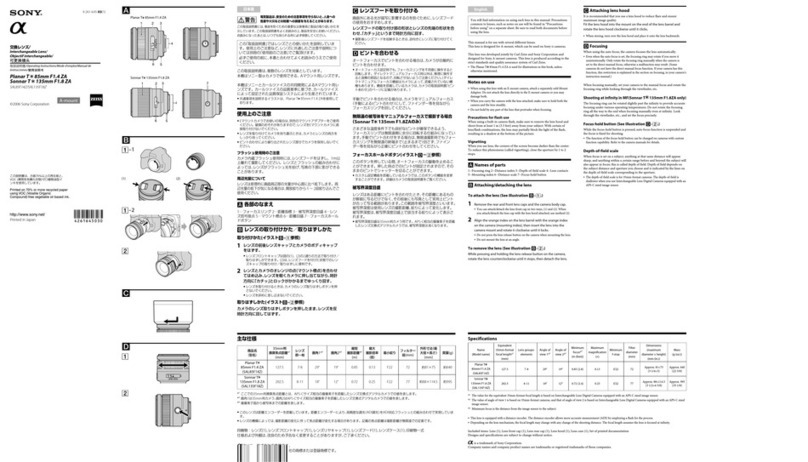

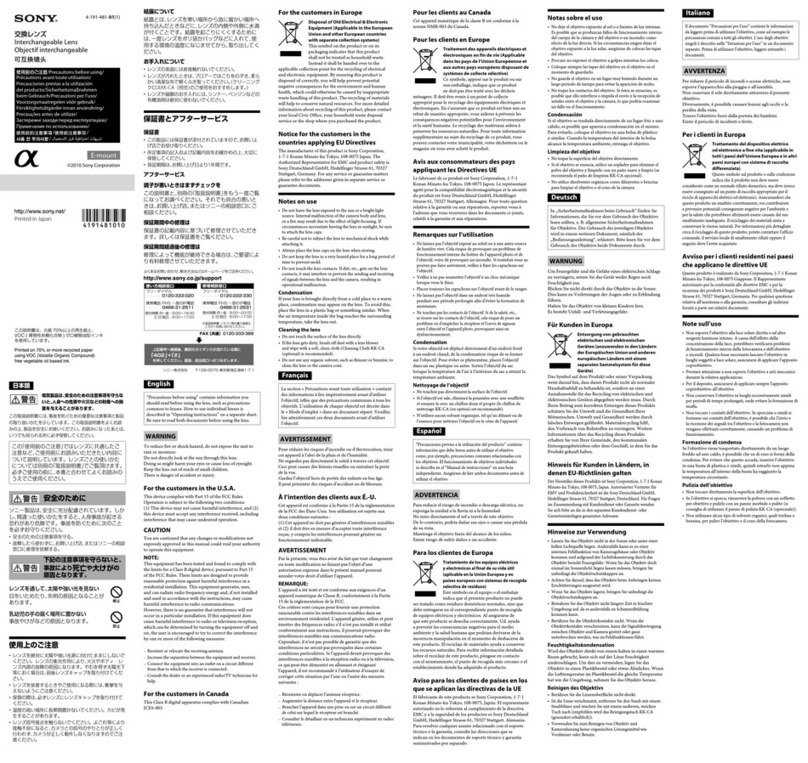

Sony SAL50F14 - 50mm f/1.4 Lens User manual

Other Sony Camera Lens manuals

Sony

Sony SEL-50F18 User manual

Sony

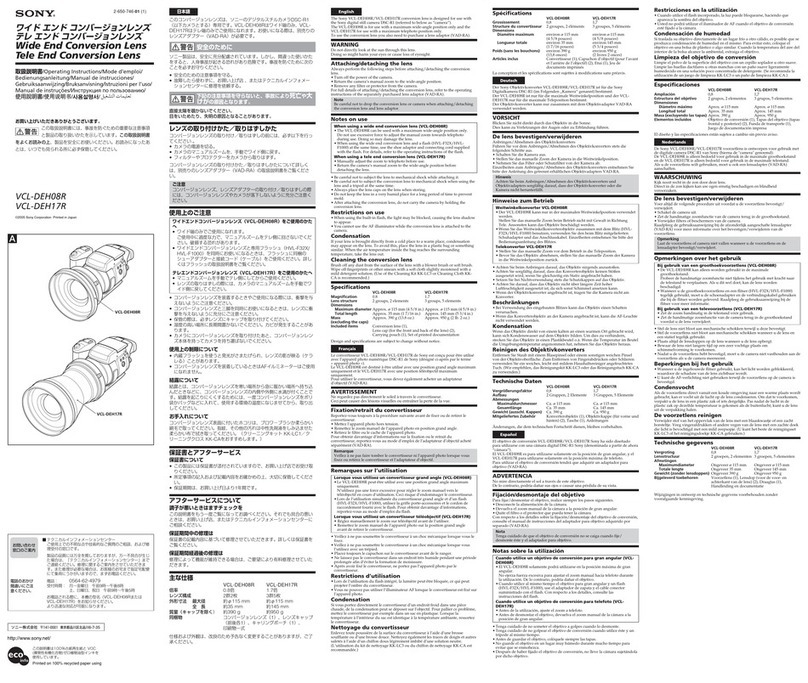

Sony VCL-DEH17R User manual

Sony

Sony SAL-135F18Z - 135mm f/1.8 Carl Zeiss Sonnar T Telephoto... Installation instructions manual

Sony

Sony VCL-ECU1 User manual

Sony

Sony E 15mm F1.4 G User manual

Sony

Sony A6000 User manual

Sony

Sony E 11mm F1.8 User manual

Sony

Sony NEX-VG10 - Digital Hd Video Camera Recorder Guide

Sony

Sony SAL50M28 - 50mm f/2.8 Macro Lens User manual

Sony

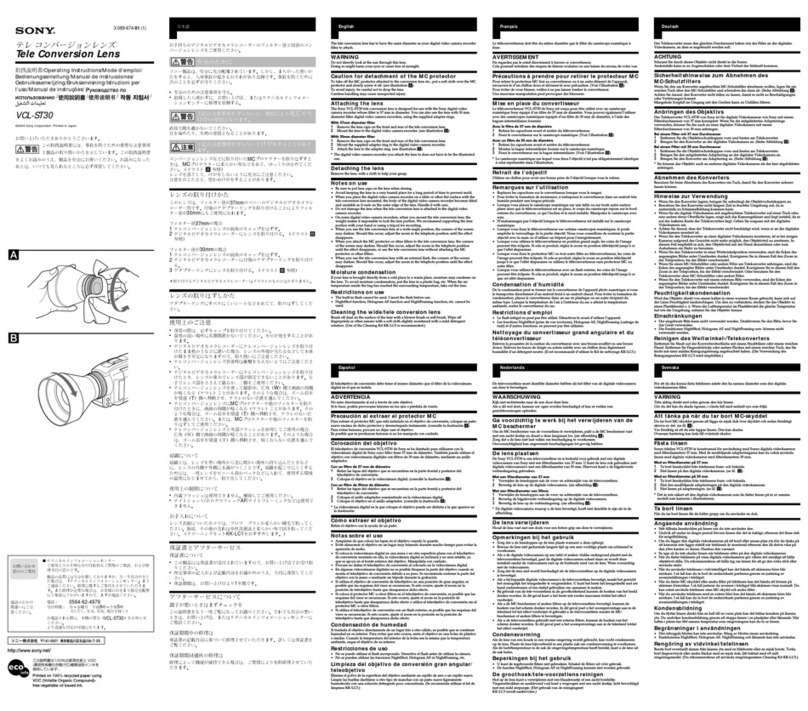

Sony VCL-ST30 User manual

Sony

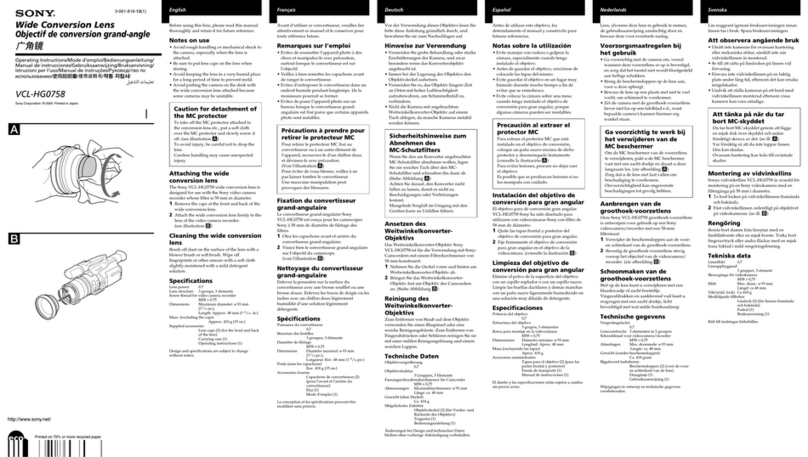

Sony VCL-HG0758 User manual

Sony

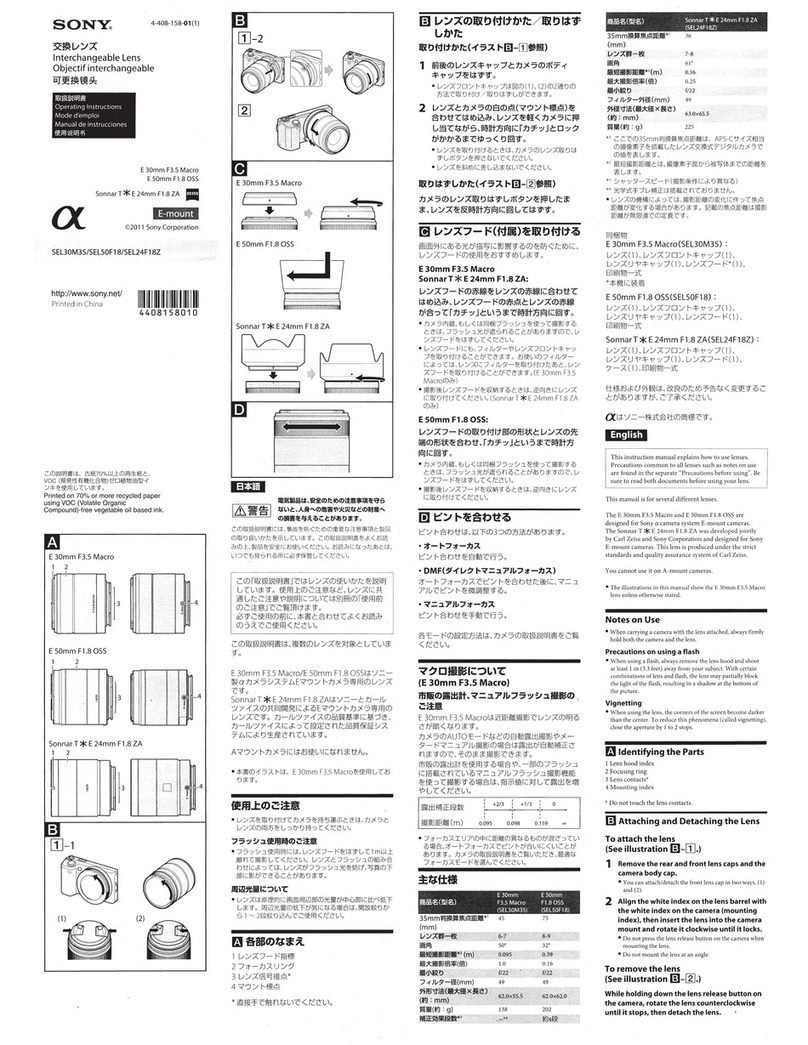

Sony E 30mm F3.5 Macro User manual

Sony

Sony SAL-35F18 User manual

Sony

Sony SAL-85F28 User manual

Sony

Sony SEL18200LE User manual

Sony

Sony SAL55200-2 User manual

Sony

Sony SEL85F14GM User manual

Sony

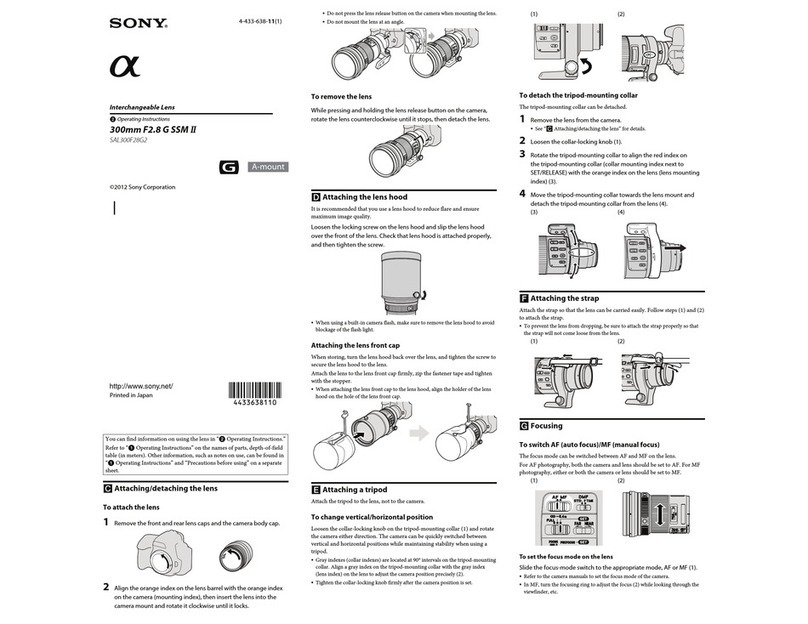

Sony SAL300F28G2 User manual

Sony

Sony SEL70200G User manual

Sony

Sony VCL-DH0774 User manual

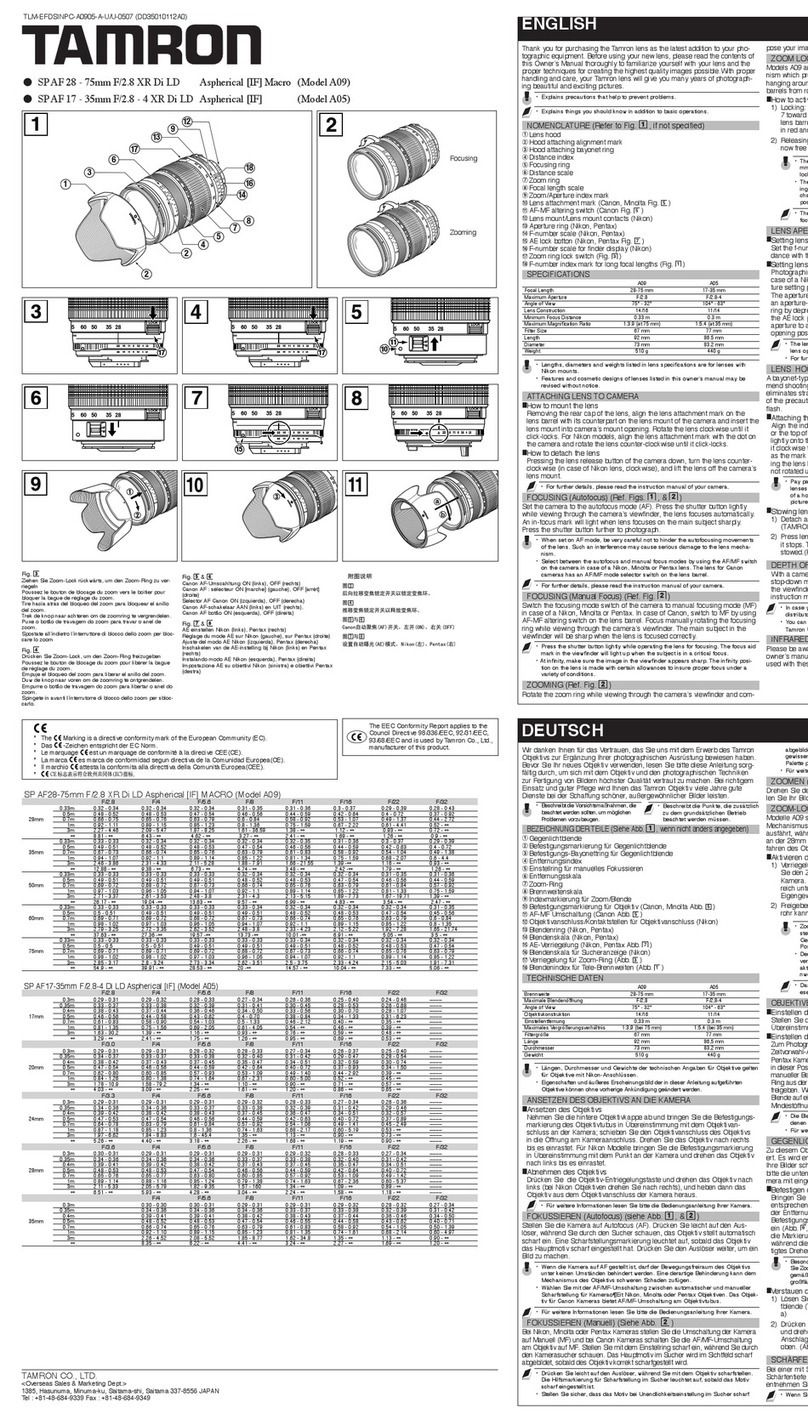

Popular Camera Lens manuals by other brands

Rokinon

Rokinon SP 85mm F1.2 instruction manual

Nikon

Nikon AF-S Zoom-Nikkor 17-35mm f/2.8D IF-ED manual

Samsung

Samsung Samsung 18-55mm user manual

FujiFilm

FujiFilm XF56mm F1.2 R APD owner's manual

FujiFilm

FujiFilm FUJINON XK6x20 SAF Operation manual

Nikon

Nikon AF-S DX Zoom-Nikkor 18-55mm f/3.5-5.6G ED II instruction manual