Sonardyne um-8370 User manual

Sonardyne International Limited

Blackbushe Business Park

Yateley, Hampshire

GU46 6GD United Kingdom

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

E. support@sonardyne.com

W. www.sonardyne.com

920-0005

UM-8370

User Manual for the Type 8370

WSM 6+ Transponder

Issue A Rev 1

Issue Date: 28 May 2015

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

ii

This user manual is the copyright and intellectual property right of Sonardyne International Limited

(“Sonardyne”) and is provided solely for the customer’s use of the Sonardyne equipment as

described in this user manual and in accordance with Sonardyne’s then prevailing terms and

conditions of sale. This user manual has been compiled to the best of Sonardyne’s knowledge and

belief, but no representation, warranty (whether express or implied) or guarantee is made to any

persons or legal entities as to the accuracy, reliability or completeness of the information contained

in this user manual.

This user manual contains the proprietary, confidential information of Sonardyne and other third

parties and as such may not be used, disclosed or placed in the public domain (by whatever means)

by the customer except expressly in accordance with and subject to the above referenced terms

and conditions of sale.

The copyright and any and all intellectual property rights of any and all third parties which may be

referenced in this user manual or which may have provided proprietary products and/or software

and/or documentation (in whatever format) to Sonardyne in respect of the Sonardyne equipment as

described in this user manual is hereby duly acknowledged.

The Sonardyne equipment described in this user manual is protected by UK Patent No. 2415113,

US Patent No. 8,139,442 and other patents internationally. 6G®and Sonardyne Wideband®are

registered trademarks of Sonardyne International Limited.

© Sonardyne International Limited 2015. All rights reserved.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

iii

Contacting the Sonardyne Support Team

24-hour Emergency Telephone Helpline: +44 (0) 1252 877600

The Sonardyne 24-hour helpline is answered at the UK Headquarters during normal office hours

(08:00 to 17:00). Outside these hours, your call is automatically transferred to an agency, which logs

the details of your emergency and alerts the appropriate Sonardyne personnel.

Our aim is to make sure emergency requests are dealt with immediately during office hours, and are

responded to within 30 minutes at all other times.

Please note the helpline is for emergency use only.

If you require non-emergency product support, please contact your nearest Sonardyne office.

Alternatively, contact the Sonardyne Head Office:

Sonardyne International Ltd

Blackbushe Business Park

Yateley

Hampshire

GU46 6GD

United Kingdom

Telephone: +44 (0) 1252 872288

Fax: +44 (0) 1252 876100

Email: [email protected]

Note

Email and telephone support is available during normal UK office hours (08:00 to 17:00).

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

iv

Contents

Contacting the Sonardyne Support Team.................................................................................. iii

Amendment History.................................................................................................................... vii

Section 1 – Introduction ............................................................................................................... 1

1.1 Scope of this Manual ............................................................................................................. 1

1.2 Purpose of this Manual .......................................................................................................... 1

1.3 Related Publications .............................................................................................................. 1

1.4 Conventions........................................................................................................................... 1

Section 2 – Safety ......................................................................................................................... 2

2.1 Introduction............................................................................................................................ 2

2.2 Safety Procedures ................................................................................................................. 2

2.2.1 Warnings .................................................................................................................... 2

2.2.2 Cautions..................................................................................................................... 3

Section 3 – Technical Description ............................................................................................... 5

3.1 Introduction............................................................................................................................ 5

3.2 WSM 6+ Types ...................................................................................................................... 5

3.3 Endcap .................................................................................................................................. 6

3.4 Connectors ............................................................................................................................ 7

3.4.1 Standard .................................................................................................................... 7

3.4.2 Remote External Release Variant .............................................................................. 7

3.5 Housing Labelling .................................................................................................................. 7

3.5.1 Manufacturing Data .................................................................................................... 7

3.5.2 Serial No. ................................................................................................................... 7

3.5.3 Config......................................................................................................................... 7

3.5.4 Transducer Type ........................................................................................................ 8

3.5.5 Housing Rating........................................................................................................... 8

3.5.6 UNIT ID ...................................................................................................................... 8

3.5.7 ADDRESS.................................................................................................................. 8

3.6 Operation............................................................................................................................... 8

3.7 Functionality .......................................................................................................................... 9

3.8 Configuration ......................................................................................................................... 9

3.9 Battery and Charger ............................................................................................................ 10

3.9.1Type ......................................................................................................................... 10

3.9.2 Charging Description................................................................................................ 10

3.9.3 Fast Charging Feature.............................................................................................. 10

3.9.4 Deeply Discharged Battery....................................................................................... 11

3.9.5 Pressure Relief Vent Valve....................................................................................... 12

Section 4 – Installation ............................................................................................................... 13

4.1 Introduction.......................................................................................................................... 13

4.2 Pre-Use Checks................................................................................................................... 13

4.2.1 Checking the Pressure Relief Vent Valve ................................................................. 13

4.2.2 Charging the Battery ................................................................................................ 14

Section 5 – Operation ................................................................................................................. 16

5.1 Introduction.......................................................................................................................... 16

5.2 Operational Modes .............................................................................................................. 16

5.2.1 Transponder Mode ................................................................................................... 16

5.2.2 Responder Mode...................................................................................................... 16

5.3 Configuring the WSM 6+...................................................................................................... 16

5.3.1 6G Terminal Lite....................................................................................................... 17

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

v

5.3.2 iWAND handheld Test Unit....................................................................................... 17

5.4 Preparing the WSM 6+ for use............................................................................................. 17

5.4.1 Check the Pressure Relief Vent Valve...................................................................... 17

5.4.2 Charging the Battery ................................................................................................ 17

5.4.3 Setting the Address .................................................................................................. 17

5.4.4 Power and Gain Configuration.................................................................................. 17

5.4.5 Navigation Mode Configuration ................................................................................ 17

5.4.6 Pulse Position Depth Aiding ..................................................................................... 17

5.5 Location on ROV ................................................................................................................. 17

5.6 Electrical Connections ......................................................................................................... 18

5.7 WSM 6+ Pre-Deployment Checklist..................................................................................... 18

5.8 After Use ............................................................................................................................. 19

Section 6 – Maintenance ............................................................................................................ 20

6.1 Introduction.......................................................................................................................... 20

6.2 Retrieval from the Water ...................................................................................................... 20

6.3 Dismantling.......................................................................................................................... 20

6.4 Inspection ............................................................................................................................ 20

6.5 Lubrication ........................................................................................................................... 20

6.5.1 Subconn and Micro-Subconn Connectors ................................................................ 20

6.6 Corrosion Removal .............................................................................................................. 21

Section 7 – Functional Testing .................................................................................................. 22

7.1 Introduction.......................................................................................................................... 22

7.2 Test Equipment ................................................................................................................... 22

7.2.1 6G Terminal Lite....................................................................................................... 22

7.2.2 iWAND Hand Held Test Unit..................................................................................... 22

7.3 Connecting the WSM 6+ to a PC ......................................................................................... 22

7.4 Functional Tests .................................................................................................................. 23

7.4.1 Serial Communications Test..................................................................................... 23

7.4.2 Transponder Test ..................................................................................................... 23

7.4.3 Responder Test........................................................................................................ 23

7.4.4 Sensor Test.............................................................................................................. 24

7.4.5 Release Test ............................................................................................................ 24

7.4.6 Battery Check........................................................................................................... 24

7.4.7 Firmware Update...................................................................................................... 24

7.4.8 Test Report .............................................................................................................. 25

Section 8 – Fault Diagnosis ....................................................................................................... 26

8.1 Introduction.......................................................................................................................... 26

8.2 Fault .................................................................................................................................... 26

8.2.1 Transponder Doesn’t Reply to Interrogations or Commands .................................... 26

8.2.2 Transponder Replies to Commands, but not to Interrogations .................................. 27

8.2.3 Transponder Replies to Commands, but Telemetry Errors are Detected.................. 27

8.2.4 Battery Life is Shorter than Expected ....................................................................... 27

Section 9 – Retrieval and Storage ............................................................................................. 28

9.1 Introduction.......................................................................................................................... 28

9.2 Retrieval .............................................................................................................................. 28

9.3 Storage................................................................................................................................ 28

Section 10 – Spares.................................................................................................................... 30

10.1 Introduction.......................................................................................................................... 30

Section 11 – Technical Specifications....................................................................................... 31

11.1 Technical Drawings ............................................................................................................. 31

11.2 Pin-Out Wiring Connections................................................................................................. 32

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

vi

11.2.1 Standard Housing Wiring Connections ..................................................................... 32

11.2.2 External Remote Release Option Wiring Connections.............................................. 33

11.3 Specifications for Type 8370-1111 & 8370-4112 WSM 6+................................................... 34

Appendix A – Frequency Tables............................................................................................ 36

A.1 HPR 400 Frequency Table .................................................................................................. 36

A.2 Sonardyne Wideband Frequency Table............................................................................... 36

Definitions ................................................................................................................................... 38

Figures

Figure 3-1 Type 8370-1111 Omni-Directional Wideband WSM 6+ .............................................6

Figure 3-2 Type 8370-4112 Directional Wideband WSM 6+ ......................................................6

Figure 3-3 Type 8370-1111 Omni-Directional WSM 6+ Endcap.................................................6

Figure 3-4 Charger/Comms Connections.................................................................................11

Figure 4-1 WSM 6+ Pressure Relief Vent Valve ......................................................................13

Figure 4-2 WSM 6+ Battery Charging Connections..................................................................15

Figure 7-1 WSM 6+ to PC Connection Configuration ...............................................................22

Figure 11-1 Type 8370-1111 Omni-Directional WSM 6+ Outline Drawing................................31

Figure 11-2 Type 8370-4112 Directional WSM 6+ Outline Drawing .........................................31

Figure 11-3 5-Way Connector Pin Out and Mating Tail ............................................................32

Figure 11-4 8-Way Connector Pin Out and Mating Tail ............................................................33

Tables

Table 1-1 Related Publications ..................................................................................................1

Table 1-2 Conventions used in this Manual ...............................................................................1

Table 3-1 Configuration Identification Table...............................................................................8

Table 3-2 WSM 6+ Configuration Options..................................................................................9

Table 5-1 WSM 6+ Pre-Deployment Checklist .........................................................................19

Table 9-1 Storage Conditions ..................................................................................................29

Table 10-1 Component Identification .......................................................................................30

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

vii

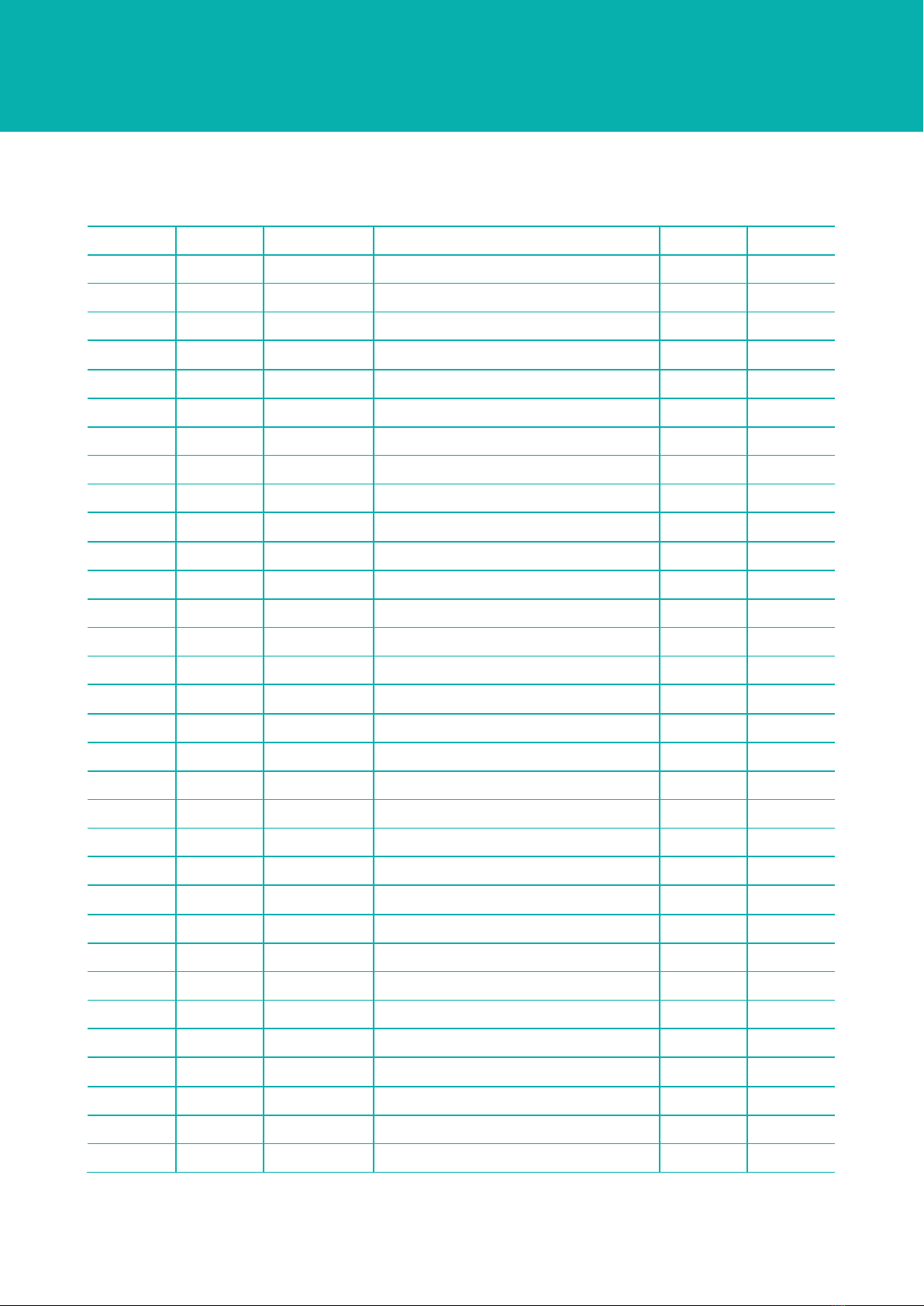

Amendment History

The amendment history records all amendments and additions made to this manual.

Issue Revision Date Comments Section Page

A 0 01-02-2015 Draft All All

A 1 28-05-2015 Initial Issue All All

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 1 – Introduction 1

Section 1 – Introduction

1.1 Scope of this Manual

This User Manual describes the safe installation and operation of the Wideband Sub-Mini 6+

(WSM 6+) Transponder / Responder. The information and procedures within this manual are based

on Sonardyne’s knowledge and experience.

1.2 Purpose of this Manual

This manual contains information for personnel involved in WSM 6+ system operations. It includes

technical information to configure, operate and maintain these systems, and specific information

concerning WSM 6+ products supplied by Sonardyne.

To make sure the safety of the installer and operator is maintained it is important that all warnings

and cautions in Section 2– Safety of this manual and in any related manuals are read and fully

understood.

1.3 Related Publications

To make sure the equipment is operated safely, a Sonardyne Safety Manual is supplied with this

user manual. It is important that the Sonardyne Safety Manual is read and fully understood before

proceeding with any activity on the equipment.

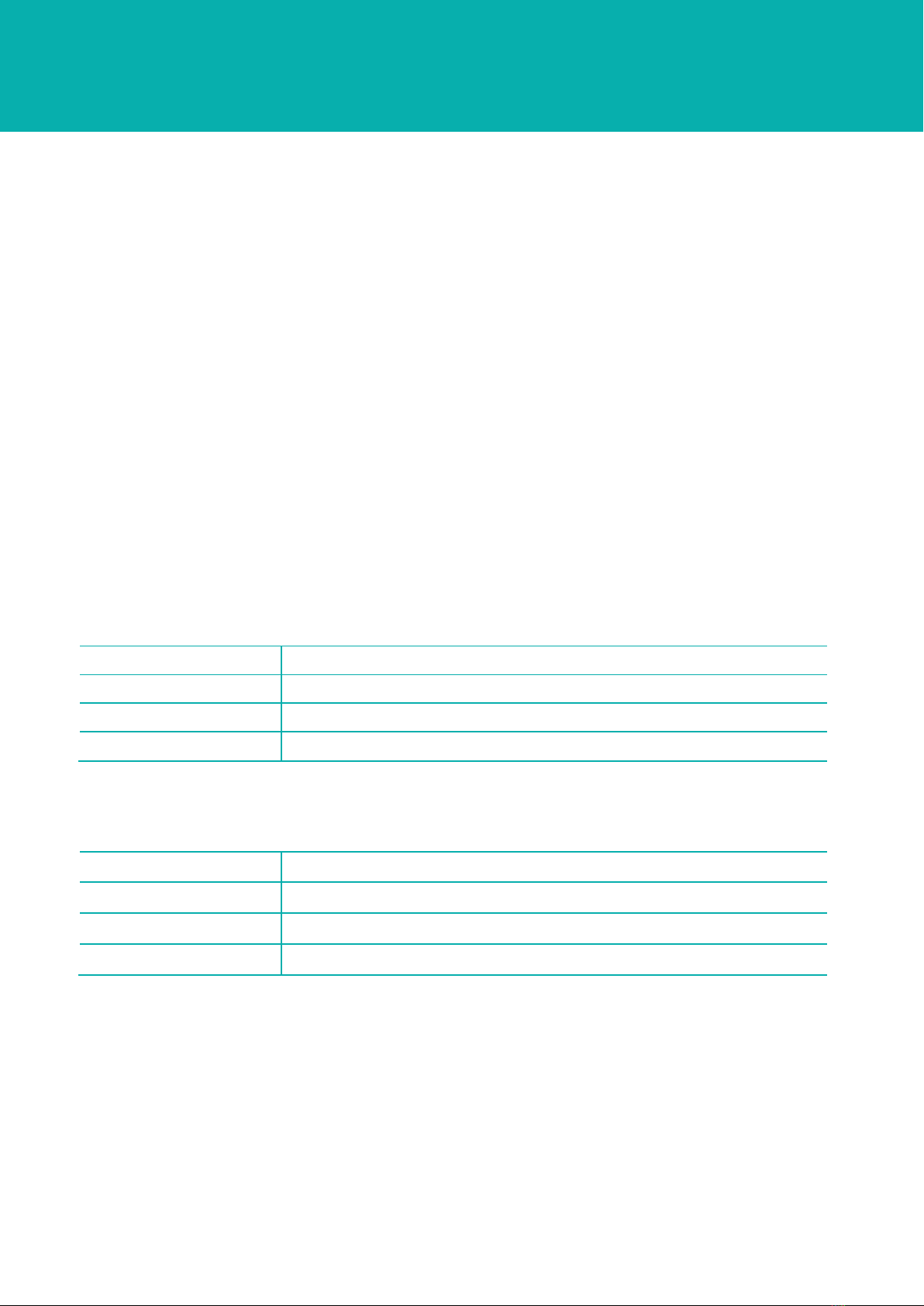

Table 1-1 Related Publications

Publication Title

Sonardyne Safety Manual Operational and Safety Precautions

UM-8300-099 User Manual for 6G Terminal Lite

UM-8315 User Manual for the Type 8315 iWAND

1.4 Conventions

Table 1-2 Conventions used in this Manual

Format Convention

Boldface Type User Input, Menu Options, Keys, e.g. Click OK

Arrow (>) Selection of an additional menu item e.g. File > Save

Italic Type References to Figures, Tables, Sections and other internal/external source

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 2 – Safety 2

Section 2 – Safety

2.1 Introduction

Before any activity is carried out on the equipment, it is recommended that the included Sonardyne

Safety Manual and all warnings and cautions in this manual are read and fully understood.

It is recommended the operator complies with the Health and Safety Regulations applicable to the

vessel and the region before operating this equipment.

Operators and service personnel must be familiar with the normal operating and safety procedures

for subsea equipment.

Documentation must be consulted whenever a or warning symbol is found on the

equipment, in order to determine the nature of the potential hazard and any actions which must be

taken.

If any additional equipment is used, any warnings and cautions in the equipment user manual must

be read and fully understood.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by

the equipment may be impaired.

The safety of any system incorporating this equipment is the responsibility of the assembler of the

system.

2.2 Safety Procedures

Before carrying out any procedure on the equipment, make sure that all of the following warnings

and cautions are read and fully understood.

2.2.1 Warnings

Personal protection. Appropriate protective equipment such as protective footwear, hard hat

and gloves must be worn when handling or carrying out any procedures involving Sonardyne and

other equipment.

Heavy equipment. Many Sonardyne products and equipment types, such as transponders,

transceivers, cable drums etc. require Manual Handling Equipment (MHE) for lifting due to their heavy

weight. If MHE is not available, it is the responsibility of the operator to perform a manual handling

risk assessment prior to carrying out manual lifting/handling. Refer to the individual equipment

documentation for weight specifications.

Dismanting. This transponder must only be accessed internally and dismantled by qualified

Sonardyne personnel.

Faulty battery pack. If a fault is suspected with the battery pack it must be investigated by

qualified Sonardyne personnel and should not be deployed.

Risk of toxic gases and Corrosive Liquids. Do not stand in direct line with the end of the

transponder when operating the Pressure Relief Vent Valve. Sudden release of high pressure gases

could cause injury to personnel. Wear Personal Protective Equipment such as goggles when

operating the Pressure Relief Vent Valve.

Risk of toxic gases. Make sure the work environment is well ventilated. Toxic gases may be

released when operating the Pressure Relief Vent Valve.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 2 – Safety 3

Hazardous substance. Molykote 44 is a mild irritant. When lubricating connector faces, Personal

Protective Equipment such as gloves and goggles must be worn.

Risk of burns. Do not carry out maintenance on the transponder if the housing is hot. Lower the

transponder into cold water and wait for the housing to cool. Wear Personal Protective Equipment

such as gloves.

2.2.2 Cautions

Battery power failure. Do not charge the battery packs in any way not outlined in this manual.

Failure to follow instructions may result in a loss of battery pack life or damage to the battery packs.

Damage to battery packs. Do not fast charge/discharge the WSM 6+ battery pack other than

when using the Type 8370-011-01 ( /-02 ) WSM 6+ comms/charger and WSM 6+ charger PSU.

Damage to battery packs. The WSM 6+ battery pack must only be charged using the Sonardyne

Type 8370-011-01 ( /-02 ) comms/charger unit and matching charger PSU.

Loss of current protection. Do not allow the transponder to be cooled or heated during the

charging process as the over current protection component characteristics may change adversely.

Equipment damage. Only use the authorised battery packs in the transponder. Failure to use the

correct batteries could cause damage to the equipment.

Equipment damage. Do NOT allow the transponder to be cooled or heated during the battery

charge level check or charging process.

Equipment damage. Do NOT continually connect the battery charger to the transponder if the

battery is fully charged as it will reduce its life and may cause damage.

Multiple beacon address Conflict. Do not operate multiple beacons on the same acoustic

address setting in the water at the same time. The address must be unique to any one beacon

operating in the same acoustic area.

Equipment damage. A standard Subconn non-shorting blanking plug must be fitted when

deployed if the connector on the unit is not being used.

Damage to external connector when submerged. The external connector must be covered while

the transponder is submerged, either by the protective dummy plug (part no. 312-6874) or by the free

plug of an external power cable.

Damage to connectors. The Subconn and Micro-Subconn connectors must not be mated

without lubrication as this will lead to delamination of the rubber from the connection pins and cause

connector failure.

Damage to connectors. Do not over apply grease to the connector faces as a build-up of grease

in the female connector will affect connector integrity.

Damage to connectors. Failure to clean sand or silt correctly could result in damage to the

connectors and O-ring seals.

Equipment damage. Failure to clean sand or silt from the connectors could result in the splaying

of the female contact and damage to the O-ring seals.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 5

Section 3 – Technical Description

3.1 Introduction

The Wideband Sub-Mini Plus (WSM 6+) transponder/responder is designed for use with Sonardyne

Wideband Navigation Systems, SIMRAD “HPR” and Sonardyne LUSBL families of range-bearing

acoustic navigation systems. The WSM 6+ can be configured to any interrogation and reply setting,

and its command address can also be changed easily using the supplied PC software, 6G Terminal

Lite.

The WSM 6+ is a small rugged beacon targeted at USBL applications such as subsea vehicle

tracking or towfish tracking. It has an operating life of at least 3 days at 1 pulse/second (see Section

11.3 “Specifications”) when powered from the Nickel Metal Hydride rechargeable battery pack.

Alternatively, the WSM 6+ can be powered by an external DC supply for continuous operation.

An external switch allows disconnection of the power to preserve battery life between deployments.

In addition to these features, all WSM 6+ beacons are fitted with a depth sensor to offer depth-aided

navigation by sending dual, time-coded reply pulses to each interrogation, or report depth as a

telemetry reply.

Note

Dismantling of the WSM 6+ must only be carried out by Sonardyne qualified personnel.

3.2 WSM 6+ Types

The WSM 6+ available types are described below (see Section 3.8 “Configuration”):

•Type 8370-1111 – Omni-directional

•Type 8370-4112 – Directional

•Type 8370-1211 – Omni-directional, dual release support (voltage)

•Type 8370-4212 – Directional, dual release support (voltage)

•Type 8370-1411 – Omni-directional, dual release support (contact closure)

•Type 8370-4412 – Directional, dual release support (contact closure)

Omni-Directional (8370-1x11) variants (see Figure 3-1) have a maximum operating depth of 1000

metres, but this may be limited by the full scale depth of the pressure sensor. Directional (8370-

4x12) variants (see Figure 3-2) have a maximum operating depth of 4000 metres.

Types 8370-1211 and 4212 also provide two bi-directional voltage outputs via the endcap connector

for applications such as driving a motor release or burnwire. The output can provide up to a

maximum of 1A current, with the ability to configure the output duration ( up to 20 minutes ) and set

a trip or hold current.

Types 8370-1411 and 4412 also provide two contact closure outputs via the endcap connector.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 6

Figure 3-1 Type 8370-1111 Omni-Directional Wideband WSM 6+

Figure 3-2 Type 8370-4112 Directional Wideband WSM 6+

3.3 Endcap

The connector endcap shields the electrical charging socket and ON/OFF switch. When not in use,

the unit should be switched OFF to preserve battery charge.

Note

The Nickel Metal Hydride batteries do self-discharge over a number of weeks so the WSM 6+

should always be fully charged before use.

Figure 3-3 shows the endcap for the Type 8370-1111 omni-directional WSM 6+ (Type 8370-4112 is

identical apart from a wider diameter and a DEPTH LIMIT 4000 m identification).

Figure 3-3 Type 8370-1111 Omni-Directional WSM 6+ Endcap

Depth Sensor cover plug 5 way connector MCBH5M for Comms / charging*

Pressure Relief Vent Valve ON/OFF rotary switch

*Refer to Section 11.2 “Pin-Out Wiring Connections”for connector pin details.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 7

3.4 Connectors

The endcap connector allows a responder electrical trigger, RS232 communications to configure the

unit, a battery charging input and a separate external dc power input.

Note

Refer to Cautions in Section 2 – Safety “Damage to external connector when submerged”.

3.4.1 Standard

The standard 5-way endcap connector is a type Subconn Micro MCBH5M and mates with a

standard in-line connector type Subconn Micro MCIL5F.

3.4.2 Remote External Release Variant

The remote external release 8-way endcap connector is a type Subconn Micro MCBH8F and mates

with a standard in-line connector type Subconn Micro MCIL8M.

3.5 Housing Labelling

Waterproof labels on the housing uniquely identify the transponder as follows:

•MANUFACTURING DATA

Serial No. 123456-789

Config. 1111

Transducer MF Omni

Housing Rating 1000 m

•UNIT ID

•ADDRESS

3.5.1 Manufacturing Data

The manufacturing data details all essential information about the equipment that will be required if

it is necessary to contact Sonardyne International Limited.

3.5.2 Serial No.

The serial no. is the unique WSM 6+ identification number and should be quoted in all

communications with Sonardyne International Ltd and their agents.

3.5.3 Config

The Config number is a four digit number that identifies the depth rating, material, housing size and

transducer type.

e.g. Config: 4112

•4 = Depth rating 4000 m

•1 = Standard

•1 = Standard

•2 = MF Dir – Type 1

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 8

Table 3-1 Configuration Identification Table

Depth Rating Variant Housing Transducer Type

1 1000 m Standard Standard MF Omni

2 2000 m Voltage Out Max MF Dir – Type 1

3 3000 m Burn Out Mini MF Dir – Type 2

4 4000 m Contact Closure Midi MF Super Dir

5 5000 m Dunker LMF Omni

6 6000 m Remote LMF Dir

7 7000 m Sphere LF Omni

8 EHF Omni

9 Special

0 No Code

3.5.4 Transducer Type

The transducer identifies the type of transducer beam-shape fitted to the transceiver. The types of

transducer can be omni or directional.

3.5.5 Housing Rating

The housing limit is the normal pressure rating of the transceiver housing. The sensor endcap may

be rated less than the housing limit. Check the endcap label and use the lower figure.

3.5.6 UNIT ID

The UNIT ID box shows the unique identification number for the transceiver or transponder. The

UNIT ID number is required to upgrade the functionality of the transceiver of transponder. The UNIT

ID cannot be changed and is stored on the device.

3.5.7 ADDRESS

The address contains the acoustic identity of the transceiver or transponder. The acoustic address

is used by the transceiver to communicate with another transceiver or transponder. The first two

digits of the address define the family group and the last two digits of the address define the channel

number. The acoustic address can be changed using a secure acoustic or serial command, which

requires the UID of the transponder. It is important that the information on the address label is kept

up to date.

3.6 Operation

The WSM 6+ is designed to be operated in both transponder and responder modes. An electrical

trigger input pin is provided on the external connector to enable operation in responder mode.

The acoustic command address and the interrogation channel are given on a separate housing

label. These can be changed by software, via the RS232 link.

All Sonardyne wideband addresses are available as well as all HPR 400 channels. A full table of

frequencies for each valid navigation channel is given in Appendix A – Frequency Tables.

Acoustic commands can be used to reconfigure the transponder and to switch on depth aiding.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 9

3.7 Functionality

Sonardyne's WSM 6+ offers wideband navigation replies which are capable of significant

improvements in ranging accuracy and repeatability, especially in responder mode. It also retains

compatibility with existing HPR and LUSBL range-bearing acoustic navigation systems. The

acoustic signal level transmitted by the Type 8370-4112 is strongest on axis and useful over a 90

degree cone. It is usually mounted with the transducer pointing upwards – typically for marking

small ROVs.

In circumstances where orientation in the general direction of the ship cannot be guaranteed, such

as for longer ranges in shallow water, the omni-directional response of the Type 8370-1111 omni-

directional transponder is recommended. The Type 8370-1111 has the same functionality as the

8370-4112 apart from depth rating and has a lower transmit acoustic source level on axis but a

wider omni-directional beam-pattern (±120°).

The WSM 6+ offers the following benefits to the user:

•High capacity nickel metal hydride rechargeable battery with at least 3 days operating life

at 1 pulse/second and rapid-charge capability by external connector.

•All “HPR 400” channels are supported.

•All Sonardyne wideband reply signals are supported giving better range accuracy and

repeatability.

•External connector for "Responder" mode trigger, external power supply, charger and

communications interface.

•ON/OFF feature via external switch.

•Acoustic commands to enable and disable the transponder and to enable the Depth Data

reply.

•Configured using 6G Terminal Lite software.

3.8 Configuration

The WSM 6+ configuration options are shown below:

Table 3-2 WSM 6+ Configuration Options

Type

Number

Transducer Depth

Rating

External Release

Option

Type Location

8370-1111 Omni-Directional Integral 1000 m

8370-1211 Omni-Directional Integral 1000 m Voltage

8370-1411 Omni-Directional Integral 1000 m Contact Closure

8370-4112 Directional Integral 4000 m

8370-4212 Directional Integral 4000 m Voltage

8370-4414 Directional Integral 4000 m Contact Closure

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 10

3.9 Battery and Charger

3.9.1 Type

The WSM 6+ is fitted with a 2000 mAh nickel metal hydride battery pack and must only be charged

with the Sonardyne Type 8370-011-01 (/-02 ) comms/charger unit and matching charger PSU.

Earlier types of transponder have different battery pack capacity, different rating AC power packs

and different versions of charger are not compatible with the WSM 6+.

3.9.2 Charging Description

A flat battery will charge for approximately 3 hours at the full rate of 1 A, during which the red Fast

Charge LED will illuminate. The charging current is applied to pin 3 of the external connector (zero

volts is pin 2). This charge time is considerably longer than the one-hour charge of the SSM. This is

due to the use of higher capacity NiMH cells in the WSM 6+, which cannot be charged at such a

high rate as the lower capacity cells in the SSM.

The charging current is controlled by electronics inside the transponder. When the battery reaches a

full charge the charging current is switched off, and the Fast Charge LED will switch off. However,

the charger also permanently supplies external power to the unit (28 V, 85 mA on pin 4) which will

trickle charge the unit and illuminate the yellow Trickle Charge LED. It is safe to leave the trickle

charge connected indefinitely.

3.9.3 Fast Charging Feature

The Fast Charge feature is controlled by electronics inside the transponder which monitors the

voltage and temperature of the battery pack to decide when to stop charging. The parameters are

first monitored some 14 minutes after connection so connecting the fast charger to a fully charged

battery will allow the full charging current to flow for that length of time.

Repeatedly connecting the fast charger to a fully charged (or near fully charged) battery will reduce

the life of the battery and may cause damage.

The charge control chip within the transponder will cut off charge current if:

•The rate of change of voltage with time indicates the pack is approaching full charge.

•The temperature of the pack rises outside limits (10–40ºC).

•A time limit is exceeded (in the WSM 6+ case this is three hours).

The current during fast charging is limited by the WSM 6+ PSU, not by the WSM 6+ charger/comms

unit.

If, in an emergency, it is necessary to charge the WSM 6+ by means other than the Type 8370-011-

01/02 dedicated comms/charger unit, then the charge supply should be 24 V at 1A constant current

for 2 hours maximum.

Note

The charging time must be reduced if the battery pack has been charged recently. The charging

current should be applied to pin 3 of the external connector with the return (zero volts) connected to

pin 2.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 11

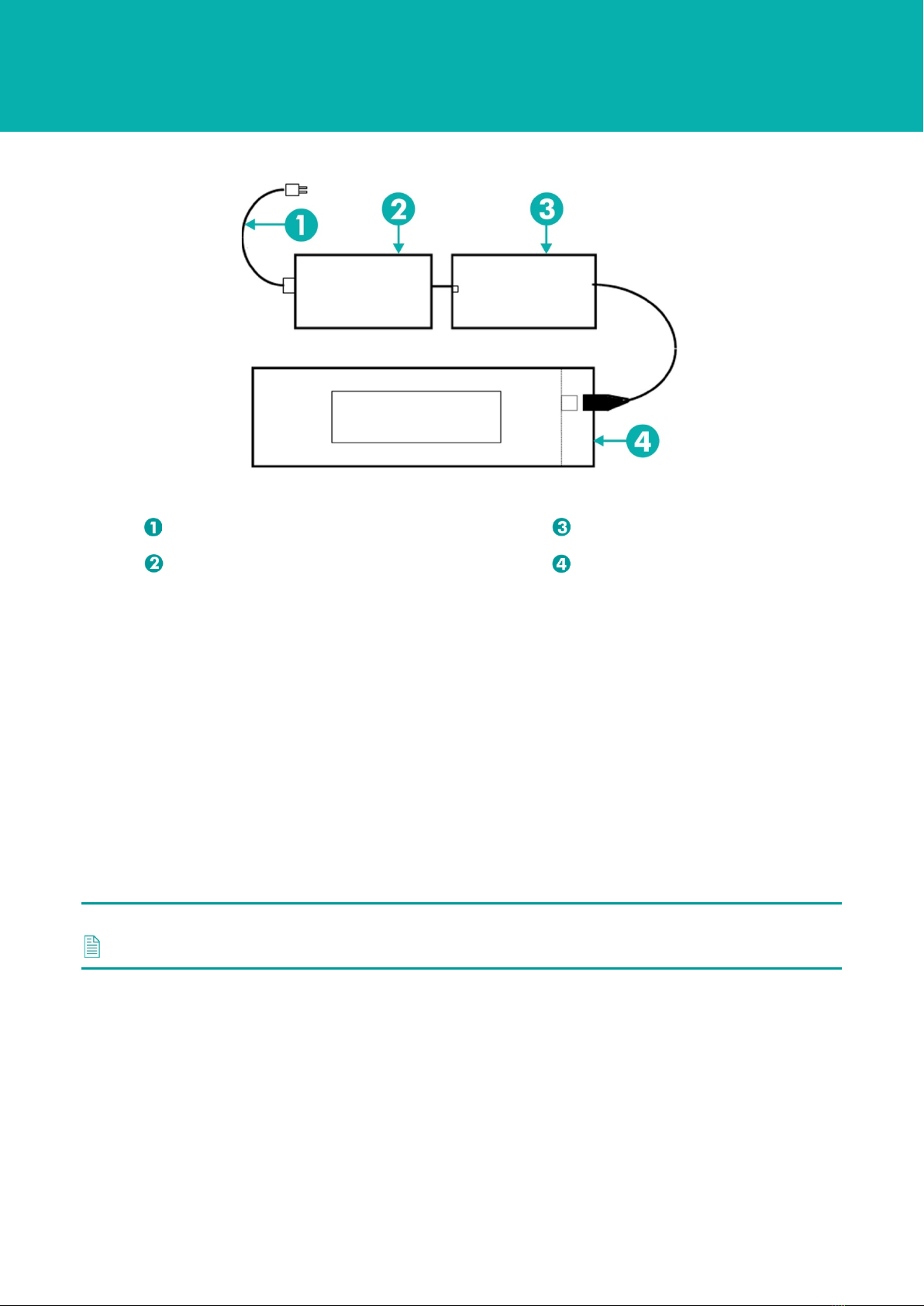

Figure 3-4 Charger/Comms Connections

AC cable option part numbers: UK 272-0345;

US 272-036C; Euro 272-0352 WSM 6+ Charger/Comms

WSM 6+ Charger PSU

WSM 6+

Various components inside the transponder are designed to limit damage due to misconnection of

the external signals. However, some damage to the electronic components may result. Under no

circumstances should mains AC power be applied to the transponder.

3.9.4 Deeply Discharged Battery

Special care must be taken if the battery has been allowed to become deeply discharged. In this

state it is possible for some cells to drop to near-zero voltage or even reverse the voltage on their

terminals. The WSM 6+ should always be switched off when not in use to minimise the chance of

entering this deep discharge state.

Once a cell has become deeply discharged, its capacity is reduced. This has the effect of

unbalancing the pack and therefore reduces the pack capacity. Usually the pack can be recovered

by fully re-charging. If not, then recovery can only be achieved by removing the pack and subjecting

it to several slow (200 mA) charge/discharge cycles. Even then the full capacity may not be

recovered.

Note

The battery pack must only be removed and replaced by qualified Sonardyne personnel.

Charging a pack which has suffered deep discharge can result in some gas being discharged by the

affected cells. If the pressure relief vent is found to be proud of its normal position, this may be an

indication that one or more cells have gassed and the appropriate action should be taken to recover

the battery pack as described above.

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 3 – Technical Description 12

3.9.5 Pressure Relief Vent Valve

A Pressure Relief Vent Valve is provided to make sure there is no build-up of gas inside the

transponder caused by the charging process. The battery manufacturer recommends the batteries

are charged in an open environment. However, they also specify that no gas is vented by the

batteries, providing the recommended charging procedures are followed. The WSM 6+ includes

special circuitry to monitor the battery pack during charging. This safety feature makes sure the

battery cannot be overcharged in normal use. For this reason it is not deemed necessary to remove

the Pressure Relief Vent Valve during charging of a fully operational transponder.

Should there be any reason to suspect that there is pressure inside the unit, or that the charging

circuitry may be faulty, it is recommended the Pressure Relief Vent Valve is extracted prior to

charging (refer to Section 4.2.1 “Checking the Pressure Relief Vent Valve”) .

User Manual for the Type 8370

WSM 6+ Transponder

UM-8370

Issue A Rev 1

Section 4 – Installation 13

Section 4 – Installation

4.1 Introduction

Before installing the equipment, make sure Section 2 – Safety is read and fully understood.

4.2 Pre-Use Checks

Before installation, checks should be carried out to make sure the WSM 6+ is serviceable and ready

for use. These checks include:

•Check the Pressure Relief Vent Valve; refer to Section 4.2.1 “Checking the Pressure

Relief Vent Valve”.

•In necessary, charge the battery; refer to Section 4.2.2 “Charging the Battery”.

4.2.1 Checking the Pressure Relief Vent Valve

A Pressure Relief Vent Valve is provided to reduce the build-up of gas inside the WSM 6+ caused

by the battery charging process.

Check the Pressure Relief Vent Valve is flush with the endcap. If the Pressure Relief Vent Valve is

not flush it could indicate a pressure build-up during previous operations due to a fault developing in

the battery pack.

Note

Refer to Warnings in Section 2 – Safety “Faulty Battery Pack”.

Figure 4-1 WSM 6+ Pressure Relief Vent Valve

Pressure Relief Vent Valve

Table of contents

Other Sonardyne Marine Radio manuals

Popular Marine Radio manuals by other brands

Garmin

Garmin GTX 327 pilot's guide

Simons Voss Technologies

Simons Voss Technologies ALLEGION 3060 Series quick guide

EnerSys

EnerSys Alpha AlphaNet DOCSIS DM3X Series Technical manual

Becker

Becker ATC 2000 Installation and operation

Cobra Marine

Cobra Marine MARINE MR F45-D owner's manual

Garrecht Avionik

Garrecht Avionik VT-01 user manual