— 2 —

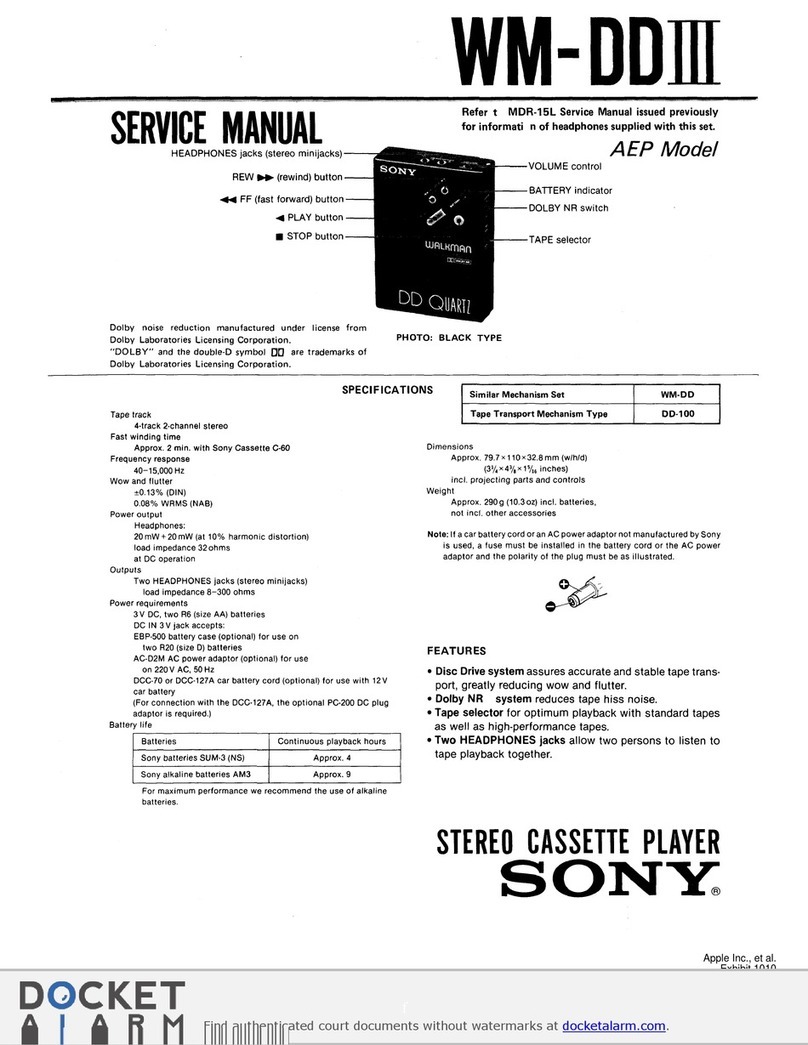

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK !OR DOTTED LINEWITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

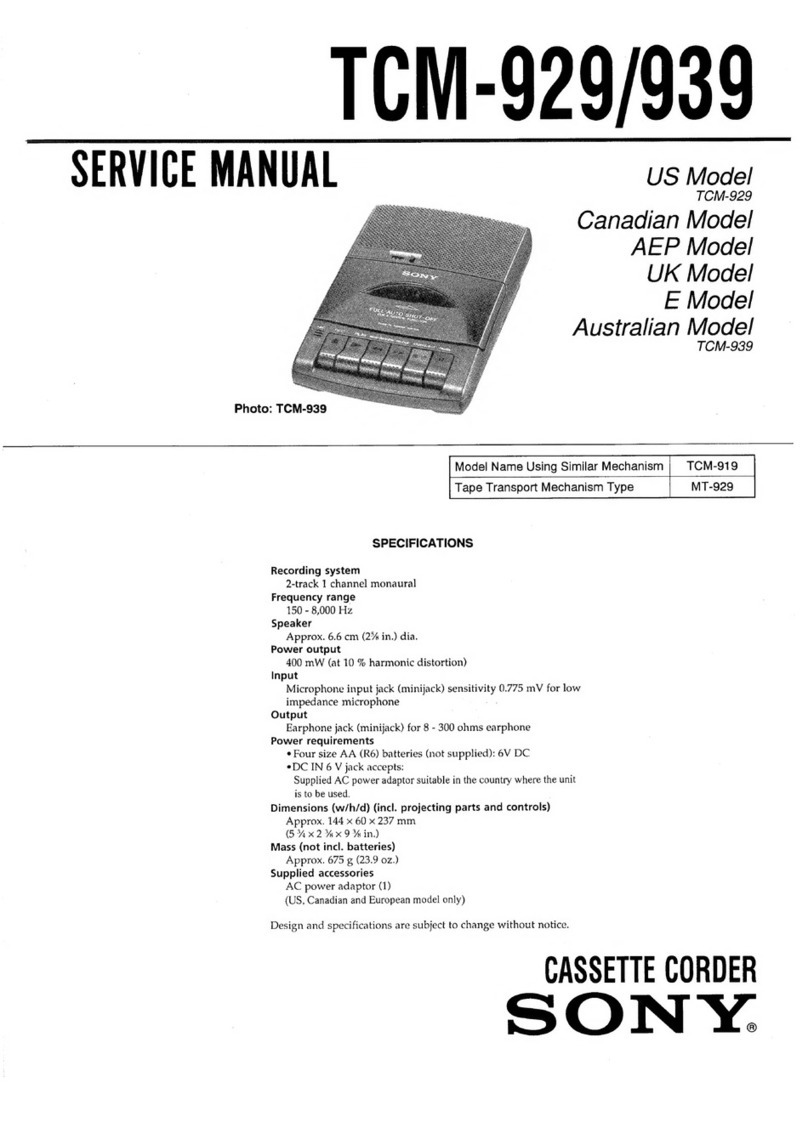

TABLE OF CONTENTS

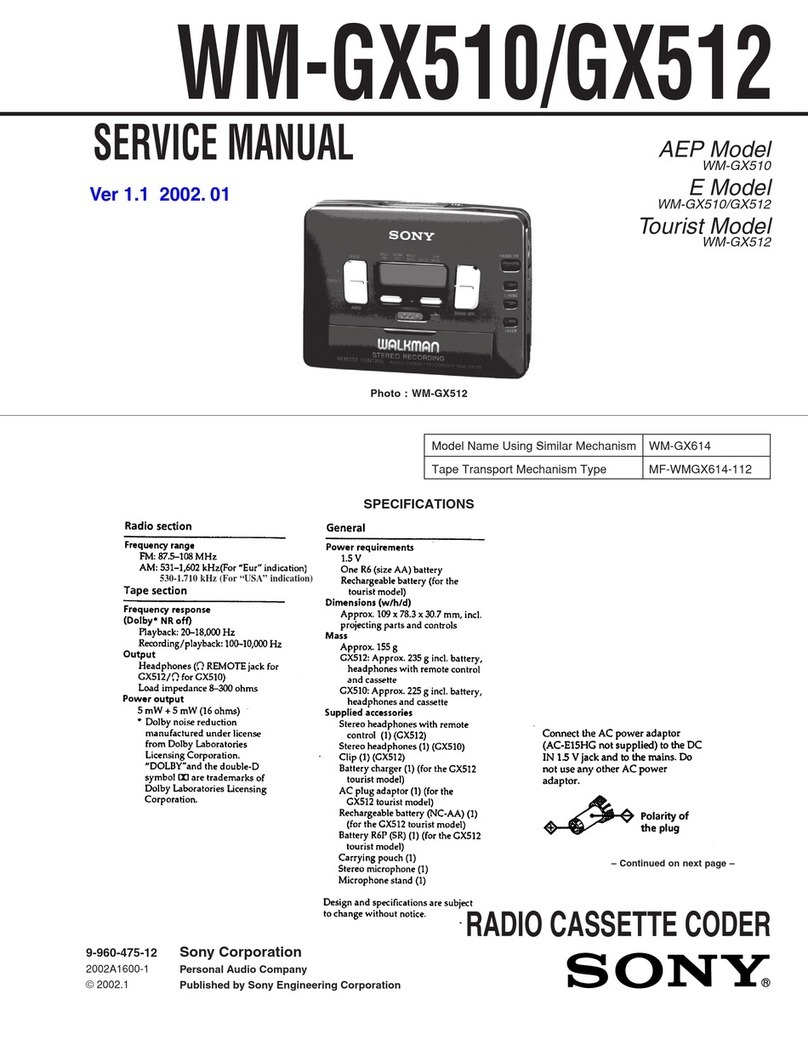

1. GENERAL ·········································································· 3

2. DISASSEMBLY

2-1. Case, Front Panel································································ 4

2-2. Mechanism Deck (TCM-ACLM572)································· 5

2-3. Control Board, Dolby Board ·············································· 5

2-4. Power Trans Board, AC Select SW Board, Power Board··· 6

2-5. Tray Assembly ···································································· 6

2-6. Mechanism Chassis Block·················································· 7

2-7. Capstan Reel Motor (M902)··············································· 7

3. DIAGRAMS

3-1. Circuit Boards Location ·····················································8

3-2. Schematic diagram — Display Section —························· 9

3-3. Printed Wiring Board — Display Section — ··················· 11

3-4. Printed Wiring Board — Main Section — ······················· 16

3-5. Schematic Diagram — Main Section — ·························· 21

3-6. IC Block Diagrams ··························································· 25

3-7. IC Pin Function Description············································· 27

4. MECHANICAL ADJUSTMENT ································ 29

5. ELECTRICAL ADJUSTMENT ·································· 29

6. EXPLODED VIEWS

6-1. Case, Front Panel Section················································· 33

6-2. Chassis Section································································· 34

6-3. Mechanism Deck Section-1 (TCM-ACLM572) ·············· 35

6-4. Mechanism Deck Section-2 (TCM-ACLM572) ·············· 36

6-5. Mechanism Deck Section-3 (TCM-ACLM572) ·············· 37

7. ELECTRICAL PARTS LIST ······································· 38