Solflex SonaSafe HD Series User manual

Other Solflex Heat Pump Accessories manuals

Popular Heat Pump Accessories manuals by other brands

AIT

AIT Hydraulic Station operating manual

Resol

Resol SBS 2000 Manual for the specialised craftsman

STIEBEL ELTRON

STIEBEL ELTRON SBB 301 WP Installation and operating instructions

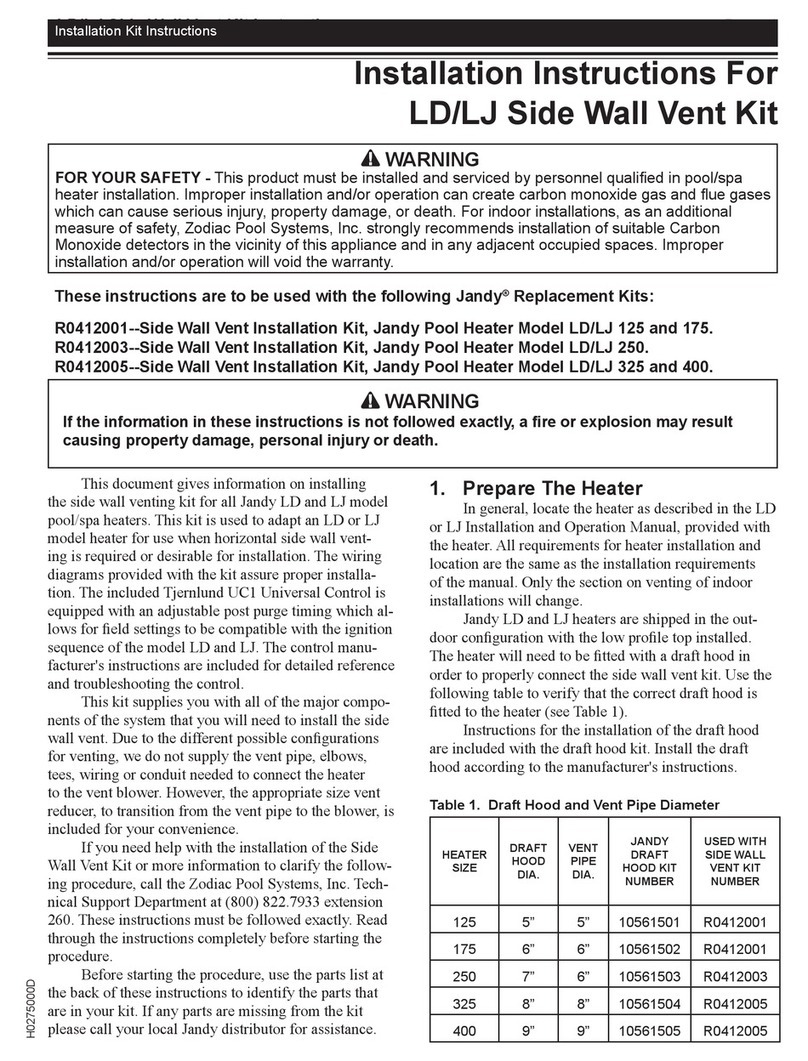

Jandy

Jandy R0412001 installation instructions

Flow

Flow HyPlex Prime Major Installation

STIEBEL ELTRON

STIEBEL ELTRON WPM Installation

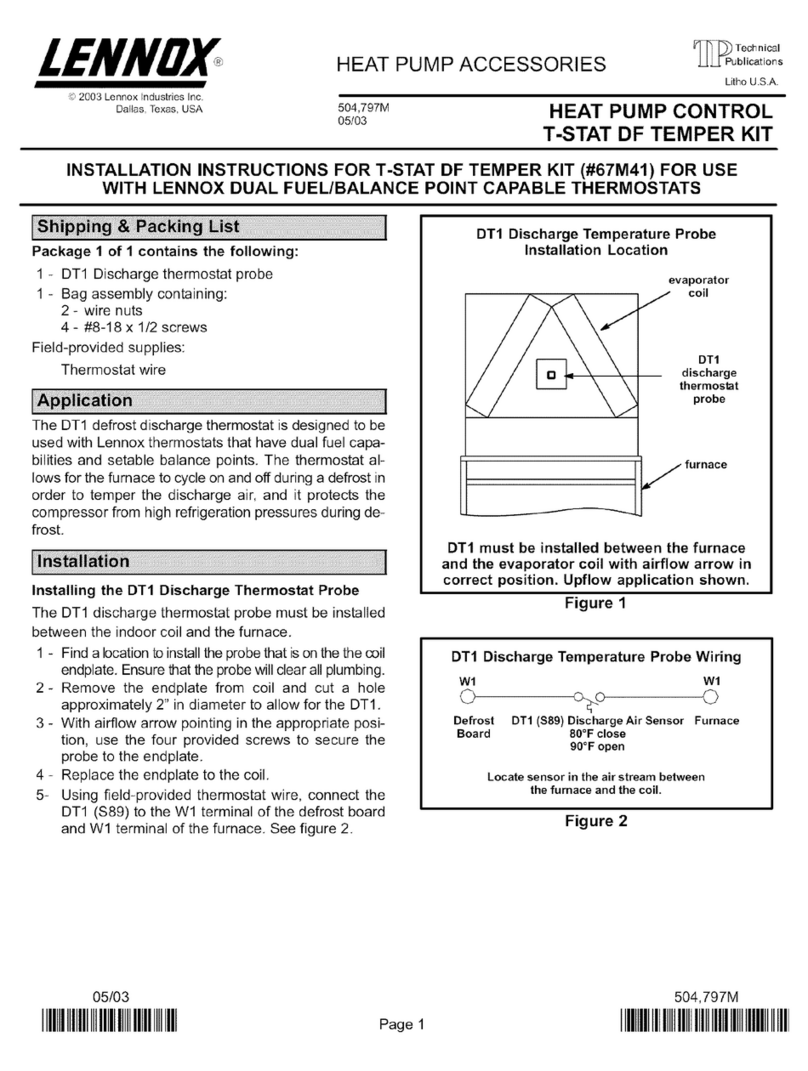

Lennox

Lennox 67M41 installation instructions

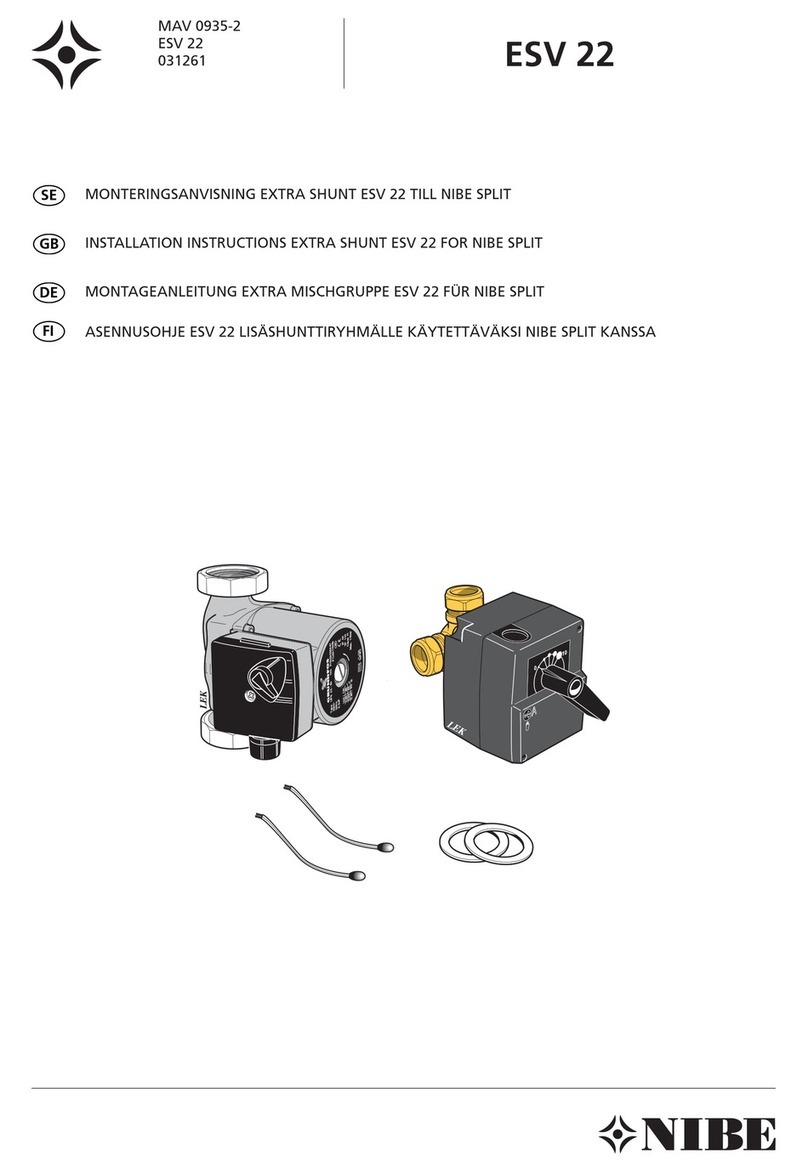

Nibe

Nibe ESV 22 installation instructions

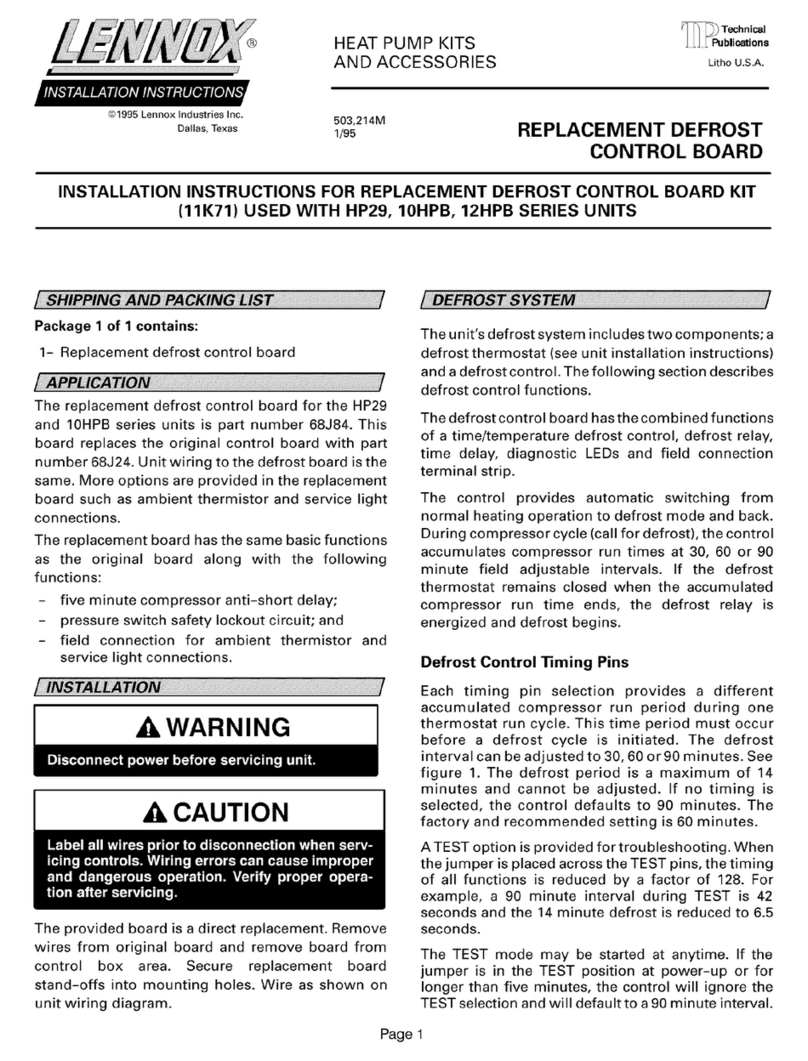

Lennox

Lennox 11K71 installation instructions

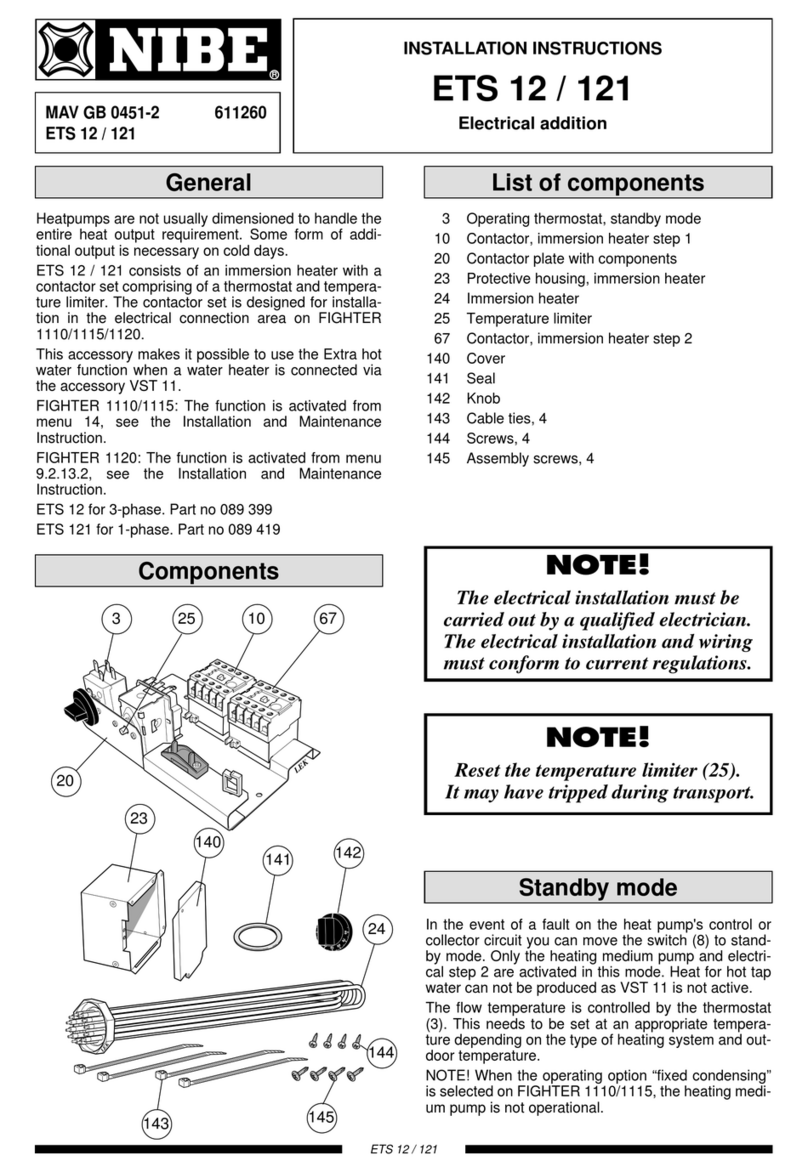

Nibe

Nibe ETS 121 installation instructions

Axiom

Axiom NT25-P18 Installation, operation and maintenance instructions

Immergas

Immergas MAGIS HERCULES PRO MINI 6 Instruction and warning book

DOMUSA TEKNIK

DOMUSA TEKNIK FUSION COMBI W 50 Installation and operating instructions

STIEBEL ELTRON

STIEBEL ELTRON MAE Operation and installation

Nibe

Nibe EF 45 Installer manual

Pentair Jung Pumpen

Pentair Jung Pumpen PKS-D 1000 Series Mounting instructions

STIEBEL ELTRON

STIEBEL ELTRON SB-VTI 100 Operation and installation

Immergas

Immergas UE AUDAX PRO V2 Instructions and warning