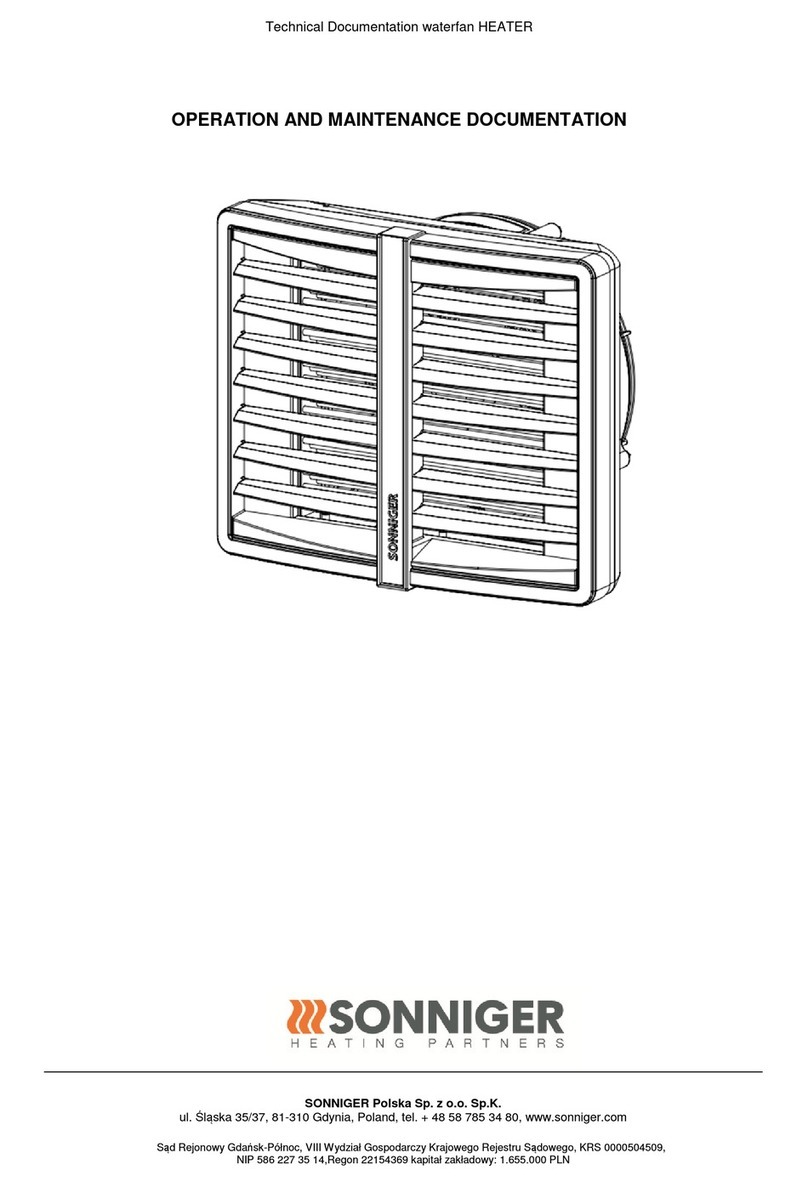

Sonniger GUARD Installation guide

Operation and Maintenance Documentation GUARD v202301

Operation and Maintenance Documentation GUARD

SONNIGER S.A.

ul. Śląska 35/37, 81-310 Gdynia, Poland, infolinia 801 055 155, tel. + 48 58 785 34 80, www.sonniger.com

Sąd Rejonowy Gdańsk-Północ, VIII Wydział Gospodarczy Krajowego Rejestru Sądowego, KRS 0000966611, NIP 5862273514,

Regon 22154369 kapitał zakładowy: 1.655.000 PLN

Operation and Maintenance Documentation GUARD v202301

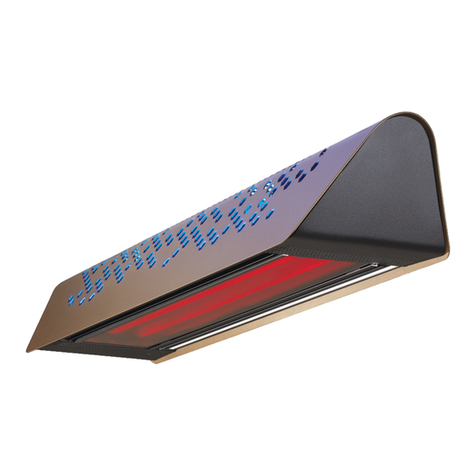

1. PURPOSE OF THE DEVICE

The air curtain is intended to be used in regions with a moderate and cold climate, in spaces where the temperature ranges

from -10 to +40°C, in conditions free from external factors such as pollens and hydrometeor (horizontal precipitation).

In winter, air curtains protect against heat loss in rooms by directing an airstream across the entrance and preventing cold air

from entering the heated space. In summer, the curtains may be used as cooling devices preventing the entry of hot air and

pollutants from outside.

The GUARD air curtains are designed to protect against heat losses in buildings of medium and high capacity and with a

required mounting height of 4 m such as:

supermarkets, large retail spaces,

car showrooms and service stations,

sports and show halls,

exhibition surfaces

2. BASIC TECHNICAL PARAMETERS

TECHNICAL PARAMETERS

Curtain with water heater Curtain with electric heater Curtain without heater

GUARD 100W

GUARD 150W

GUARD 200W

GUARD 100E

GUARD 150E

GUARD 200E

GUARD 100C

GUARD 150C

GUARD 200C

Lenght of unit m 1 1.5 2 1 1.5 2 1 1.5 2

Max installation height m 4 4 4

Max air output m³/h 1200/1550/2000

2200/3000/3600

2900/4000/4800

1200/1550/2000

2200/3000/3600

2900/4000/4800

1250/1600/2100

2250/3100/3700

3000/4200/5000

Heat output * kW 10-16 20-29 25-40 4 - 7 6,5 - 11 8,5 - 14 - - -

Temperaturę increase ΔT **

ΔT - - - 12 13 14 - - -

Max working pressure MPa 1,6 - - - - - -

Diameter of connection

nozzels ˝ 1/2' - - - - - -

Motor power supply,

consumption V/Hz A

230/50 1,45A 230/50 1,45A 230/50 2,0A 230/50 1,45A 230/50 1,45A 230/50 2,0A 230/50 1,45A 230/50 1,45A 230/50 2,0A

Motor power supply,

consumption *** V/Hz A

220/60 1,8A 220/60 1,7A 220/60 2,2A 220/60 1,8A 220/60 1,7A 220/60 2,2A 220/60 1,8A 220/60 1,7A 220/60 2,2A

Motor power kW 0,16 0,18 0,26 0,16 0,18 0,26 0,16 0,18 0,26

Electric heater power

supply, consumption **** V/Hz A

- - - 400/50 12,6A 400/50 19,1A 400/50 25,1A - - -

Weight with water/without

water kg 18,0 / 16,5 22,6 / 20,5 31,0 / 28,0 17 21,5 29 15 18,5 25

Volume leveleg I / II / III dB (A) 44 / 49 / 59 45 / 49 / 61 46 / 49 / 61 44 / 49 / 59 45 / 49 / 61 46 / 49 / 61 45 / 50 / 60 46 / 50 / 61 47 / 50 /61

Protection class IP IP21 IP21 IP21

* heat output for water agent 90/70 and inlet air temperature 0°C

** temperature increase for 18°C ambient air

*** version for KSA, Egypt

**** power consumption for ambient air temperature 18°C and cable length 10m

Energy consumption [A] goes higher in relation to decrease of air inlet temperature or extension of supply cables lenght

Noise level measured in distance of 3 m in open space building

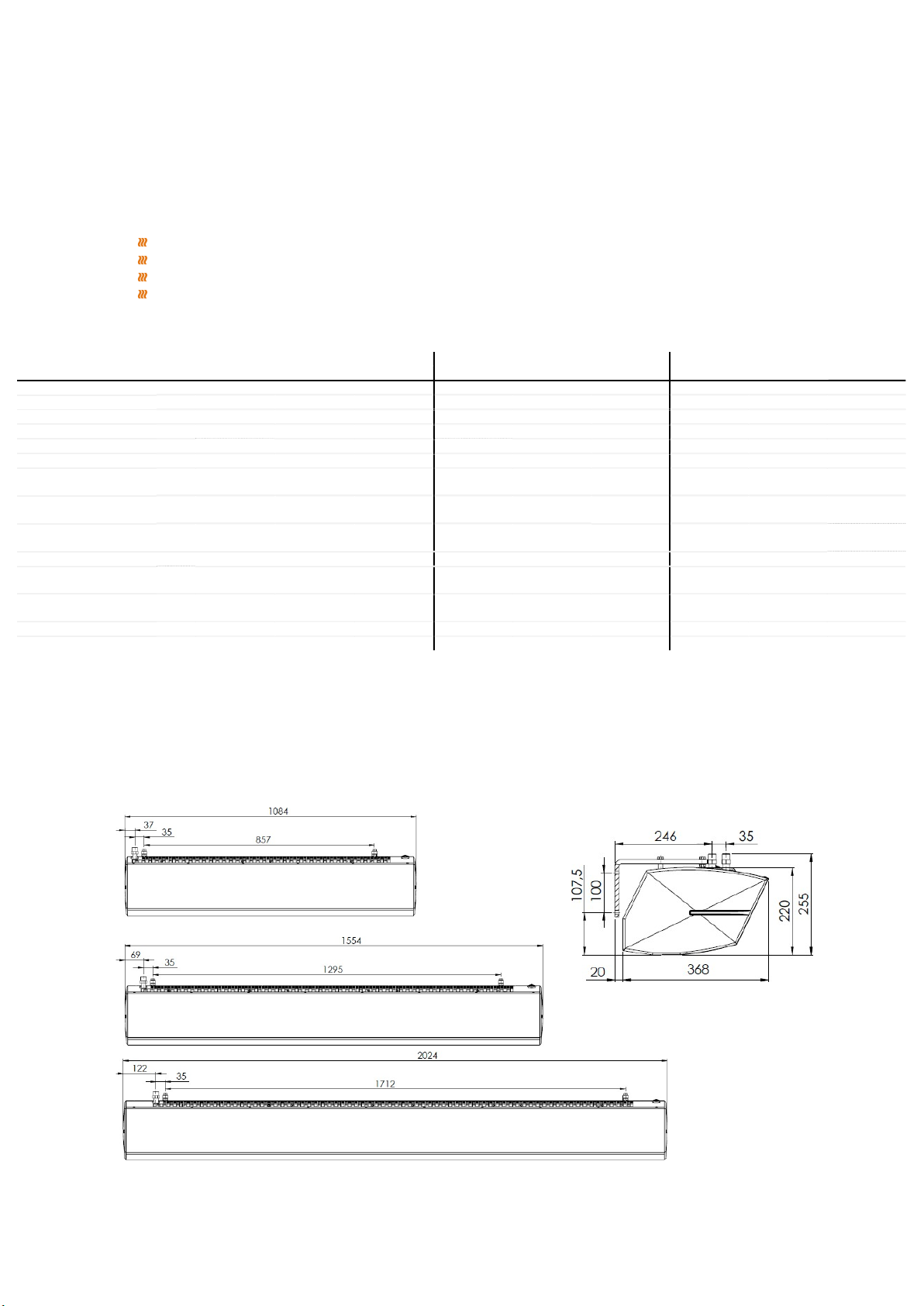

DIMENSIONS OF THE GUARD 100-150-200 W, E, C CURTAINS

Operation and Maintenance Documentation GUARD v202301

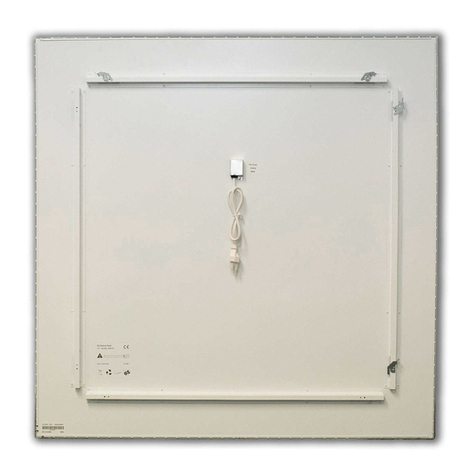

GUARD 100-150-200 E Air curtains with electric heater

GUARD E series (with electric heater) is based on a new type of PTC electric coils It is a modern and safe solution, additional

advantages of PTC heaters

Lack of voltage on the surface of the electric coil

Significantly lower coil temperature in comparison to the old type of electric

heaters (e.g. heating wires, spirals)

Large heat exchange surface (surface of contact of the heat exchanger with

heated air)

Fully automatic heat control depending on airflow

Complete elimination of the risk of a system overheating due to self-

regulating heating modules (heat capacity automatically reduces when airflow

goes down)

Low energy consumption

3. HEAT OUTPUT RANGES GUARD W

0 5 10 15 20 0 5 10 15 20 0 5 10 15 20 0 5 10 15 20 0 5 10 15 20

heat output kW 6,6 5,6 4,6 3,6 2,6 9,0 7,9 6,9 5,8 4,8 11,3 10,3 9,2 8,1 7,1 13,7 12,6 11,5 10,5 9,4 16,0 14,9 13,9 12,8 11,7

outlet air temperature

°

C

11,4 14,9 18,3 21,9 25,4 14,9 18,3 21,8 25,2 28,7 18,4 21,8 25,2 28,7 32,1 21,9 25,3 28,7 32,1 35,5 25,4 28,8 32,2 35,6 39,0

water flow m

3

/h 0,2 0,2 0,2 0,1 0,1 0,4 0,3 0,3 0,2 0,2 0,5 0,4 0,4 0,3 0,3 0,6 0,5 0,5 0,4 0,4 0,7 0,6 0,6 0,5 0,5

pressure drop kPa 1,0 1,0 0,6 0,6 0,3 2,0 2,0 1,0 1,0 1,0 4,0 3,0 2,0 2,0 1,0 5,0 5,0 4,0 3,0 2,0 7,0 6,0 5,0 5,0 4,0

heat output kW 5,9 5,0 4,2 3,3 2,4 7,9 7,0 6,1 5,3 4,4 10,0 9,1 8,2 7,2 6,3 12,0 11,1 10,2 9,2 8,3 14,0 13,1 12,2 11,2 10,3

outlet air temperature

°

C

12,5 15,8 19,1 22,4 25,8 16,4 19,6 22,9 26,2 29,5 20,3 23,5 26,8 30,0 33,3 24,2 27,4 30,6 33,9 37,1 28,0 31,3 34,5 37,7 40,9

water flow m

3

/h 0,2 0,2 0,1 0,1 0,1 0,3 0,3 0,2 0,2 0,2 0,4 0,4 0,3 0,3 0,2 0,5 0,4 0,4 0,4 0,3 0,6 0,5 0,5 0,5 0,4

pressure drop kPa 1,0 1,0 0,5 0,5 0,2 2,0 2,0 1,0 1,0 0,0 3,0 2,0 2,0 1,0 1,0 4,0 3,0 3,0 2,0 2,0 6,0 5,0 4,0 4,0 3,0

heat output kW 5,3 4,5 3,8 3,0 2,3 7,0 6,3 5,5 4,7 3,9 8,8 8,0 7,2 6,4 5,6 10,5 9,7 8,9 8,1 7,3 12,2 11,4 10,6 9,8 9,0

outlet air temperature

°

C

13,7 16,8 19,9 23,0 26,2 18,0 21,1 24,1 27,2 30,3 22,3 25,3 28,4 31,5 34,5 26,6 29,6 32,7 35,7 38,8 30,9 33,9 36,9 40,0 43,0

water flow m

3

/h 0,2 0,2 0,1 0,1 0,1 0,3 0,2 0,2 0,2 0,1 0,3 0,3 0,3 0,2 0,2 0,4 0,4 0,4 0,3 0,3 0,5 0,5 0,4 0,4 0,4

pressure drop kPa 1,0 0,8 0,5 0,5 0,2 1,0 1,0 1,0 0,7 0,6 2,0 2,0 1,0 1,0 1,0 3,0 3,0 2,0 2,0 1,0 4,0 4,0 3,0 3,0 2,0

0 5 10 15 20 0 5 10 15 20 0 5 10 15 20 0 5 10 15 20 0 5 10 15 20

heat output kW 13,5 11,7 10,0 8,2 6,4 17,4 15,6 13,8 12,1 10,3 21,3 19,5 17,7 15,9 14,1 25,1 23,3 21,6 19,7 18,0 29,0 27,2 25,4 23,6 21,8

outlet air temperature

°

C

11,9 15,4 18,9 22,5 26,0 15,1 18,6 22,1 25,7 29,2 18,3 21,8 25,3 28,9 32,4 21,5 25,0 28,6 32,0 35,6 24,7 28,2 31,7 35,2 38,7

water flow m

3

/h 0,5 0,4 0,3 0,2 0,2 0,6 0,6 0,5 0,4 0,3 0,8 0,7 0,7 0,6 0,5 1,0 0,9 0,8 0,7 0,7 1,2 1,1 1,0 0,9 0,8

pressure drop kPa 4,0 3,0 2,0 1,0 1,0 8,0 6,0 4,0 3,0 2,0 12,0 10,0 8,0 6,0 5,0 17,0 14,0 12,0 10,0 8,0 22,0 19,0 17,0 14,0 12,0

heat output kW 12,5 10,9 9,3 7,8 6,1 16,1 14,4 12,8 11,2 9,6 19,6 17,9 16,3 14,7 13,1 23,1 21,4 19,8 18,2 16,6 26,5 24,9 23,3 21,6 20,0

outlet air temperature

°

C

12,7 16,1 19,5 22,9 26,3 16,2 19,6 23,0 26,4 29,8 19,7 23,1 26,5 29,9 33,2 23,2 26,5 29,9 33,3 36,7 26,6 30,0 33,4 36,7 40,1

water flow m

3

/h 0,4 0,4 0,3 0,2 0,2 0,6 0,5 0,4 0,4 0,3 0,7 0,7 0,6 0,5 0,5 0,9 0,8 0,8 0,7 0,6 1,1 1,0 0,9 0,8 0,8

pressure drop kPa 4,0 3,0 2,0 1,0 0,6 6,0 5,0 4,0 3,0 2,0 10,0 8,0 6,0 5,0 4,0 14,0 12,0 10,0 8,0 7,0 18,0 16,0 14,0 12,0 10,0

heat output kW 11,0 9,7 8,4 7,0 5,7 14,0 12,6 11,3 9,9 8,6 16,9 15,5 14,2 12,9 11,5 19,8 18,4 17,1 15,7 14,4 22,7 21,3 20,0 18,6 17,3

outlet air temperature

°

C

14,2 17,4 20,6 23,7 26,9 18,2 21,3 24,5 27,7 30,9 22,1 25,3 28,5 31,6 34,8 26,1 29,2 32,4 35,6 38,7 30,0 33,1 36,3 39,5 42,6

water flow m

3

/h 0,4 0,3 0,2 0,2 0,1 0,5 0,4 0,4 0,3 0,3 0,6 0,6 0,5 0,4 0,4 0,8 0,7 0,6 0,6 0,5 0,9 0,8 0,8 0,7 0,6

pressure drop kPa 3,0 2,0 1,0 1,0 0,6 5,0 4,0 3,0 2,0 1,0 7,0 6,0 5,0 4,0 3,0 10,0 8,0 7,0 6,0 5,0 13,0 11,0 10,0 8,0 7,0

0 5 10 15 20 0 5 10 15 20 0 5 10 15 20 0 5 10 15 20 0 5 10 15 20

heat output kW 19,5 17,2 14,8 12,4 9,9 24,7 22,3 19,9 17,5 15,1 29,8 27,4 25,0 22,6 20,2 34,9 32,5 30,1 27,7 25,3 40,0 37,6 35,2 32,8 30,4

outlet air temperature

°

C

12,5 16,0 19,5 23,0 26,5 15,7 19,2 22,7 26,2 29,7 18,9 22,4 25,9 29,4 32,9 22,1 25,6 29,1 32,6 36,1 25,2 28,7 32,2 35,7 39,2

water flow m

3

/h 0,7 0,6 0,5 0,4 0,2 0,9 0,8 0,7 0,6 0,5 1,1 1,0 0,9 0,8 0,7 1,4 1,2 1,1 1,0 0,9 1,6 1,5 1,4 1,3 1,2

pressure drop kPa 9,0 6,0 4,0 3,0 1,0 15,0 12,0 9,0 7,0 5,0 22,0 19,0 15,0 12,0 9,0 32,0 27,0 23,0 19,0 15,0 42,0 37,0 32,0 27,0 23,0

heat output kW 18,2 16,0 13,8 11,7 9,4 22,8 20,7 18,5 16,3 14,1 27,5 25,3 23,1 20,9 18,8 32,1 29,9 27,7 25,5 23,4 36,6 34,5 32,3 30,1 27,9

outlet air temperature

°

C

13,3 16,7 20,1 23,5 26,8 16,8 20,2 23,6 27,0 30,3 20,3 23,7 27,0 30,4 33,8 23,7 27,1 30,5 33,8 37,2 27,1 30,5 33,9 37,3 40,6

water flow m

3

/h 0,6 0,5 0,4 0,3 0,2 0,8 0,7 0,6 0,5 0,4 1,0 0,9 0,8 0,7 0,6 1,2 1,1 1,0 0,9 0,8 1,4 1,3 1,2 1,1 1,0

pressure drop kPa 7,0 5,0 4,0 2,0 1,0 12,0 10,0 7,0 5,0 4,0 19,0 16,0 13,0 10,0 8,0 26,0 22,0 19,0 16,0 13,0 35,0 30,0 26,0 22,0 19,0

heat output kW 15,9 14,1 12,3 10,5 8,7 19,8 18,0 16,2 14,4 12,6 23,6 21,8 20,0 18,2 16,4 27,4 25,6 23,8 22,0 20,2 31,2 29,4 27,6 25,8 24,0

outlet air temperature

°

C

15,0 18,1 21,3 24,4 27,5 18,9 22,1 25,2 28,4 31,5 22,9 26,0 29,2 32,3 35,5 26,8 29,9 33,1 36,2 39,4 30,7 33,8 37,0 40,1 43,3

water flow m

3

/h 0,5 0,4 0,4 0,3 0,2 0,7 0,6 0,5 0,4 0,4 0,8 0,8 0,7 0,6 0,5 1,0 0,9 0,9 0,8 0,7 1,2 1,1 1,0 1,0 0,9

pressure drop kPa 5,0 4,0 3,0 2,0 1,0 9,0 7,0 5,0 4,0 3,0 13,0 11,0 9,0 7,0 5,0 18,0 16,0 13,0 11,0 9,0 24,0 21,0 18,0 16,0 13,0

inlet air temperature

90/70

inlet/outlet water temperature

inlet air temperature

GUARD 200W

inlet/outlet water temperature 50/30 60/40 70/50 80/60

inlet air temperature

GUARD 150W

inlet/outlet water temperature 50/30 60/40 70/50 80/60

GUARD 100W

90/70

90/70

III - max air flow - 3600 m3/h

II - mid air flow - 3000 m3/h

I - low air flow - 2200 m3/h

70/50 80/60

III - max air flow - 4800 m3/h

II - mid air flow - 4000 m3/h

I - low air flow - 2900 m3/h

III - max air flow - 2000 m3/h

II - mid air flow - 1550 m3/h

I - low air flow - 1200 m3/h

50/30 60/40

Operation and Maintenance Documentation GUARD v202301

4. GENERAL AND SAFETY PRINCIPLES

The GUARD air curtains are manufactured in compliance with the rules and standards concerning quality, ecology, utility, and

work comfort. Before starting the device be sure to read the Manual carefully.

The GUARD air curtains are delivered ready-to-use in a cardboard package that is to protect from any mechanical damage. The

package consists of the device, the Manual (Operation and Maintenance Documentation), and the Guarantee. If the optional

automatic control is ordered, it shall be delivered in a separate package. Make sure all the aforementioned elements are in the

package immediately after delivery. In the absence of any element, please fill in the suitable carrier document.

NOTICE!

Do not use the curtain in rooms containing any flammable and/or combustible substances, biological substances, or in

environments with corrosive air components.

Do not use the curtain in rooms with relative humidity above 80%

Do not leave the curtain ON unattended for long periods

Do not use the curtain without proper grounding

Do not turn the curtain on without a protective cover in place

Before conducting any maintenance or cleaning work or during the break-in operation for an extended period, make

sure you unplug the power cable

To connect the air curtain, use a supply cable with a fork that protects against unintended disconnecting from the

power

When the air curtain is connected directly to the cable, please make sure there is a splitter protecting against any

undesired disconnecting

Pay special attention while transporting the device not to damage the casing

When the device is being operated, ensure the safety rules following the labor standards relating to the operation of

any electrical devices

Do not place any objects on the curtain or reduce the airflow to ensure fire safety and if sparks or a damaged supply

cable are noticed, discontinue the operation immediately

The electricity network, to which the curtain is connected, should be protected against overloading and short circuit

CAUTION!

To avoid the serious danger of electric shock, installation must be performed by a qualified electrician

To avoid the danger of electric shock disconnect the power supply before conducting any repair or maintenance work

Any leakage repairs of the heating medium in the device, of which pipes are under pressure, are strictly prohibited

A cut-off/stop valve must be used to supply a heating medium

It is prohibited to connect the grounding-type plug to water pipes, gas tubes, lightning conductors, telephone or

antenna network

Wait for at least 3 hours before connecting the device to the power supply if the temperature while transporting is

below zero

5. INSTALLATION

When deciding on the air curtain position you should take into account such factors as:

Ease of access for servicing,

Access to water and electricity supplies

It is recommended to install the air curtain in position above the entrance opening, on the wall or under the ceiling, on support

pins or horizontal mounting brackets. It is also possible to mount it vertically to a wall or other structure using vertical mounting

brackets.

It’s important to make sure that the unit is properly leveled. In case of positioning in a different way than horizontally or

vertically, during installation, damage to the fan may occur and as a consequence malfunction of the unit.

Inlets and outlets cannot be blocked by any objects. When installing the curtains, keep in mind that you will have free access to

the control panel. With larger door openings, it is possible to mount more curtains of the same type, one by one, to create an

uninterrupted airflow. The curtain is permanently mounted in either a horizontal or vertical position (on the left/right side of the

entrance).

Curtain connection should be done in a serviceable manner, manual shut-off valves should be installed on both nozzles to

enable disconnection. In the case of a solenoid valve (option - automatics), it must be connected to the water outlet of the

device, otherwise, it may be damaged. When tightening the pipeline to the exchanger, the heater connection must be protected

against torque (which may cause leakage in the exchanger).

NOTICE !

Before mounting the device, read the manual carefully and adhere to the rules concerning the mounting

procedures. Not applying to the rules may result in the inappropriate functioning of the device and the loss of

the guarantee rights.

Pay special attention when working with electrical elements of the device.

Operation and Maintenance Documentation GUARD v202301

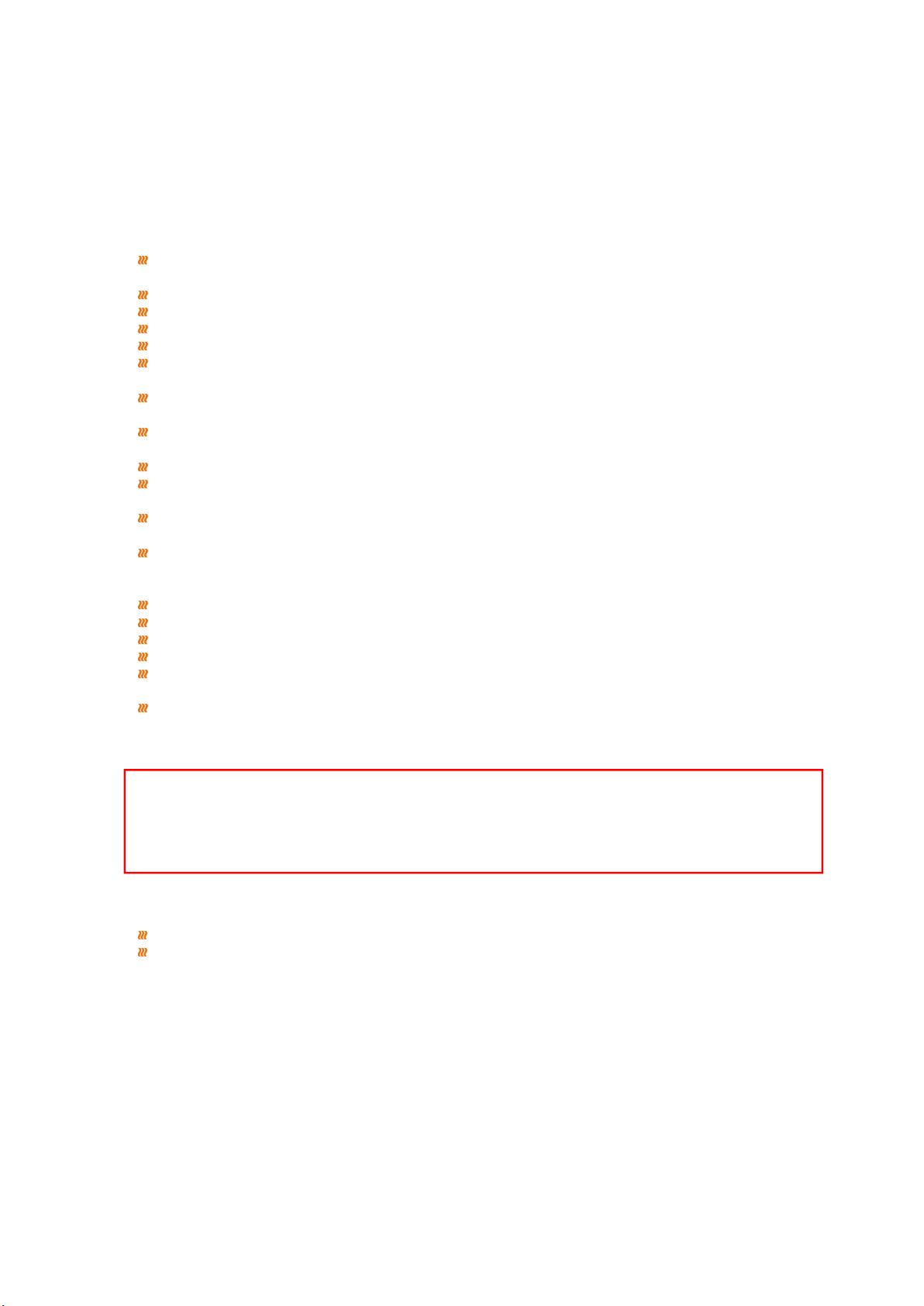

Horizontal installation under the ceiling using mounting pins

Installation under the ceiling is done by using 4 M8 pins. To hang the device on the pins, drill holes Ø 8-9mm in the EPP

housing directly in front of the existing holes in the steel inlet grille. The exact location is indicated by special tags on the EPP

housing. The pins should be screwed into the nippers at a depth of 9 mm.

Drawing below shows the position of the mounting holes for the pins

Curtain size

A(mm)

C(mm)

Nuber of pins M8

100 72 857 4

150 104 1295 4

200 157 1712 4

Wall installation by means of a horizontal brackets

The curtain can be mounted to the wall in a horizontal position using 2 mounting

brackets to the horizontal system. In the brackets there are Ø9mm holes for M8

screws. In the EPP housing, drill holes Ø 12-13mm in front of existing holes in the

steel intake grille. The exact location is indicated by the special tags on the EPP

housing and the figure below. Then insert the spacer sleeves into the holes and fix

the brackets. Screw the remaining screws into the nuts under the steel intake grille

so that both grips are in one plane. Locknuts under the handles are used to secure

the screws from unscrewing.

Operation and Maintenance Documentation GUARD v202301

Installation using brackets for vertical mounting

It is also possible to install the unit vertically with the engine downwards and upwards.

Two vertical mounts are used for this purpose. In the brackets there are Ø9mm holes for

M8 screws. In the EPP housing, drill holes Ø 12-13mm in front of existing holes in the

steel intake grille. The exact location is indicated by special tags on the EPP housing and

the figure below. Then insert the spacer sleeves into the holes and fix the brackets.

Screw the remaining screws into the nuts under the steel intake grille so that both grips

are in one plane. Locknuts under the handles are used to secure the screws from

unscrewing.

Connection of heating medium

The connection of the heating medium to the heat curtain, using G 1/2" threaded

connections should be made based on a design by an authorized designer. If the air

curtain is connected to a district heating network without a mixing unit, a water filter is

required. The direction of connection to the water heater does not affect air curtain

works.

In the case of horizontal and vertical mounting with nozzles at the top, the exchanger is

vented through the nozzles. If the device is mounted vertically with nozzles at the

bottom to vent the exchanger, use a vent that is located on the exchanger collector on

the engine side.

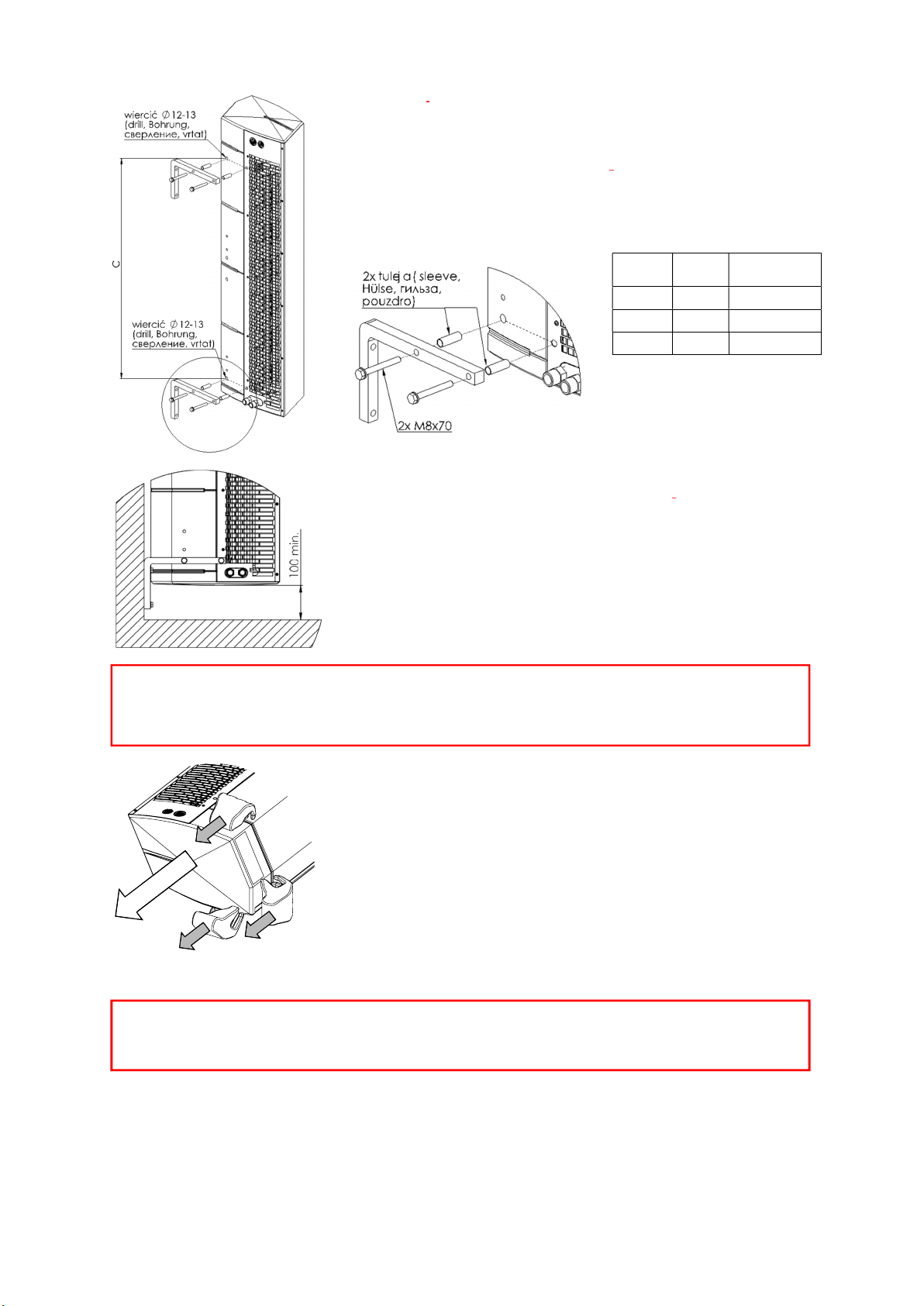

Connecting the power supply and control system of the curtain

To connect the power supply, control and/or bleed the Exchange move out the right

lid, which is fastened with the lock to the lower steel housing and the main housing

EPP. The lid is disassembled in the direction shown by the arrows in the figure below.

The lid should be grasped in the following places indicated in the drawing and should

be gradually "released" from the locks for several millimeters. Cable entries for power

and control cables are located on the inlet grille.

Curtain

size C(mm)

Number of

brackets

100 857 2

150 1295 2

200 1712 2

ATTENTION !

It is necessary to ensure that the unit is properly leveled. When it is mounted in a position other than vertical

or horizontal there is a risk of fan damage and unit malfunction

The minimum distance between device and floor cannot be less than 100 mm

ATTENTION !

Ensure that no connection wire is clamped between the lid and the rest of the curtains before assembling the lid.

Operation and Maintenance Documentation GUARD v202301

6. CONTROL PANEL

A set of automatic control may be used (powered 230V) that consists of the following:

COMFORT NEW panel – including room thermostat and switch for regulation of 3 speeds of the fan.

One COMFORT panel may regulate up to 2 pcs of GUARD

2-way water valve with actuator; valve should be installed on a return stub of the heater

INTELLIGENT electronic control panel with an automatic speed controller, weekly program, and BMS communication.

One INTELLIGENT panel may regulate up to 2 pcs of GUARD

Splitter MULTI 6 - control up to 6 pcs of GUARD

The system is ready to start once the connections between the thermostat and the valve actuator are done, 230V power is

supplied to the thermostat and the fan’s motor is powered by the revs controlle.

COMFORT NEW panel description

OFF-I-II-III - switch and fan speed regulation

HEAT - the thermostat gives an operation signal to the actuator and fan, the fan turns off when the set

temperature is reached, the valve closes the water supply

FAN - device fan operation according to the thermostat, valves or electric heaters do not work

COOL - the thermostat gives an operation signal to the actuator and fan, the device starts to work

when the set temperature is reached

It is possible to use an additional change of the SR1 to SR1 CONST jumper position, in this case the fan can operate regardless

of the thermostat. Thermostatic operation is only for valves. In this case:

HEAT - fan operation regardless of the thermostat, valves work up to the set temperature

FAN - device fan operation, regardless of the thermostat, valves do not work

COOL - fan operation regardless of the thermostat, valves work from the set temperature

7. GUARD DOOR SWITCH

The GUARD (DC) door switch is an additional element for switching the curtain on/off, depending on the opening of the door.

It is designed for indoor installation. It includes:

Relay cabinet - reed relay switchboard

Reed relay - Reinforcement for door-fitting, hermetic magnetic switch, consisting of a movable and fixed element

Scheme of the relay cabinet – reed relay interface

When installing the GUARD door switch, remove the factory-made jumper:

NC-1 for curtain GUARD W (curtain with a water heater) / GUARD C (curtain without a water heater)

NC-COM for curtain GUARD E (curtain with an electric heater)

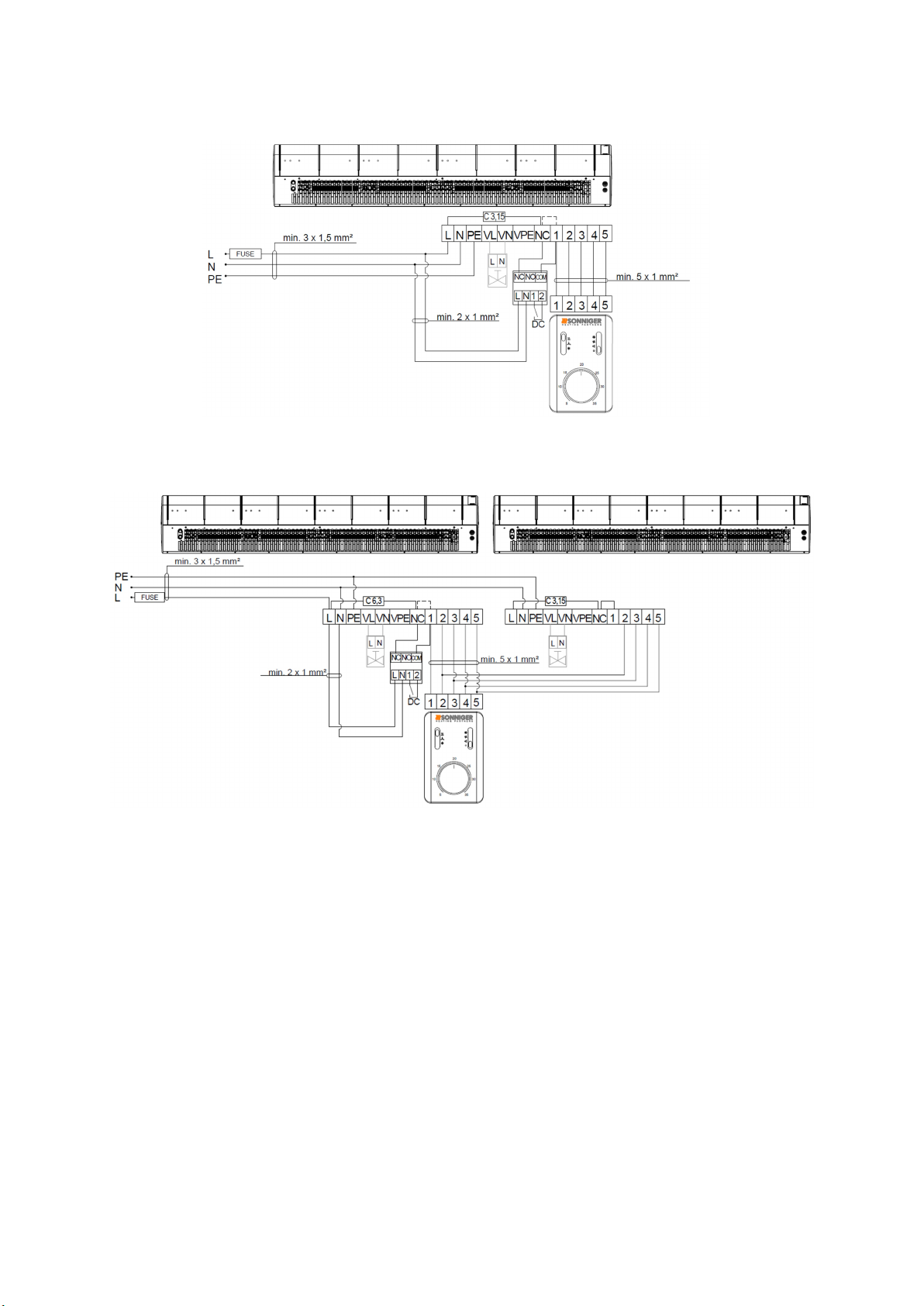

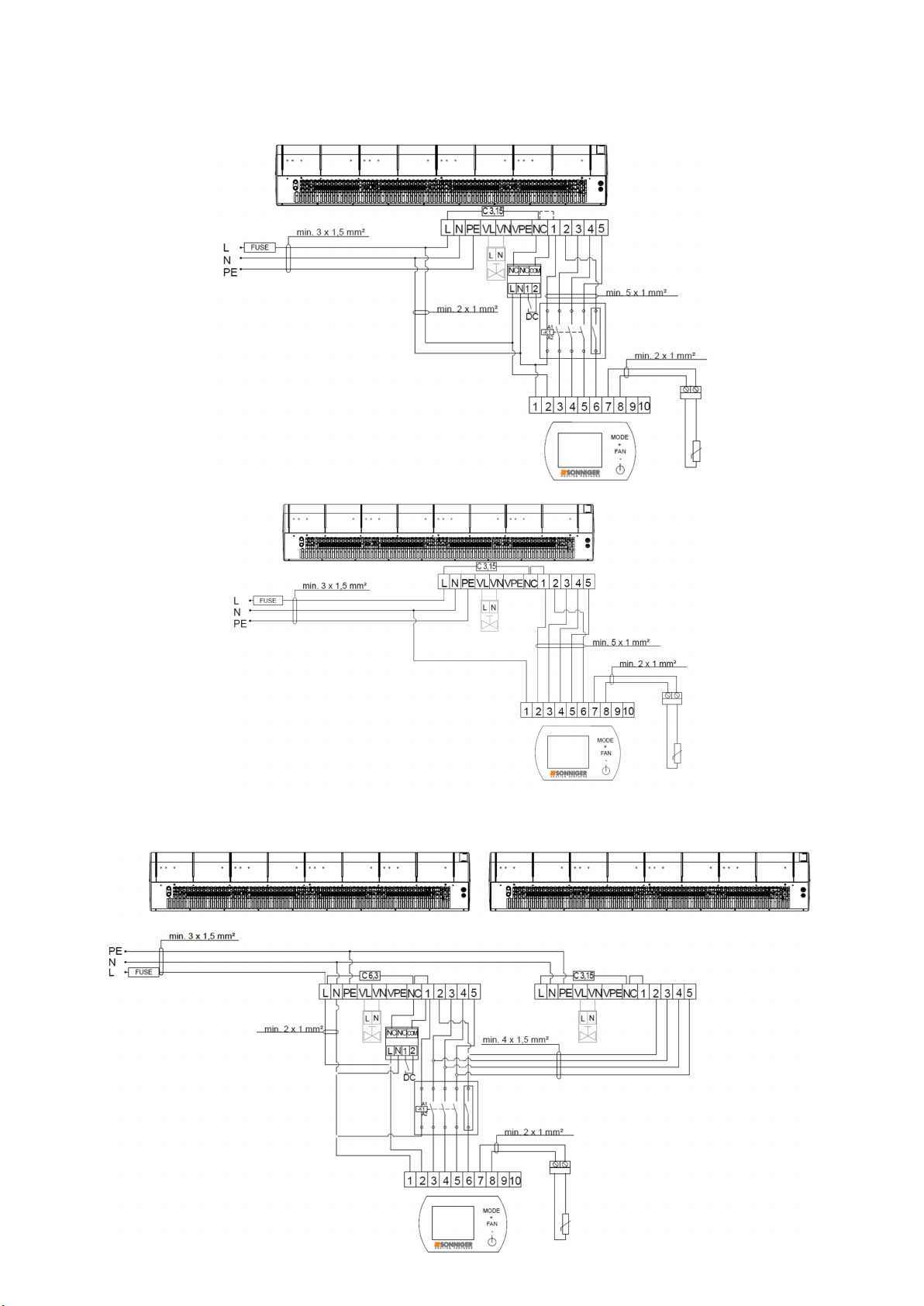

8. DIAGRAMS OF ELECTRICAL CONNECTIONS

The electrical network to which the curtain will be connected should protect against overheating and short-circuiting. It is

necessary to protect the air curtain by grounding. Electrical installation and connection to the air curtain must be following

applicable building codes and regulations, electrical connection should be carried out by a qualified person familiar with the

above instruction. The fan motor has standard internal thermal protection to protect the motor from overheating. The set does

not include: a power cord, or main switch

*diameter and length of the cable should be following local regulations (some deviations are acceptable)

Operation and Maintenance Documentation GUARD v202301

8.1 Diagram of connecting one GUARD 100-150-200 W (water heater) and C (without heater) to the COMFORT panel

*The unit set does not consist of: a master switch, a fuse, a feeding cable

In case of working without DOOR SWITCH the bridge between terminal NC-COM need to be keep.

8.2 Diagram of connecting two GUARD 100-150-200 W (water heater) and C (without heater) to one COMFORT panel

*The unit set does not consist of: a master switch, a fuse, a feeding cable

In case of working without DOOR SWITCH the bridge between terminal NC-COM need to be keep.

In the MASTER curtain between the L-NC terminals, replace the factory-made fuse (C 3.15) with C 6.3 (for work with DOOR

SWITCH remove the bridge between terminal NC-1)

Operation and Maintenance Documentation GUARD v202301

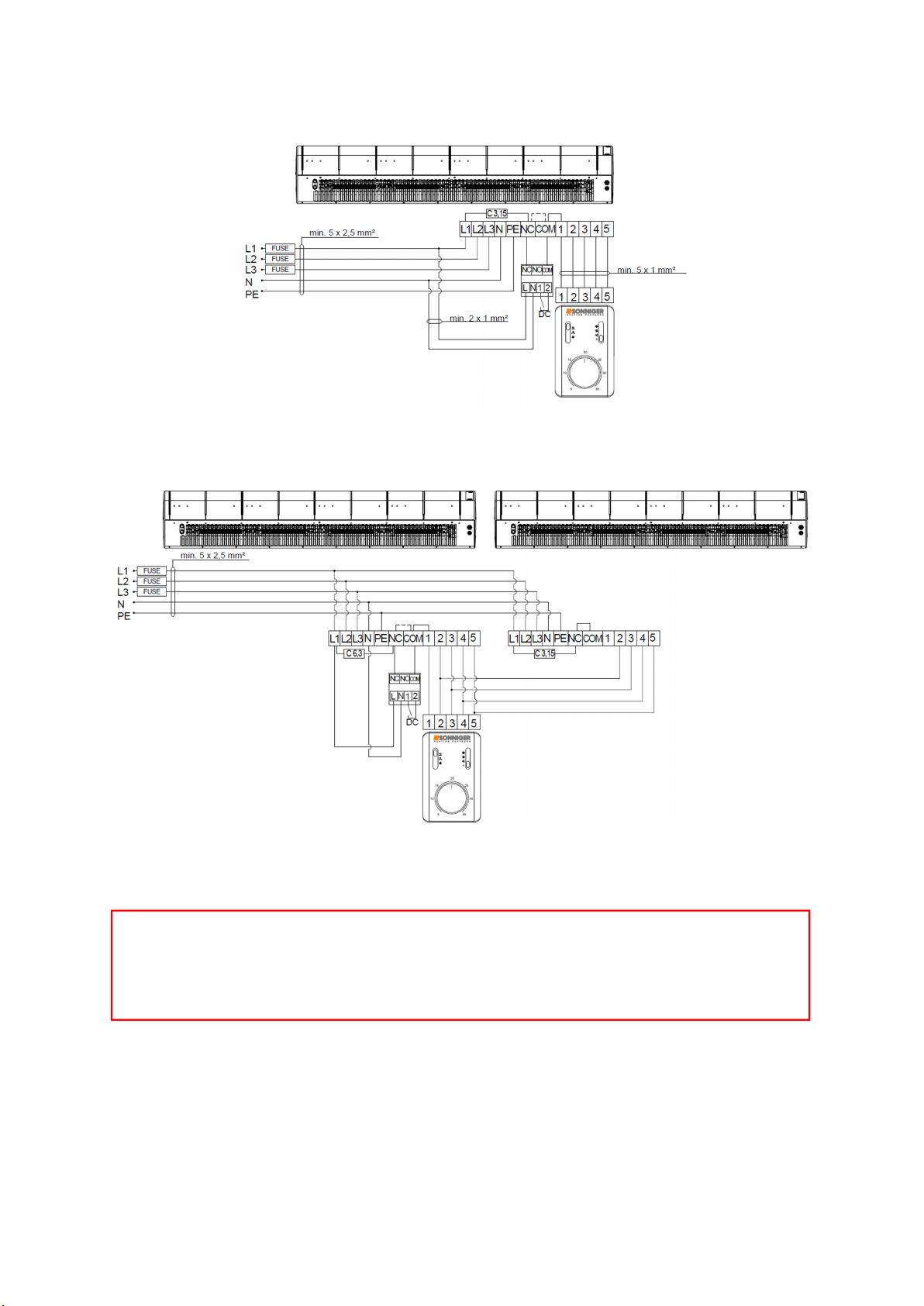

ATTENTION!

PTC heaters power supply 3x400V/50Hz or 3x400V/60Hz

min. 5 x 2,5 mm for G100E; (B16)

min. 5 x 4 mm for G150E; (B20)

min. 5 x 6 mm for G200E; (B25)

8.3 Diagram of connection of one GUARD 100-150-200 E curtain (electric heater) to the COMFORT panel

*The unit set does not consist of: a master switch, a fuse, a feeding cable

In case of working without DOOR SWITCH the bridge between terminal NC-COM need to be keep.

8.4 Diagram of connection of two GUARD 100-150-200 E curtain (electric heater) to one COMFORT panel

*The unit set does not consist of: a master switch, a fuse, a feeding cable

In case of working without DOOR SWITCH the bridge between terminal NC-COM need to be keep.

In the MASTER curtain between the L-NC terminals, replace the factory-made fuse (C 3.15) with C 6.3 (for work with DOOR

SWITCH remove the bridge between terminal NC-COM)

Operation and Maintenance Documentation GUARD v202301

8.5 Connection diagram of GUARD 100-150-200 W and C with INTELLIGENT

8.5.1 With DOOR SWITCH

8.5.2 Without DOOR SWITCH

8.6 Diagram of connecting two GUARD 100-150-200 W and C to the INTELLIGENT panel

8.6.1 With DOOR SWITCH

Operation and Maintenance Documentation GUARD v202301

In the MASTER curtain between the L-NC terminals, replace the factory-made fuse (C 3.15) with C 6.3 (for work with DOOR

SWITCH remove the bridge between terminal NC-COM).

8.6.2 Without DOOR SWITCH

8.7 Diagram of connecting one GUARD 100-150-200 E (electric heater) to the INTELLIGENT panel

8.7.1 With DOOR SWITCH

Operation and Maintenance Documentation GUARD v202301

8.7.2 Without DOOR SWITCH

8.8 Diagram of connecting two GUARD 100-150-200 E (electric heater) to the INTELLIGENT panel

8.8.1 With DOOR SWITCH

In the MASTER curtain between the L-NC terminals, replace the factory-made fuse (C 3.15) with C 6.3 (for work with DOOR

SWITCH remove the bridge between terminal NC-COM).

Operation and Maintenance Documentation GUARD v202301

ATTENTION!

PTC heaters power supply 3x400V/50Hz or 3x400V/60Hz

min. 5 x 2,5 mm for G100E; (B16)

min. 5 x 4 mm for G150E; (B20)

min. 5 x 6 mm for G200E; (B25)

8.8.2 Without DOOR SWITCH

In the MASTER curtain between the L-NC terminals, replace the factory-made fuse (C 3.15) with C 6.3.

9. OPERATION AND MAINTENANCE

The engine and fan of the GUARD air curtains are maintenance-free devices but regular check-ups are advised, especially the

motor and bearing (the fan’s rotor should rotate freely, free from any axial and radial throws/run-outs and undesired

knocks/rattles.

The heat exchanger requires systematical cleaning of all dirt/impurities off. Before the start of the heating period, the heat

exchanger is advised to be cleaned with compressed air directed to the air outlets; there is no need for dismantling the device.

Pay special attention when cleaning the exchanger’s fin due to the high possibility of damaging them. If the fin is bent use a

special tool. If the device has not been used for a longer period, unplug it before the next use.

The heat exchanger is not equipped with any fire protection device. The heat exchanger may be damaged if the room

temperature goes below 0°C; anti-freeze liquid must be added to the water circulation/system. Anti-freeze liquid must be

appropriate for the material the exchanger is made of (copper) as well as other elements of the hydraulic system/circulation.

The liquid must be diluted with water accordingly to the manufacturer’s recommendation.

ATTENTION!

Any repair and maintenance work must be conducted with the power off and the heat input disconnected.

Only suitably qualified staff well acquainted with the safety regulations concerning handling an electrical device

must be employed when the device is being installed, started, and operated

In the event of a coolant leak, when the water system is under pressure, any repairs of the leakage are strictly

prohibited.

Any repairs to the device must be conducted only if the device is disconnected from the power supply.

If the device being operated gives a metallic clatter, or vibration or the level of noise is increasing, check if the

mounting of the fan has not become loose – in case of any problems contact the installer of the device or the

SONNIGER Authorized Service immediately.

Operation and Maintenance Documentation GUARD v202301

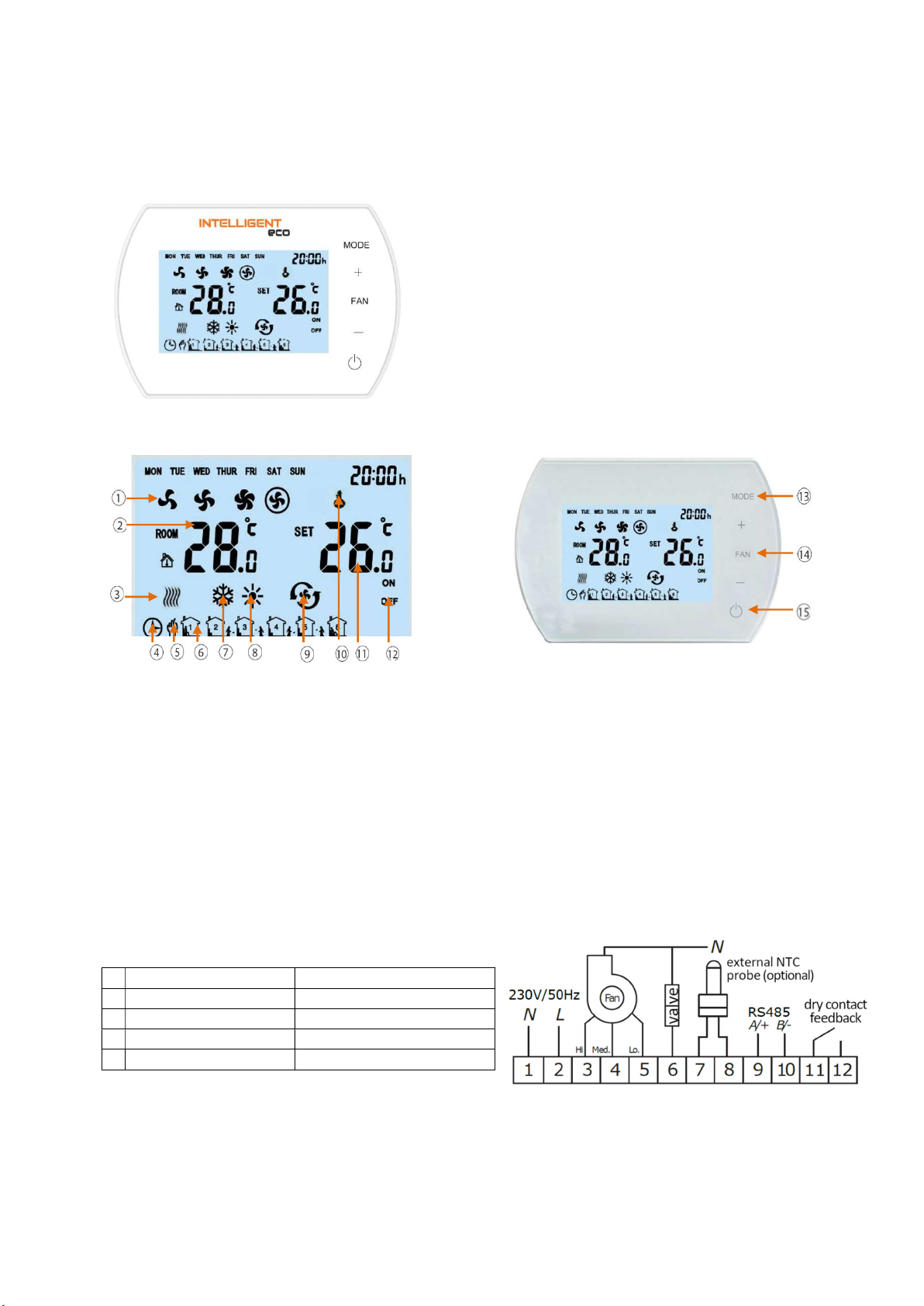

10 PANEL INTELLIGENT WIFI – programmable controller manual

Panel Intelligent WIFI controls actuators/valves and automatically regulates the fan’s speed depending on the required room

temperature. The lower temperature in the room the higher the air output is set. Fan speed changes automatically at a lower

rate when the temperature in a room gets closer to the desired one. Intelligent WIFI allows to management work of the device

via the mobile app TUYA SMART.

Functions

Panel INTELLIGENT is designed for the SONNIGER products

Weekly thermostat (5/1/1 days)

Automatic or manual 3-step fan speed adjustment.

Control room temperature (by opening/closing the valve, or by

adjusting air volume automatically).

Antifreeze mode- protection against dropping room

temperature below critical level 5 ~ 15 °C.

Possibility to connect external NTC temperature sensor.

BMS communication by MODBUS protocol

Wireless control via the TUYA SMART app

Dry contact feedback

Panel description

1. Fan Speed: LOW, MED, HI and AUTO

2. ROOM TEMP. or NTC EXTERNAL SENSOR TEMP. (measured

temperature)

3. Anti-freeze indication

4. Automatic programable mode

5. Manual mode

6. 6 Time Zones for each day

7. Cooling Mode

8. Heating Mode

9. Ventilation Mode

10. Buttons Lock

11. SET TEMP. (desired room temperature)

12. ON/OFF status of time zones

Technical parameters

1 Power supply 230VAC/50Hz

2 Temperature setting range 5°C 40°C

3 Temperature working range -10°C 60°C

4 IP class 20

5 Temperature sensor Internal / external NTC (optional)

13

MODE

Press shortly to select manual or automatic

mode Press and hold for 3 s and select colling,

heating or ventilation mode

14 FAN Press shortly and select fan speed: Low, Med,

High or Auto

15 ON/OFF INTELLIGENT Panel

Operation and Maintenance Documentation GUARD v202301

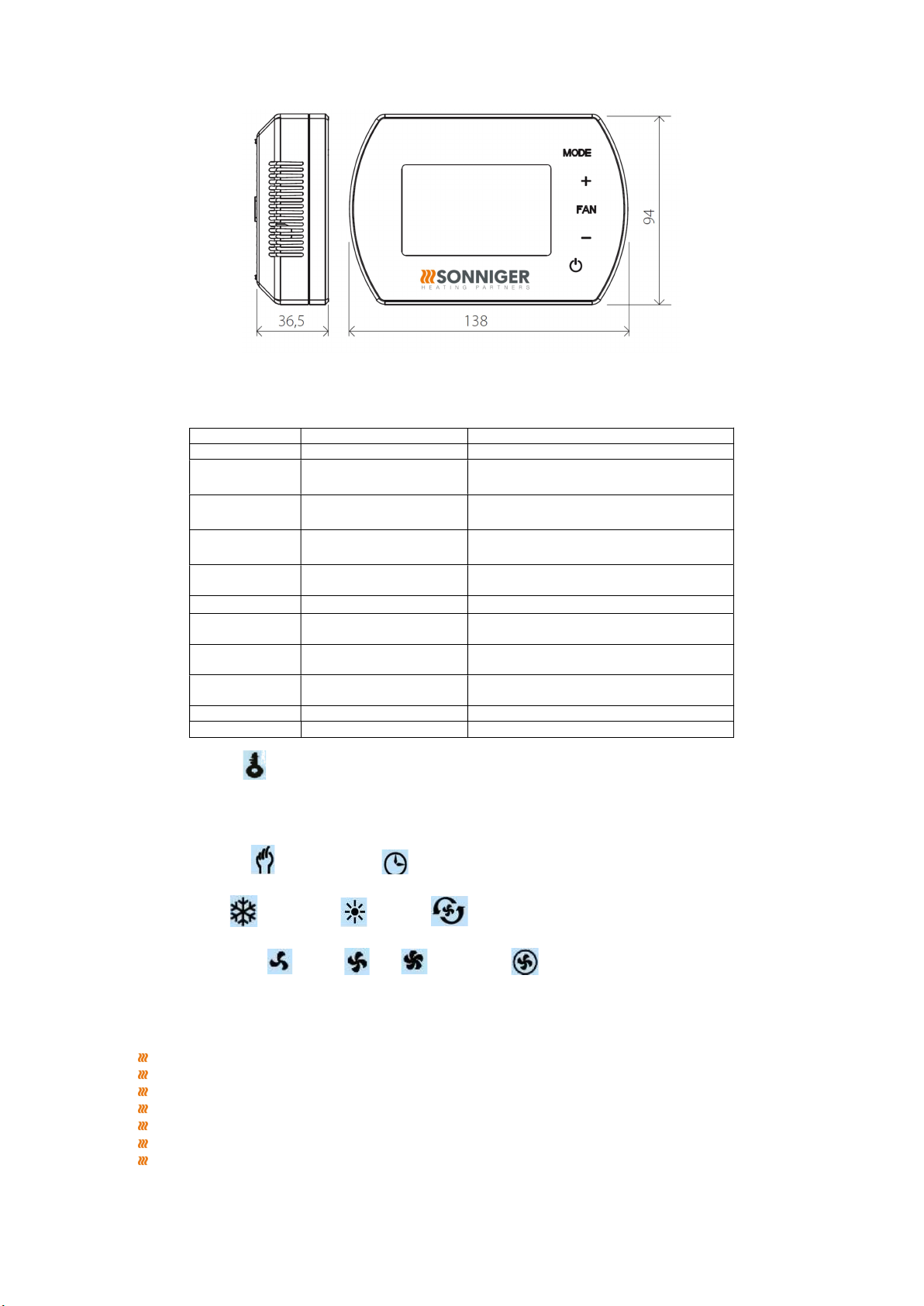

Dimensions

Settings menu

When Panel Intelligent is switched off, press and hold MODE for 5 seconds

To change option use MODE button.

To change value use +/- buttons.

Setting menu

Option

Value

1

Temperature calibration

–

9°C ~ +9°C

2 EEPROM

0:

no memory

1: memory

3 Fan status

C1:

Thermostatic mode

C2: Continuous mode

4 Temperature sensor

0: Internal Sensor

1: External Sensor NTC (optional)

5 Antifreeze

0:

Off

1: On

6

Antifreeze range

+5°C ~ +15°C

7 ALARM

0: disable

1: enable

8 Drycontact

0: NO

1: NC

9 MODBUS

0: disable

1: enable

10

BMS speed

0

-

2400 / 1

-

9600 / 2

-

19200

11

Modbus ID

1~247 (01~F7)

Button lock / unlock

To LOCK buttons press and hold + and then – and hold both of them for 5 seconds.

To UNLOCK buttons press and hold + and then – and hold both of them for 5 seconds.

Press MODE

Change on manual mode or automatic mode

Hold MODE for 5 seconds

Change to cool mode , heating mode , ventilation

Press FAN

Change of the fan speed low , medium , high , automatyczna

Hold FAN for 5 seconds

Manual callendar programming Monday – Friday, Saturday, Sunday 6 settings per day

BMS Functions

Setting/Reading work parameters

Work/Stop conditions

Weekly program

Temperature

Fan speed

Heating, ventilation, cool mode

Antifreeze mode

Operation and Maintenance Documentation GUARD v202301

WIFI functions

Setting/Reading work parameters

Work/Stop conditions

Weekly program

Temperature

Fan speed

Heating, ventilation, cool mode

CONNECTION INTELLIGENT WIFI WITH TUYA SMAR APP

1. Download the Tuya Smart app (available at App Store and Google Play)

2. The Control panel connects to the power supply and device, Panel INTELLIGENT should stay off

3. Turn on the Tuya app and follow the instruction in the app

4. For the connection process, please enable the GPS and Bluetooth in the phone

5. To activate the paring mode in the INTELLIGENT Panel tap twice and hold the “+” symbol for 5 seconds until the

“SA” symbol shows on the left side of the screen

6. Choose the „Add device” function, and the app should find the control panel automatically, press the "Add" button,

and after completing the configuration process, press "Next" and "Finished"

7. In the absence of the "Add" function, select the "Small devices" tab and the "Thermostat (Wi-Fi)" function. After that

enter the data to connect to the selected WiFi network and confirm, and then "Blink slowly".

8. A screen will be displayed with information about searching for a device. After detecting the driver, the connection

process is automatic. after completing the configuration process, press "Next" and "Finished"

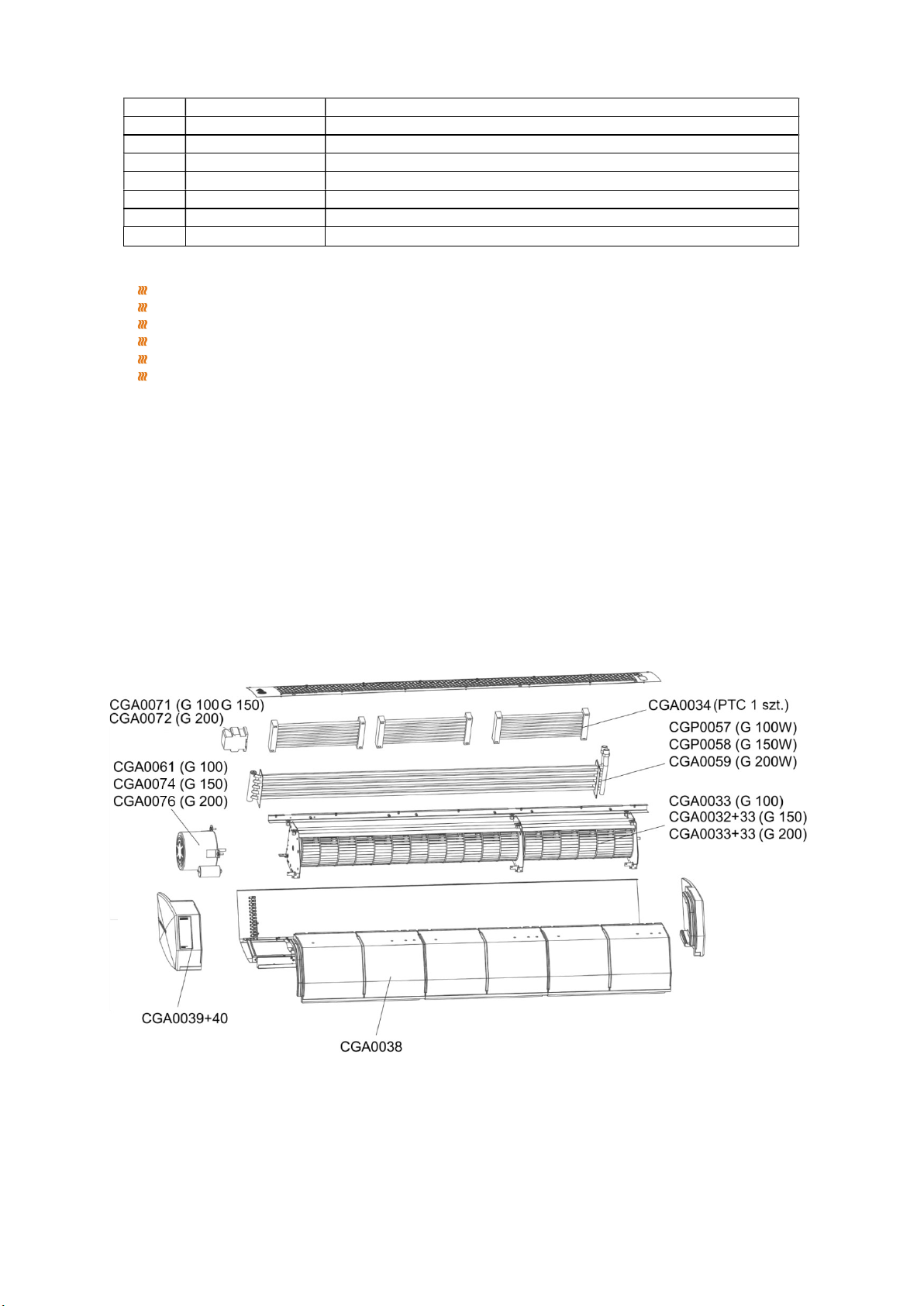

SPARE PARTS

No.

Setting

Paremeters

1

Working

Mode

RS485 Semi

-

duplex; PC or main controller is master; thermostat is slave

2

Interface

A(+),B(

-

), 2 wires

3

Baud Rate

0

-

2400 / 1

-

9600 / 2

-

19200

4

Byte

9 bits in total: 8 data bit + 1 stop bit

5

Modbus

RTU Mode

6

Transmittion

RTU (

Remote Terminal

Unit

) format

(

please refer to MOBUS instruction)

7 Thermostat address 1-247;(0 is broadcast address and stand for all thermostat without response)

Operation and Maintenance Documentation GUARD v202301

COMPLIANCE WITH WEEE 2012/19 / EU

In accordance with applicable legal regulations, at the time of purchasing new electrical or electronic equipment with the

following mark:

REMEMBER IT IS FORBIDDEN TO PLACE THE WORN EQUIPMENT WITH OTHER WASTE

For information on the waste collection system of electrical and electronic equipment, please contact your

distributor

GUARANTEE TERMS AND CONDITIONS

§ 1 Guarantee Scope

1. This Guarantee covers material defects of the device which make its functioning impossible. This Warranty does not

extend to the installation and maintenance works.

2. The Guarantee for the product sold by the Seller covers 24 months. The guarantee period commences upon the delivery of

the device to the Buyer specified in the sales invoice. The warranty covers any parts/components specified in the scope of

the delivery.

3. Products delivered by third persons are not guaranteed by this supplier.

4. Devices may be started and serviced only by qualified persons trained in the areas of maintenance and operation of the

device. Any operations related to starting, maintenance, and repairs must be noted that such operations have occurred in

the Guarantee Card.

5. The precondition for issuing the Guarantee by the manufacturer is the assembly and activation of the device following the

Operation and Maintenance Documentation not later than 6 months after the date of the purchase.

6. The product is guaranteed for a full period of warranty only if service works implied in the Operation and Maintenance

Documentation for the device specified in the ‘Maintenance’ section are carried out. All services related to the maintenance

of the device are carried out at the User’s cost and expense.

7. The provision of warranty services does not cease or suspend the duration of the Warranty. The warranty for replaced or

repaired parts/elements shall end with the expiry of the Guarantee for the device.

§ 2 Warranty Exclusions/Disclaimers

1. The Warranty does not extend to the mechanical damages and damages to electrical parts caused by improper use,

transport, abnormal voltage, or other damages arising from a product defect. For the above reasons, the Warranty is

solely limited to the replacement of parts/components having construction defects that shall be delivered without any

additional costs only if the defective part/component has been returned.

2. The Warranty for devices does not apply when technical mistakes occurred during the procedures concerning installation,

regulation, and control including any of the following:

a) Defects caused by connecting a device to an inappropriately designed ventilation system that allows additional heat

loads that do not meet any standards and decrease the efficiency of the heat exchanger.

b) Defects caused by connecting to the components or parts that are part of the heating system but have not been

delivered by the Seller and whose inappropriate functioning harms the device’s functioning.

c) Defects caused by connecting spare parts to components that are not original parts.

d) Defects incurred by reselling the product by the first buyer/user to another buyer who dismantles/installs the device

that was previously installed and operated in a specific building and its conditions.

e) Defects caused by improper expertise and insufficient knowledge of the installer and technical staff who, improperly

carry out after-sale service of the device

f) Defects caused by special conditions of use that differ from typical/standard applications unless the parties (the Seller

and customer’s technical staff) have previously agreed otherwise in writing.

g) Defects incurred by natural disasters such as fire, explosions, and other incidents that may result in damages to

mechanical, electrical, and protection devices

h) Defects are caused by inappropriate cleaning of the technical facility or place where the device has been installed;

cleaning must take place periodically to suit the specific working conditions and the amount of dust.

i) Defects arised from the absence or improper cleaning of heat exchangers; cleaning must be done periodically to suit

the specific working conditions and the amount of dust.

j) Defects incurred by the inappropriate installation - inadequate for the low outside temperature of working conditions.

k) Defects incurred by the low temperature if no protection device is installed by the installing contractor to avoid:

low temperatures on electrical and mechanical parts such as valves, electric and electronic controlling devices,

water condensation and frost/ice near the device,

thermal shock of the heater and heat exchanger caused by sudden changes of the outside temperature.

§3. SONNIGER Poland is not liable to:

1. Current maintenance works, and inspections follow from Operation and Maintenance Documentation and device

programming.

2. Defects caused by banking of a device while waiting for the warranty service.

3. Any defects caused to the company’s property.

Operation and Maintenance Documentation GUARD v202301

§4. Complaint Procedure

1. In the event of a complaint under the Warranty conditions, the user may complain directly to the Distributor.

2. All repairs covered by the warranty shall be done as part of the activity of an installation company and Factory Service. All

repairs ensuing from the guarantee shall be done in a place where the device is installed.

3. Any services under the Warranty are to be carried out within 14 days from the date of request. In exceptional cases, the

deadline may be extended, especially if the warranty service requires ordering parts or components from subcontractors.

4. The user concerning the service activities is obliged to:

Allow having full access to the rooms where the devices were installed and provide the necessary facilities allowing

direct access to the device (lift, scaffolding, etc.) to do all the servicing covered by the guarantee.

Present the original of the Guarantee Card and VAT invoice recording the purchase,

Ensure safety while doing the servicing,

Allow starting works immediately after the arrival of the Service.

5. In order to make a complaint under the warranty it is necessary to deliver to the Distributor’s address the following

documents:

a) correctly filled-in complaint form that is available at the website of www.sonniger.com

b) copy of the Guarantee Card

c) copy of the proof-of-purchase - the sales invoice

6. The repair service including the replacement of the parts shall be done free of charge only if the representative of the

installing contractor or the Service claims that the defect or malfunctioning of the device is caused by the fault of the

producer.

7. Any costs (cost of repair, travel, and exchanged components) incurred due to the unjustified complaint, especially in the

situation when the representative of the Installing Contractor of the Factory Repair Service claims that defect/damage was

caused as a result of breaching the guidelines provided in the Operation and Maintenance Documentation or notices the

exclusions under §2 (Warranty exclusions) will be requested from the Buyer/Customer who reported the failure.

8. The Claimant is obliged to give a written confirmation of the service provided.

9. Sonniger Poland is entitled to refuse the warranty service if Sonniger Poland has not received full payment for the product

complained about under the Guarantee or any previous servicing activities.

Operation and Maintenance Documentation GUARD v202301

GUARANTEE CARD

INVESTEMENT: ……………………………………………………………………………

Device model:…………………………………………………………………………………………….…

Serial number:……………………………………………………………………………………………...

Date of purchase:……………………………………………………………………………….................

Start date: …………………………………………………………………………………………………..

Details of installation company:

Person activating the device:………………………………………………………………...

Name of company:………………………………………………………………………………………….

…………………………………………………………………………………………………………….….

Address:……………………………………………………………………………………………………..

Telephone:……………………………………………………………………………………………………

Signature of a person who has started the device:………………………………………………………

Installation works, check-ups/inspections, repairs:

Date The scope of installation works, inspections, repairs Signature and installation company stamp

Dokumentacja techniczno-ruchowa kurtyna standardowa GUARD v202301

Dokumentacja techniczno-ruchowa GUARD

SONNIGER S.A.

ul. Śląska 35/37, 81-310 Gdynia, Poland, infolinia 801 055 155, tel. + 48 58 785 34 80, www.sonniger.com

Sąd Rejonowy Gdańsk-Północ, VIII Wydział Gospodarczy Krajowego Rejestru Sądowego, KRS 0000966611, NIP 586 227 35 14

Regon 22154369 kapitał zakładowy: 1.655.000 PLN

Other manuals for GUARD

1

This manual suits for next models

9

Table of contents

Languages:

Other Sonniger Heater manuals

Sonniger

Sonniger GUARD Installation guide

Sonniger

Sonniger GUARDPRO Series Installation guide

Sonniger

Sonniger GUARD PRO Installation guide

Sonniger

Sonniger GUARD PRO Installation guide

Sonniger

Sonniger CR ONE Installation guide

Sonniger

Sonniger HEATER CONDENS Installation guide

Sonniger

Sonniger Heater R2 User manual

Sonniger

Sonniger Heater R1 User manual

Sonniger

Sonniger GUARD 100W Installation guide