3

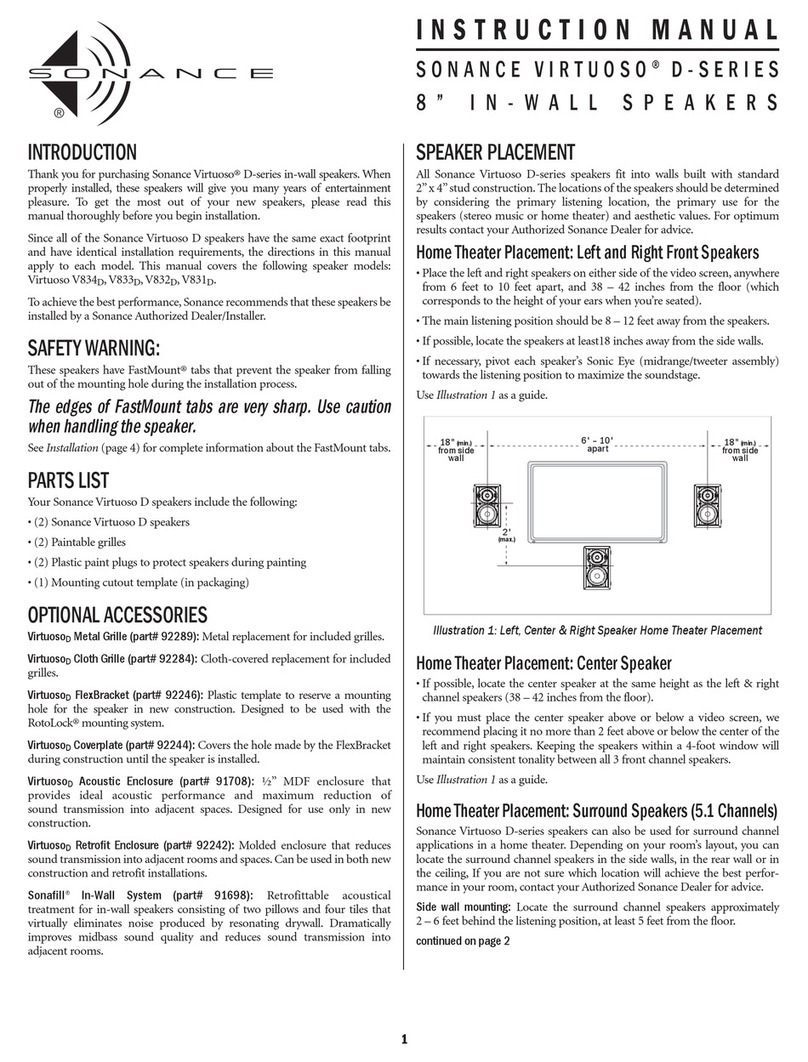

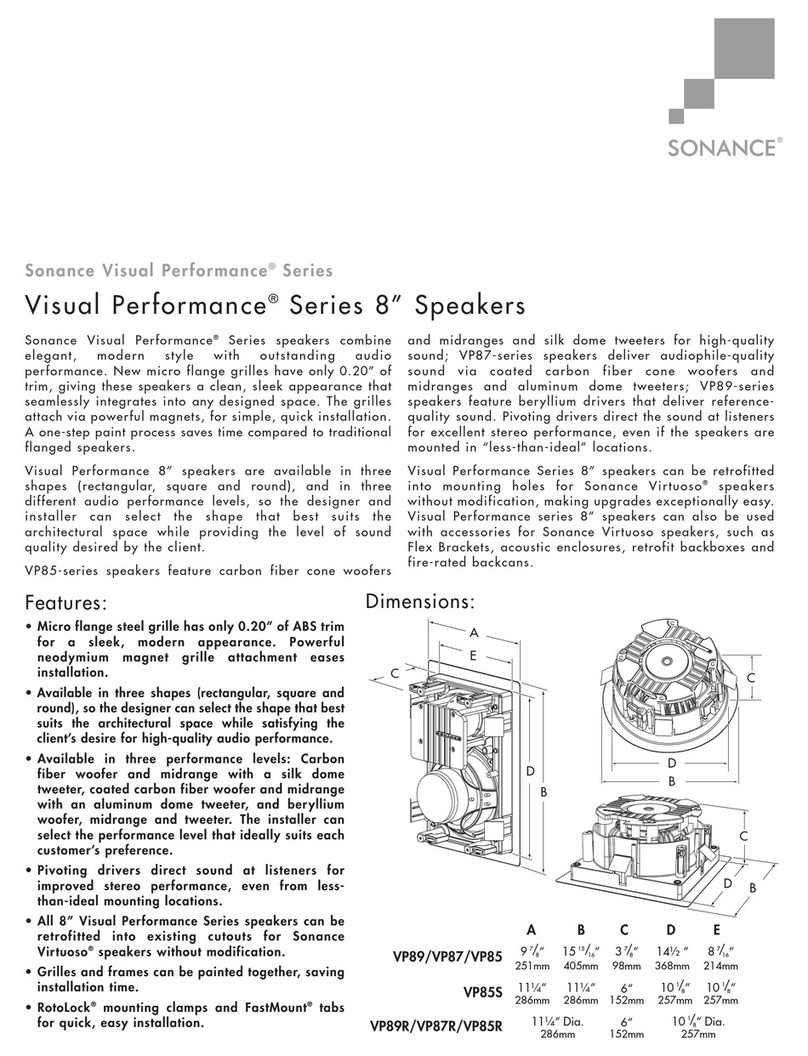

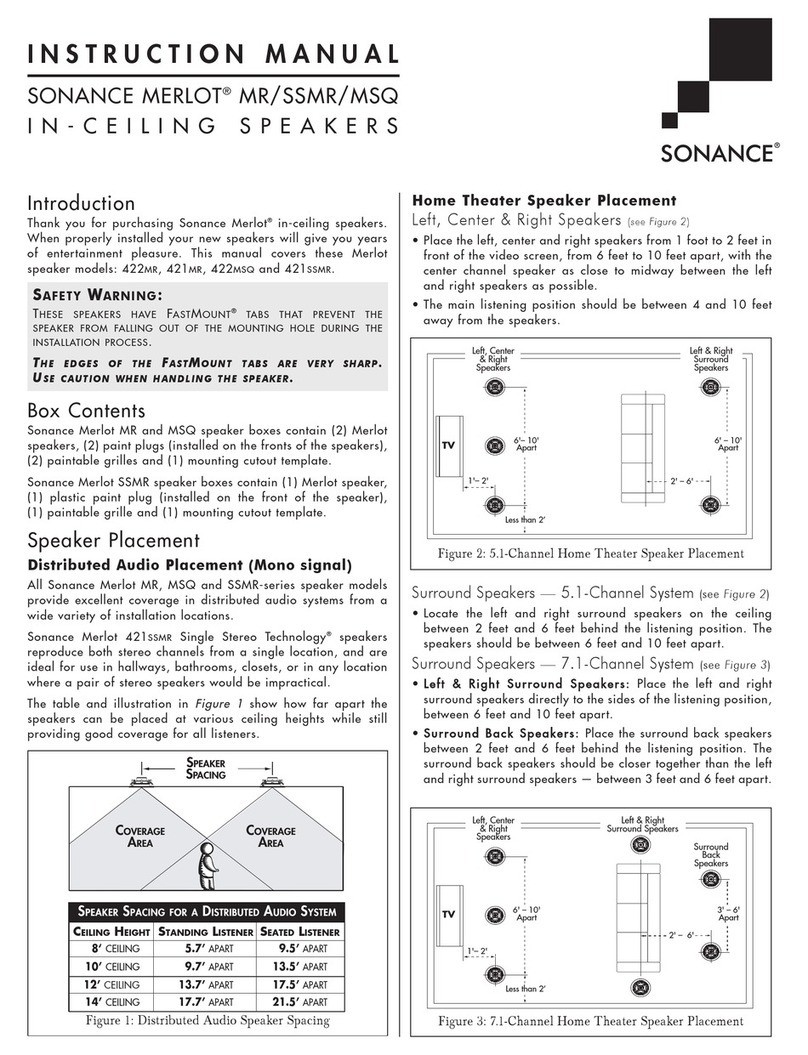

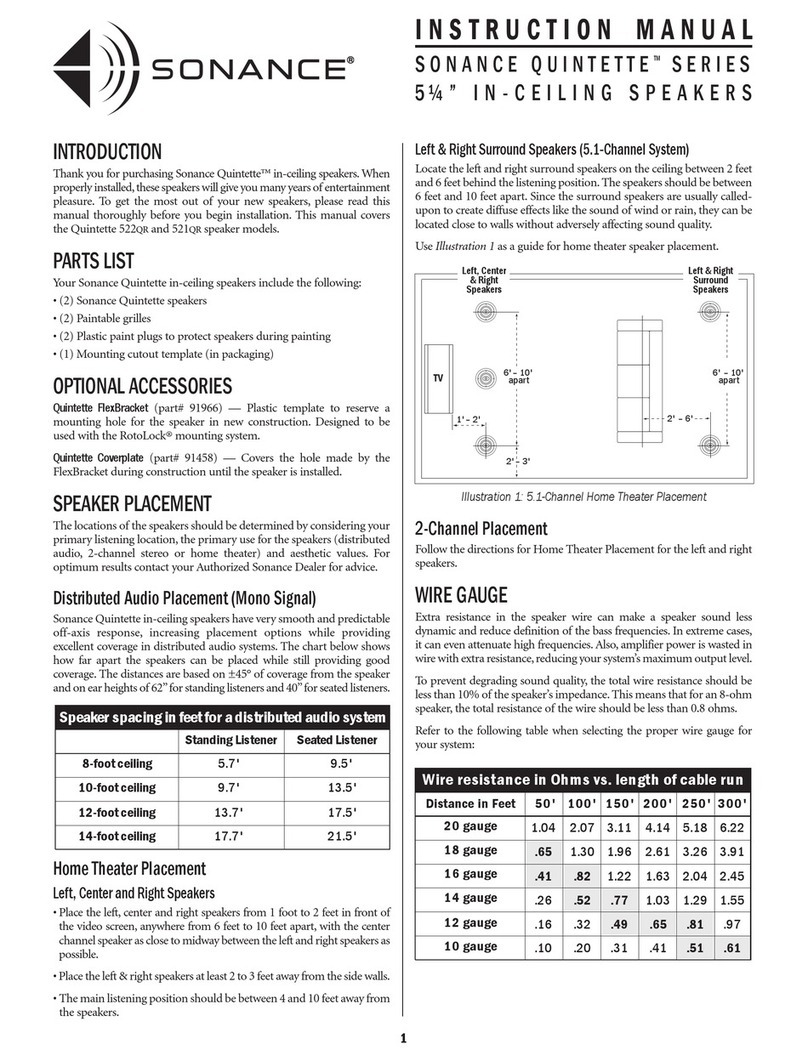

SPEAKER PLACEMENT

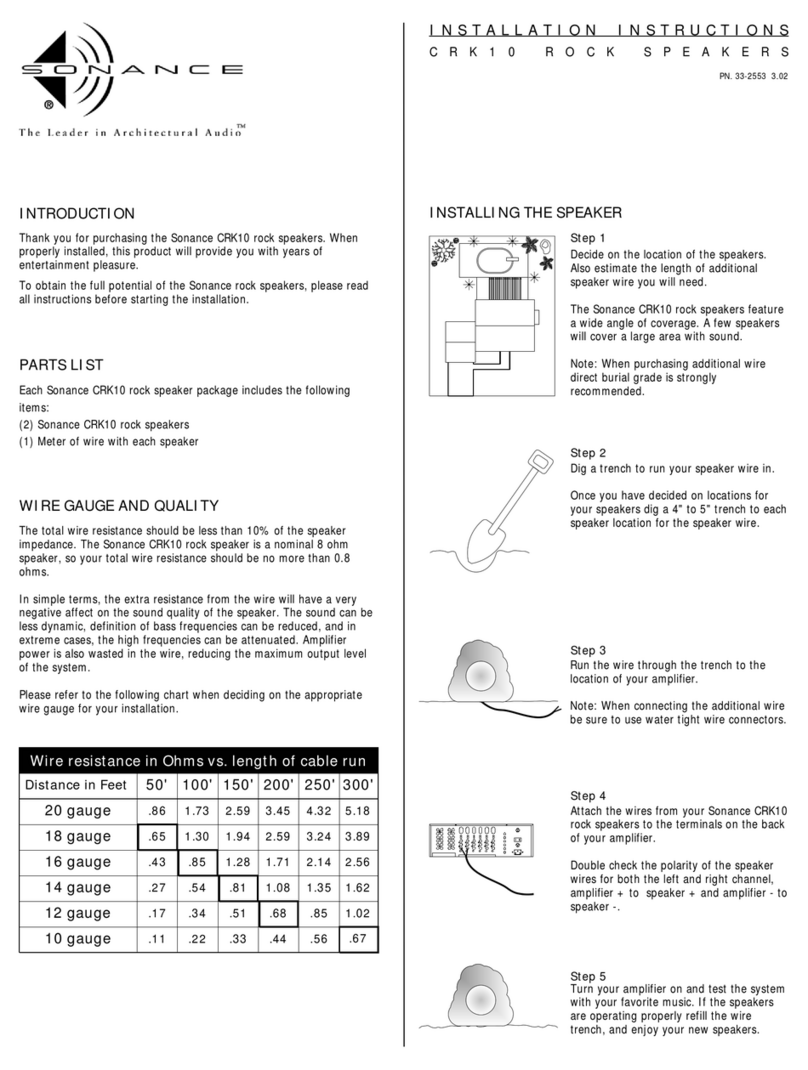

Sonance Professional Series speakers possess extremely

smooth and predictable off-axis frequency response. The

chart below shows how far apart the speakers can be

placed in a distributed audio system (see Figure 2). The

calculations are based on +/- 45 degrees of coverage from

the speaker, and listener ear heights of 62” for standing

and 40” for seated.

AMPLIFIER SELECTION

When choosing an amplier the maximum number of

speakers and the output level of each speaker must be

known. The sum of the tap settings should never exceed

80% of the amplier’s rated output. For example, if there

are ve speakers and the taps are set at 15 watts, the load

would be 75 watts (5 x 15 watts = 75 watts). To arrive at

the needed power for this number of speakers, simply

divide the total load by 0.8. In this case, 75 / 0.8 = 93.75

watts. Therefore, a standard 100 watt amp would safely

drive this load. To calculate the amount of usable power

an amp offers, simply multiply the rated output by 0.8,

i.e., 100 watts x 0.8 = 80 watts.

The most common wire used on commercial 70 volt

systems is 18 gauge, 2 conductor, stranded, and jacketed

without a shield. The wire starts at the amplier location

and is paralleled at each speaker location. Wire length

using 18 gauge is appropriate up to 700ft with a 100 watt

load. If you double the load (sum of your tap settings),

you will reduce the footage by half, to 350ft. Conversely, if

you halve the load, you may double the acceptable wire

length, i.e., a 50 watt load is safe over 1,400ft of 18 gauge.

Stepping up to 16 gauge wire extends the allowable run

length by approximately 35%. For example, a 100 watt

load can go 700ft on 18 gauge; the same load may be

placed on 1,100ft of 16 gauge.

When using Sonance Professional Series loudspeakers

in an 8 ohm system the total wire resistance should be

less than 10% of the speaker impedance. The speakers

are nominally 8 ohms impedance, so your total wire

resistance should be no more than 8 ohms. In simple

terms, the extra resistance from the wire will have a

very negative affect on the sound quality of the speaker.

The sound can be less dynamic, denition of bass

frequencies can be reduced, and in extreme cases, the

high frequencies can be attenuated. Amplier power is

also wasted in the wire, reducing the maximum output

level of the system. Please refer to the following chart

when deciding on the appropriate wire gauge for your

installation (see Figure 1).

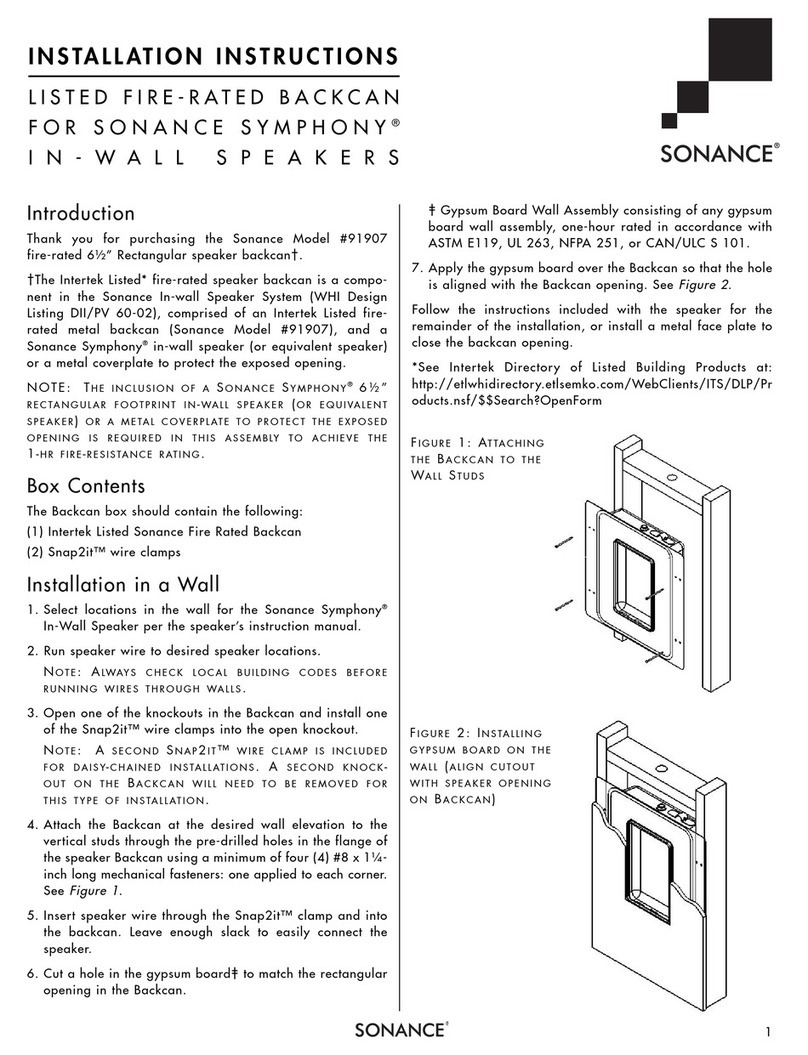

Figure 1: Wire Resistance

Figure 2: Speaker Spacing

WIRE RESISTANCE IN OHMS VS. LENGTH OF CABLE RUN

20 Gauge

50’ 100’ 150’ 200’ 250’ 300’

0.86 1.73 2.59 3.45 4.32 5.18

0.65 1.30 1.94 2.59 3.24 3.89

0.43 0.85 1.28 1.71 2.14 2.56

0.27 0.54 0.81 1.08 1.35 1.62

0.17 0.34 0.51 0.68 0.85 1.02

Distance in Feet

18 Gauge

16 Gauge

14 Gauge

12 Gauge

SPEAKER

SPACING

COVERAGE

AREA

COVERAGE

AREA

Speaker Spacing in Feet for a Distributed Audio System

8-Foot Ceiling 5.7’ (1.7m) Apart

9.7’ (3.0m) Apart

13.7’ (4.2m) Apart

17.7’ (5.4m) Apart

9.5’ (2.9m) Apart

13.5’ (4.1m) Apart

17.5’ (5.3m) Apart

21.5’ (6.6m) Apart

Standing Listener Seated Listener

10-Foot Ceiling

12-Foot Ceiling

14-Foot Ceiling

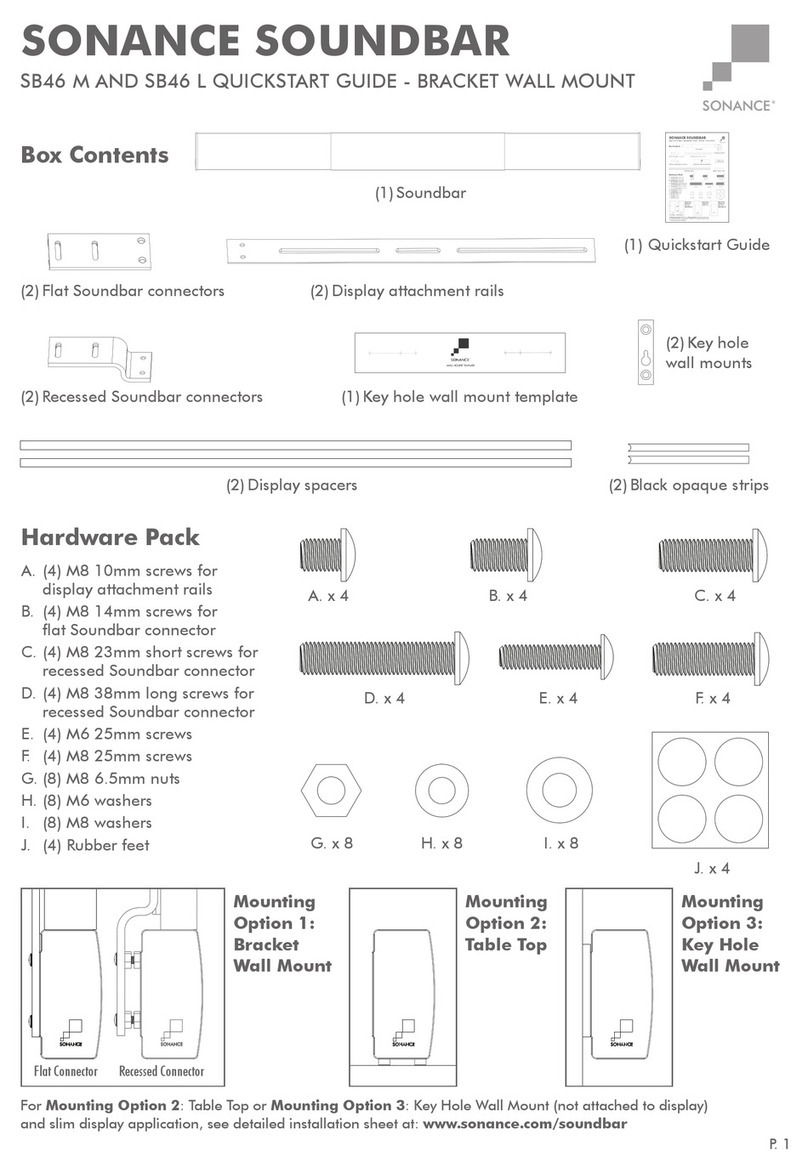

1. Prime the grille with a metal primer/bonder in

a spray can. Carefully follow the manufacturer’s

directions on the can.

2. We recommend using water-based latex paint on the

grilles. Thin the paint with a proper thinning agent to

a ratio of 1:1 paint-to-thinner, and strain it through a

standard mesh strainer to remove any lumps.

3. Use a small touch-up gun or cap-spray gun with a #3

tip for painting.

• Set the nozzle with a medium to wide fan

• Set the pressure regulator to 60psi

• Lightly spray the front of the grille in three quick

strokes from approximately 10” away

• Let the paint set for one minute, then turn the grille

90º and lightly spray the grille again in three quick

strokes. Repeat this step until all four sides of the

grille have been evenly painted.

4. While the paint is still wet, inspect the grille and

make sure that excess paint has not collected

underneath the grille frame, and that none of the

grille perforations are lled with paint. If any are,

use compressed air to blow the paint out of the

perforations. IMPORTANT: If you nd any grille

perforations that are plugged with paint after the

paint has dried, use a straight pin or sewing needle to

carefully remove the paint.