Content

SensorMonitoring Unit - SMU en(us) Page 4 / 100

BeWa SMU1200 3854281 V2.0x en(us) 2013-08-20 2013-08-20

Interface G.................................................................................................31

HSI (Hydac Sensor Interface) – SMU 126x … .......................................31

ETH (Ethernet) – SMU 127x … ..............................................................31

Connecting the sensors .............................................................................32

Examples of connection.............................................................................34

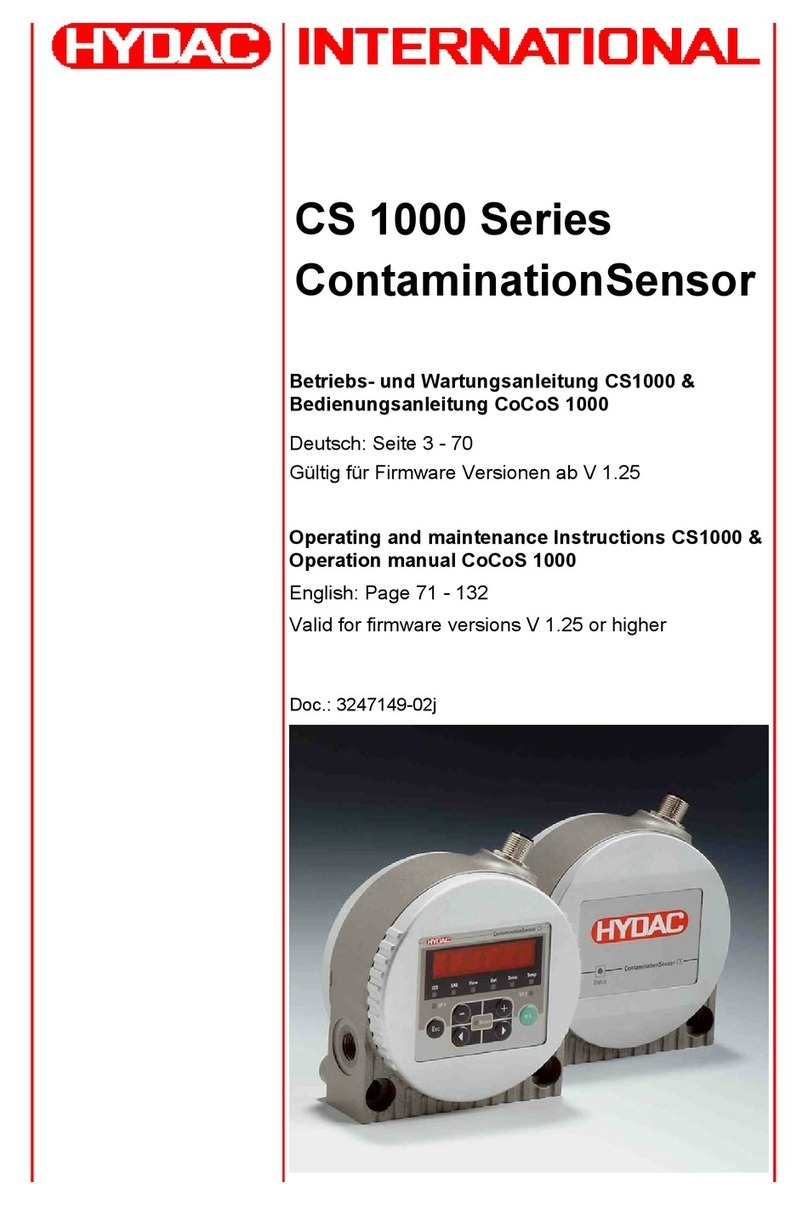

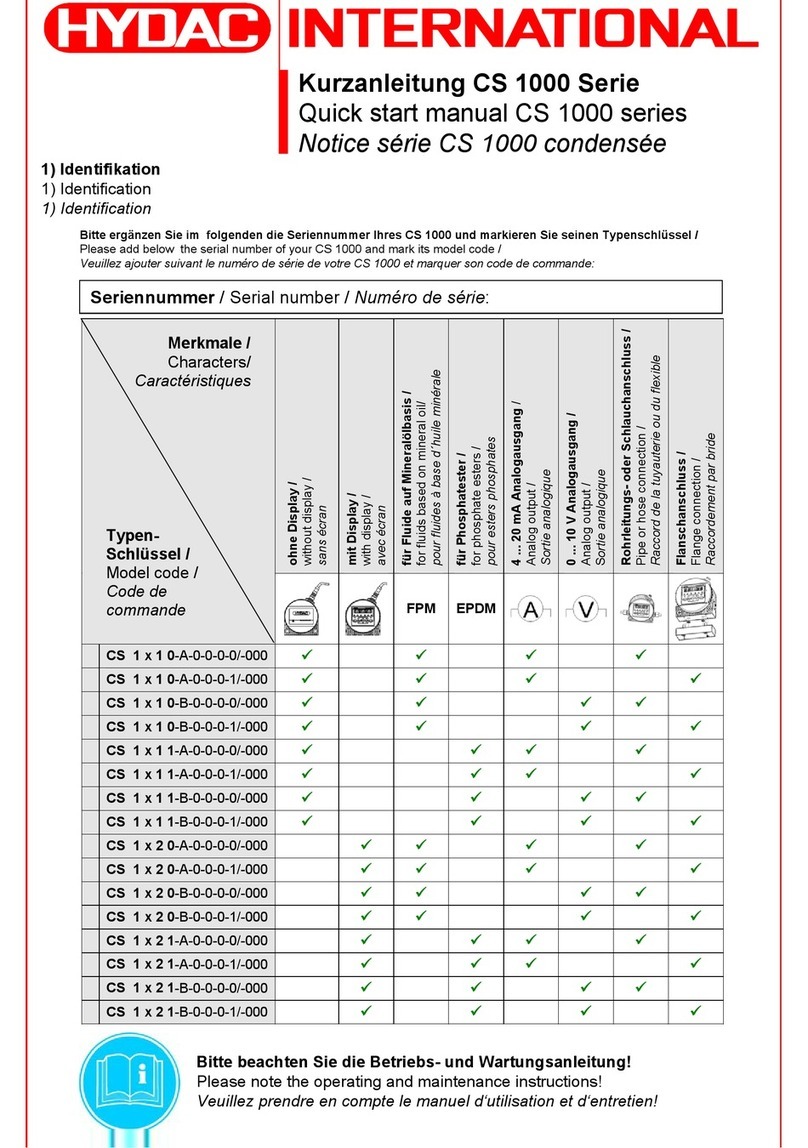

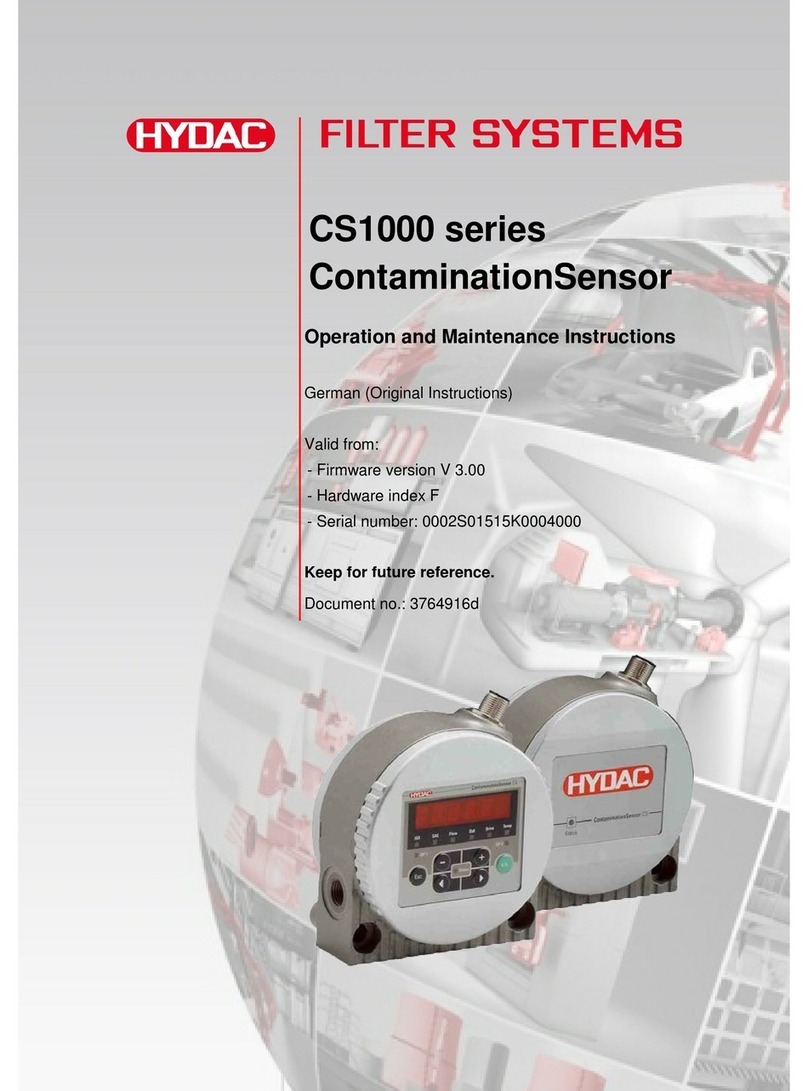

SMU126x <-> CS1000 / AS1000...............................................................34

SMU12x1 <-> Bluetooth ............................................................................35

SMU127x <-> CS1000 / AS1000 -> LAN...................................................36

Operating the SMU......................................................................................37

Display (CS1000 and AS1000)..................................................................37

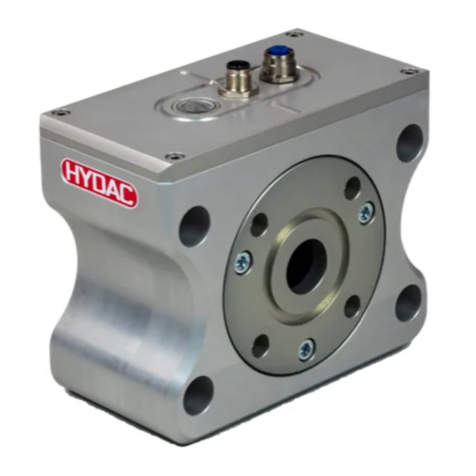

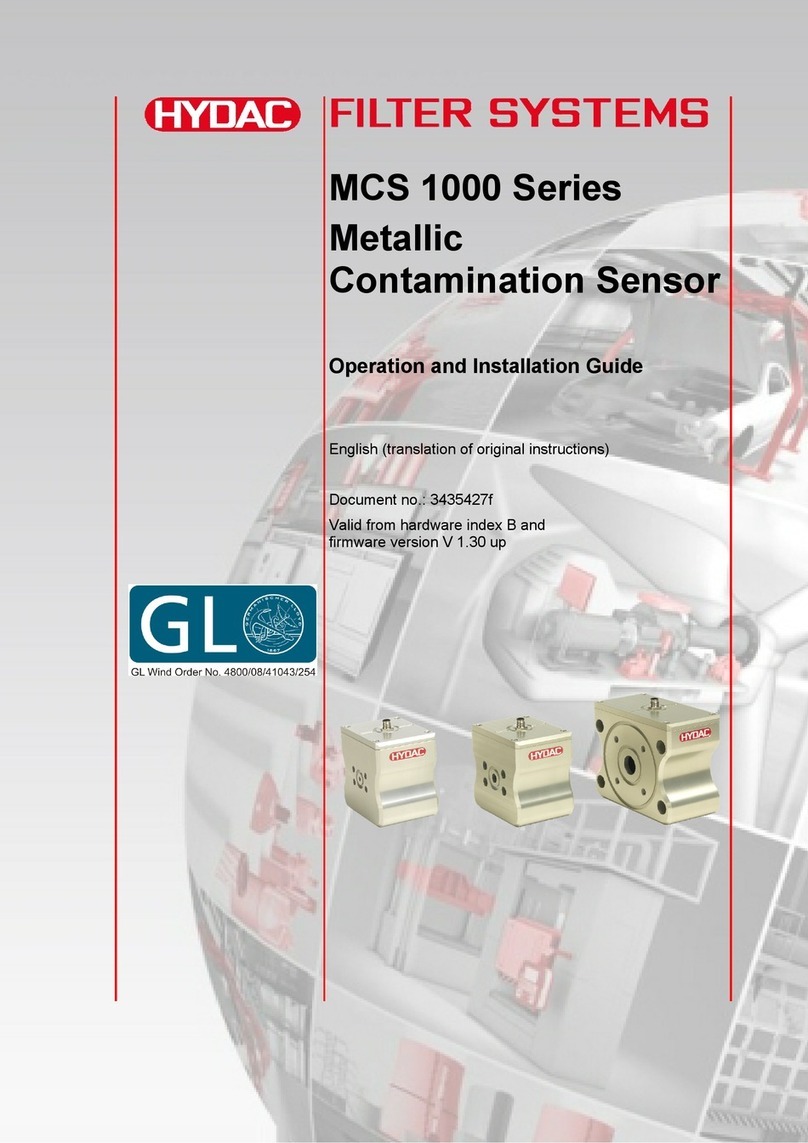

Display (MCS1000 and AS1000)...............................................................38

Internal measurement data memory..........................................................39

Keyboard elements....................................................................................40

Activating/deactivating key lock .................................................................40

Switching the display on and off ................................................................41

Scrolling through the displays ..................................................................42

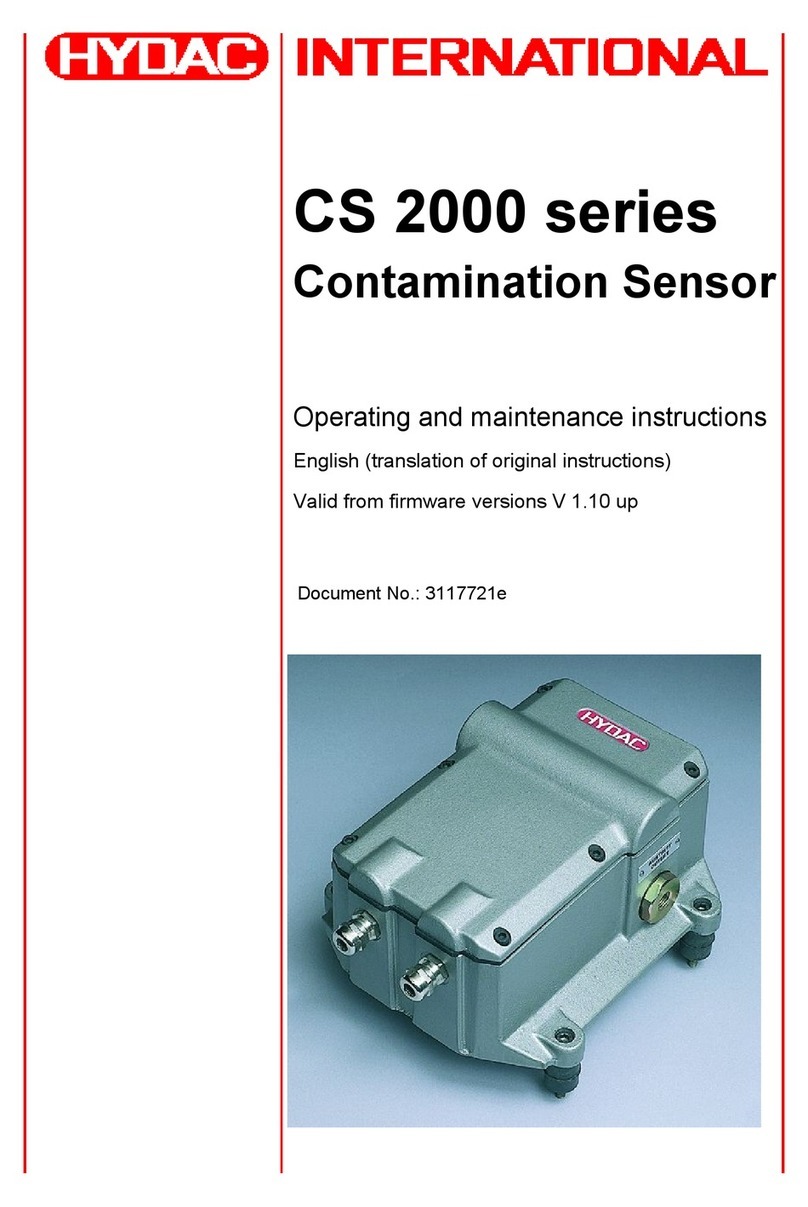

CS1000 displays........................................................................................42

Display ISO.SAE ....................................................................................42

Display ISO.NAS ....................................................................................43

Measured variables CS1000 .....................................................................44

Measured variable "ISO" ........................................................................44

Measured variable "SAE" .......................................................................44

Measured variable "NAS" .......................................................................44

Service variables (only for CS1000) ..........................................................45

Service variable "Flow"...........................................................................45

Service category "Out" ...........................................................................45

Service variable "Drive"..........................................................................45

Service category "Temp"........................................................................45

MCS1000 displays.....................................................................................46

Measured variables MCS1000 ..................................................................47

Measured variable "SUM" ......................................................................47

Measured variable "CYCLE" ..................................................................47

Representation of numbers over 9999 ...................................................47

Service variables (only for MCS1000) .......................................................48

Service variable "Status" ........................................................................48

Service variable "Fi" ...............................................................................48

Service category "Temp"........................................................................48

AquaSensor AS1000 measured variables..............................................49

Measured variable "Water saturation" ....................................................49

Measured variable "Temperature"..........................................................49

Configuring the SMU ..................................................................................50

PowerUp Menu..........................................................................................51