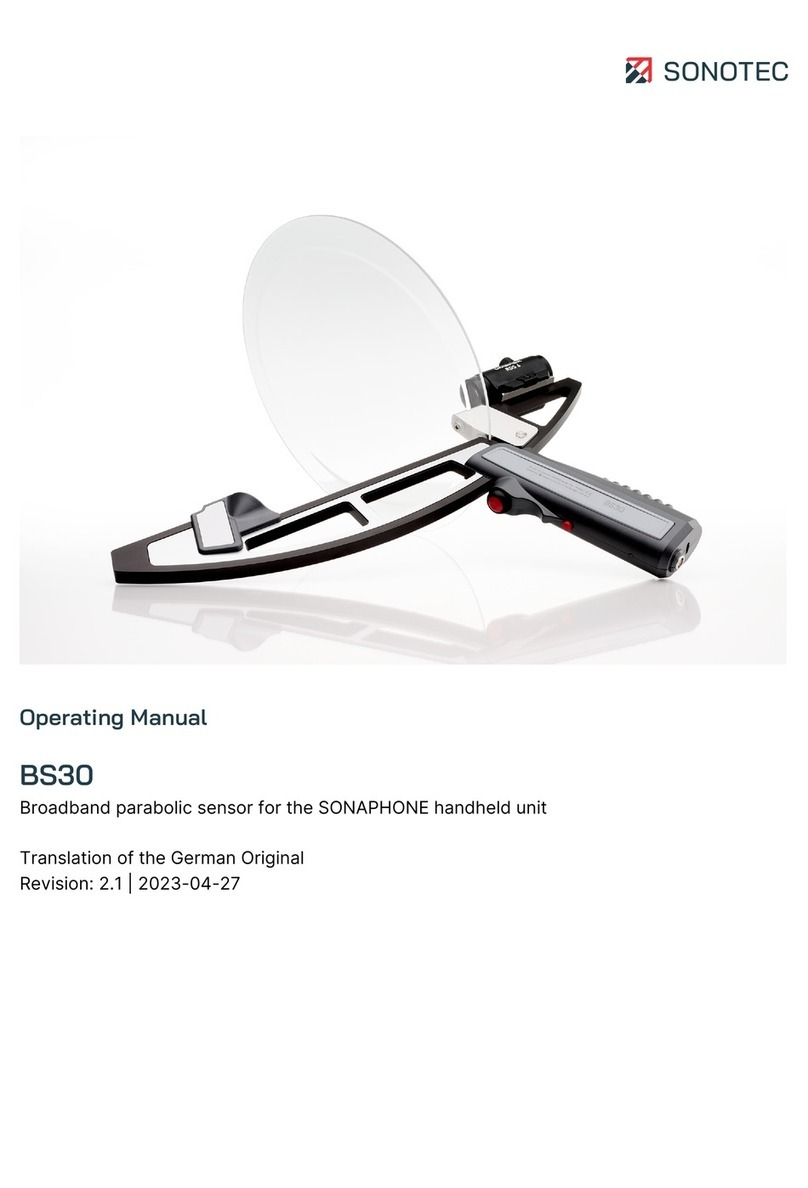

Sonotec SONAPHONE BS20 Operator's manual

Ultrasonic Testing Device for Preventive Maintenance

User Documentation:

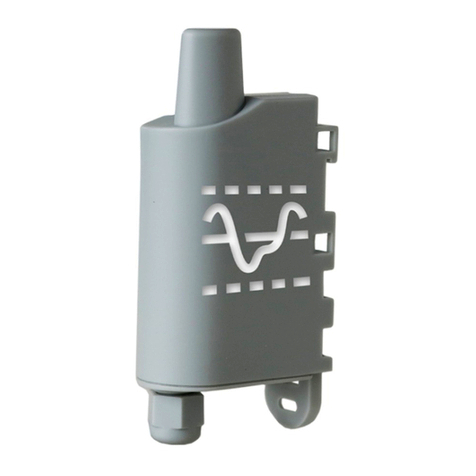

Structure-Borne Sound Sensor BS20

© SONOTEC Ultraschallsensorik Halle GmbH

All rights reserved.

Revision: 1.0; Date: 2017-11-06

Subject to technical modifications!

Structure-Borne Sound Sensor BS20

II - II - 3

Revision: 1.0; Date: 2017-11-06

Content

1Information on this document.............................................................................................................. 5

1.1 General...........................................................................................................................................5

1.2 Symbols used.................................................................................................................................6

2Sensor description................................................................................................................................ 7

2.1 Applications and designated use ...................................................................................................7

2.2 Functioning.....................................................................................................................................7

2.3 Connections, operating and display elements ...............................................................................8

2.4 Accessories for the structure-borne sound & temperature sensor BS20 ....................................10

2.5 Device identification/type label.....................................................................................................11

3Sensor operation................................................................................................................................. 12

3.1 Connecting the sensor .................................................................................................................12

3.2 Assembling and disassembling waveguides................................................................................13

3.3 Using the waveguides..................................................................................................................14

3.4 Operation via the buttons on the sensor......................................................................................14

3.5 Temperature measurements........................................................................................................15

3.6 Cleaning and maintenance ..........................................................................................................15

4Disposal................................................................................................................................................ 16

5Warranty............................................................................................................................................... 17

Structure-Borne Sound Sensor BS20

II - II - 4

Revision: 1.0; Date: 2017-11-06

(This page has been deliberately left empty)

Structure-Borne Sound Sensor BS20

II - II - 5

Revision: 1.0; Date: 2017-11-06

1 Information on this document

1.1 General

This document forms part of the structure-borne sound sensor BS20 and should therefore be

stored in its immediate vicinity where it can be accessed by all operators at any time. It contains

all the instructions to ensure safe operation of the structure-borne sound sensor with the

SONAPHONE, as well as all the information needed to ensure proper and efficient use. It must

therefore be read prior to first use and before carrying out any further steps.

The structure-borne sound sensor BS20 must only be operated by users

who have read (in full) and understood the safety information in the

corresponding document and the provided user documentation.

This document has been created with all due care. SONOTEC does not assume any guarantee

of the completeness, correctness and current validity of the provided data and is not liable for

errors or omissions.

Please note that the user documentation for the SONAPHONE is made up of different sections

due to the device's modular construction. The scope of supply will vary depending on the device

and accessory options that have been ordered.

Structure-Borne Sound Sensor BS20

1 Information on this document

II - II - 6

Revision: 1.0; Date: 2017-11-06

1.2 Symbols used

Hazards or special information are indicated in the following ways:

Warns of possible imminent dangerswhich, if ignored, may lead to

lasting adverse health effects and/or serious material damage.

Warns of dangers which, if ignored, may lead to injury and/or material

damage - including financial losses due to operational interruptions.

Warns of dangers which, if ignored, may lead to material damage –

including financial losses due to operational interruptions.

Note

This section provides information or draws attention to special features.

Structure-Borne Sound Sensor BS20

II - II - 7

Revision: 1.0; Date: 2017-11-06

2 Sensor description

2.1 Applications and designated use

The structure-borne sound sensor with exchangeable waveguides is used for applications

including:

Status monitoring of machines, systems and plant components

Function checking of steam traps and valves

Monitoring of wear and malfunctions in bearings

Monitoring of lubrication conditions

2.2 Functioning

The waveguide conducts the ultrasonic waves from the test point to the ultrasonic transducer.

The ultrasonic transducer converts ultrasonic waves (vibrations) to an electrical signal over a

wide frequency range. This electrical signal is amplified and digitalized within the sensor.

Further data processing and output takes place in the testing device.

The integrated infrared temperature sensor allows for contactless and quick recording of the

test object's surface temperature. The size of the visual recording field depends on the distance

between the sensor and the test object.

The LED lights act as a torch, making it easier to connect the sensor to test points in poorly lit

environments.

Structure-Borne Sound Sensor BS20

2 Sensor description

II - II - 8

Revision: 1.0; Date: 2017-11-06

2.3 Connections, operating and display elements

No. Operating and display elements

1 Sensor accessory: Short waveguide (standard)

2 Adjusting the volume

3 Starting/stopping the measurement recording

4 LED lights (torch) on/off

5 Status LED

3

4

2

5

1

Structure-Borne Sound Sensor BS20

2 Sensor description

II - II - 9

Revision: 1.0; Date: 2017-11-06

No. Sensor elements and connections

1 LED lights (torches)

2 Ultrasonic transducer – coupling surface (internal thread M5)

3 Infrared temperature sensor

No. Connections

1 USB connection (for service work only)

2 Socket for sensor cable with marked plug-in position

1

2

3

1

2

Structure-Borne Sound Sensor BS20

2 Sensor description

II - II - 10

Revision: 1.0; Date: 2017-11-06

2.4 Accessories for the structure-borne sound & temperature sensor BS20

The intensity and behavior of ultrasonic signals depend on factors such as the process during

which they are generated. Options for verifying and recording the signals and for providing

these to the user in high-quality format so that useful statements can be made with regard to

system conditions are also dependent upon a number of different factors.

In order to record high-quality signals for processing in the structure-borne sound & temperature

sensor BS20, waveguides are available for different testing tasks.

In order to ensure optimal results, please observe the fields of application for the accessories as

well as the corresponding instructions.

Short waveguide BS20-1

Accessory for structure-borne sound and temperature

sensor BS20 (standard)

Fig. 1: Short waveguide BS20-1

The waveguide is used to record ultrasonic waves that spread in solid structures, and to pass

these on for processing in the sensor. Sufficient contact pressure is required in order for this to

work correctly.

Note: For comparable results, sound should always be recorded from the same position. It may

be useful to attach a punch point at the required position.

Long waveguide BS20-2

(optional)

Accessory for structure-borne sound and temperature

sensor BS20

Application:

Tests on hard-to-access points

Fig. 2: Long waveguide BS20-2

This waveguide, which is longer than the BS-20-1, makes it possible to reach test points that

are harder to access. The long waveguide also makes it possible to carry out tests on hot

surfaces.

The signals will be slightly modified as a result of the longer sound path, and this will need to be

taken into account in the evaluation.

Structure-Borne Sound Sensor BS20

2 Sensor description

II - II - 11

Revision: 1.0; Date: 2017-11-06

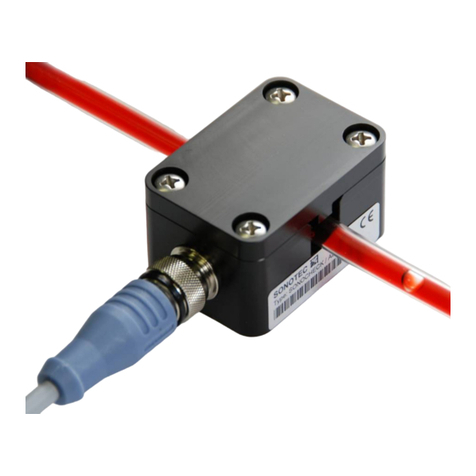

Magnetic waveguide BS20-3

(optional)

Accessory for structure-borne sound and

temperature sensor BS20

Application:

For connection at the test point for long-term testing

and for ensuring even contact pressure

Fig. 3: Magnetic waveguide BS20-3

In order to ensure usable test results with long-term testing or comparative tests, even contact

pressure is required. This can be achieved using the magnetic waveguide. Following connection

to the test point, the magnetic coupling ensures even recording of ultrasonic signals.

2.5 Device identification/type label

The type label is located on the back of the device, and should be to hand in the event of a

service call. As well as the sensor designation, the following information can also be found on

the housing:

Structure-Borne Sound Sensor BS20

II - II - 12

Revision: 1.0; Date: 2017-11-06

3 Sensor operation

Danger of injury!

•The sharp ends of the waveguides can cause injuries, and even serious

injuries in the case of the long waveguide. Make sure never to injure

anyone with the sharp ends of the waveguides. Never direct the tip at

other people.

•The high magnetic force of the waveguide can lead to crushing injuries

to the hands. Place the magnetic waveguide onto the test object at an

incline and as slowly as possible.

3.1 Connecting the sensor

Risk of damage to the connectors!

Take note of the red dots indicating the plug-in position on the plug and

socket.

Connect the sensor to the SONAPHONE in accordance with the red dots, making sure to

use the designated cable.

The sensor is powered via the cable, and the test data is transferred to the SONAPHONE

automatically.

The sensor is ready for operation when the operating display LED lights up green.

Structure-Borne Sound Sensor BS20

3 Sensor operation

II - II - 13

Revision: 1.0; Date: 2017-11-06

3.2 Assembling and disassembling waveguides

Risk of device damage and incorrect test values!

•Risk of destruction of the waveguide holder as a result of incorrect

assembly and disassembly. Always use the two elements of wrench set

BS20 (see image below) to assemble and disassemble the waveguides.

•Make sure that the waveguides are securely screwed into the holder.

The ultrasound is guided to the ultrasonic transducer by the waveguides.

Loose waveguides may have an impact on the signals.

The screw thread in the waveguide holder is used to attach the sensor accessory parts onto the

sensor shaft. The wrench set BS20 prevents damage when screwing the waveguides on and

off.

Fig. 4: Assembly and disassembly of the waveguides using the wrench set BS-20

Note!

The warranty will become invalid in the event of damage due to removing

the waveguides without the wrench set BS20.

!

Structure-Borne Sound Sensor BS20

3 Sensor operation

II - II - 14

Revision: 1.0; Date: 2017-11-06

3.3 Using the waveguides

During testing, the sensor should be pressed against the object being tested in as vertical a

position as possible and using gentle, even pressure.

Fig. 5: Optimal contact angle for testing with waveguides

3.4 Operation via the buttons on the sensor

Measurements can be controlled via the touchscreen on the device or via the buttons on the

sensor itself.

The acoustic playback volume can be adjusted using the function buttons. Testing can also be

started and stopped. The LED lights (torches) also help with the precise location of damage

areas.

The internal thread on the sensor and the magnetic waveguide BS20-3 make it possible to carry

out quasi-stationary tests using the SONAPHONE.

90°

Structure-Borne Sound Sensor BS20

3 Sensor operation

II - II - 15

Revision: 1.0; Date: 2017-11-06

3.5 Temperature measurements

Note!

For correct temperature measurements, make sure that the surface of the

temperature sensor is free from contamination.

The infrared temperature sensor is calibrated on a black emitter that emits the maximum

possible temperature (100 % emission → emissivity value ε = 1). As the emission

characteristics of the surfaces of measurement objects will deviate from this value, this will need

to be taken into account for the contactless temperature measurement.

Painted or oxidized surfaces usually have an emissivity value of 0.9. This setting is suitable for

many measurement tasks. Additional values for frequently used materials can be found in

emissivity value tables.

The emissivity value can be set at the SONAPHONE as follows:

In the LevelMeter app, under the

Settings Temperature measurement

menu item, a material with a stored emissivity value can be selected, or an emissivity value

specified manually.

3.6 Cleaning and maintenance

The sensor is maintenance-free. It can be cleaned externally using a damp cloth and a mild,

non-abrasive cleaning agent.

D = 38 mm

D = 11 mm

Structure-Borne Sound Sensor BS20

II - II - 16

Revision: 1.0; Date: 2017-11-06

4 Disposal

Electrical and electronic equipment can pose serious health and environmental risks if it is

not properly disposed of. For this reason it must not be disposed of in domestic waste according

to WEEE directive 2012/19/EU (Waste Electrical and Electronic Equipment Directive) but

separately at designated collection points or has to be sent back to the manufacturer.

The following symbol on the device refers to the legal obligation in Germany to arrange a

separate disposal for electronic equipment.

It has to be handled according to specific processes (e.g. concerning the batteries or circuit

boards) to ensure a safe, environmentally-friendly recycling or the separate disposal of different

device components.

The taking back of used equipment is regulated differently in the various countries and regions.

Consult the local authorities and other competent public authorities to inform yourself about the

taking back conditions of commercially used electrical equipment. The device and also the

battery do not contain harmful substances that have to be labelled separately regarding the

disposal as mercury (Hg), cadmium (Cd), lead (Pb) or hexavalent chromium (e.g. in galvanized

parts or circuit boards).

Structure-Borne Sound Sensor BS20

II - II - 17

Revision: 1.0; Date: 2017-11-06

5 Warranty

The ultrasonic testing device and its corresponding sensors comply with the current state of the

art and the safety regulations. All devices and accessory parts are factory tested and are

delivered in a safe condition for operation. We reserve the right to make modifications to the

device as part of ongoing product development, and to make changes to the shape and color.

Within the warranty period, SONOTEC Ultraschallsensorik Halle GmbH will rectify, free of

charge, all defects caused by material or manufacturing errors. At its own discretion, SONOTEC

Ultraschallsensorik Halle GmbH will provide a guarantee in the form of either a repair or the

replacement of the defective device or component. The warranty does not cover the internal

batteries or damage caused by improper use, wear or interventions in the device or sensors.

The warranty also does not cover any defects that have only a negligible impact on the value or

usability of the device.

The recording of valid test results, the interpretation of these results and any measures that are

derived as a result are exclusively the responsibility of the user. SONOTEC does not assume

any guarantee for the correctness of the recorded test values or test results. SONOTEC accepts

no liability for any errors or damages that arise as a result of the further use of the recorded test

and measurement values.

MANUFACTURER

Headquarters

SONOTEC Ultraschallsensorik Halle GmbH

Nauendorfer Str. 2

06112 Halle (Saale)

Phone: +49 (0)345 133 17-0

Fax: +49 (0)345 133 17-99

Email: sonotec@sonotec.de

Internet: www.sonotec.de

USA contact details

SONOTEC US Inc.

190 Blydenburgh rd

Suite 8 2nd floor

Phone: +1 631/415 4758

Email: sales@sonotecusa.com

Internet: www.sonotecusa.com

Technical Data Sheet

V - III - 1

Revision: 1.0; Date: 2017-11-06

Structure-borne sound and temperature sensor BS20

The structure-borne sound sensor BS20 with

exchangeable attachments is used in connection with the

SONAPHONE for applications including:

•Condition monitoring of machines, systems and plant

components

•Function checking of steam traps and valves

•Monitoring of wear and malfunctions in rolling or slide

bearings, for example

•Monitoring of lubrication conditions

The acoustic playback volume can be adjusted using the function buttons. Testing can be sta

rted

and stopped

in the same way. The integrated temperature sensor improves the evaluation

reliability of the test data for a wide range of different test sequences, such as tests on steam traps.

GENERAL SENSOR DATA

Design Contact sensor for the detection of structure-borne sound with exchangeable

waveguides, contactless infrared temperature sensor, LED light

Operation Via buttons on the sensor or on the device

Buttons: Start/stop testing, LED light, volume

Frequency range 20 … 100 kHz

Temperature

measurement range -70 … +380 °C object temperature

Measurement resolution Ultrasound: 1 dB, temperature: 1 K

Power supply and

communication Cable connection with the SONAPHONE (160 cm): LEMO connection

Dimensions (W x H x D) 30 x 155 x 30 mm

Weight 140 g (without accessories)

Materials Sensor housing: plastic (polycarbonate: ABS), gray; waveguides: stainless

steel

AMBIENT CONDITIONS

Operating temperature -10 °C … +40 °C

Storage temperature -20 °C … +60 °C

Protection type IP40

Technical Data Sheet

Structure-borne sound sensor BS20

V - III - 2

Revision: 1.0; Date: 2017-11-06

Standards and

guidelines EMC Directive 2014/30/EU; WEEE Directive 2012/19/EU;

RoHS Directive 2011/65/EU

Accessories

(some of which are

optional)

Short waveguide BS20-1:

Length: 22 mm, diameter: 18 mm, weight: 15 g

Long waveguide BS20-2:

Length: 150 mm, diameter: 18 mm, weight: 33 g

Magnetic holder BS20-3

Wrench set for assembling and disassembling waveguides

Subject to technical modifications!

MANUFACTURER

SONOTEC

Ultraschallsensorik Halle GmbH

Nauendorfer Straße 2

06112 Halle (Saale), Germany

Tel.: +49 (0)345/133 17

- 0

sonotec@sonotec.de

www.sonotec.de

USA CONTACT DETAILS

SONOT

EC US Inc.

190 Blydenburgh rd

Suite 8 2

nd floor

Islandia, New York 11749, USA

Tel.: +1 631/415 4758

sales@sonotecusa.com

www.sonotecusa.com

Other manuals for SONAPHONE BS20

1

Table of contents

Other Sonotec Accessories manuals

Sonotec

Sonotec SONOCHECK ABD06 Series User manual

Sonotec

Sonotec SONAPHONE BS30 User manual

Sonotec

Sonotec SONOFLOW IL.52/3 V2.0 User manual

Sonotec

Sonotec SONAPHONE BS30 User manual

Sonotec

Sonotec Airborne Sound Sensor BS10 User manual

Sonotec

Sonotec SONAPHONE BS20 User manual

Sonotec

Sonotec BS40 User manual