Sonotec SONOFLOW IL.52/3 V2.0 User manual

Ultrasonic Flow Sensor

SONOFLOW®IL.52 V2.0

User Documentation

Including

Technical Data Sheet

Operating Manual

Certificates

(This page has been deliberately left empty)

Technical Data Sheet SONOFLOW®IL.52/3 V2.0

Ultrasonic Flow Sensor

1

Revision: 1.3; Date: 2020-05-18

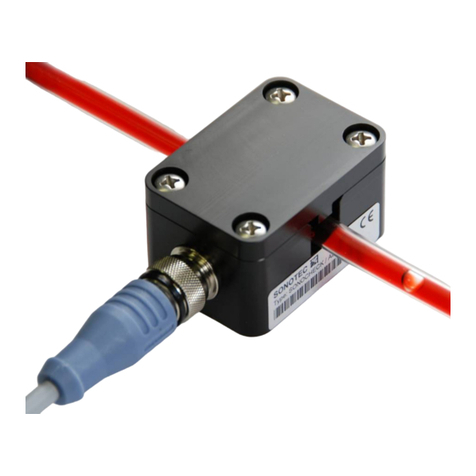

The inline compact sensor SONOFLOW®

IL.52/3 V2.0 serves to detect smallest flow

rates of liquids quickly.

Constructed as a built-in component for

machines and apparatuses, the sensor

could be easily mechanically installed and

electrically integrated into the control system.

Due to the current, frequency and switching

outputs industrial dosing applications can be

supported. The RS485 interface

(SONOTEC®protocol; MODBUS®via

software settings) allows bus operation of up

to 12 sensors in rough industrial

environments.

Specifically designed for the use in areas

with rigorous hygiene requirements, the

sensor is suitable for circulation cleaning

and steam sterilization.

General data

SONOFLOW®IL.52/3 V2.0

Ultrasonic Flow Sensor for Liquids

Order-No. IL.52/3 PEEK / Viton®* 200 08 0001

IL.52/3 PEEK / FFKM 200 08 0044

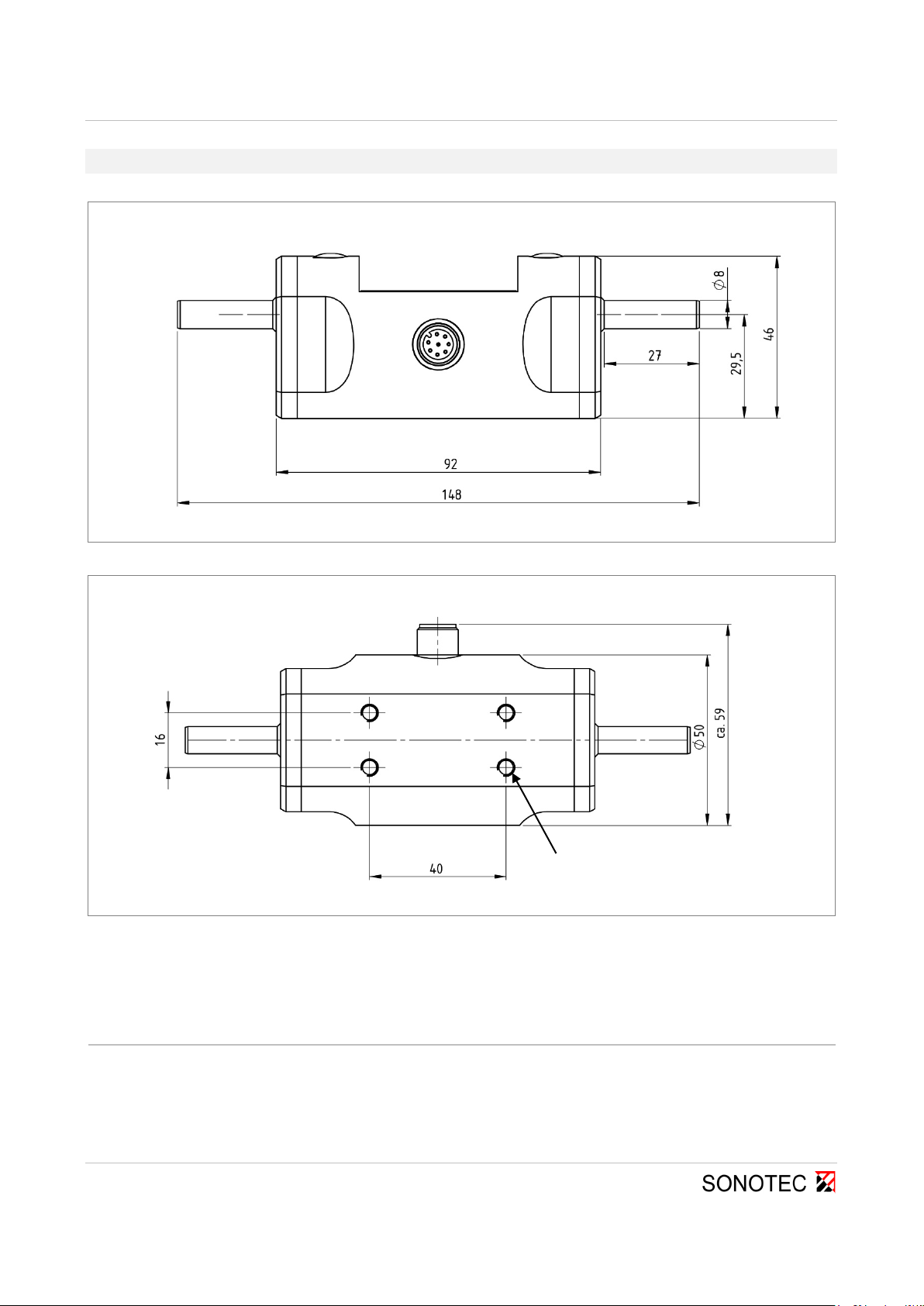

Dimensions (L x W x H) 148 x 59 x 46 mm

Weight 370 g

Media Water or other acoustically transparent, low-viscosity liquids (for applications with

high-viscosity liquids, e.g. fats / special paints, screening tests must be made)

Upper range value 3 000 ml/min

Accuracy for water

(at 23° C ± 2 K and 1 bar)

0 … 30 ml/min: ± 0.3 ml/min

30 ... 3 000 ml/min: ± 1.0 %

Calibration Factory calibrated for water at 23 °C ±2 K, outlet of the tubes depressurized

(0 bar), other calibration on request

Zero stability 0.375 ml/min

Pressure drop at

nominal flow rate

0.95 bar

* Viton®is a registered trademark of DuPont de Nemours, Inc.

SONOFLOW®IL.52/3 V2.0 Technical Data Sheet

Ultrasonic Flow Sensor

2

Revision: 1.3; Date: 2020-05-18

Measuring method Ultrasound, time of flight measurement

Measuring cycle Typical 20 ms (minimum 4 ms)

Indirect temperature

measurement

Integrated sensor at the inlet

(accuracy of temperature sensor ±1 °C, with Tambient 23 °C and Q 1 l/min)

Mounting Fixed installation: 4 x recessed threaded holes M5, depth: 10 mm

Measuring channel Ø 3.0 mm

Adaptor for tube

connection

Outer diameter 8 mm, inner diameter 4 mm

Pressure rating PN10

Material

(in contact with fluid)

Measuring channel and measuring cell: PEEK,

Seals: Viton®/ FFKM

Operating voltage 12 … 30 VDC, ripple max. 10 %, protection against reverse polarity

(external fuse, if required: min. 200 mA)

Current consumption Maximum 50 mA (with open current, frequency and switching output,

depending on supply voltage)

Electrical connection 8-pin M12 connector, DIN EN 61076-2-101:2013

Shielding Required: via cable / housing (mounting screws)

Interfaces

•Current output for flow rate: 0/4 … 20 mA

•Frequency output for flow rate: 0 … 20 kHz, 5 V digital

•RS485 interface: bus-capable (SONOTEC®protocol, optional MODBUS®)

•Switching output: configurable as PNP / NPN / Push-Pull, 0 … 30 V

•Digital input (MODBus on request)

Current output

for flow rate

NOTE: Load to GND. The max. load depends on the operating voltage:

12 V 250 Ω, 15 V 500 Ω, 24 V 1 kΩ, 30 V 1.2 kΩ

Load

Input

Current output

+UB

HOST

SENSOR

Ground

+UB

Ground

Technical Data Sheet SONOFLOW®IL.52/3 V2.0

Ultrasonic Flow Sensor

3

Revision: 1.3; Date: 2020-05-18

Frequency output

for flow rate

RS485 interface SONOTEC®protocol: Half-duplex operation / 115.200 baud / no parity / 1

stop bit / no handshaking (MODBUS®via software settings)

NOTE: Please find the description of the serial protocol for details

(upon request).

Recommended electrical connection of the RS 485 interface

CAUTION! If the interface is not used, it does not necessarily has to be

connected; the two pins A and B can remain open.

RS485 Bus operation The sensor supports bus operation with max. 12 subscribers. The default

address is #01.

NOTE:

The address can be changed by software settings (see opt. accessories).

Permitted are addresses from #01 … #12.

Menu: Identification | RS485 address

Switching output Freely configurable: e.g. adapting batch process or threshold switch of flow,

maximum 100 mA

10 kΩ

B

A

+3.3 or +5 V

HOST

SENSOR

Ground

+3.3 V

Ground

A

B

10 kΩ

10 kΩ

10 kΩ

Recommended

2 ... 5 kΩ

Load min. 5 kΩ

Input

Frequency output 5 V

HOST

SENSOR

Ground

Ground

SONOFLOW®IL.52/3 V2.0 Technical Data Sheet

Ultrasonic Flow Sensor

4

Revision: 1.3; Date: 2020-05-18

Digital input Freely configurable: for example for zero point calibration of flow or start

dosing processes

Voltage resistant up to 30 V

Protection class IP65

Cleaning and

sterilization

Maximum liquid temperature: temporarily +145 °C;

Resistant to cleaning agents (e.g. caustic soda or 3 percent nitric acid)

NOTE: Verify that the sensor materials (PEEK, Viton®/ FFKM)

are resistant against the cleaning agent.

Media temperature 0 ... +100 °C (T > 70 °C without voltage, temporarily +145 °C)

Ambient temperature 0 ... +70 °C

Storage temperature -20 ... +70 °C

Directives and

standards

•EMC directive 2014/30/EU

•RoHS: 2011/65/EU, exception: III 7cI/ IV 15

•Acoustic emission: IEC 61157

Maintenance Maintenance-free

Scope of delivery

•SONOFLOW®IL.52/3 V2.0 according to specification

•User documentation

Optional accessories

•8-pole M12 sensor cable, length 2 m / 5 m

•Calibration protocol

SONOFLOW®C3Software for testing parameter settings, to adjust sensors

for a specific application and for recording measurements consisting of

•USB Data Converter, type 013 for the connection to a computer

•USB cable, type A-B, length 2 m

•8-pole M12 connecting cable, length 2 m

•Switching power supply (12 VDC)

•USB flash drive with SONOFLOW®C3Software and driver for Windows

Digital input

HOST

SENSOR

Ground

Ground

Technical Data Sheet SONOFLOW®IL.52/3 V2.0

Ultrasonic Flow Sensor

5

Revision: 1.3; Date: 2020-05-18

Electrical connection

Male connector

(at the sensor)

Female connector

(at the cable)

M12 connecting cable Pin Color Connection

Assignment 1 White Ground

2 Brown Operating voltage +12 ... 30 VDC

3 Green Current output (0/4 … 20 mA)

4 Yellow RS485 B

5 Grey RS485 A

6 Pink Frequency output 0 … 20 kHz

7 Blue Switching output: PNP / NPN / Push-Pull

8 Red Digital input

SONOFLOW®IL.52/3 V2.0 Technical Data Sheet

Ultrasonic Flow Sensor

6

Revision: 1.3; Date: 2020-05-18

Technical drawings

Figure 1: Dimensions SONOFLOW®IL.52/3 V2.0 – Side view

Figure 2: Rear side with drill holes for mounting

4x threaded holes M5/ depth: 10

Drawings are not to scale. Dimensions in mm, unless otherwise specified. Information is subject to change without notice.

HEADQUARTERS GERMANY

SONOTEC GmbH

Nauendorfer Str. 2

06112 Halle (Saale)

Germany

Tel.: +49 (0)345 / 133 17

- 0

sales_eu@sonotec.de

www.sonotec.eu

AMERICA

S

SONOTEC US Inc.

190 Blydenburgh

Rd

Suite 8

, 2nd Floor

Islandia, New York 11749, USA

Phone: +1 631 / 415 4758

sales@sonotecusa.com

www.sonotecusa.com

Ultrasonic Flow Sensor

Type SONOFLOW IL.52 V2.0

Operating Manual

© SONOTEC Ultraschallsensorik Halle GmbH

All rights reserved.

Revision: 1.0; Date: 2018-10-26

Information is subject to change without notice!

Operating Manual SONOFLOW IL.52 V2.0

3

Revision: 1.0; Date: 2018-10-26

Contents

1Notes on operating manual.................................................................................................................. 5

1.1 General...........................................................................................................................................5

1.2 Symbols used.................................................................................................................................5

2Safety regulations ................................................................................................................................. 7

2.1 User qualifications..........................................................................................................................7

2.2 General safety information.............................................................................................................8

3Sensor description................................................................................................................................ 9

3.1 Intended use...................................................................................................................................9

3.2 Construction...................................................................................................................................9

3.3 Measuring method and functioning..............................................................................................10

3.4 Requirements for Liquid...............................................................................................................10

3.5 Parameterization, calibration and readout of measuring values (Accessories)...........................10

4Installation and commissioning......................................................................................................... 11

4.1 Attaching the Sensor SONOFLOW IL.52 V2.0 ............................................................................11

5Output Configuration and Settings ................................................................................................... 12

5.1 Current output for flow rate ..........................................................................................................12

5.2 Frequency output for flow rate .....................................................................................................12

5.3 Switching output...........................................................................................................................13

5.4 RS485 interface ...........................................................................................................................13

5.5 Digital input...................................................................................................................................14

6Operating the sensor .......................................................................................................................... 15

6.1 Preparatory work..........................................................................................................................15

6.2 Cleaning and Disinfection ............................................................................................................15

7Troubleshooting and maintenance.................................................................................................... 16

8Disposal................................................................................................................................................ 17

SONOFLOW IL.52 V2.0 Operating Manual

4

Revision: 1.0; Date: 2018-10-26

(This page has been deliberately left empty)

Operating Manual SONOFLOW IL.52 V2.0

5

Revision: 1.0; Date: 2018-10-26

1 Notes on operating manual

1.1 General

Thank you for choosing a sensor from the SONOFLOW IL.52 V2.0 series.

This manual forms part of the sensor and should therefore be stored in its immediate vicinity

where it can be accessed by all operators at any time. It contains all the information needed to

ensure proper and efficient use, along with all the instructions to ensure safe operation of the

SONOFLOW IL.52 V2.0.

1.2 Symbols used

Hazards or special information is indicated in the following ways:

Warns of imminent threat of danger with very high risk. If not avoided,

it will result in death or serious injury.

Warns of possibly imminent danger with moderate risk. If not avoided,

it could result in death or serious injury.

Warns of danger with low risk. If not avoided, it may result in minor or

moderate injury.

Warns of danger. If not avoided, it may result in material damage.

NOTE!

This paragraph provides information or draws attention to special features.

SONOFLOW IL.52 V2.0 Operating Manual

6

Revision: 1.0; Date: 2018-10-26

(This page has been deliberately left empty)

Operating Manual SONOFLOW IL.52 V2.0

7

Revision: 1.0; Date: 2018-10-26

2 Safety regulations

2.1 User qualifications

The SONOFLOW IL.52 V2.0 may only be installed and operated by users

who have read and understood the entire operating manual and the

Technical Data Sheet.

Make sure to read all safety regulations.

NEVER CHANGE SETTINGS of the sensor before you have saved all

parameters with the help of SONOFLOW Monitor.

Ignoring the safety instructions or changing parameters can cause

malfunction of the sensor. Depending on the application this can have

unforeseeable consequences and lead to serious injury with lasting health

consequences for personnel and damage or demolition of device

components.

SONOFLOW IL.52 V2.0 Operating Manual

2 Safety regulations

8

Revision: 1.0; Date: 2018-10-26

2.2 General safety information

The SONOFLOW IL.52 V2.0 is a state of the art product that complies with all applicable safety

regulations. All sensors are factory tested and delivered in a safe condition for operation.

The following safety instructions apply:

Incorrect installation and use of the SONOFLOW IL.52 V2.0 sensor and its

components can present a hazard for the user.

Installation may only be performed by qualified personnel. The

applicable planning and installation regulations must be followed. The

plant operator is responsible for the legal compliance of the installation

and documentation.

All listed conditions in the Technical Data Sheet –especially regarding

temperatures and voltage range –must be met unconditionally. Values

are not allowed to exceed or to fall below the specified limits, not even

temporarily.

The sensor may only be exposed to a minimal risk of mechanical

damage. In case of higher risks, the sensor must be protected against

mechanical influences.

If there is visible damage, the sensor must be taken out of operation

immediately.

The Sensor may not be immersed.

The use of cleaning agents depends on the sensor version (seals and

their resistance). Make sure, that the seals made of FFKM or Viton are

not damaged. Follow the instructions in chapter 6.2.

The sensor must never be opened. This impairs the product safety.

The sensor does not contain any user-serviceable parts. Repairs must

be carried out by the manufacturer.

Settings and parameters of the sensor can be changed with the

SONOFLOW Monitor. Make sure to read the corresponding document.

Never change settings before you have saved the default settings.

Operating Manual SONOFLOW IL.52 V2.0

9

Revision: 1.0; Date: 2018-10-26

3 Sensor description

3.1 Intended use

The ultrasonic flow sensor SONOFLOW IL.52 V2.0 serves for the precise measurement of

smallest flow rates and flow velocities of liquids.

Any use other than the designated use is prohibited and can result in personal injury or damage

to property. SONOTEC Ultraschallsensorik Halle GmbH accepts no liability for damage,

including to third parties, caused by improper handling of the sensors.

3.2 Construction

The SONOFLOW IL.52 V2.0 consists of two ultrasonic transducers, appropriate control

electronics and evaluation electronics. For the measurement of the media temperature a

temperature sensor is integrated.

Via the output (configurable current, pulse, frequency or switching output) the signals are

transmitted to the customer control unit.

Figure 1: Construction of the SONOFLOW IL.52 V2.0

Mode

Function

1

Adaptor for tube connection

2

M12 connector for operating voltage and outputs 1 and 2

Table 1: Interfaces of the SONOFLOW IL.52 V2.0

1

2

SONOFLOW IL.52 V2.0 Operating Manual

3 Sensor description

10

Revision: 1.0; Date: 2018-10-26

With respect to material resistance the following sensor versions are available:

Seals (in contact with the medium)

Order number

Viton

200 08 0001

FFKM

200 08 0044

Table 2: Versions of SONOFLOW IL.52 V2.0

3.3 Measuring method and functioning

The ultrasonic sensor works with the time-of-flight measurement principle. The flow rate is

derived from the time difference of the ultrasound with and against the flow direction and the

geometry of the measuring cell. Multiple measuring data are collected by adequate evaluation

algorithms before processing the data for higher accuracy.

The flow rate can be indicated by a current output of [0/] 4 to 20 mA serving as the process

interface.

Additionally the following interfaces are available:

Frequency output for flow rate: 0 to 20 kHz, 5 V digital

RS485 interface: bus-capable

Switching output: configurable as PNP / NPN / Push-Pull, 0 to 30 V

Digital input (MODBus on request)

Please find the descriptions in the “Technical Data Sheet.”

3.4 Requirements for Liquid

The measuring method using ultrasound is suitable for all sound transparent, low-viscosity

liquids.

For industrial applications with high-viscosity liquids such as fats or special paints a higher

pressure drop (at nominal flow) has to be expected. In this case the specified value for nominal

flow cannot be achieved.

3.5 Parameterization, calibration and readout of measuring values (Accessories)

With the SONOFLOW Monitor software (optional) in conjunction with a computer the sensor can

be validated and adjusted to particular measuring tasks. Furthermore using the Monitor, the

measured values can be displayed on a screen. The measurement data can be recorded in a

table and be saved to a file.

All available accessories are listed in the “Technical Data Sheet”.

Operating Manual SONOFLOW IL.52 V2.0

11

Revision: 1.0; Date: 2018-10-26

4 Installation and commissioning

The SONOFLOW IL.52 V2.0 is intended as component to be integrated into devices or machines.

The sensor is mechanically and electrically incorporated into the customer control unit.

4.1 Attaching the Sensor SONOFLOW IL.52 V2.0

The geometric layout always determines flow characteristics in a fluid system. The sensor

accuracy depends among other things on the mounting position in the flow system.

Incorrect installation may have an impact on the measuring accuracy.

Depending on the application this can have unforeseeable consequences.

Mechanical vibrations can affect sensor functions. Ensure that the

mounting or the tubes (lines) do not transmit vibrations to the sensor.

Recommended is an installation position with a flow direction against the force of gravity.

Use the drilled holes on the rear side of the sensor to attach the sensor.

(For dimensions: see the Technical Data Sheet).

Connect the tubing with the sensor via the designated adaptors:

Outer diameter: 8 mm

Inner diameter: 4 mm

Connect the sensor to power supply via the M12 plug-in connector as described in the

“Technical Data Sheet”.

NOTE!

A shielding is not necessary but recommended for long lines (> 30 m)

or in harsh industrial environments.

If pins at the connector are not used, they should be covered to protect

them against moisture and contamination

Use the service interface only in conjunction with the SONOFLOW Monitor

(optional accessory).

SONOFLOW IL.52 V2.0 Operating Manual

12

Revision: 1.0; Date: 2018-10-26

5 Output Configuration and Settings

The settings can be adapted for special measuring tasks using the SONOFLOW Monitor

(optional accessory).

5.1 Current output for flow rate

The default settings for current output are:

Parameter

Default setting

Further options

(via SONOFLOW Monitor)

Configuration

Flow

Off |

Test current (0 … 22 mA)

Range

4 … 20 mA

0 … 20 mA

Limit

> 20 mA

≤20 mA

Flow min.

0 ml/min (4 mA)

0 … 3 000 ml/min

Flow max.

3 000 ml/min (20 mA)

0 … 3 000 ml/min

Measuring Error

2 mA

0 … 22 mA

Device Fault

0 mA

0 … 22 mA

Table 3: Default settings for current output

5.2 Frequency output for flow rate

Parameter

Default setting

Further options

(via SONOFLOW Monitor)

Configuration

Flow

Off |

Test frequency (0 … 20 kHz)

Flow min.

0.00 ml/min (0 kHz)

0 … 3 000 ml/min

Flow max.

3000 ml/min (20 kHz)

0 … 3 000 ml/min

Max. frequency

20 kHz

1 … 20 kHz

Measuring Error

0 kHz

0 … 20 kHz

Device Fault

0 kHz

0 … 20 kHz

Table 4: Default settings for frequency output

This manual suits for next models

4

Table of contents

Other Sonotec Accessories manuals

Sonotec

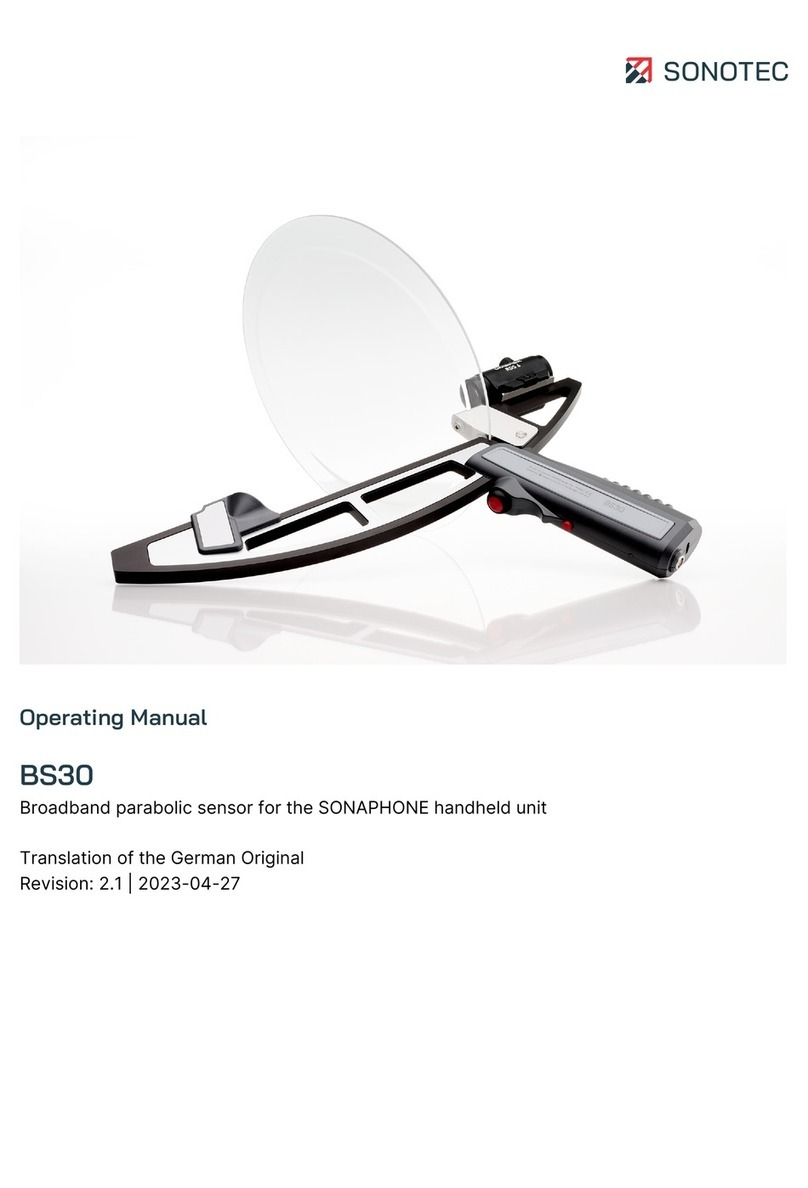

Sonotec SONAPHONE BS30 User manual

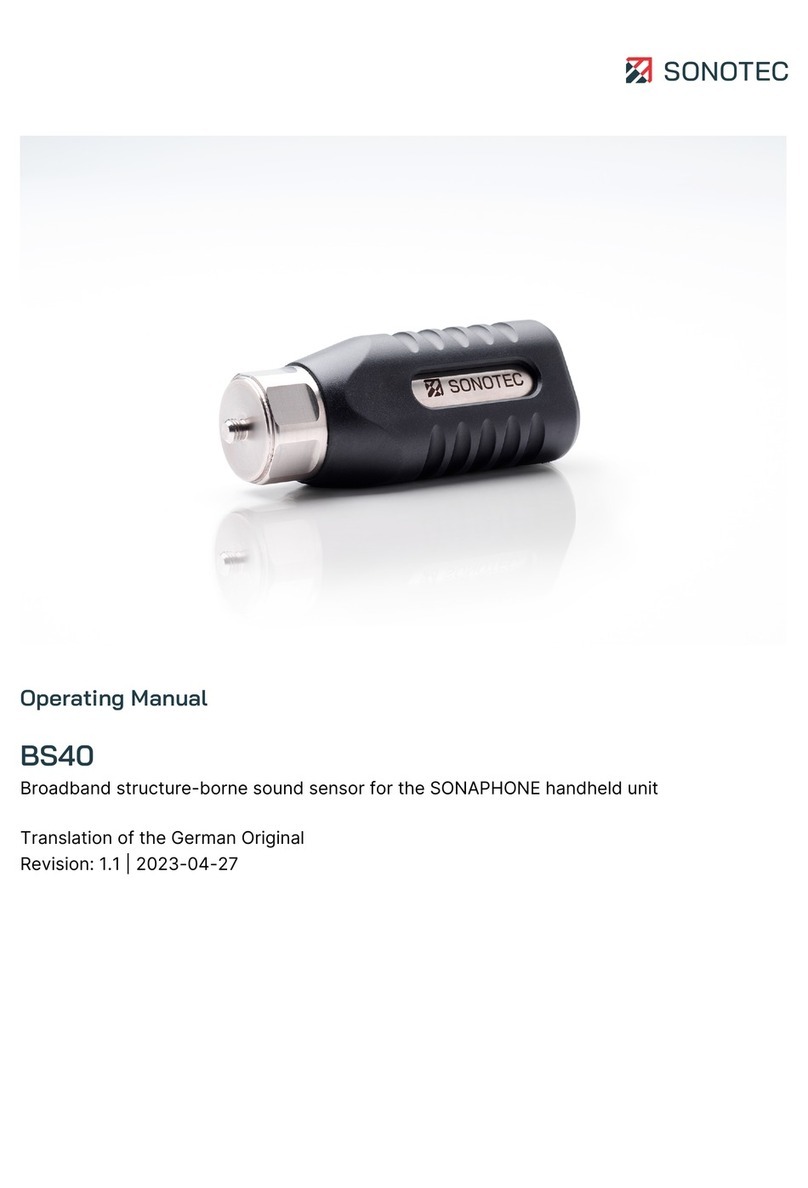

Sonotec

Sonotec BS40 User manual

Sonotec

Sonotec SONOCHECK ABD06 Series User manual

Sonotec

Sonotec SONAPHONE BS30 User manual

Sonotec

Sonotec SONAPHONE BS20 User manual

Sonotec

Sonotec SONAPHONE BS20 Operator's manual

Sonotec

Sonotec Airborne Sound Sensor BS10 User manual