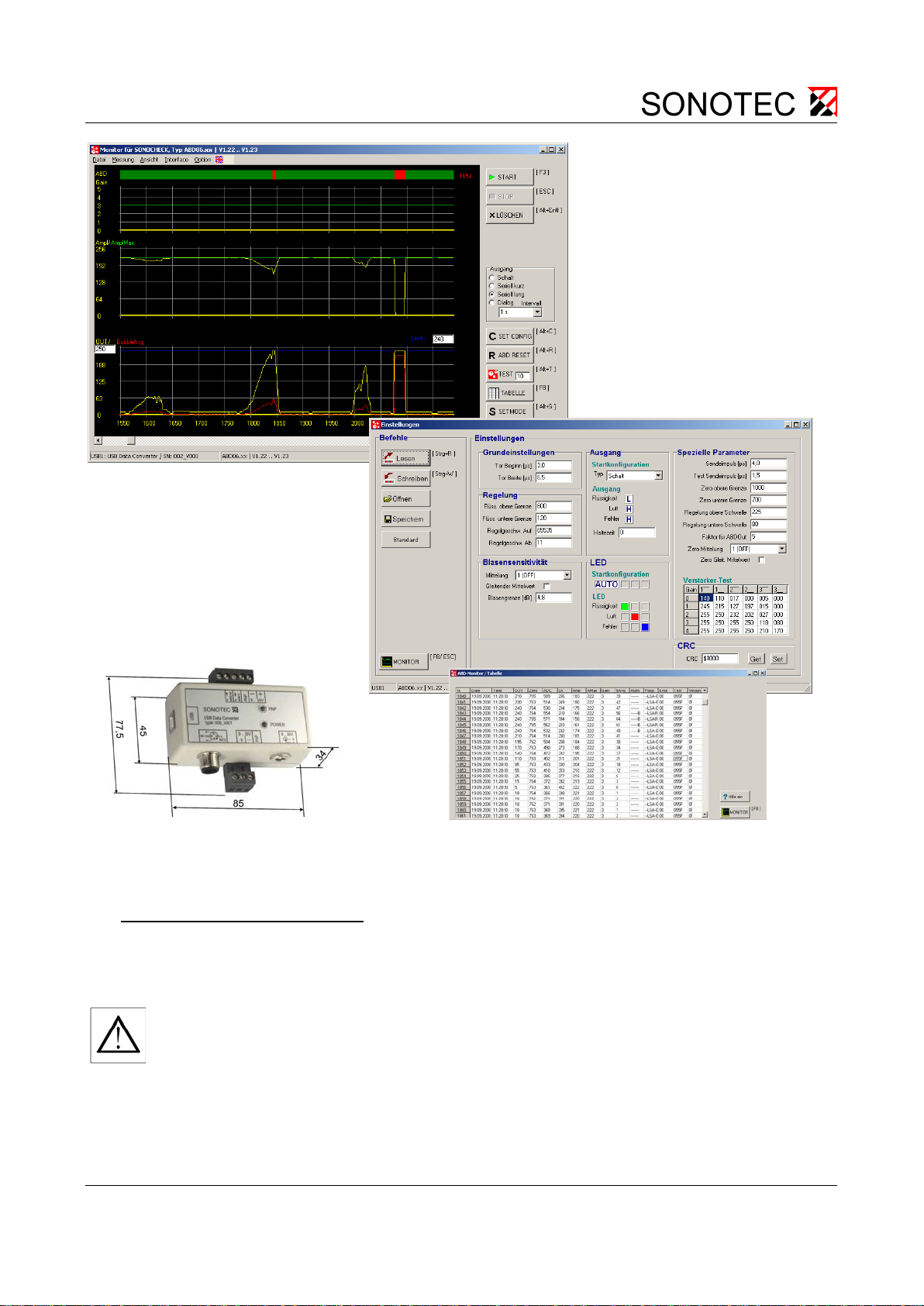

SONOCHECK – Air Bubble Detector Type ABD06.xx

ABD 06.xx 4

1 General Information

1.1 Safety information

The SONOCHECK ABD06 is a state of the art product that complies with all applicable safety

regulations. The sensor is factory tested and is delivered in a safe condition for operation.

The following safety instructions apply:

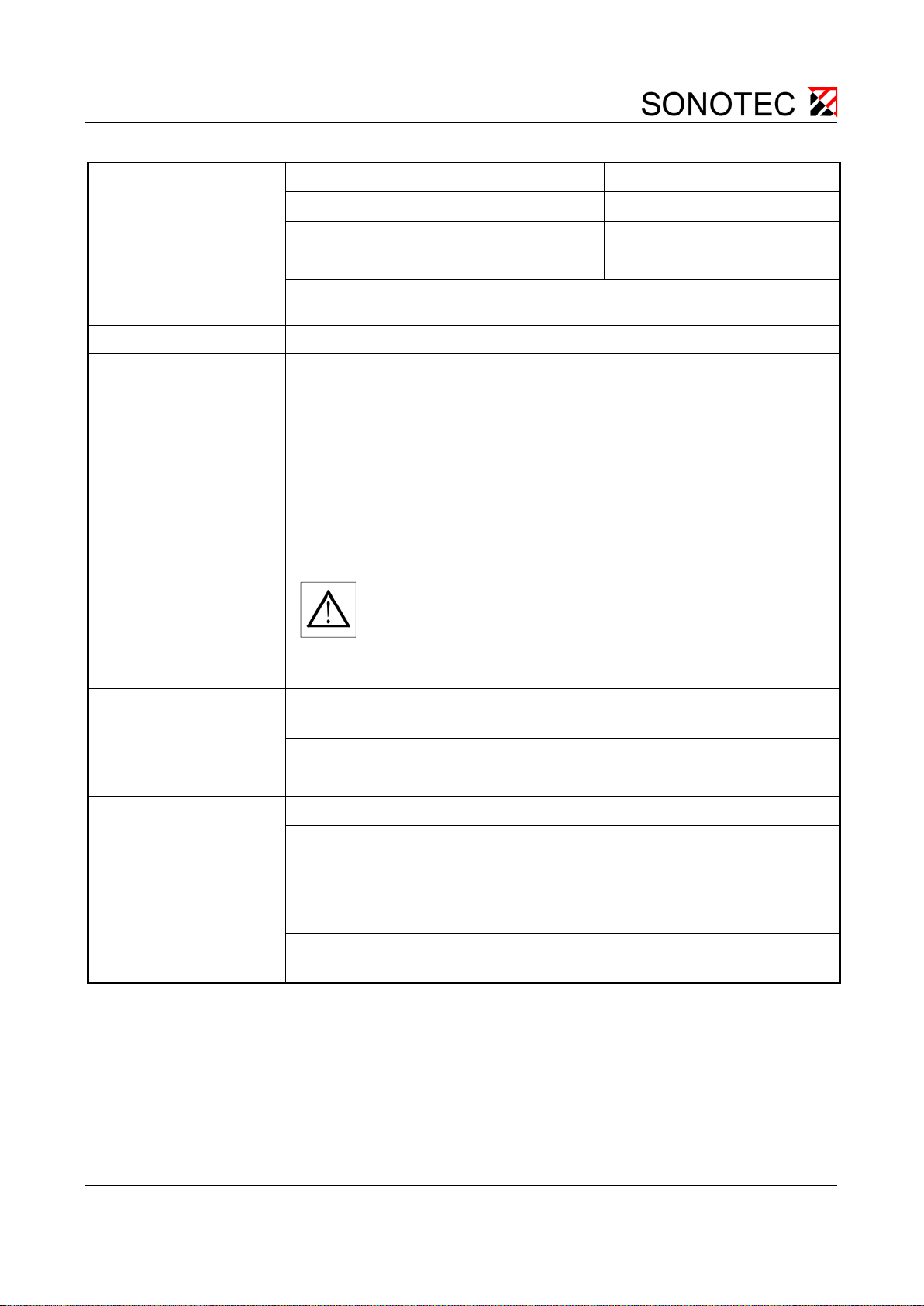

Warning!

Incorrect installation and use of the ABD06 sensor and its components can present a

hazard for the user.

• The plant operator is responsible for the legal compliance of the SONOCHECK ABD06

installation and documentation.

• The SONOCHECK ABD06 may only be operated with power sources in the operating

voltage range specified in the technical data.

• Operation and storage of the SONOCHECK ABD06 outside the temperature ranges

specified in the technical data is not permitted.

• The SONOCHECK ABD06 may not be immersed.

• The SONOCHECK ABD06 may only be exposed to a minimal risk of mechanical damage.

In other cases, the sensor must be protected against mechanical influences.

• If there is visible damage, the SONOCHECK ABD06 must be taken out of operation

immediately.

1.2 Application

The air bubble detector is used for the recognition of air bubbles in liquid filled tubes made of

synthetic material. It is also suitable for wet/dry indication at tubes.

The sensor is used especially in the fields of medical and food technology, since it has no contact

with the liquid. The sensor is also suitable for industrial applications such as the bubble detection

at tubes filled with glue or paint.

The type and dimensions of the sensor depend on the diameter and the flexibility of the tube as

well as on the kind of liquid.

Without using any coupling medium the tube is easily put into the sensor and enables a smooth

and uncomplicated change.

The sensor is constructed as a component to be integrated into machines and apparatus. The

mechanical installation and electrical integration into the control system can be carried out easily.

Besides standardized applications the sensors can also be adapted to customized applications.

1.3 Measuring Principle

An ultrasonic principle with short high-frequency pulses is used for measuring. If there is liquid in

the tube, a part of the ultrasonic sound is transmitted from the emitter through the tube to the

receiver. If the tube is empty or a bubble is placed in the measuring point, the part of sound is

much smaller. The amplitude of the received ultrasonic pulses is analysed.

The sensor adapts to dynamically changing acoustic conditions. Hence, a high reading stability

against varying environmental conditions can be ensured.