APT250/APT500/APT1000 Operation Manual

7

True Soltec Co., Ltd.

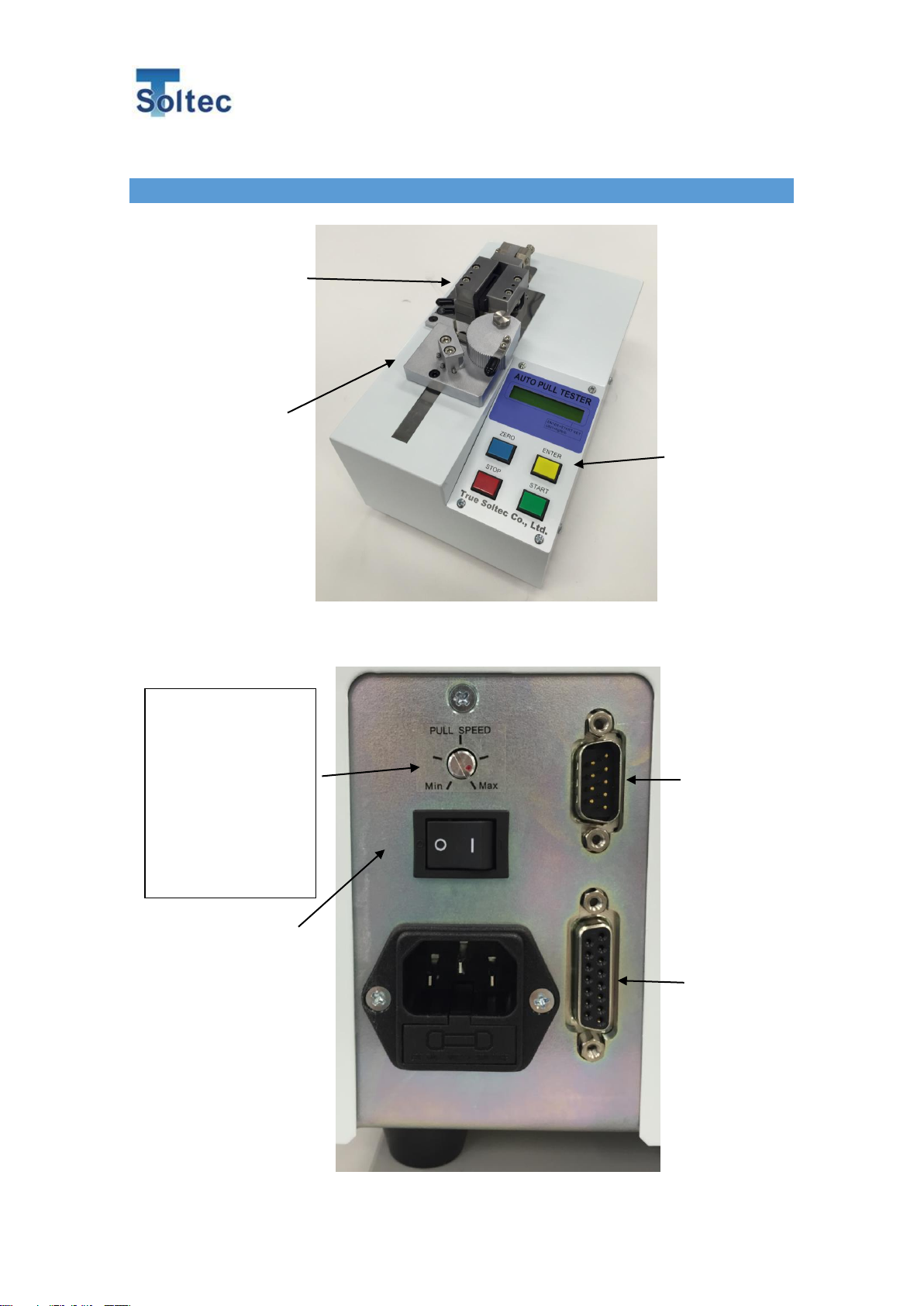

5. Start Pull Test

1. Confirm that the cable clamper is at the

home position.

2. Push the terminal clamper open lever and

set a terminal to the terminal clamper.

Releasing the terminal clamper open lever

allows the terminal to be fixed.

3. Push the START button on the controller

panel.

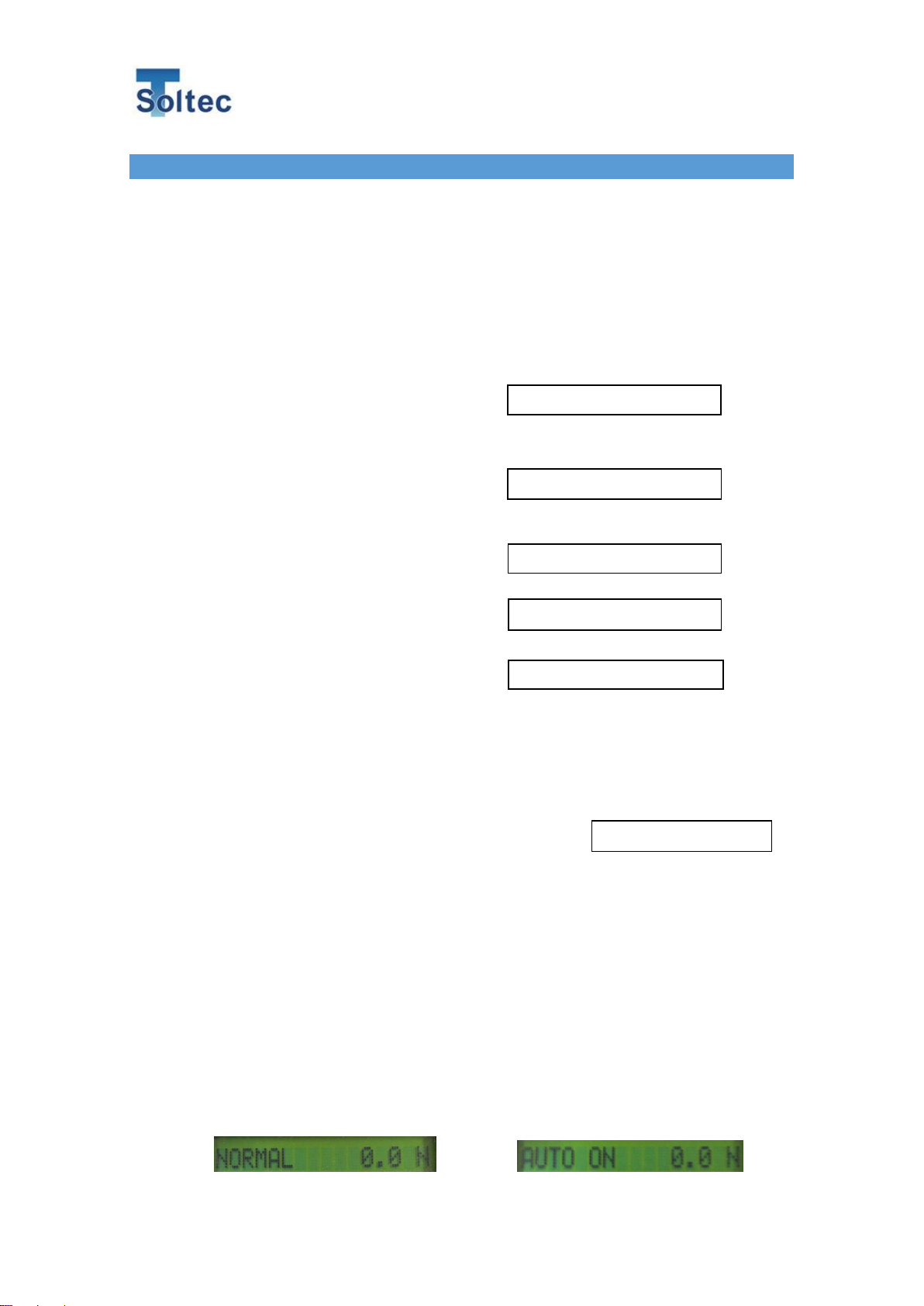

A pull test starts. The cable clamper

automatically goes backward while the cable

is caught in the clamp roller. The display

indicates a pull force in real time mode.

The controller detects a wire-strands

breakage automatically and stops the motor

rotation. The display indicates the peak value of its pull test.

Note:

The peak value remains on the display until the

ENTER or START button is pushed again.

When [ENTER] button is pushed:

When the RS232C port on the back

panel is connected to PC, the peak load

value is sent to the PC.

When [START] button is pushed:

When the RS232C port on the back

panel is connected to PC, the peak load

value is not sent to PC.

Note:

When the RS232C port on the back

panel is not connected to PC, pushing

either of the ENTER button or START

button makes no differences.

The RS232C cable is not included in

the accessory. Use a D-SUB9pins

RS232C cross cable commercially available.

4. Push the ENTER or START button and the cable clamper goes back to the home

position, while the cable is automatically released. Remove it from the pull tester.

Wire strands breakage and Peak Value

Motor reverse rotation for home