Operating Manual | Content

BS40

2 / 25

Revision: 1.1 | 2023-04-27

Content

1Introduction .......................................................................................................................3

1.1 Notes on this documentation.........................................................................................3

1.2 Representations in this documentation........................................................................3

1.3 Identification of warning instructions ...........................................................................4

2Safety instructions............................................................................................................5

2.1 Introduction......................................................................................................................5

2.2 Basic hazards...................................................................................................................5

2.3 Personnel and qualifications..........................................................................................6

2.4 Safety-conscious working practices ............................................................................6

2.5 Use of the product ..........................................................................................................7

2.6 Modifications and alterations.........................................................................................8

3Description of the sensor..................................................................................................9

3.1 Intended use ....................................................................................................................9

3.2 Prohibited use..................................................................................................................9

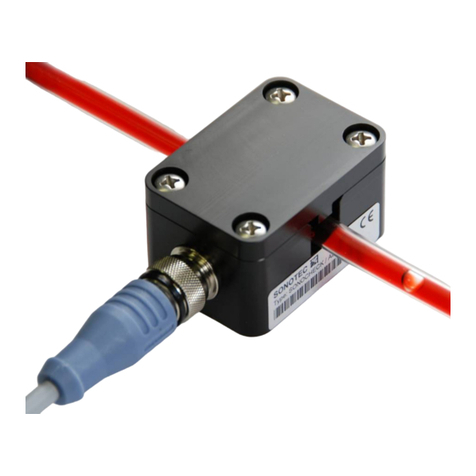

3.3 Sensor construction......................................................................................................10

3.4 Sensor identification ......................................................................................................11

3.5 Accessories.................................................................................................................... 12

4Operation of the sensor ..................................................................................................14

4.1 Requirements on the point of measurement..............................................................14

4.2 Preparing the point of measurement .......................................................................... 15

4.3 Coupling the sensor...................................................................................................... 15

4.3.1 Magnetic coupling for temporary measurements ......................................... 16

Uncoupling............................................................................................................................... 18

4.3.2 Screwed coupling for semi-stationary measurements................................. 19

5Cleaning and maintenance ............................................................................................ 20

5.1 Cleaning..........................................................................................................................20

5.2 Maintenance ..................................................................................................................20

6Technical data ................................................................................................................. 21

7Disposal .......................................................................................................................... 23

8Warranty ......................................................................................................................... 24

9Manufacturer information...............................................................................................25