64

7.5.6 TEST/MAINTENANCE in RVS-DN 1000V and RVS-DN 1200V...................................64

7.6 Mode Pages..............................................................................................................................65

7.7 Overview of All Mode Pages and Factory Defaults ..................................................................66

7.7.1 Display Mode – Page 0 .................................................................................................68

7.7.2 Main Parameters – Page 1 ...........................................................................................69

7.7.2.1 Overload Calculation..............................................................................................71

7.7.3 Start Parameters – Page 2............................................................................................72

7.7.3.1 Soft Start Parameters.............................................................................................75

7.7.4 Stop Parameters – Page 3............................................................................................77

7.7.4.1 Soft Stop Parameters.............................................................................................78

7.7.5 Dual Adjustment Parameters – Page 4.........................................................................79

7.7.6 Energy Save & Slow Speed Parameters – page 5 .......................................................80

7.7.7 Fault Parameters – Page 6 ...........................................................................................81

7.7.8 I/O Programming Parameters – Page 7........................................................................83

7.7.8.1 Terminal 7 and 8 Programming..............................................................................84

7.7.9 Comm. Parameters – Page 8 – With the Modbus Card................................................85

7.7.10 Comm. Parameters – Page 8 – With the Profibus Card ...............................................85

7.7.11 Statistical Data – page 9 ...............................................................................................86

7.8 Non Adjustable Protection and Fault Reset..............................................................................87

7.8.1 Under/Over Frequency..................................................................................................87

7.8.2 Phase Loss ...................................................................................................................87

7.8.3 Phase Sequence...........................................................................................................87

7.8.4 Wrong Connection ........................................................................................................87

7.8.5 Shorted SCR .................................................................................................................87

4 • Table of content

__________________________________________________________________________________

7.8.6 Heat-Sink Over Temperature ........................................................................................87

7.8.7 External Fault ................................................................................................................87

7.8.8 Fault and Reset.............................................................................................................87

7.8.9 Auto Reset ....................................................................................................................88

7.9 Timing Occurrence Table .........................................................................................................88

8. Starting Procedure .................................................................................................................89

8.1 Standard Starting Procedure ....................................................................................................90

8.2 Examples of Starting Curves ....................................................................................................91

8.2.1 Light Loads - Pumps, Etc. .............................................................................................91

8.2.2 High Inertia Loads: Crushers, Centrifuges, Mixers, Etc. ...............................................91

8.2.3 Special Starting Using DUAL ADJUSTMENT ...............................................................92

8.2.3.1 Special Starting – Using DUAL ADJUSTMENT – Wiring Diagram ........................92

8.2.4 Choosing a Suitable Pump Curve (Centrifugal Pumps) ................................................93

8.2.4.1 Starting Curve ........................................................................................................93

8.2.4.2 Stopping Curve ......................................................................................................93

8.2.4.3 FINAL TORQUE During Soft-Stopping a Pump Motor...........................................94

9. Trouble Shooting....................................................................................................................95

9.1 Warranty Claim and Fault Inquiry .............................................................................................98

10. Technical Specifications........................................................................................................99

5 • Safety & Warnings

__________________________________________________________________________________________

2. SAFETY & WARNINGS

2.1 Safety

1 Read this manual carefully before operating the equipment and follow its

instructions.

2 Installation, operation and maintenance should be in strict accordance

with this manual, national codes and good practice.

3 Installation or operation not performed in strict accordance with these

instructions will void manufacturer’s warranty.

4 Disconnect all power inputs before servicing the soft starter and/or the

motor.

5 After installation, check and verify that no parts (bolts, washers, etc.)

have fallen into the power section of the RVS-DN.

6

During shipping, the RVS-DN might have been roughly handled,

therefore, it is recommended to initialize the RVS-DN by connecting

supply voltage prior to operating the RVS-DN with a motor.

2.2 Attention

1 This product was designed for compliance with IEC 60947-4-2 for class A

equipment.

2 RVS-DN 8 - 820 are UL approved (when this option is specified). RVS-

DN 950 - 3000 are designed to meet UL requirements.

3

RVS-DN 8 - 1400 are LR approved (when this option is specified). RVS-

DN 1800 - 3000 are designed to meet LR requirements (when this option

is specified).

4

Use of the product in domestic environments may cause radio

interference, in which case the user may be required to employ additional

mitigation methods.

5 Utilization category is AC-53a or AC53b, Form 1. For further information,

see Technical Specification.

2.3 Warnings

1

Internal components and PCBs are at mains potential when the RVS-DN

is connected to mains. This voltage is extremely dangerous and contact

with it will cause death or severe injury.

2

When the RVS-DN is connected to mains full voltage may appear on the

RVS-DN’s output terminals and motor’s terminals, even if control

voltage is disconnected and motor is stopped.

3 The RVS-DN must be grounded to ensure correct operation, safety and

to prevent damage.

4 Check that Power Factor capacitors are not connected to the output side

of the RVS-DN.

5 Do not interchange line and load connections.

The company reserves the right to make any improvements or modifications to its products without

prior notice.

6 • Technical Data

_____________________________________________________________________________________________

3. TECHNICAL DATA

3.1 Introduction

The RVS-DN is a highly sophisticated and reliable soft starter designed for use with standard three-phase,

three-wire and six-wire, squirrel cage induction motors. It provides the best method of reducing current and

torque during motor starting.

The RVS-DN starts the motor by supplying a slowly increasing voltage to the motor. This provides soft start

and smooth, stepless acceleration while drawing the minimum current necessary to start the motor.

The third generation, microprocessor based digital control provides unique features like pump control, slow

speed, electronic reversing and accurate motor protection. RVS-DN models can be supplied with options for

insulation protection, thermistor input & analog output, etc.

The optional RS 485 Communication with Modbus protocol or the optional Profibus protocol enables full

control (START, STOP, DUAL ADJUST, Command, etc.) and supervision.

Advantages at a Glance

Complete line 8-3000A, 220-1200V

Heavy duty, fully rated design

Robust construction

Superior starting & stopping characteristics

Comprehensive motor protection package

User friendly

Line or Inside Delta connection

Rated ambient temperature: 50°C

Unique optional features including:

Motor insulation tester

RS 485 comm. Modbus / Profibus

Thermistor input / analog output

Starting & Stopping

Soft start & soft stop

Current limit

Pump control program

Torque and current control for optimized

starting & stopping process

Dual adjustments - two starting & stopping

characteristics

Slow speed with electronic reversing

Pulse start

Linear acceleration (tacho feedback)

Energy Save for improved power factor

Standard Ratings

230V, 400V, 480V, 600V, 690V, 1000V, 1200V

Motor & Starter Protection

Too many starts

Long start time (stall)

Shear-pin

Electronic overload with selectable curves

Under current with adjustable delays

Phase loss & phase sequence

Under, over & no voltage

Load loss (motor not connected)

Shorted SCR

Starter over-temperature

Displays LCD & LEDs

Illuminated LCD - 2 lines x 16 characters

Selectable languages: English, German,

French

and Spanish (Russian - optional)

Two display modes for basic and advanced

applications

Friendly operation with default parameters

Eight LEDs for quick operational status

Statistical data including:

Total run time

Total number of starts

Total number of trips

Last start current

Last start time

Last trip

Current at trip

7 • Technical Data

________________________________________________________________________________________________

Options

Analog output (see details below)

Thermistor input (see details below)

Motor insulation test (see details below)

Preparation for bypass - to maintain

protection when bypass is closed

Special anti-corrosive treatment - special coating

for harsh environments

Special tacho feedback circuitry

Modbus RTU - enables setting, control &

supervision

Profibus DP – enables setting, control &

supervision

Analog Card (Optional)

Incorporates two functions:

Thermistor input, PTC or NTC

Analog output, related to motor's current,

programmable as 0-10VDC, 4-20mA, 0-20mA or

inverse (inverse available in RVS-DN 1000V& RVS-

DN1200V models)

Motor Insulation Tester (Optional)

A unique feature for submersible pumps, motors

installed in harsh environments, etc.

The system measures motor insulation when motor is

not running.

Two programmable levels are available:

Alarm level, adjustable 0.2-5 Mohm

Start disable level, adjustable 0.2-5 Mohm,

preventing starting when insulation is below

acceptable levels

Auxiliary Relays

Three standard programmable relays (each relay with

one C.O. 8A, 220VAC contacts)

Immediate with adjustable on and off delays.

Can be dedicated for shear-pin (jam) protection

End of acceleration, with adjustable on delay

Fault, programmable as fault or fault-fail safe

operation.

Low motor insulation alarm (optional relay)

Applications - Industrial

Pumps

Hydraulic systems

Fans and blowers

Compressors

Conveyors

Applications - Marine & Offshore

Water, ballast and fire-fighting pumps

Refrigeration chillers and compressors

Hydraulic pumps and power packs

Thrusters

Main propulsion motors

Unique protection for corrosive environments

Generator ready - auto frequency tracking

Sustains variations of 45-65Hz while starting

Heavy duty, fully rated design

Applications - 1000V &1200V for Mining,

Quarries & Mixers

Digital Soft Starter for 105-460A, robust, heavy

duty, fully featured, fiber-optically controlled

(210-460A)

Stainless steel with copper heatsink is available

below 100A – consult factory for details

The RVS-DN has Lloyds Type Approval for

ENV1, ENV2. As well as, Germaniche Lloyds,

Rina and DNV - consult factory for details

8 • Technical Data

_____________________________________________________________________________________________

3.2 Rated Currents and Frame Sizes

RVS-DN Model

RVS-DN

FLC

[A]

Frame

Size

Dimensions WxHxD

[mm]

Weight

[Kg]

RVS-DN 8 8 A 153x310x170 4.5

RVS-DN 17 17 A 153x310x170 4.5

RVS-DN 31 31 A 153x310x170 6.0

RVS-DN 44 44 A 153x310x217 7.5

RVS-DN 58 58 A 153x310x217 7.5

RVS-DN 72 72 A 153x310x217 7.5

RVS-DN 85 85 B 274x385x238 14.5

RVS-DN 105 105 B 274x385x238 14.5

RVS-DN 145 145 B 274x385x238 14.5

RVS-DN 170 170 B 274x385x238 14.5

RVS-DN 210 210 C380x455x292 (1) 32

RVS-DN 310 310 C380x455x292 (1) 32

RVS-DN 390 390 C380x455x292 (1) 32

RVS-DN 460 460 D 380x555x292 (1) 39

RVS-DN 580 580 D 470x640x302 (1)

470x655x302 (2) 48

RVS-DN 820 820 D 470x710x302 (1)

470x715x302 (2) 65

RVS-DN 950 950 D 623x660x290 (3) 83.5

RVS-DN 1100 1100 E723x1100x370 (3) 170

RVS-DN 1400 1400 E 723x1100x370 (3) 170

RVS-DN 1800 1800 E 723x1100x370 (3) 170

RVS-DN 2150 2150 F 750x1300x392 (3) 240

RVS-DN 2400 2400 G 900x1300x410 (3) (4) 350

RVS-DN 2700 2700 G 900x1300x410 (3) (4) 350

RVS-DN 3000 3000 G900x1300x410 (3) (4) 350

RVS-DN 105 1000V 105 325x400x300 (5)

RVS-DN 170 1000V, 1200V 170 592x500x345 (5)

RVS-DN 210 1000V, 1200V 210 592x500x345 (5)

RVS-DN 310 1000V, 1200V 310 592x500x345 (5)

RVS-DN 390 1000V, 1200V 390 592x500x345 (5)

RVS-DN 460 1000V, 1200V 460 592x500x345 (5)

3.3 RVS-DN Selection

The RVS-DN should be selected in accordance with the criteria of motor current and starting conditions.

3.3.1 Motor Current and Starting Conditions

Select the RVS-DN according to motor's Full Load Ampere (FLA) - as indicated on its nameplate (even if the

motor will not be fully loaded).

The RVS-DN is designed to operate under the following maximum conditions:

Ambient

Temperature

[°C]

Starting Current

[A]

Acceleration

Time

[sec]

50 400%xIn 30

Max. starts per hour: 4 starts per hour at maximum ratings and up to 60 starts per hour at light load

applications (consult factory).

Note:

For very frequent starts (inching applications) the inching current should be considered as the Full Load

Current (FLC) (consult factory).

Notes:

(1) – Different dimensions when ordered with UL/cUL/marine approvals.

Refer to section 5.3 page 47 for dimensions when ordered with these approvals.

(2) – Dimensions with preparation for bypass.

(3) – Must be operated with bypass contactor. Add space for current transformers and bus

bars for preparation for bypass.

(4) – Control module is installed separately. Refer to section 5.1.1 page 45 for dimensions.

(5) – Consult factory.

Refer to section 5 on page 34 for detailed dimensions.

9 • Technical Data

________________________________________________________________________________________________

3.4 Mains and Control Description

Refer to drawing on page 13

Indication Description Remarks

L1, L2, L3 Connection to mains voltage up to

1200V

Thyristor’s PIV rating, internal circuitry and insulation

defines five voltage levels:

400V for 230-400V +10%/ -15% 50/60Hz

480V for 480V +10% /-15% 50/60Hz

600V for 600V +10% /-15% 50/60Hz

690V for 690V +10% /-15% 50/60Hz

1000V for 1000V +10% / -15% 50/60Hz

1200V for 1200V +10% / -15% 50/60Hz

Each RVS-DN is suitable for one of the above levels

& for 50/60 Hz.

L1b, L2b, L3b Preparation for bypass

connection (optional)

All models from RVS-DN 950A and up, RVS-DN

1000V and RVS-DN 1200V models must be

operated with a bypass contactor.

Bypass preparation is standard in models RVS-

DN85-170A.

Refer to section 3.5.1 page 14 for more details.

U, V, W Connection to motor

G Connection to ground For proper operation and for safety reasons soft

RVS-DN must be properly grounded.

Terminal 1 Control phase (positive – for DC

control)

The control voltage operates the electronic circuitry

and the fans (when they exist).

Terminal 3 Control neutral (return) Three control voltages are available:

115 for 115V +10%/ -15% 50/60Hz

230 for 230V +10%/ -15% 50/60Hz

110VDC for 110V +10%/ -15% DC

Terminal 2 Fan control An internal jumper, connected between the fan and

terminal 2 enables three modes of operation (refer to

section 6.6 page 58).

For fan power consumption, see technical

specification in section 10 page 99.

Terminal 4 Input – STOP command.

•Input from a N.C. contact

•To stop the motor, disconnect

Control Input voltage from

terminal 4 for at least 250mSec.

(no SOFT STOP)

•Control Input voltage (STOP, SOFT STOP,

START, terminal inputs 7 and 8) can be the same

as Control Supply (terminals 1, 3) or voltage from a

different source.

•The Control Inputs are opto-coupled and isolated

from the microprocessor circuitry.

Terminal 5 Input – SOFT STOP command.

•Input from a N.C. contact

•To SOFT STOP the motor

disconnect Control Input voltage

from terminal 5 for at least

250mS

Note:

If SOFT STOP is not required,

connect a jumper between

terminals 4 and 5.

Control Input voltages available:

230 for 90-230V +10%/ 50/60Hz or DC.

24 for 24V +10%/ -15% 50/60Hz or DC.

48 for 48V +10%/ -15% 50/60Hz or DC.

10 • Technical Data

_____________________________________________________________________________________________

Indication Description Remarks

Terminal 6 Input – START command.

•Input from a N.O. contact.

•To SOFT START the motor,

connect Control Input voltage to

terminal 4 for at least 250mSec.

Notes:

•Motor will start only if STOP

(terminal 4) and SOFT STOP

(terminal 5) terminals are

connected to Control Input

voltage.

•To reset a fault the START

command must be removed.

Terminal 7 Programmable input –

ENERGY SAVE / SLOW

SPEED / RESET

Refer to section 3.5.2 page 16.

Terminal 8 Programmable input –

DUAL ADJUSTMENT /

REVERSING / RESET

Refer to section 3.5.3 page 16.

Terminal 9 Common to terminals 4-8.

This terminal is a reference for terminals 4, 5, 6, 7 &

8.

Note:

When Control Supply and Control Input voltage are

from the same source, connect a jumper between

terminals 3 and 9.

Terminal 10 Programmable IMM/S.PIN

RELAY (N.O.)

IMM/S.PIN RELAY is the immediate/shear pin output

relay.

•

Terminal 11 Programmable IMM/S.PIN

RELAY (N.C.)

•Voltage free 8A, 250VAC, 2000VA max.

•Selection between functions is made from the

keypad or through the communication.

Terminal 12 Programmable IMM/S.PIN

RELAY (Common)

•Refer to section 7.7.8 page 83 for IMM/ S.PIN

RELAY programming.

•Refer to section 3.5.4 page 16 for more details.

Terminal 13 Programmable Fault

Output relay (N.O.)

Voltage free 8A, 250VAC, 2000VA max. changes its

position upon fault.

Terminal 14 Programmable Fault

Output relay (N.C.)

The contact is programmable to function as FAULT

or FAULT-FAIL SAFE.

Terminal 15 Programmable Fault

Output relay (Common)

When the FAULT function is selected, the relay is

energized upon fault. The contact returns to its

original position when one of the following occurs:

•The fault has been removed and RVS-DN was

reset

•Disconnection of Control Supply

When the FAULT-FAIL SAFE function is selected,

the relay is energized immediately when the Control

Supply is connected and de-energizes when one of

the following occurs:

•Fault

•Control Supply disconnection

Refer to section 7.7.8 page 83 for FAULT RELAY

TYPE programming.

11 • Technical Data

________________________________________________________________________________________________

Indication Description Remarks

Terminal 16 Programmable End of

Acceleration (Run) Output relay

(N.O.)

Voltage free 8A, 250VAC, 2000VA max. changes its

position at the end of acceleration, after an

adjustable time delay (Contact Delay), 0 – 120 sec.

Terminal 17 Programmable End of

Acceleration (Run) Output relay

(N.C.)

The contact returns to its original position when

ENERGY SAVE is operated, on SOFT STOP or

STOP signals, on FAULT condition, or upon voltage

outage.

Terminal 18 Programmable End of

Acceleration (Run) Output

relay (Common)

The End of Acceleration contact (Run) can be used

for:

•Closing a bypass contactor

•Activating a valve after compressor has reached full

speed

•Loading a conveyor after motor reached full speed.

Refer to section 7.7.3 page 72 for RUN CONTACT

DELAY programming

Terminal 19 External Fault input Input from a N.O. contact that is connected between

terminals 19 and 21. The RVS-DN will trip 2 seconds

after the contact closes.

Notes:

•Wires connecting the External Fault contact to

terminal 19 should not exceed 1 meter in length.

•External Fault can be used only when terminal 21 is

connected to neutral or ground.

•Do not use External Fault while using the Insulation

Alarm option.

•Only potential free contacts may be connected to

terminal 19.

•Do not connect any voltage to terminal 19.

•Any connection of voltage to this terminal may

disrupt RVS-DN operation, and cause RVS-DN or

motor damage.

•Refer to section 4.12 page 24 for the External Fault

wiring diagram.

Terminal 20 Tacho Feedback input (optional) •Provides linear acceleration and deceleration.

•Requires high quality tacho generator on motor

shaft, output voltage 0-10VDC, linear

speed/voltage ratio.

•Consult factory for further information before using

the tacho feedback feature.

Terminal 21 Neutral connection When a mains neutral wire is available, connect

terminal 21 to neutral. Terminal 21 serves only as a

voltage reference to the control circuitry.

Notes:

•RVS-DN circuitry incorporates an internal artificial

neutral, which should only be used, when the

system is not grounded and mains neutral

connection is not available.

•Only potential free contacts may be connected to

terminal 21.

•Do not connect any voltage to terminal 21.

Any connection of voltage to this terminal may

disrupt RVS-DN operation, and cause RVS-DN or

motor damage.

•Refer to section 14.1 on page 19 for terminal 21

connection.

12 • Technical Data

_____________________________________________________________________________________________

Indication Description Remarks

Terminal 22 No connection (optional) •Standard RS485, half duplex with Modbus protocol,

baud rate 1200, 2400, 4800, 9600 BPS.

Terminal 23 RS-485 communication (-)

(optional)

•Twisted shielded pair should be used.

Connect shield to ground on the PLC/Computer

side.

Terminal 24 RS-485 communication (+)

(optional)

•Terminals 4 & 5 must be wired to Control Supply for

operation in communication mode (refer to section

4.16 page 27 for wiring diagram).

•Up 32 units can be connected for Modbus RS485

communication. For reliable communication, units

should be installed in the vicinity of 200m

maximum, from the first to the last unit.

•Refer to section 7.7.9 page 85 for programming.

•Consult the communication manual (ask factory).

Terminal 25 Programmable Insulation Alarm

Output relay (Common) (optional)

Voltage free 8A, 250VAC, 2000VA max. is energized

when the motor insulation level decreases below the

Insulation Alarm level.

Terminal 26 Programmable Insulation Alarm

Output relay (N.O.) (optional)

The relay is de-energized and the alarm will

disappear if on of the following occurs:

•The insulation level returns to normal for more than

60 seconds

•RVS-DN resets

•Control Supply disconnection

Refer to section 7.7.7 on page 81 for more details.

Terminal 27 Programmable Insulation

Alarm Output relay (N.C.)

(optional)

Notes:

•Do not use External Fault while using Insulation test

option.

•Insulation test can be performed only when main

voltage is not connected to the RVS-DN,

(upstream isolation device must be opened.)

•For correct operation of Insulation test, it is

important that the RVS-DN is properly grounded

and that the control module is properly fastened to

the power section.

•Insulation test option and analog output option can

not be applied together.

•Refer to section 7.7.7 page 81 for insulation test

programming.

Terminal 28 Thermistor input (T1) (optional) Thermistor input is programmable as a PTC or NTC

type thermistor. The trip value is adjustable between

1-10Kohm, preset delay of 2 Sec.

Terminal 29 Thermistor input (T2) (optional) Connect thermistor and/or Analog output shield to

ground terminal.

Terminal 30 Ground (optional) Analog output (0-10VDC or 0-20mA or 4-20mA)

Terminal 31 Analog output (-) (optional) reflects motor current and is related to 2xFLA. i.e.,

Full scale (10VDC or 20mA) is related to 2xFLA.

Terminal 32 Analog output (+) (optional) Note:

In the RVS-DN 1000V & 1200V models the analog

output reflects motor current and is related to

2xFLC.Dip switches allow selection between: 0-

10VDC, 0-20mA or 4-20mA.

•Refer to section 6.7 page 59 for analog output dip

switch setting.

•Refer to section 7.7.8 page 83 for analog output

programming.

•Refer to section 7.7.7 page 81 for thermistor input

programming.

13 • Technical Data

________________________________________________________________________________________________

Indication Description Remarks

D-9 connector Profibus communication (optional) •Profibus DPV0 and DPV1, up to 12 MBPS.

•D type 9 pin connector is applied.

•Control, monitoring and setting parameters can be

achieved via the Profibus connection.

•Setting is possible only when DPV1 is

implemented.

•Refer to section 7.7.10 page 85 for programming.

•Consult the Profibus manual (request from the

factory).

3.5 Input/Output Indication

14 • Technical Data

_____________________________________________________________________________________________

3.5.1 Preparation for Bypass Contactor

Under normal operating conditions the heat dissipated by an RVS-DN causes heating of the enclosure and

energy losses. The heating and losses can be eliminated by the use of a bypass contactor, which bypasses

the RVS-DN after completion of start-up so that motor current will flow through the bypass contactor.

In models RVS-DN 950A and up, current transformers CT1 and CT2 are mounted outside the RVS-DN and

need to be connected to the RVS-DN by the customer. In this case the customer MUST NOT ground the

secondaries of current transformers!

Heat dissipation from the RVS-DN is calculated as:

Ploss=3x1.3xI+FAN loss

where:

I represents motor current. Note that the motor current during the start process is higher than the motor rated

current.

FAN loss represents power loss caused by all internal fans (refer to section 10 page 99 for fan loss per

model).

For example, during start of a 820A motor when CURRENT LIMIT is set to 400%, heat dissipation can be

calculated as:

Ploss=3x1.3x4x820+150=12,792Watt≈12.8kW

While a 820A motor is running and the motor current is 820A, heat dissipation can be calculated as:

Ploss=3x1.3x820+150=3,198Watt≈3.2kW

When a bypass contactor is used this changes the previous calculation to:

Ploss=3x1.3x0+150=150Watt≈0.15kW

It is obvious that using a bypass contactor can significantly reduce energy consumption.

Notes:

•All models from RVS-DN 950A and up, RVS-DN 1000V and RVS-DN 1200V must be implemented with a

bypass contactor (see section 3.5.1.2 page 15).

•Bypass preparation is standard in models RVS-DN 85-170A.

3.5.1.1 Maintaining Current Protection after Bypass Closes

Current flow during soft start and soft stop.

Bypass contactor is open.

15 • Technical Data

________________________________________________________________________________________________

Current flow during RUN when the bypass contactor bypasses the RSV-DN.

Current transformers CT1 and CT2 are able to measure motor current, thus the motor current

protections of the RVS-DN are operable.

Note:

If the RVS-DN is bypassed without using the preparation for bypass the following protections are not operable

during RUN:

•UNDER CURRENT

•O/C SHEAR PIN

•OVERLOAD TRIP

3.5.1.2 Maintaining Current Protection after Bypass Closes - RVS-DN 950-3000a

RVS-DN 950-3000A models are supplied without preparation for bypass. However bypass must be applied

for these models.

Current transformers CT1 and CT2 are supplied separately and must be connected to the RVS-DN as shown

below.

Note:

Do not ground current transformers secondaries!

Current flow during RUN when the bypass contactor bypasses the RVS-DN. The customer

must perform the bypass connections shown.

Current transformers CT1 and CT2 are supplied with the RVS-DN. Do NOT ground the CTs!

16 • Technical Data

_____________________________________________________________________________________________

3.5.2 Input Terminal 7 - Energy Save/Slow Speed/Reset

Input from a N.O. contact - selection between above functions is made from the keypad (refer to section

7.7.8 page 83) or through the communication (Modbus or Profibus).

When ENERGY SAVE function is selected - connect terminal 7 to control input voltage by a jumper for

automatic operation, upon load decrease.

When connected through a N.O. contact, closing the contact operates Energy Save.

When SLOW SPEED function is selected - connect control input voltage to terminal 7 before starting. When

start command is initiated motor will run at 1/6 nominal speed for 30 seconds maximum. Closing terminal 7

while motor is running will not have any effect.

When RESET function is selected - connect terminal 7 to control input voltage (use a N.O. momentary

contact) to reset the RVS-DN.

Refer to section 4.10 page 23 for the wiring diagram.

3.5.3 Input Terminal 8 - Dual Adjust/Reverse/Reset

Input from a N.O. contact - selection between above functions is made from the keypad (refer to section

7.7.8 page 83) or through the communication (Modbus or Profibus).

When DUAL ADJUSTMENT function is selected - connect terminal 8 to Control Input voltage to operate the

RVS-DN with the DUAL ADJUSTMENT characteristic. DUAL ADJUSTMENT characteristic is programmed as

explained in section 7.7.5 page 79. You can switch between the primary and DUAL ADJUSTMENT settings

before and/or during starting.

When dip switch #3 is set to on, DUAL ADJUSTMENT operates as D.ADJ.:GENERATOR PARAMETERS.

Use this mode if the normal starting process fails, i.e., SHORTED SCR or WRONG CONNECTION faults

occur and, after testing, operator is sure that SCRs, motor and motor connections are not faulty.

Refer to section 4.17 page 29 for D.ADJ.:GENERATOR PARAMETERS wiring.

Refer to section 9 page 95 for trouble shooting.

When SLOW SPEED REVERSE function is selected - connect Control Input voltage to terminal 8 to reverse

direction. In order to operate in SLOW SPEED REVERSE, terminal 7 must be programmed as SLOW SPEED

and Control Input voltage must be connected to terminal 7 as well.

You can give the reverse command before the motor is started or during operation at SLOW SPEED.

Connecting Control Input voltage to terminal 8 before motor is started, starts the motor in reverse direction.

Connecting Control Input voltage while motor is running at SLOW SPEED stops the motor for 0.6 – 2 sec

(according to motor size) before reversing its direction.

Refer to section 4.10 page 23 for wiring diagram.

When RESET function is selected - connect terminal 8 to Control Input voltage (use a N.O. momentary

contact) to reset the RVS-DN.

Refer to section 4.10 page 23 for the wiring diagram.

3.5.4 Output Terminals 10, 11 & 12 – Immediate/Shear Pin Relay

Programmable functions (refer to section 7.7.8 page 83):

IMMEDIATE (after start signal) - when immediate is selected, the relay is energized upon the START signal.

The relay is de-energized when one of the following occurs:

•Fault

•Control Supply outage

•STOP signal

When SOFT STOP is operated - the relay is de-energized at the end of the SOFT STOP process.

The relay incorporates on and off delays of 0-3600 sec. each.

The immediate relay can be used for the following purposes:

•Release a brake of a motor

•Interlock with other systems

17 • Technical Data

________________________________________________________________________________________________

•Signalling

•Delay the opening of a line contactor at the end of SOFT STOP, thus allowing current to decrease to zero

before opening the contactor

•Switch to / from Dual Adjustment settings with a time delay from the START signal (see Special Starting

section 8.2.3.1 page 92).

O/C SHEAR PIN detection - when O/C Shear-pin is selected, the relay is energized upon SHEAR-PIN

detection (RVS-DN’s trip can be delayed 0-5 sec).

In this case, the relay incorporates on and off delays of 0-5 sec. each.

The O/C SHEAR PIN relay can be used for the following purposes:

•Interlock with other systems

•Signalling

•Delay for operating a reversing combination of upstream contactors when SHEAR PIN is detected, thus

allowing clearing of a jam condition.

18 • Technical Data

_____________________________________________________________________________________________

3.6 Ordering Information

RVS-DN 31- 400- 230 230- 0- S

Full load Current Mains Voltage Control Supply

Voltage

Control Input

Voltage

Options Front Panel

Full load Current

Specify Description

RVS-DN’s

FLC [A]

8, 17, 31, 44, 58, 72, 85(2), 105(2), 145(2), 170(2), 210, 310, 390, 460, 580, 820, 950(1), 1100(1),

1400(1), 1800(1), 2150(1), 2400(1), 2700(1), 3000(1).

Mains Voltage

Specify Description

400 230 – 400 VAC, +10% -15%, 50/60Hz

480 480 VAC, +10% -15%, 50/60Hz

600 600 VAC, +10% -15%, 50/60Hz

690 690 VAC, +10% -15%, 50/60Hz

1000(1) 1000 VAC +10% -15%, 50/60Hz; Models: 105A, 170A, 210A, 310A, 390A, 460A.

1200(1) 1200 VAC +10% -15%, 50/60Hz; Models: 170A, 210A, 310A, 390A, 460A.

Control Supply Voltage (Terminals 1 and 3)

Specify Description

115 115 VAC, 50/60Hz, +10% -15%

230 230 VAC, 50/60Hz, +10% -15%

110VDC 110 VDC, +10% -15%

Control Input Voltage (Terminals 4 to 9)

Specify Description

115 or

230

90-230 VAC, 50/60Hz, +10%

24 24V AC/DC, +10% -15%

48 48V AC/DC, +10% -15%

Options

Specify Description

0 No options

3M Communication - RS-485 (Modbus) (3) (5)

3P Communication - Profibus(3) (Must be factory supplied).

4 Insulation tester

(4) (5)

5 Analog card – Thermistor in and Analog out (4) (5)

8 Harsh environment treatment. (Must be factory supplied).

9 Preparation for Bypass contactor (1) (2)

B Line and load bus bars at bottom (Applicable in Marine/UL models 210-820A)

D Remote panel mounting replacing the original panel.( supplied with 1.5 m cable)

H Special character set LCD display

M Marine approval (consult factory)

U UL & cUL approval (8-820A models only and up to 600V)

T Tachometer card for special drive systems (consult factory) (4) (5)

ROC Chinese display

Front Panel

Specify Description

S Standard

RU Russian front panel and Russian characters LCD display.

Notes:

(1) RVS-DN 950-3000A, RVS-DN 1000V and RVS-DN 1200V must be operated with a bypass contactor. For

usage without bypass contactor consult the factory.

(2) Preparation for bypass contactor is standard in RVS-DN 85-170A.

(3) Only one option, either 3M or 3P may be installed in one RVS-DN.

(4) Only one option, either 4 or 5 or T may be installed in one RVS-DN.

(5) All options must be factory installed in RVS-DN 8-72A.

(6) Current transformers (CTs) for RVS-DN950A and up are designed to allow installation within 1.5m from

the RVS-DN (use the CTs for the RVS-DN only!)

(7) If you need more than one option, make sure to indicate it with a plus sign (+), for example 8+9 for Harsh

environment and preparation for bypass contactor.

Ordering Example: RVS-DN rated 820A, mains voltage - 230V, Control Supply voltage - 115V, Control Input

- 115V Modbus communication card, Analog card, Harsh environment treatment, preparation for bypass and

standard front panel:

RVS-DN 820 - 400 - 115 – 115 - 3M + 5+ 8 + 9 – S

19 • Recommended Wiring diagrams

________________________________________________________________________________________________

4. RECOMMENDED WIRING DIAGRAMS

4.1 Terminal 21 Connections With Various Mains

Mains Diagram Terminal 21 Connection

WARNINGS! Only potential free contacts may be connected to terminal 21!

Do not connect any voltage to terminal 21!

Any connection of voltage to terminal 21 may disrupt RVS-DN operation, and

cause damage to the RVS-DN or the motor!

3P+N - Connect terminal 21 to neutral

3P+GR - Connect terminal 21 to ground

3P - Leave terminal 21 unconnected

3P - Leave terminal 21 unconnected

3P+GR - Leave terminal 21 unconnected

3P+N+GR - Connect terminal 21 to neutral

20 • Recommended Wiring diagrams

_____________________________________________________________________________________________

4.2 Control Supply, Control Input and Mains are From the Same Source, Neutral Connected to

Terminal 21

Notes:

•Use this diagram when Control

Supply, Control Input and mains are

all from the same source, and

terminal 21 is connected to neutral

as per section 4.1 page 19.

•Supply must be protected for short

circuit and over load. 6A fuse is

recommended.

•It is recommended to use a separate

fuse for the auxiliary circuits.

4.3 Control Supply and Control Input From the Same Source, Neutral not Connected to

Terminal 21

Notes:

•Use this diagram when mains and

control voltage are not from the

same source

or

when mains and control voltage are

from the same source, but terminal

21 is not connected to neutral as

per section 4.1 page 19.

In this case leave terminal 21 open.

•Supply must be protected for short

circuit and over load. 6A fuse is

recommended.

•It is recommended to use a separate

fuse for the auxiliary circuits.

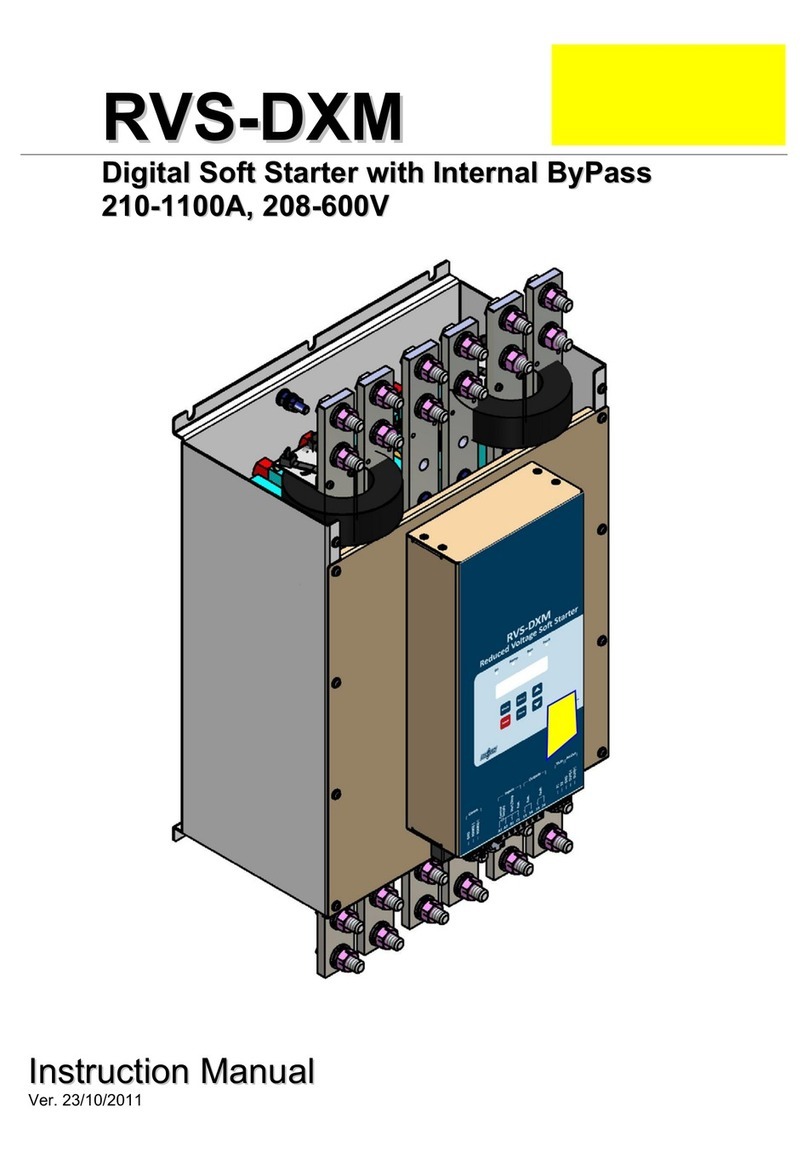

This manual suits for next models

23

Table of contents

Other Solcon Controllers manuals