Soldo S.r.l.

Via Monte Baldo, 60

25015 Desenzano d/G (Brescia) Italy

Tel +39 030 999.13.09 - Fax +39 030 914.19.77

http: //www.soldo.net

Installation & Operating Manual

IOM-SX_SH01-01 SX

SH

IOM-SX_SH01-01 Page 1 / 2

READ THIS INSTRUCTION FIRST

To avoid serious or fatal personal injury or major property damage, read and follow all safety instruction in this manual.

If you require additional assistance, please contact SOLDO.

SAVE THIS INSTRUCTION

Declaration of conformity as defined by the

ATEX directive 94/9/EC

Doc.: CE001-06

Herewith we declare that the SOLDO “limit switch box SX series”,

II 2 G Ex d IIB T6/T5/ T4

II 2 D Ex tD B21 T85°C/T100°C/T135°C

and the SOLDO “limit switch box SH series”,

II 2 G Ex d IIB+H2 T6/T5/ T4

II 2 D Ex tD B21 T85°C/T100°C/T135°C

are in conformity with the provision of the ATEX directive 94/9/EC “Equipment or Protective

Systems intended for use in potentially explosive atmospheres” and with national

implementing legislation and that appropriate harmonized standards have been applied:

EN 60079-0 : 2006 EN 60079-1 : 2007 EN 61241-0 : 2006 EN 61241-1 : 2004

Directive 89/336/CEE Electromagnetic compatibility.

EN 61326-1:2006

Directive 73/23/CEE Low tension

EN 60529:1991 EN 60730-1:2000

EC- Type examination certificate

ATEX: ITS 09ATEX 16281X IECEx: IECEx ITS 09.0020X

Production quality assurance notification:

ATEX: ITS 08ATEXQ5820 IECEx: GB/ITS/QAR09.0004/00

WARNING!

Warns of hazard that MAY cause serious personal injury, death or major property damage.

HAZARDOUS VOLTAGE. Disconnect all power before servicing equipment.

DO NOT REMOVE COVER WHEN ENERGISED.

CAUTION !

Do not exceed the limit switch performance limitation. Exceeding the limitation may cause damage to the limit

switch, actuator and valve.

The conduit plug supplied with the switch boxes are for transit purposes only. IP67 protection depends on

cable gland and cabling methods used. Limit switchbox for quarter-turn valve device (90° rotation).

Maximum shaft angular velocity 250 rpm.

Follow switch adjustment & indicator setting before servicing the limit switch box.

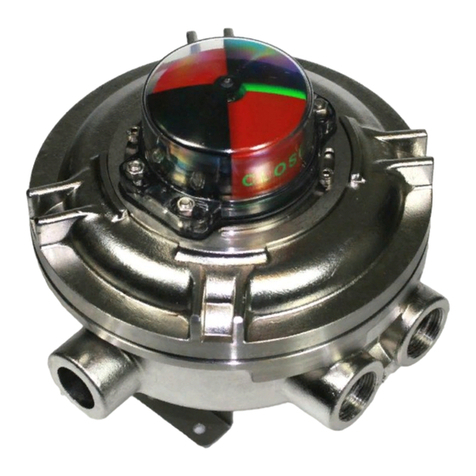

1 INSTALLATION

1.1 Attach proper mounting bracket (1) to the box (4) housing using four M 6X8 bolts (2).

1.2 Align shaft (5) to actuator shaft and engage it.

1.3 Attach bracket to actuator using hardware provided (3).

2 SWITCH ADJUSTMENT

2.1 Loose the screws (8) and remove box cover (7).

2.2 Follows indication in “Cams setting” Page 2.

2.3 Box with 3-4 switches, set the actuator in the extra position you have to signal. Act according to indications

in “Cams setting ” to set cams of the switch number 3 and 4.

2.4 Replace box cover (7). WARNINGS: check seal (6) is properly fitted in slot. Turn manually cover’s shaft (15)

cheeking to align it to switch box shaft and engage it. Tightening screws (8).

GB For other languages visit WWW.SOLDO.NET

IT Per altre lingue visitare il sito WWW.SOLDO.NET

FR Pour les autres langues visite WWW.SOLDO.NET

DE Für andere Sprachen besuchen WWW.SOLDO.NET

ES Para otros idiomas, visite WWW.SOLDO.NET

Safety instruction to hazardous area installation

Doc.: SI001-03

Model numbers covered SX_ _ _ _ _-_ or SH _ _ _ _ _-_ ( _ indicates options in switches,

switches quantity, terminal strip, colour, cable entries). The following instructions applies to

equipment covered by ATEX certificate number: ITS 09ATEX 16281X

And by IECEX certificate number: IECEx ITS 09.0020X

SX limit switch boxes may be used in an hazardous area with flammable gases, vapours and

powder, group IIB with the following temperature classes:

T6: -25°C ≤T amb. ≤+ 60° C Surface temperature T 85°C

T5: -25°C ≤T amb. ≤+ 75° C Surface temperature T 100°C

T4: -25°C ≤T amb. ≤+ 105° C Surface temperature T 135°C

Special options for -40°C

defined by “LT1” at the

end of the switch box code

SH limit switch boxes may be used in an hazardous area with flammable gases, vapours and

powder, group IIB+H2 with the following temperature classes:

T6: -25°C ≤T amb. ≤+ 60° C Surface temperature T 85°C

T5: -25°C ≤T amb. ≤+ 75° C Surface temperature T 100°C

T4: -25°C ≤T amb. ≤+ 105° C Surface temperature T 135°C

Suitably trained personnel shall carry out installation in accordance with applicable code of

practice

The user should not repair this equipment.

The user should provide suitable systems to limit heating coming from valve; max ambient

temp 105°C

If the equipment is likely to come into contact with aggressive substances, it is responsibility of

the user to take suitable precautions that prevent it from being adversely affected, thus

ensuring that the type of protection is not compromised. Agressive substances – es. Acidic

liquids or gases that may attack metal .

The following precautions must be observed:

i The metallic alloy used for the enclosure, in the event of a rare accident, could cause ignition

sources due to impact or friction (sparks may occur). This shall be considered when the box is

installed in group II category 2G areas.

ii Due to electrostatic charge of plastic pieces, the limit switch box shell only be cleaned with a

damp cloth.

NOMENCLATURE

SX

SH 01 2 0 0 - 1 -Extra digit

To define

special option

Cable entry

Colour

Terminal strip

Switch quantity

Switch type