Sonardyne UM-8300-Compatt 6 User manual

UM-8300-Compatt 6

User Manual for the Type 8300 Compatt 6 (and

Variants)

Issue B, Rev 3

Date of Issue:24th April 2019

Sonardyne International Limited

Blackbushe Business Park

Yateley, Hampshire

GU46 6GD, United Kingdom

920-0026

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

E. support@sonardyne.com

www.sonardyne.com

© 2016–2019 Sonardyne International Limited. All rights reserved.

This user manual is the copyright and intellectual property right of Sonardyne International Limited

(“Sonardyne”) and is provided solely for the customer’s use of the Sonardyne equipment as described

in this user manual and in accordance with Sonardyne’s then prevailing terms and conditions of sale.

This user manual has been compiled to the best of Sonardyne’s knowledge and belief, but no

representation, warranty (whether express or implied) or guarantee is made to any persons or legal

entities as to the accuracy, reliability or completeness of the information contained in this user manual.

This user manual contains the proprietary, confidential information of Sonardyne and other third parties

and as such may not be used, disclosed or placed in the public domain (by whatever means) by the

customer except expressly in accordance with and subject to the above referenced terms and

conditions of sale.

The copyright and any and all intellectual property rights of any and all third parties which may be

referenced in this user manual or which may have provided proprietary products and/or software

and/or documentation (in whatever format) to Sonardyne in respect of the Sonardyne equipment as

described in this user manual are hereby duly acknowledged. The provision of any and all such

products and/or software and/or documentation by Sonardyne shall be subject to and in accordance

with the relevant third parties’ terms and conditions or the Sonardyne then prevailing conditions of sale,

as appropriate.

The Sonardyne equipment described in this user manual is protected by various UK and US Patents

and other patents internationally and registered trademarks of Sonardyne International Limited.

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

i

Contacting the Sonardyne Support Team

24-hour Emergency Telephone Helpline: +44 (0) 1252 877600

The Sonardyne 24-hour helpline is answered at the UK Headquarters during normal office hours

(08:00 to 17:00). Outside these hours, your call is automatically transferred to an agency, which logs

the details of your emergency and alerts the appropriate Sonardyne personnel.

Our aim is to make sure emergency requests are dealt with immediately during office hours, and are

responded to within 30 minutes at all other times.

Please note the helpline is for emergency use only.

If you require NON-EMERGENCY product support, please contact your nearest Sonardyne office.

Alternatively, contact the Sonardyne Head Office:

Sonardyne International Ltd

Blackbushe Business Park

Yateley

Hampshire

GU46 6GD

United Kingdom

Telephone: +44 (0) 1252 872288

Fax: +44 (0) 1252 876100

Email: support@sonardyne.com

Note

Email and telephone support is available during normal UK office hours (08:00 to 17:00).

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

ii

Contents

Contacting the Sonardyne Support Team ii

Amendment History x

Section 1 – Introduction 1

1.1 Scope of this Manual 1

1.2 Purpose of this Manual 1

1.3 Related Publications 1

1.4 Conventions 1

Section 2 – Safety 2

2.1 Introduction 2

2.2 Safety Procedures 2

2.2.1 Warnings 2

2.2.2 Cautions 3

2.2.3 Handling Procedures for CMOS Devices and Circuit Boards 4

Section 3 – Technical Description 5

3.1 Introduction 5

3.2 Compatt 6 Series (Type 8300) 5

3.2.1 Compatt 6 5

3.2.2 Midi Compatt 6 6

3.2.3 Mini Compatt 6 6

3.2.4 Maxi Compatt 6 7

3.3 Type 8300 Variants 7

3.3.1 Dynamic Positioning Transponder 6 (Type 8301) 7

3.3.2 Pressure Inverted Echo Sounder (Type 8302) 8

3.3.3 Autonomous Monitoring Transponder (Type 8305) 8

3.3.4 Modem 6 Transponder (Type 8307) 9

3.3.5 Sensor Logging Transponder (Type 8308) 9

3.4 Housing Labelling 10

3.4.1 Top Label 10

3.4.2 Bottom Label 10

3.5 Endcaps 12

3.5.1 Transducer Endcap 12

3.5.2 Sensor Endcap 13

3.6 Connector 14

3.7 Battery 14

3.7.1 Battery Type 14

3.7.2 Battery Disconnect Fob 15

3.7.3 Battery Replacement 15

Section 4 – Installation 17

4.1 Introduction 17

4.2 Pre-Use Checks 17

4.2.1 Check the Pressure Relief Vent Valve 17

4.2.2 Floatation 17

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

iii

4.2.3 Anchor Weights 17

4.2.4 Strops 18

4.2.5 Mounting Guidelines for Endcaps with an Inclinometer 18

Section 5 – Deployment 22

5.1 Introduction 22

5.2 Lifting 22

5.3 Deployment from Ship 22

5.3.1 Recommended Method 22

5.3.2 Additional Deployment methods 22

Section 6 – Operation 26

6.1 Introduction 26

6.2 Operational Modes 26

6.2.1 Responder Mode 26

6.2.2 Operating Notes for External Power Out 26

6.2.3 Modem 6 27

6.2.4 Operating Notes for Inclinometer Variants 27

Section 7 – Retrieval and Storage 28

7.1 Introduction 28

7.2 Retrieval Planning 28

7.3 Retrieval from the Water 28

7.4 After Retrieval 28

7.5 Storage 29

Section 8 – Maintenance 30

8.1 Introduction 30

8.2 Retrieval from the Water 30

8.3 Cleaning 30

8.4 Inspection 30

8.5 Lubrication 31

8.5.1 Subconn Connectors 31

8.5.2 Endcap O-Rings 31

8.6 Scheduled Maintenance and Recalibration 32

8.6.1 Pressure Sensor Oil Top-Up 33

8.6.2 Depth Sensor (Digiquartz®) Recalibration 33

8.7 Pressure Relief Vent Valve 34

8.7.1 Operating the Pressure Relief Vent Valve 34

8.8 Battery Maintenance 35

8.8.1 Checking the Battery Condition 35

8.8.2 Disconnecting and Replacing the Battery 35

8.9 Removal and Fitment of a Directional Transducer Endcap 39

8.9.1 Directional Transducer Endcap Removal 39

8.9.2 Fitment of the Directional Transducer Endcap 41

8.10 Removal and Fitment of Omni-Directional Transducer Endcap 43

8.10.1 Omni-Directional Transducer Endcap Removal 43

8.10.2 Fitment of the Omni-Directional Transducer Endcap 46

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

iv

8.11 Removal and Fitment of the Sensor Endcap 47

8.11.1 Sensor Endcap Removal 47

8.11.2 Sensor Endcap Fitment 52

8.12 Corrosion Removal 58

Section 9 – Functional Test 59

9.1 Introduction 59

9.2 Test Equipment 59

9.2.1 6G Terminal Lite 59

9.2.2 iWAND Hand Test Device 59

9.3 Operational Testing 60

9.3.1 Connecting the Dual Serial Cable 61

9.3.2 Checking the Wideband Acoustics 63

9.3.3 Checking the Sensor Measurements 67

9.3.4 Checking the Release Mechanism 69

9.3.5 Creating a Test Report 74

Section 10 – Firmware Update 77

10.1 Introduction 77

10.2 Firmware Update Procedure 77

10.3 DAS Firmware Update 80

Section 11 – Fault Diagnosis 84

11.1 Introduction 84

11.2 Fault Types 84

Section 12 – Spares 86

12.1 Introduction 86

12.2 Recommended Spares 86

12.2.1 Batteries 86

12.2.2 Sonardyne Upgrades 86

12.2.3 Miscellaneous Parts 86

12.2.4 Cables 87

Section 13 – Technical Specifications 88

13.1 Mechanical – Compatt 6 Type 3111 with Release Endcap 88

13.2 Mechanical – Mini Compatt 6 Type 3131 88

13.3 Mechanical – Midi Compatt 6 Type 3141 with Release Endcap 88

13.4 Mechanical – Maxi Compatt 6 Type 3141 with Release Endcap 89

13.5 Battery Life 89

13.6 6G Battery Life Estimator 90

13.7 Communication Port 91

13.8 Acoustic 91

13.9 Environmental 91

13.10 Sensors 91

13.11 Responder Input Trigger (Sync Input) 92

13.12 Nett Upthrust 93

13.13 Outline Drawings 93

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

v

13.13.1 3,000 m Omni-Directional 93

13.13.2 3,000 m MF Omni-Directional Aluminium Housings 93

13.13.3 3,000 m MF Directional Aluminium Housings 98

13.13.4 3,000 m LMF Omni-Directional Aluminium Housings 102

13.13.5 3,000 m LMF Directional Aluminium Housings 106

13.13.6 3,000 m MF Omni-Directional Super Duplex Housings 109

13.13.7 3,000 m LMF Omni-Directional Super Duplex Housings 111

13.13.8 5,000 m MF Omni-Directional Aluminium Housings 113

13.13.9 5,000 m MF Directional Aluminium Housings 116

Appendix A – Acoustic Positioning Methods 119

A.1 Long Baseline (LBL) 119

A.1.1 Hardware 119

A.1.2 Principles 119

A.1.3 Beacon Numbers 120

A.1.4 Baseline Distance 120

A.1.5 Calibration 120

A.2 Short Baseline (SBL) 120

A.2.1 Hardware 120

A.2.2 Baseline Distances 121

A.2.3 Principles 121

A.3 Ultra-short Baseline (USBL) 122

A.3.1 Hardware 122

A.3.2 Principles 122

A.4 Long / Ultra-short Baseline (L/USBL) 123

A.4.1 Hardware 123

A.4.2 Principles 123

A.4.3 Non-Critical Operations 123

A.4.4 Critical Operations 123

A.4.5 Dual Operation 124

A.5 Long-short USBL (LSUSBL) 124

A.5.1 Hardware 124

A.5.2 Principles 124

Appendix A – Basic Principles of Transponder Interrogation and Reply 125

A.1 Transceivers 126

A.2 Command and Telemetry Functions 126

A.3 Communicating via RS232 126

A.4 Acoustic Navigation System Principles 127

Definitions 128

Figures

Figure 3–1 Compatt 6 Transponder – Omni-Directional 6

Figure 3–2 Compatt 6 Transponder – Directional 6

Figure 3–3 Midi Compatt 6 6

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

vi

Figure 3–4 Mini Compatt 6 7

Figure 3–5 Maxi Compatt 6 7

Figure 3–6 Dynamic Positioning Transponder 6 Transponder 8

Figure 3–7 Pressure Inverted Echo Sounder Transponder 8

Figure 3–8 Autonomous Monitoring Transponder 9

Figure 3–9 Sensor Logging Transponder 10

Figure 3–10 Transducer Endcap Internal Connectors 12

Figure 3–11 Example of a Sensor Endcap 13

Figure 3–12 Subconn MCBH8F Connector 14

Figure 3–13 Battery Disconnect Fob 15

Figure 4–1 Example of Inclinometer Mounting Kit 19

Figure 4–2 Example of Stab Mounting Kit 20

Figure 4–3 Recommended Specification for Inclinometer Endcap Mounting Plate 21

Figure 5–1 Rolling the Transponder off the Deck 22

Figure 5–2 Lowered by Vessel Crane or A-Frame – Single Transponder Installation 23

Figure 5–3 Lowered by Vessel Crane or A-Frame – Multiple Transponder Installation 23

Figure 5–4 Acoustic Release used as a Crane Hook 24

Figure 5–5 Slip Hook with Integral Swivel 25

Figure 5–6 ROV grabs one metre loop of Rope 25

Figure 6–1 Responder Input 26

Figure 8–1 Fitting the Bulkhead Plate 38

Figure 8–2 Inspecting the Transducer Endcap 38

Figure 8–3 Removing the Protective Guard 39

Figure 8–4 Removing the Guard and Bump Stop 40

Figure 8–5 Removing Transducer Housing using the Opening Tools (Omni-Directional shown for

Reference) 40

Figure 8–6 Cleaning the O-ring Seals (Omni-Directional shown for Reference) 41

Figure 8–7 Refitting the Guard and Bump Stop 42

Figure 8–8 Securing the Bump Stop and Guard 43

Figure 8–9 Removing the Clamp Rings 44

Figure 8–10 Removing the Rubber Bump Stop 44

Figure 8–11 Removing Transducer Housing using the Opening Tools 45

Figure 8–12 Cleaning the O-ring Seals 45

Figure 8–13 Fitting Clamp Rings and Bumper Stop 47

Figure 8–14 Securing Bump Stop to Clamp Rings 47

Figure 8–15 Figure 0-13 Remove the Sensor Endcap 48

Figure 8–16 Removing the Sensor Endcap 49

Figure 8–17 Sensor Endcap and Chassis 49

Figure 8–18 Disconnecting PL1 Connection from the Interface PCB Assembly 50

Figure 8–19 Disconnecting PL2 Connection from the Interface PCB Assembly 50

Figure 8–20 Disconnecting the Ribbon Cable from the Interface PCB Assembly 51

Figure 8–21 Disconnecting the Sensor Endcap from the Main Chassis 51

Figure 8–22 Abutting Chassis and Sensor Endcap 53

Figure 8–23 Securing the Sensor Endcap to the Chassis 53

Figure 8–24 Interface PCB Connections 54

Figure 8–25 Inserting the Chassis into the Housing 54

Figure 8–26 Fitting the Bulkhead Plate over the Pins 57

Figure 9–1 Compatt 6 Connected to the PC using the Dual Serial Cable 60

Figure 9–2 Dual Serial Cable 61

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

vii

Figure 9–3 Release Mechanism Fully Open 70

Figure 9–4 Release Mechanism Fully Closed 70

Figure 9–5 Release Mechanism Rotating Lock 70

Figure 9–6 Release Test 71

Figure 9–7 Manually Closing the Release Mechanism 73

Figure 9–8 Transponder Test Report pdf 76

Figure 13–1 Estimated Battery Life (Alkaline) 89

Figure 13–2 Estimated Battery Life (Standard Lithium) 90

Figure 13–3 6G Battery Life Estimator App. 90

Figure 13–4 6G Battery Life Estimator App. QR Code 90

Figure 13–5 Type 830x-3111 (Standard Length 3,000 m MF Omni-Directional) 94

Figure 13–6 Type 830x-3121 (Maxi 3,000 m MF Omni-Directional) 95

Figure 13–7 Type 830x-3131 (Mini 3,000 m MF Omni-Directional) 96

Figure 13–8 Type 830x-3141 (Midi 3,000 m MF Omni-Directional) 97

Figure 13–9 Type 830x-3113 (Standard Length 3,000 m MF Directional) 98

Figure 13–10 Figure 0-10 Type 830x-3123 (Maxi 3,000 m MF Directional) 99

Figure 13–11 Type 830x-3133 (Mini 3,000 m MF Directional) 100

Figure 13–12 Type 830x-3143 (Midi 3,000 m MF Directional) 101

Figure 13–13 Type 830x-3115 (Standard Length 3,000 m LMF Omni-Directional) 102

Figure 13–14 Type 830x-3125 (Maxi 3,000 m LMF Omni-Directional) 103

Figure 13–15 Type 830x-3135 (Mini 3,000 m LMF Omni-Directional) 104

Figure 13–16 Type 830x-3145 (Midi 3,000 m LMF Omni-Directional) 105

Figure 13–17 Type 830x-3116 (Standard Length 3,000 m LMF Directional) 106

Figure 13–18 Type 830x-3126 (Maxi 3,000 m LMF Directional) 107

Figure 13–19 Type 830x-3146 (Midi 3,000 m LMF Directional) 108

Figure 13–20 Type 830x-3311 (Standard Length 3,000 m MF Omni-Directional) 109

Figure 13–21 Type 830x-3321 (Maxi 3,000 m MF Omni-Directional) 110

Figure 13–22 Type 830x-3315 (Standard Length 3,000 m LMF Omni-Directional) 111

Figure 13–23 Type 830x-3325 (Maxi 3,000 m LMF Omni-Directional) 112

Figure 13–24 Type 830x-5211 (Standard Length 5,000 m MF Omni-Directional) 113

Figure 13–25 Type 830x-5221 (Maxi 5,000 m MF Omni-Directional) 114

Figure 13–26 Type 830x-5241 (Midi 5,000 m MF Omni-Directional) 115

Figure 13–27 Type 830x-5213 (Standard Length 5,000 m MF Directional) 116

Figure 13–28 Type 830x-5223 (Maxi 5,000 m MF Directional) 117

Figure 13–29 Type 830x-5243 (Midi 5,000 m MF Directional) 118

Figure A–1 Typical LBL System 119

Figure A–2 Typical SBL System 121

Figure A–3 Typical USBL System 122

Figure A–4 Typical L/USBL system 123

Tables

Table 1–1 Related Publications 1

Table 1–2 Conventions used in this Manual 1

Table 3–1 Type Number Identification 11

Table 3–2 Address Range 12

Table 7–1 Storage Conditions 29

Table 8–1 Lubricants 31

Table 8–2 Maintenance and Recalibration Schedule 33

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

viii

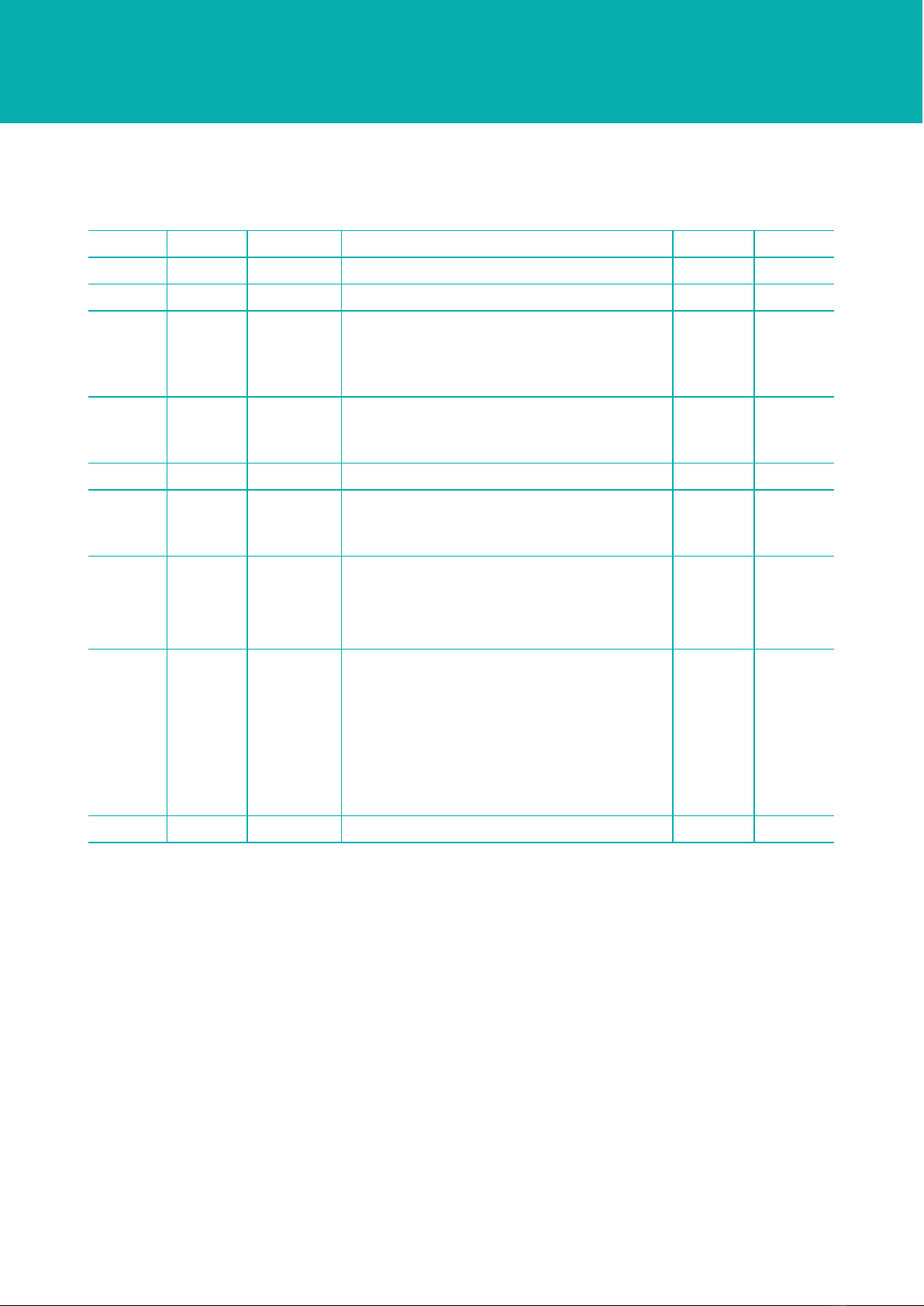

Amendment History

The amendment history records all amendments and additions made to this manual.

Issue Revision Date Comments Section Page

A 0 30/09/2010 First Issue All All

A 1 30/11/2010 Minor Changes All -

A 2 07/12/2010 Removed Section 4.2 – changing the

inclinometer scaling range as this no longer

applies for 6th Generation Transponders. Other

minor typographical changes.

4.2 -

A 3 17/01/2011 Improved drawing resolution and details in

Section 15. Section 4.1 inclinometer endcap

drawing and mounting instructions clarified.

4.1, 15 -

A 4 21/01/2011 Improved the wording consistency. 2 -

B 0 18/02/2013 Reformatted the manual. Improved overall

construction and consistency. Include new 6G

Terminal Lite Software.

All All

B 1 19/08/2013 ECN12238

Stock code for PCBs in recommended spares

listing changed.

Section 6.3 External Connector Pin-Out.

12

6.3

111

29

B 2 25/10/2016 OB11543/11657

Maintenance Section updated.

Storage details added.

References to iWAND added.

References to battery disconnect fob added.

Outline Drawings updated.

Sections re-organised and general update.

7

7.5

8

All

13.13

All

All

24

All

All

88–110

All

B 3 24/04/2019 General update All All

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

x

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Section 1 – Introduction

1.1 Scope of this Manual

This User Manual describes the safe installation, operation and maintenance of the Type 8300 (and

variants) wideband transponder. The information and procedures within this manual are based on

Sonardyne’s experience and knowledge.

1.2 Purpose of this Manual

This user manual contains information for anyone involved with installing, operating and maintaining

the Type 8300 (and variants) wideband transponder.

This manual may be printed in part or whole but cannot be copied or changed. Copyright of this

manual remains with Sonardyne International Limited at all times.

To ensure the safety of the installer and operator is maintained it is important that all warnings and

cautions in Section 2 "Safety" of this manual and in any related manuals are read and fully understood.

1.3 Related Publications

To ensure the equipment is operated safely, a Sonardyne Safety Manual is supplied with this user

manual. It is important that the Sonardyne Safety Manual is read and fully understood before

proceeding with any activity on the equipment.

Publication Title

Sonardyne Safety Manual Operational and Safety Precautions

UM-8300-099 User Manual for 6G Terminal Lite (included on the 6G Utilities media)

UM-8315 User Manual for the Type 8315 iWAND (included with the iWAND)

IM-Modem 6 Modem 6 Integration Manual

Table 1–1 Related Publications

1.4 Conventions

Format Convention

Boldface Type User Input, Menu Options, Keys, e.g. Click OK

Arrow (>) Selection of an additional menu item e.g. File>Save

Italic Type References to Figures, Tables, Sections and internal/external source

Table 1–2 Conventions used in this Manual

Section 1 – Introduction 1

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Section 2 – Safety

2.1 Introduction

Before any activity is carried out on the equipment, it is recommended that the included Sonardyne

Safety Manual and all warnings and cautions in this manual are read and fully understood.

It is recommended that the operator complies with the Health and Safety Regulations applicable to the

vessel and the region before operating this equipment.

Operators and service personnel must be familiar with the normal operating and safety procedures for

the subsea equipment being operated.

Documentation must be consulted whenever a or warning symbol is found on the equipment,

in order to determine the nature of the potential hazard and any actions which must be taken.

If any additional equipment is used, any warnings and cautions in the equipment user manual must be

read and fully understood and the equipment must only be used as specified by the manufacturer.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

The safety of any system incorporating this equipment is the responsibility of the assembler of the

system.

2.2 Safety Procedures

Warning and Caution terms used in this manual are described below:

lWarning: indicates potential for property damage, personal injury or death.

lCaution: indicates either potential damage to hardware, malfunction or loss of data.

2.2.1 Warnings

Personal protection. Appropriate protective equipment such as protective footwear, hard hat and

gloves must be worn when handling or carrying out any procedures involving Sonardyne and other

equipment.

Heavy equipment. Many Sonardyne products and equipment types, such as transponders,

transceivers, cable drums etc. require Manual Handling Equipment (MHE) for lifting due to their heavy

weight. If MHE is not available, it is the responsibility of the operator to perform a manual handling risk

assessment prior to carrying out manual lifting/handling. See the individual equipment documentation

for weight specifications.

Electric shock. Electric shock hazard risk is present when dismantling or assembling the

equipment. High voltages are present inside the transponder. Dismantling or assembling the

equipment must only be carried out by trained personnel.

High Internal Pressures Risk. Due to the high internal pressure risk, dismantling the sub-sea

equipment must only be carried out by trained personnel.

High Internal Pressures Risk. Make sure the pressure relief vent valve is manually operated to

release any internal pressure before attempting to dismantle the equipment.

Section 2 – Safety 2

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Risk of toxic gases and corrosive liquids. Do not stand in direct line with the end of the transponder

when operating the pressure relief vent valve. Sudden release of high pressure gases could cause

injury to personnel. Wear Personal Protective Equipment such as goggles when operating the

pressure relief vent valve.

Risk of burns. If the battery pack has been exposed to flooding, corrosive liquids may be present.

Personal protective equipment, such as gloves and goggles, must be worn to handle the battery pack.

Risk of burns. Do not carry out maintenance on the transponder if the housing is hot. Lower the

transponder into cold water and wait for the housing to cool. Wear Personal Protective Equipment

such as gloves.

Risk of impact injury. Do not stand in line with the endcap when removing from the transponder.

Any internal pressure could rapidly force the endcap from the transponder like a projectile.

Risk of Explosion. Do not fit unauthorised battery pack types into the transponder.

Risk of Explosion. For lithium and lithium Ion battery packs, Class D fire extinguishers should be

used. Do not use any other type of extinguisher.

Crush Risk. Do not place hands near the Release Mechanism when in operation. The mechanism

is opened with a high pressure spring which could trap fingers.

2.2.2 Cautions

Risk of equipment damage. All instruments must be maintained according to their individual

operating manuals. Failure to follow recommended procedures could result in instrument failure, and

loss of system integrity.

Irritant chemicals. Molykote 44 is a mild irritant. When lubricating the connector faces, personal

protective equipment such as gloves and goggles must be worn.

Battery Power Failure. Do not charge the battery packs in any way not outlined in this manual.

Failure to follow instructions may result in a loss of battery pack life or damage to the battery packs.

Dispose of batteries in accordance with local health and safety and environmental regulations.

Loss of Current Protection. Do not allow the transponder to be cooled or heated during the

charging process as the over current protection component characteristics may change adversely.

Damage to Sealing. Make sure the O-ring seals do not become damaged during removal of the

endcaps.

Damage to Connectors. Failure to clean sand or silt correctly could result in damage to the

connectors and O-ring seals.

Multiple beacon address conflict. Do not operate multiple beacons on the same Quickset

Wideband settings in the water at the same time. The address must be unique to any one beacon

operating in the same acoustic area.

Loss of Connector Integrity. Do not over apply grease to the female connector. Grease build up

will affect connector integrity.

Section 2 – Safety 3

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Equipment Damage. Only use the authorised battery packs in the transponder. Failure to use the

correct batteries could cause damage to the equipment.

Protective coating failure. Do not use any abrasive brushes or sharp tools to remove marine

growth when cleaning the instrument as this will damage the protective coating and increase the risk

of corrosion.

2.2.3 Handling Procedures for CMOS Devices and Circuit Boards

Complementary Metal Oxide Semi-Conductor (CMOS) devices have diode input protection against

adverse electrical environments such as electrostatic discharge.

Severe electrical transient voltages can be generated during handling.

Static voltages generated by a person walking across a common waxed floor have been measured in

the 4 to 15 kilovolt range. These static high voltages are potentially dangerous when discharged into a

CMOS electronic device, due to the energy stored in the capacity (~300 pF) of the human body at

these voltage levels.

Present CMOS gate protection structures can generally protect against over-voltages. This is usually

sufficient except in the severe cases.

All CMOS devices should be stored and transported in materials that are anti-static. CMOS devices

must not be inserted into conventional plastic “snow”, Styrofoam or plastic trays, but should be left in

their original container until ready for use.

Operators must comply with safety precautions.

Completed assemblies should be placed in anti-static containers before being moved to stations.

All low impedance equipment (pulse generators, etc.) should be connected to CMOS inputs only after

the CMOS is powered up. This type of equipment should be disconnected before power is turned off.

A circuit board containing CMOS devices is an extension of the device and the same handling

precautions apply. Unprotected handling of any board containing edge connectors wired directly to

CMOS device inputs can cause damage.

Do not insert or remove CMOS devices from their original or test sockets with power applied. Check

all power supplies to be used for testing CMOS devices to ensure there are no voltage transients

present.

All CMOS devices should be placed on a grounded bench surface and operators should ground

themselves prior to handling devices, since a person can be statically charged with respect to the

bench surface. Wrist straps in contact with skin are strongly recommended.

Nylon or other static generating materials should not come in contact with CMOS circuits.

When lead straightening or hand soldering is necessary, provide ground straps for the apparatus used

and ensure the soldering irons are grounded.

Section 2 – Safety 4

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Section 3 – Technical Description

3.1 Introduction

The Type 8300 (and variants) series Wideband®2 Transponders are designed for positioning, data

telemetry, data logging functions and remote monitoring of subsea instrumentation.

The Wideband®2 technology uses a correlation reception technique with phase encoded signals over

a wide range of carrier frequencies. Signal coding allows for hundreds of channels enabling multiple

users to work in the same area without interference.

The 8300 (and variants) series Wideband®2 transponders can be fully integrated with other

Sonardyne products from the 6G®range.

This manual covers the following Wideband®2 Transponders:

lType 8300 – Compatt 6 Transponder, including:

oStandard length

oMini

oMidi

oMaxi

lVariants, including:

oType 8301 – Dynamic Positioning Transponder 6 (DPT 6)

oType 8302 – Pressure Inverted Echo Sounder (PIES)

oType 8305 – Autonomous Monitoring Transponder 6 (AMT)

oType 8307 – Modem

oType 8308 – Sensor Logging Transponder (SLT)

3.2 Compatt 6 Series (Type 8300)

The Compatt 6 transponder is designed specifically for full Long Baseline (LBL) subsea deployments.

The standard transducer housing is hard anodised aluminium but it is also available in aluminium

bronze and super duplex stainless steel as well as standard, mini, midi and maxi lengths, depending

on the operational requirements.

The Compatt 6 has a depth rating of 3,000 to 7,000 metres and is available as an omni-directional and

directional transducer. The transponders are available with different sensor options and release

mechanisms. The Compatt 6 is identified by a red coloured housing label.

3.2.1 Compatt 6

The Compatt 6 is approximately 1035 mm overall length (depending on transducer type and sensor

options) with a hard anodised pressure housing approximately 135 mm diameter, protected by a red

sleeve. The sensor endcap can contain a stainless steel release mechanism for releasing an anchor

weight. The Compatt 6 can be fitted with either a lithium or alkaline battery.

Section 3 – Technical Description 5

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Figure 3–1 Compatt 6 Transponder – Omni-Directional

Figure 3–2 Compatt 6 Transponder – Directional

3.2.2 Midi Compatt 6

The Midi is approximately 784 mm overall length (depending on transducer type and sensor options).

The hard-anodised pressure housing is approximately 135 mm diameter. The lithium battery has

approximately 30% of the capacity of the standard lithium battery with the same functionality.

Figure 3–3 Midi Compatt 6

3.2.3 Mini Compatt 6

The Mini is approximately 570 mm overall length (depending on transducer type) and is basically the

same as the Midi Compatt 6 but without any sensor options. The hard-anodised pressure housing is

approximately 135 mm diameter. The lithium battery has approximately 30% of the capacity of the

standard lithium battery with the same functionality.

Section 3 – Technical Description 6

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Figure 3–4 Mini Compatt 6

3.2.4 Maxi Compatt 6

The Maxi is approximately 1604 mm overall length (depending on transducer type and sensor options)

and is designed for long life and/or high intensity applications. The hard-anodised pressure housing is

approximately 135 mm diameter. The lithium battery has twice the capacity of the standard lithium

battery with the same functionality.

Figure 3–5 Maxi Compatt 6

3.3 Type 8300 Variants

Many of the Type 8300 variants shown below are also available in mini, midi and maxi lengths.

3.3.1 Dynamic Positioning Transponder 6 (Type 8301)

The Dynamic Positioning Transponder 6 (DPT 6) is a USBL focused beacon designed specifically for

dynamic positioning applications where structure tracking and baseline measurements are not

required. The transducer is available as an omni-directional and directional, with a depth rating of

3000 and 5000 metres. The transponder’s pressure housing is hard anodised and protected by a red

sleeve. The sensor endcap can contain a stainless steel release mechanism for releasing an anchor

weight. The DPT 6 is identified by an orange coloured housing label.

Section 3 – Technical Description 7

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Figure 3–6 Dynamic Positioning Transponder 6 Transponder

3.3.2 Pressure Inverted Echo Sounder (Type 8302)

The Pressure Inverted Echo Sounder (PIES) is a long-life sensor logging node that measures the

average sound velocity through a column of water from the seabed to the sea surface. The transducer

is LMF directional, with a depth rating of 3000 and 6000 metres. The transponder’s pressure housing

is hard anodised and protected by a red sleeve. The sensor endcap can contain a stainless steel

release mechanism for releasing an anchor weight. The PIES is identified by a blue coloured housing

label.

Figure 3–7 Pressure Inverted Echo Sounder Transponder

3.3.3 Autonomous Monitoring Transponder (Type 8305)

The Autonomous Monitoring Transponder (AMT) has the same capabilities as the Compatt 6 with

additional capabilities to periodically log sensor readings and make acoustic baseline measurements.

The AMT has a depth rating of 3000 metres and is available as an omni-directional and directional

transducer. The transponder’s pressure housing is hard anodised and protected by a red sleeve. The

sensor endcap can contain a stainless steel release mechanism for releasing an anchor weight. The

AMT is identified by a yellow coloured housing label.

Section 3 – Technical Description 8

User Manual for the Type 8300 Compatt 6

(and Variants)

UM-8300-Compatt 6

Issue B3

Figure 3–8 Autonomous Monitoring Transponder

3.3.4 Modem 6 Transponder (Type 8307)

The Modem 6 Transponder has the same capabilities and mechanical specification as the Compatt 6

but operates as a modem only. The Modem is identified by a green coloured label.

A Modem 6 Integration Manual (IM-Modem 6) is available for configuring the Modem 6 for operational

use.

3.3.5 Sensor Logging Transponder (Type 8308)

The Sensor Logging Transponder (SLT) has the same capabilities as the Compatt 6 with additional

capabilities of autonomously acquiring sensor data without surface control. The SLT has a depth

rating of 3000 metres and is available as an omni-directional and directional transducer. The

transponder’s pressure housing is hard anodised and protected by a red sleeve. The sensor endcap

can contain a stainless steel release mechanism for releasing an anchor weight. The SLT is identified

by a blue coloured housing label.

Section 3 – Technical Description 9

This manual suits for next models

4

Table of contents

Other Sonardyne Marine Radio manuals

Popular Marine Radio manuals by other brands

West Marine

West Marine VHF 150 owner's manual

Uniden

Uniden MC 1020 operating guide

Garmin

Garmin WORKFORCE 320 installation manual

Enrock Marine

Enrock Marine EMC56W Installation & owner's manual

uAvionix

uAvionix tailBeaconX STC Instructions for Continued Airworthiness and Maintenance Manual

Icom

Icom IC-M802 Programming instructions