Sonel ERP-1 User manual

11

INSTRUKCJA OBSŁUGI 1

USER MANUAL 17

ERP-1

v1.6 04.05.2020

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

1717

USER MANUAL

ERP-1 ADAPTER

SONEL S.A.

Wokulskiego 11

58-100 Świdnica

Poland

Version 1.6 04.05.2020

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

18

CONTENTS

1Safety ..............................................................................................................19

2Description of the adapter ............................................................................20

3Measurements................................................................................................21

4Power supply of the adapter.........................................................................26

4.1 Monitoring the power supply voltage...................................................................... 26

4.2 Replacing (rechargeable) batteries ........................................................................ 26

4.3 Charging the rechargeable batteries......................................................................26

5Cleaning and maintenance ...........................................................................27

6Storage............................................................................................................27

7Dismantling and Disposal.............................................................................27

8Technical specifications ...............................................................................28

8.1 Basic data .............................................................................................................. 28

8.2 Additional data ....................................................................................................... 30

9Accessories....................................................................................................31

9.1 Standard accessories............................................................................................. 31

9.2 Optional accessories.............................................................................................. 31

9.3 Sales sets............................................................................................................... 31

10 Manufacturer ..................................................................................................31

11 Laboratory services.......................................................................................32

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

19

1 Safety

ERP-1 adapter is designed to adapt MRU meters (manufactured by Sonel SA) for the measure-

ments of earth resistance of various objects e.g. power pillars, using flexible clamps (Rogowski coil).

The adapter is designed to work with earth resistance meters that provide the user with a choice of

performing the measurement using 3-wire method with measurement clamps. In order to ensure cor-

rect operation, the following recommendations must be observed:

xBefore you proceed to operate the adapter, acquaint yourself thoroughly with this manual and ob-

serve the safety regulations and specifications provided by the producer.

xAny application that differs from those specified in the present manual may result in a damage to

the adapter and constitute a source of danger for the user.

xThe Adapter should be operated only by suitably qualified persons having the necessary permis-

sions to carry out measurements on electrical systems. Operating the Adapter by unauthorised

personnel may result in damage to the device and constitute a source of danger for the user.

xUsing this manual does not exclude the need to comply with occupational health and safety regu-

lations and with other relevant fire regulations required during the performance of a particular type

of work. Before starting the work with the device in special environments, e.g. potentially fire-

risk/explosive environment, it is necessary to consult it with the person responsible for health and

safety.

xIt is unacceptable to operate the device when:

it is damaged and completely or partially out of order,

its cords and cables have damaged insulation,

it has been stored for an excessive period of time in disadvantageous conditions (e.g. exces-

sive humidity). After moving the device from a cool to a warm place with a high level of

relative humidity, do not start measurements until the device is warmed up to the ambi-

ent temperature (approximately 30 minutes).

xDo not operate the adapter with an open or incorrectly closed battery (accumulator) compartment

or power it from other sources than those specified in the present manual.

xRepairs may be performed only by an authorised service point.

xThe device meets the requirements of EN 61010-1.

xThe manufacturer reserves the right to introduce changes in the design, accessories

and technical data of the adapter.

x

ERP-1 Adapter is not a stand-

alone measuring device. This is an accessory de-

signed to work with earth resistance meters of MRU series man

ufactured by

SONEL S.A.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

20

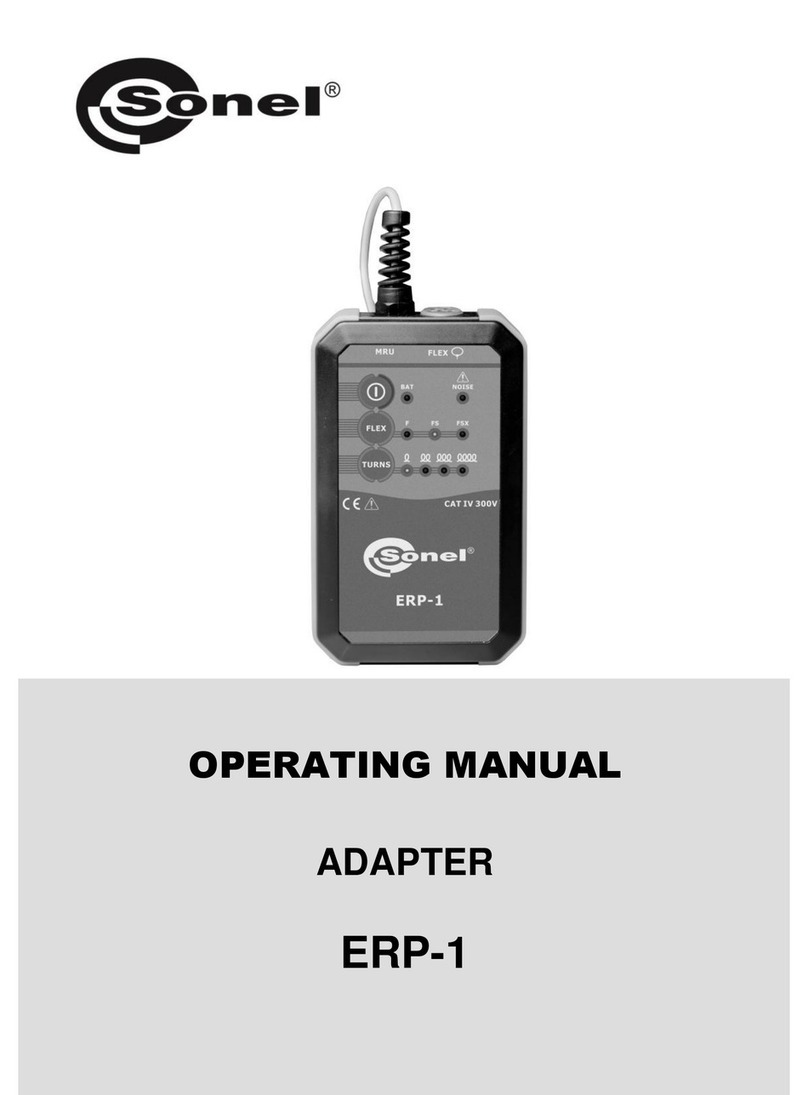

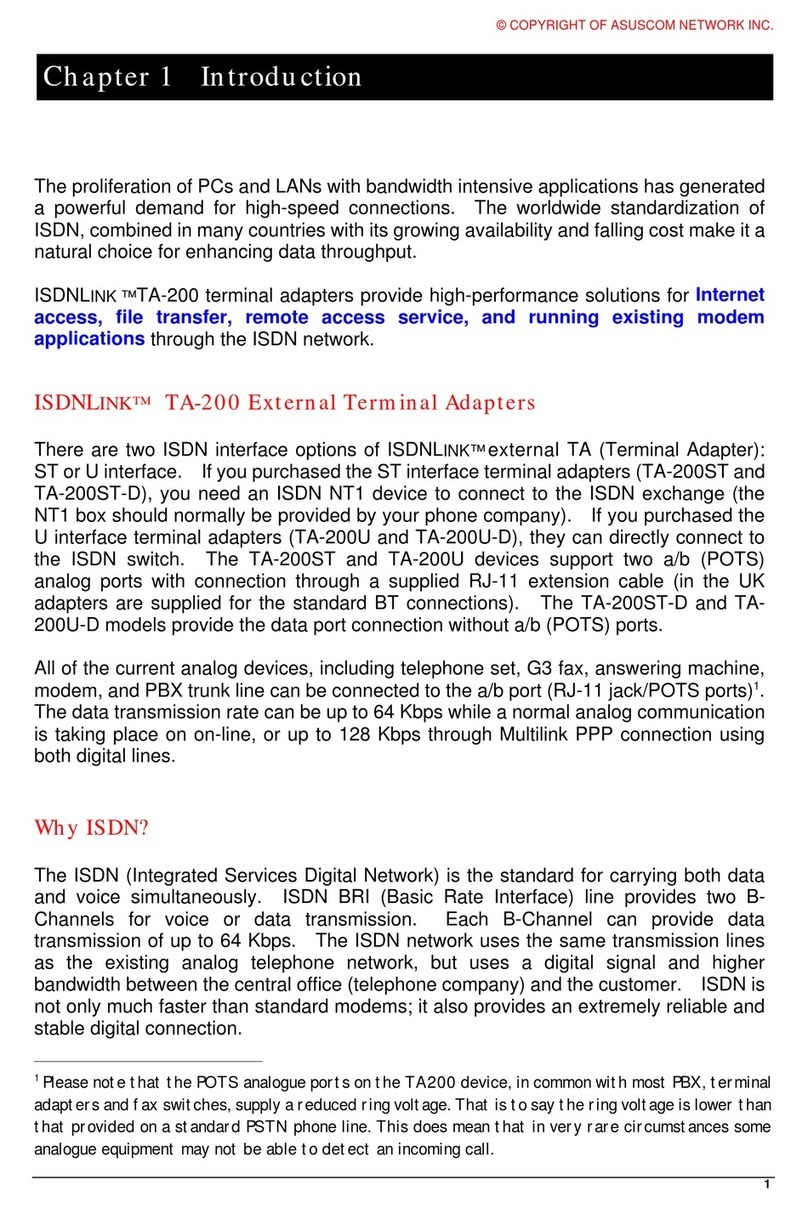

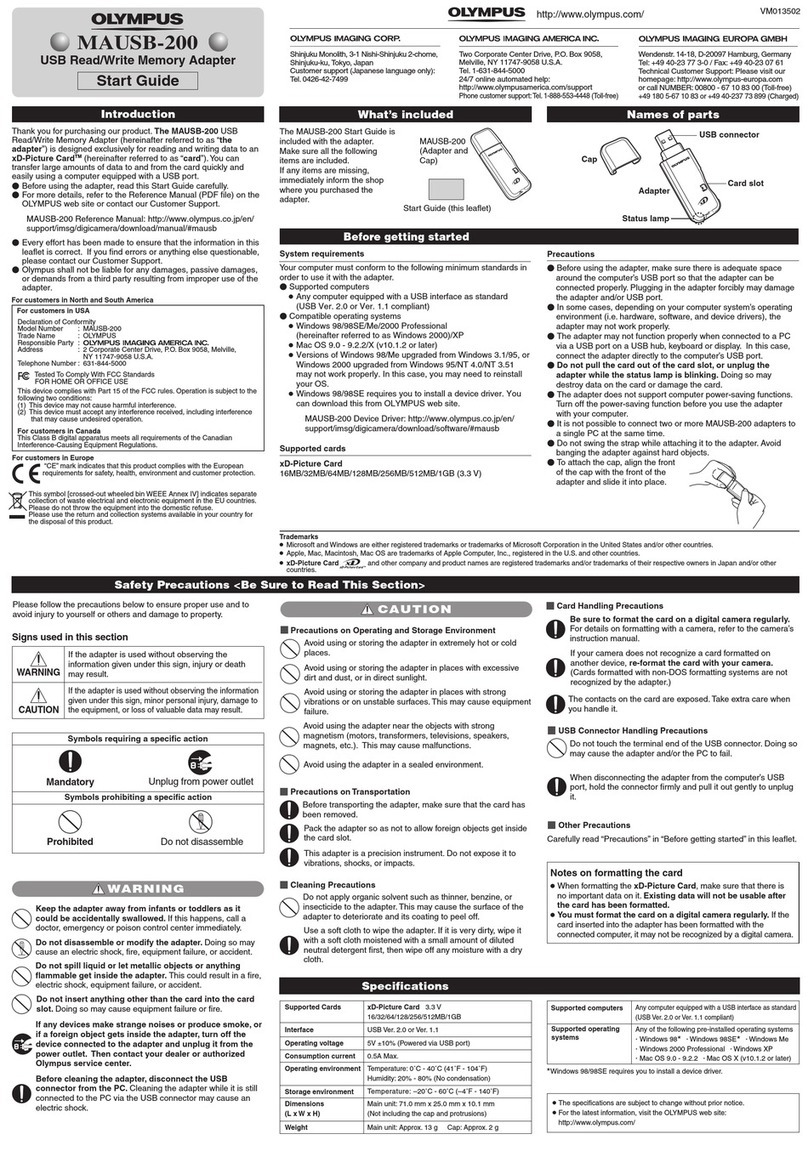

2 Description of the adapter

Switching the adapter

ON/OFF

Selected flexible clamps

connected to the device

Selected number of flexible clamp

wraps around the pole leg

LEDs indicating the number of flexible

clamp wraps around the pole leg

LEDs indicating selected type of

flexible clamps

LED indicating exceeded level of in-

terference

LED indicating low battery level

Terminal for connecting the cable of flexible

clamps

Cable for connecting the adapter to

the plug for clamps in the meter

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

21

3 Measurements

NOTE: Before the measurement arrange the spacing of the electrodes and the test leads taking into

account considerable distances. In case of truss structures, the distance between the legs at their

base may exceed a few meters. The spot of connecting the meter to the structure with a cable from

terminal E, should be free of dirt and contaminants such as paint, rust, etc., as they may affect the

measurement result.

1. Turn the adapter ON by pressing button.

2. LED will light up for 5 seconds indicating the stabilization process of the measuring

system.

3. LED will turn off and at the same time LEDs for selecting clamps and indicating the

number of wraps around the structure leg will light up: and .

4. Connect the adapter to MRU meter using the cable (length: 2 m) coming out from the

terminal marked with letters . This cable is an integral part of ERP-1 adapter.

5. Connect flexible clamps (Rogowski coil) to the adapter using the cable coming out from the

terminal marked with symbol .

6. Press button on the adapter to select the type of flexible clamps - follow the labelling

on the clamps.

7. Press button on the adapter to specify the number of clamp wraps around the leg of

the structure/object.

8. On the MRU meter select the measurement method as 3p+clamps, setting the rotational

function selector in the position shown here:

.

9. Flexible clamps connected to ERP-1 adapter should be wrapped around the leg of the

structure and around the steel strip (hoop) - if present - below the connecting point of cable

E to the structure leg. (Remember that flexible clamps should not be placed directly onto

the test leads as their interference may impact the measurement results). Wrap the clamps

as many times as its possible due to their length (max 4 times).

When wrapping the clamps around the leg of the tested structure, remember that the ar-

row stamped on clamps (indicating the direction of current flow) should be downward (in-

dicati

ng the ground).

10. Trigger the measurement on MRU meter by pressing START button, after selecting the

measuring voltage and frequency of the tested network.

11. After completing the measurement on the first leg of the structure/object (when there is

more than one leg), proceed to perform similar measurement on the next leg.

12. After obtaining the results of earth resistance for each leg, calculate the resultant resistance

of the whole structure, using the formula [1].

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

22

n

E

RR

R1

...

11

1

where:

R

E–resultant resistance of the object,

R1–resistance of the first leg of the object,

Rn–resistance of the last leg of the object,

n –number of legs of the object.

In case of measurements on a damaged structure or on a structure with defective

grounding system, the result calculated with the above formula [1] may be burdened

with a considerable error.

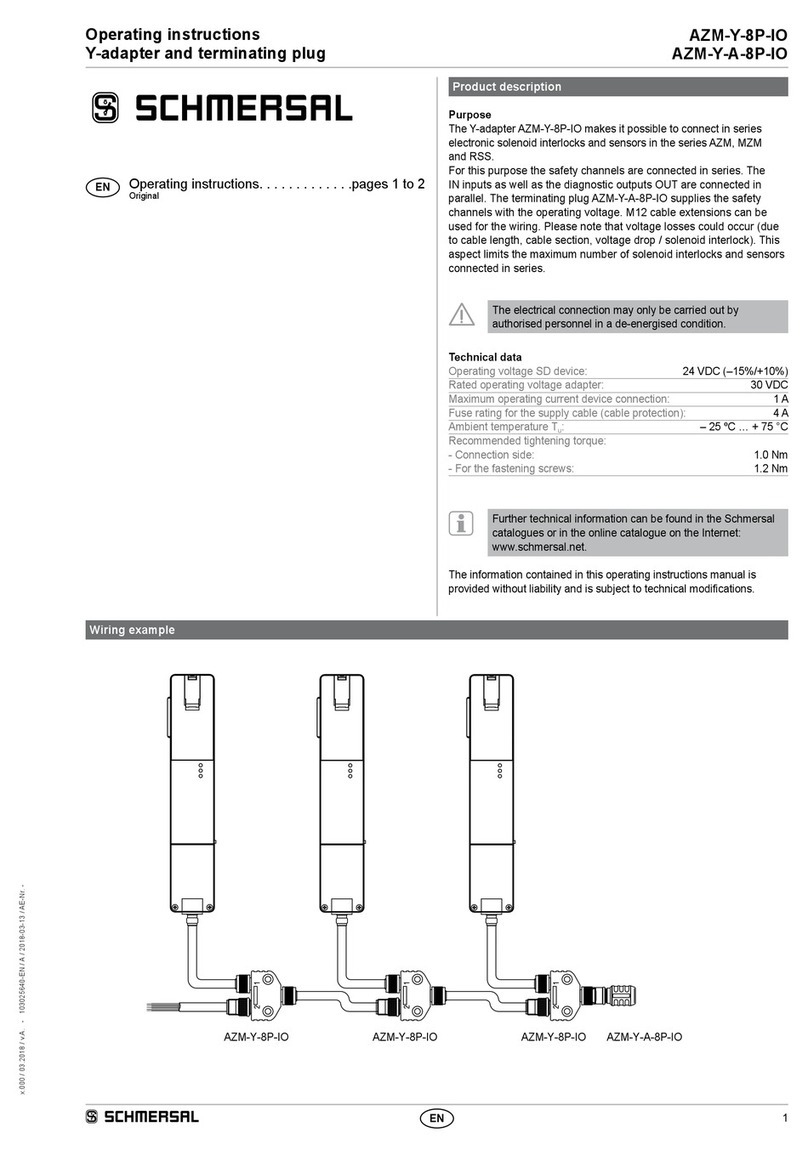

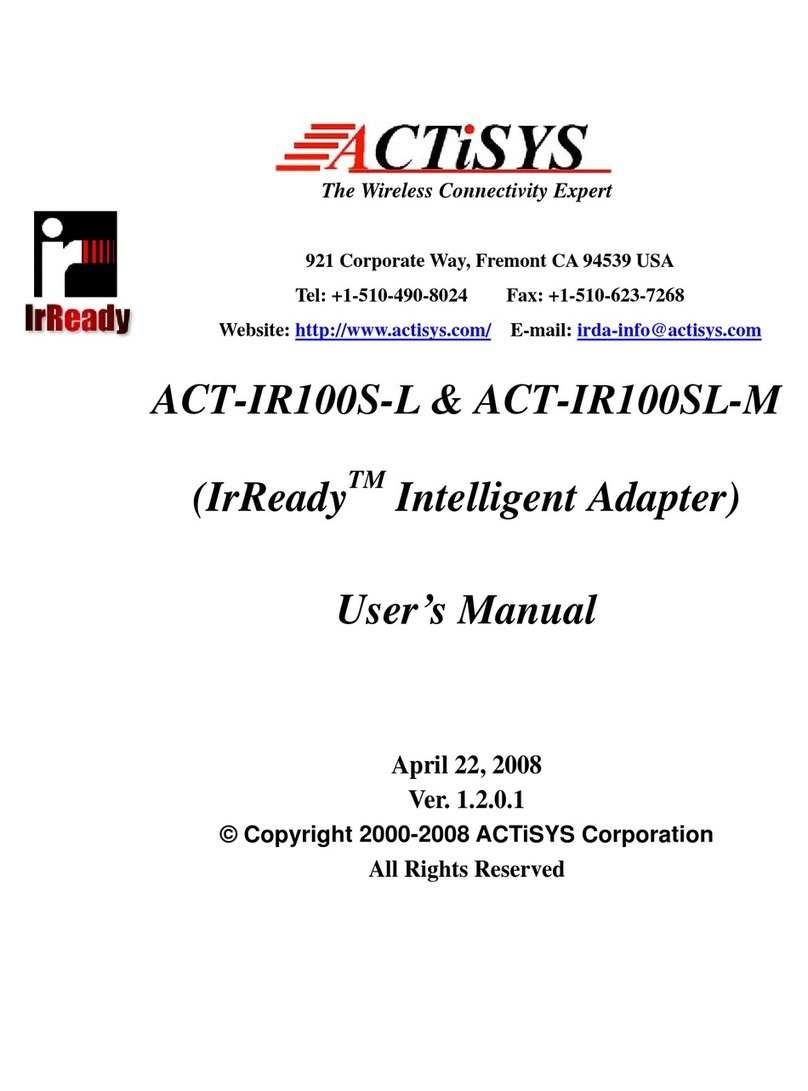

IE1…IE4 –current flowing to the ground through the individual legs of the pole

IS–current flowing upwards to the lightning protection wire

E, S, H –markings on the meter sockets

Fig. 1 Schematic diagram of the static resistance measurement on electricity poles using

measurement clamps and MRU-200 meter.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

23

Before using FLEX clamps for the first time, they should be calibrated according to the

descri

ption included in the u

of MRU earth resistance meter. Repeat the procedure

each time you change the clamps. It is recommended to perform the calibration every

time the clamp type is changed. The number of wraps (coils) of clamps around the leg

of the pole

during the measurement should be identical to the number of wraps used

during their calibration. This will ensure using the appropriate calibration factor during

the measurements.

APPENDIX for MRU-200 and MRU-200-GPS METERS

As additional functions are available in MRU-200 and MRU-200-GPS meters (measurements with flex-

ible clamps), the manufacturer provided an additional option for automatic calculation of the resultant

resistance of the measurement system. Please upgrade your MRU-200/MRU-200-GPS meter to the

latest software version, available at: www.sonel.pl ►DOWNLOAD ►FIRMWARE.

a) After selecting 3P+clamps, the following screen is displayed:

b) After pressing F2 button, the window for selecting clamps is shown. You may select between

hard clams (C-3) and ERP-1 adapter by operating buttons , . Accept your choice by

pressing ENTER. Exit without saving the change by pressing ESC.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

24

c) After pressing F3 you may select the number of legs of the tested structure/object using but-

tons , . Accept your choice by pressing ENTER. Exit without saving the change by

pressing ESC.

d) After selecting an object with four legs the following screen is shown. After connecting the

clamps to ERP-1 adapter and connecting the adapter to the meter; when the number of wraps

and type of clamps are set, the right side of the screen will show the following values: UN–in-

terference voltage, fN–interference frequency and IL–leakage current:

e) Press START button to display the following screen. Follow the command on the screen and

fix the clamps to the first leg (if not already done). The measurement will be triggered by

pressing again START button.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

25

f) This screen is shown for 5 seconds from the moment of displaying calculated R1value, then

screen "before the second measurement" will be shown. You may recall the last measurement

result by pressing ENTER (the screen with the first measurement is shown for 5 seconds).

Similarly to the situation before the first measurement. The same applies before the meas-

urement on third and fourth leg.

g) After completing the measurements on the last leg of the structure and after displaying (for 5

seconds) the resistance result (R4), the following screen will be displayed:

After completing a series of measurements (on each leg), the screen will display the resultant

earth resistance RE. Use buttons and to change results displayed by the auxiliary screen

on the right.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

26

4 Power supply of the adapter

4.1 Monitoring the power supply voltage

The adapter is powered by three 1.5 V LR6 batteries or by three 1.2 V LR6 rechargeable batteries

of NiMH type. When BAT LED is light up, it indicates the need to replace the batteries or to recharge

the rechargeable batteries.

4.2 Replacing (rechargeable) batteries

To replace the (rechargeable) batteries:

xdisconnect clamps and switch the adapter off,

xunscrew the screw and remove the cover of the battery compartment (in the bottom of the hous-

ing).

xreplace all (rechargeable) batteries, observing the correct polarity.

xinstall the cover back and fix it with the screw.

NOTE!

Do not use the adapter when the battery compartment is removed or open. Do not

power the meter from other sources than those mentioned in this manual.

4.3 Charging the rechargeable batteries

Rechargeable batteries must be recharged in an external charger.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

27

5 Cleaning and maintenance

UWAGA!

Use only the maintenance methods specified by the manufacturer in this manual.

The casing of the adapter may be cleaned with a soft, damp cloth using all-purpose detergents.

Do not use any solvents or cleaning agents which might scratch the casing (powders, pastes, etc.).

Clamps and test leads should be cleaned with water and detergents, and then dried.

The electronic system of the Adapter does not require maintenance.

6 Storage

During the storage of the device, the following recommendations must be observed:

xdisconnect the clamps from the adapter.

xthoroughly clean the adapter and clamps.

xIf adapter is to be stored for a prolonged period of time, the batteries must be removed from the

device.

xIn order to prevent a total discharge of the battery in the case of a prolonged storage, remove and

charge the batteries in an external charger from time to time.

7 Dismantling and Disposal

Worn-out electric and electronic equipment should be gathered selectively, i.e. it must not be

placed with waste of another kind.

Worn-out electronic equipment should be sent to a collection point in accordance with the law of

waste electrical and electronic equipment.

Before the equipment is sent to a collection point, do not dismantle any elements.

Observe local regulations concerning disposal of packages, waste batteries and accumulators.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

28

8 Technical specifications

xAbbreviation "m.v." used in the specification of measurement uncertainty means a standard

measured value.

8.1 Basic data

Flexible clamps F

REmeasurement

Uncertainty of the adapter:

Range

0.000 …1999 *

±(8% m.v. + 10 digits)

±(8% m.v. + 10 digits)

(7% m.v. + 10 digits)

±(7% m.v.+ 4 digits)

*forR

E> 500 Ωuncertainty unspecified

Uncertainty specified for MRU-200/MRU-200-GPS

For flexible clamps, uncertainty F is not specified.

Current measurement

Range Resolution

Basic

uncertainty

0.0 mA ... 99.9 mA

0.1 mA

unspecified

100 mA...999 mA

1 mA

±(8% m.v.+3digits)*

1.00 A...4.99 A

0.01 A

±(5% m.v. + 5 digits)**

* unspecified in the range of 0 mA…199 mA

** above 5 A the uncertainty is unspecified

Flexible clamps FS-2

REmeasurement

Uncertainty of the adapter

Range

0.000 …1999 *

±( 6% m.v. + 8 digits)

±(6% m.v. + 8

digits)

±(6% m.v. + 6

digits)

±(6% m.v. + 4

digits)

Uncertainty specified for MRU-200/MRU-200-GPS

Basic uncertainty for Un= 25V

Range

Resolution

0.000 …3.999

0.001

±(14% m.v. + 4 dig-

its)

±(14% m.v. + 4 dig-

its)

±(12% m.v. + 4 dig-

its)

±(12% m.v. + 4 dig-

its)

4.00 …39.99

0.01

±(14% m.v. + 3 dig-

its)

±(14% m.v. + 3 dig-

its)

±(12% m.v. + 3 dig-

its)

±(12% m.v. + 3 dig-

its)

40.0 …399.9

0.1

400 …1999 *

1

Basic uncertainty for Un= 50V

Range

Resolution

0.000 …3.999

0.001

±(12% m.v. + 4 dig-

its)

±(12% m.v. + 4 dig-

its)

±(10% m.v. + 4 dig-

its)

±(10% m.v. + 4 dig-

its)

4.00 …39.99

0.01

±(12% m.v. + 3 dig-

its)

±(12% m.v. + 3 dig-

its)

±(10% m.v. + 3 dig-

its)

±(10% m.v. + 3 dig-

its)

40.0 …399.9

0.1

400 …1999 *

1

*forR

E> 500 Ωuncertainty unspecified

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

29

Current measurement

Range Resolution

Basic

uncertainty

0.0 mA ... 99.9 mA

0.1 mA

unspecified

100 mA...999 mA

1 mA

±(8% m.w.+3 digits)

1.00 A...4.99 A

0.01 A

±(5% m.w.+5 digits)*

* above 5 A the uncertainty is unspecified

Flexible clamps FSX-3

REmeasurement

Uncertainty of the adapter

Current range

0.000 …1999 *

±( 5% m.v. + 6 digits)

±(5% m.v.+ 4 digits)

±(5% m.v. + 4 digits)

±(5% m.v.+ 4 digits)

Uncertainty specified for MRU-200/MRU-200-GPS

Basic uncertainty for Un= 25V

Range

Resolution

0.000 …3.999

0.001

±(12% m.v. + 4 dig-

its)

±(12% m.v. + 4 dig-

its)

±(10% m.v. + 4 dig-

its)

±(10% m.v. + 4 dig-

its)

4.00 …39.99

0.01

±(12% m.v. + 3 dig-

its)

±(12% m.v. + 3 dig-

its)

±(10% m.v. + 3 dig-

its)

±(10% m.v. + 3 dig-

its)

40.0 …399.9

0.1

400 …1999 *

1

Measurement uncertainty(basic) for Un= 50V

Range

Resolution

0.000 …3.999

0.001

±(10% m.v. + 4 dig-

its)

±(10% m.v. + 4 dig-

its)

±(8% m.v. + 4 dig-

its)

±(8% m.v. + 4 dig-

its)

4.00 …39.99

0.01

±(10% m.v. + 3 dig-

its)

±(10% m.v. + 3 dig-

its)

±(8% m.v. + 3 dig-

its)

±(8% m.v. + 3 dig-

its)

40.0 …399.9

0.1

400 …1999 *

1

*forR

E> 500 Ωuncertainty unspecified

Current measurement

Range Resolution

Basic

uncertainty

0.0 mA ... 99.9 mA

0.1 mA

±(8% m.v.+3digits)*

100 mA...999 mA

1 mA

±(8% m.v.+3digits)

1.00 A...4.99 A

0.01 A

±(5% m.v. + 5 digits)**

* unspecified in the range of 0 mA…50 mA

** above 5 A the uncertainty is unspecified

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

30

Other technical specifications

a) type of insulation .....................................................................................double, according to EN 61010-1 and IEC 61557

b) measurement category ..................................................................................................IV 300 V according to EN 61010-1

c) degree of housing protection acc. to EN 60529............................................................................................................ IP67

d) power supply of the meter ..................................................................................................................3 LR6 1.5 V batteries

.............................................................................................................................3 NiMH LR6 1.2 V rechargeable batteries

e) time of automatic shut-off of the device (Auto-Off) ........................................................................................... approx. 2 h

f) dimensions ..............................................................................................................................................146 x88 x 33 mm

g) weight of the adapter with batteries ...............................................................................................................approx. 340 g

h) operating temperature ........................................................................................................................................-10..+50qC

i) reference temperature ............................................................................................................................................ 23 ±2qC

j) storage temperature ...........................................................................................................................................-20..+80qC

k) relative humidity .......................................................................................................................................................20..90%

l) nominal relative humidity .........................................................................................................................................40..60%

m) altitude (above sea level) .......................................................................................................................................<2000 m

n) electric field ..........................................................................................................................................................max 3 V/m

o) quality standard, ..................................................................................design and manufacturing are ISO 9001 compliant

p) the product meets the EMC requirements according to ....................................................EN 61326-1 and EN 61326-2-2

8.2 Additional data

Thresholds for triggering NOISE LED for sinusoidal current of 50 Hz

F

>5 A

FS-2

>5 A

>3.3 A

>2.5 A

FSX-3

>3.5 A

>1.7 A

>1.2 A

>0.9 A

Additional uncertainty of the electrodes determined for MRU-200/MRU-200-GPS

RE

RH,RS

Additional uncertainty caused by the electrodes for Un= 25 V [%]

0.000

…3.999

RH500 and RS500

Within the basicuncertainty

R

H

>500 or

RS>500 or

RHand RS>500

)104)

1

1(105

200

200

10

(43

2

6

rH

EHE

H

S

SR

RRR R

RR

>3.999

RH1 kand RS1 k

Within the basicuncertainty

R

H

>1 kor

RS>1 kor

RH and RS>1 k

)1020105

200

200

10

(

43

2

6

r

H

HE

H

S

S

R

RR R

R

R

RE

RH,RS

Additional uncertainty caused by the electrodes for Un= 50 V [%]

0.000

…3.999

RH500 and RS500

Within the basicuncertainty

R

H

>500 or

RS>500 or

RHand RS>500

)104)

1

1(105

200

200

10

(43

2

6

rH

EHE

H

S

SR

RRR R

RR

>3.999

RH1 kand RS1 k

Within the basicuncertainty

R

H

>1 kor

RS>1 kor

RH and RS>1 k

)1015105

200

200

10

(43

2

6

rH

HE

H

S

SR

RR R

R

R

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

31

9 Accessories

The current list of accessories can be found on the manufacturer's website.

9.1 Standard accessories

xAdapter ERP-1

x3 AA batteries

xUser manual

9.2 Optional accessories

xFlexible clamps FSX-3 –WACEGFSX3OKR

xFlexible clamps FS-2 –WACEGFS2OKR

xHard case XL8 –WAWALXL8

xCase M6 –WAFUTM6

9.3 Sales sets

xAdapter ERP-1 –WAADAERP1

xAdapter ERP-1 with flexible clamps FS-2 and case –WAADAERP1V2

xAdapter ERP-1 with flexible clamps FSX-3 and case –WAADAERP1V3

10 Manufacturer

SONEL S.A.

NOTE!

Service repairs must be performed only by the manufacturer.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ERP-1 –USER MANUAL

32

11 Laboratory services

SONEL Testing and Calibration Laboratory has been accredited by the

Polish Center for Accreditation (PCA) - certificate no. AP 173.

Laboratory offers calibration for the following instruments that are used

for measuring electrical and non-electrical parameters.

●METERS FOR MEASUREMENTS OF ELECTRICAL PARAMETERS

ovoltage meters,

ocurrent meters (including clamp meters),

oresistance meters,

oinsulation resistance meters,

oearth resistance and resistivity meters,

oRCD meters,

oshort-circuit loop impedance meters,

opower quality analyzers,

oportable appliance testers (PAT),

opower meters,

omultimeters,

omultifunction meters covering the functions of the above-mentioned instruments,

●ELECTRICAL STANDARDS

ocalibrators,

oresistance standards,

●METERS FOR MEASUREMENTS OF NON-ELECTRICAL PARAMETERS

opyrometers,

othermal imagers,

oluxmeters.

The Calibration Certificate is a document that presents a relation between the calibration standard of

known accuracy and meter indications with associated measurement uncertainties. The calibration

standards are normally traceable to the national standard held by the National Metrological Institute.

According to ILAC-G24 „Guidelines for determination of calibration intervals of measuring instru-

ments”, SONEL S.A. recommends periodical metrological inspection of the instruments it manufac-

tures no less frequently than once every 12 months.

For new instruments provided with the Calibration Certificate or Validation Certificate at the factory, re-

calibration should be performed within 12 months from the date of purchase, however, no later than

24 months from the date of purchase.

ATTENTION!

The person performing the measurements should be absolutely sure about the effi-

ciency of the device being used. Measurements made with an inefficient meter can

contribute to an incorrect assessment of the effectiveness of health protection and

even human life.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

3333

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Other manuals for ERP-1

2

This manual suits for next models

1

Table of contents

Other Sonel Adapter manuals