TCM-500DV

77

SECTION 4

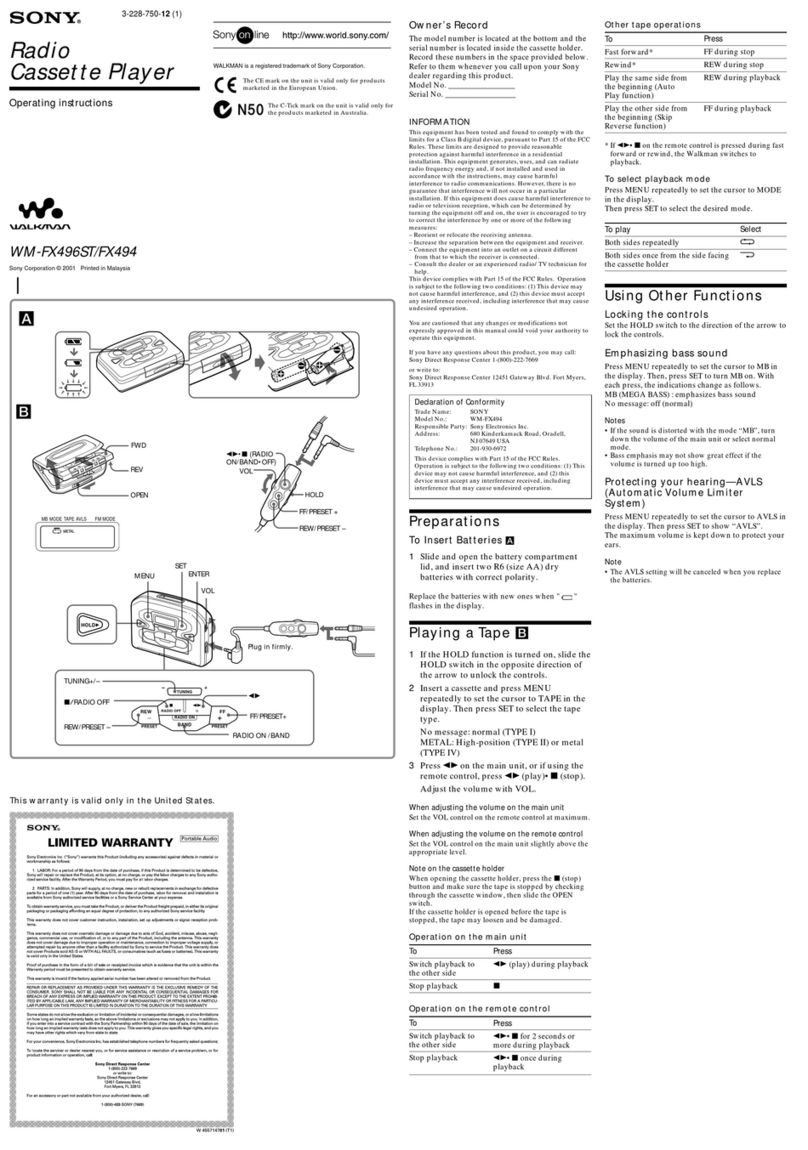

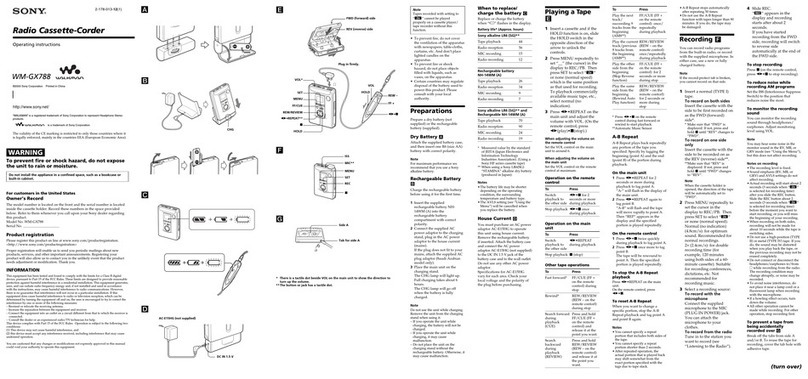

MECHANICAL ADJUSTMENTS

TapeTension Measurement

1. Clean the following parts with a denatured-alcohol-moistened

swab: record/playback/erase head pinch roller

capstan rubber belt

2. Demagnetize the record/playback/erase head with a head demag

netizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power supply

voltage (3 V) unless otherwise noted.

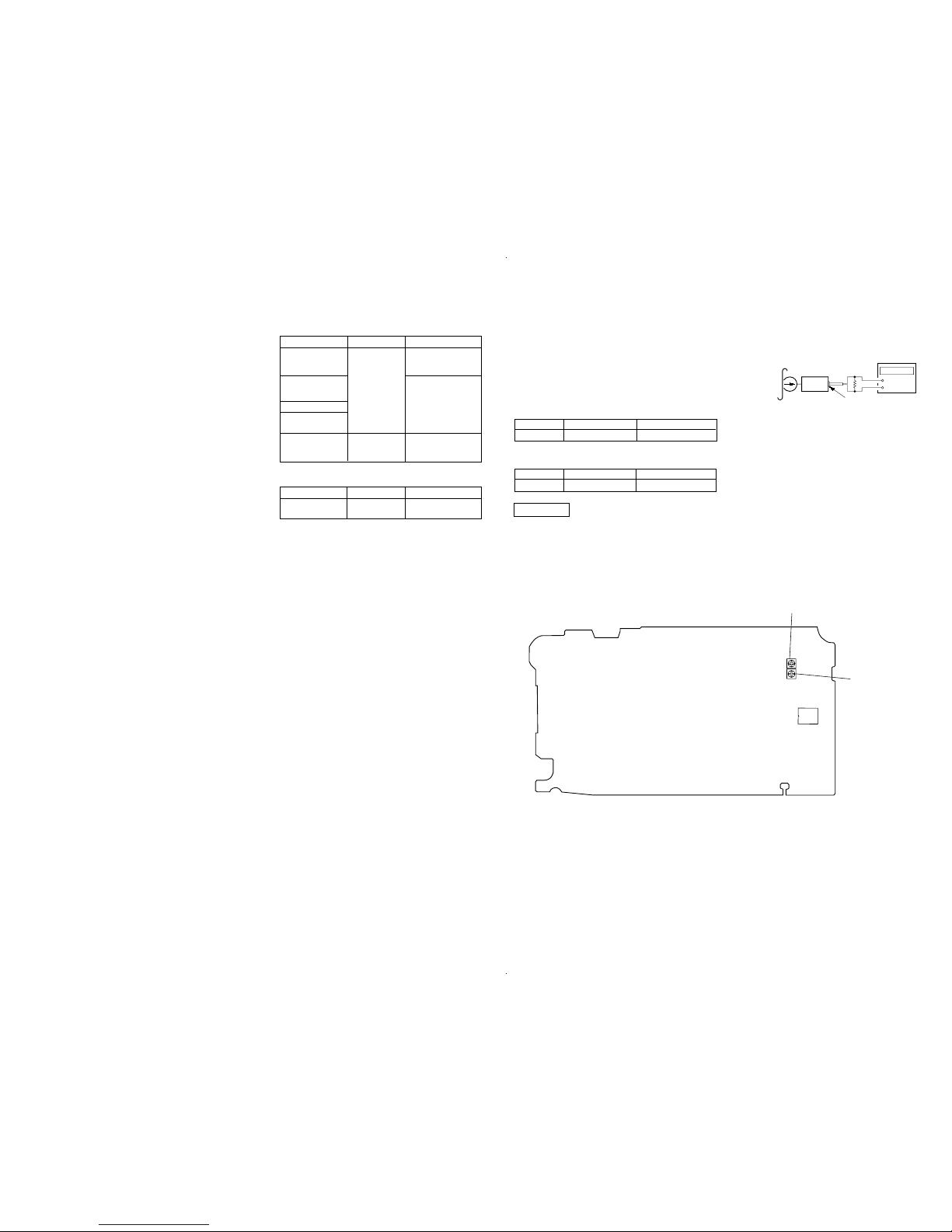

Mode Torque Meter Meter Reading

1.97 – 3.92mN•m

FWD (20 – 40 g•cm)

CQ-102C (0.28 – 0.55 oz•inch)

FWD

Back Tension 0.05 – 0.49 mN•m

REV (0.5– 5 g•cm)

REV (0.007 – 0.069 oz•inch)

Back Tension

FF, REW CQ-201B more than 4.91 mN•m

(more than 50 g•cm)

(more than 0.69 oz•inch)

Mode Tension Meter Meter Reading

FWD CQ-403A more than 50 g

(more than 1.76 oz)

Torque Measurement

SECTION 5

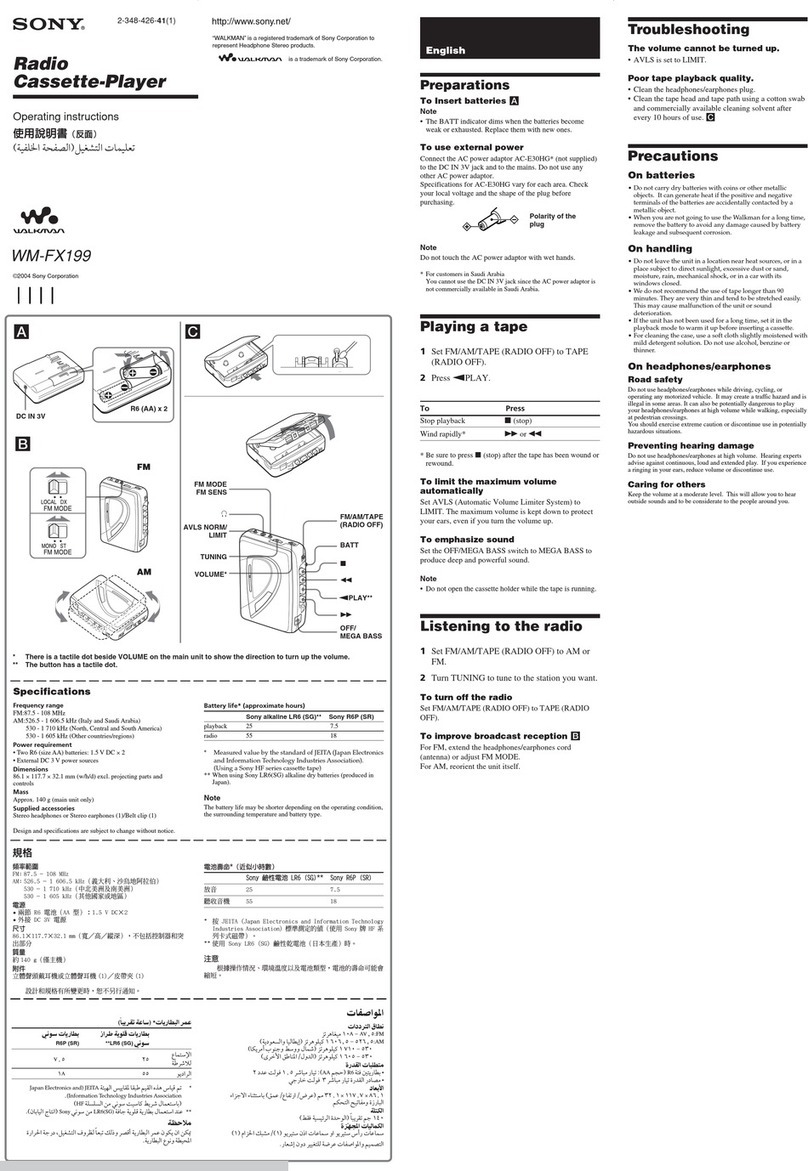

ELECTRICAL ADJUSTMENTS

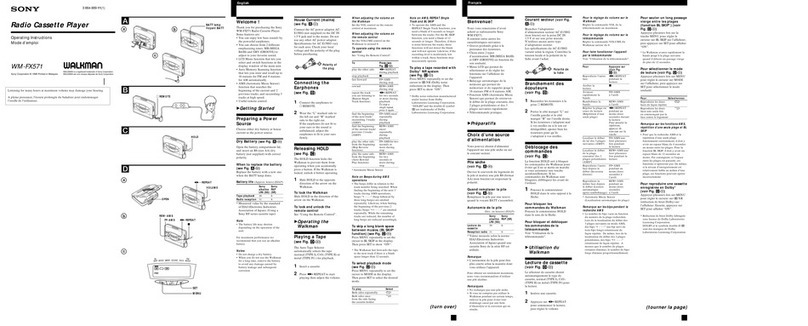

Tape Speed Adjustment

Mode: playback

Procedure:

1. Set [REC TIME] switch (S401) to NORMAL (4.8 cm/s) posi-

tion, and playback the tape (WS-48A) .

2. Adjust RV602 so that frequency counter reading becomes 3,010

Hz.

3. Set [REC TIME] switch (S401) to DOUBLE (2.4 cm/s) posi-

tion.

4.Playback the tape from the beginning for two minutes, then ad-

just RV601 so that frequency counter reading becomes 1,505 Hz.

Confirm that deflection of the frequency counter reading between

the beginning and the end of tape is within 2% (NORMAL: approx.

60 Hz, DOUBLE: approx. 30 Hz) .

Setting:

•Supplied voltage: 3 V (DC)

•Switch and control position

VOL contorl (RV101) : mechanical center

REC SPEED switch (S401) : normal (4.8cm/s)

PAUSE switch (S601) : OFF

SPEED CONTROL (RV201) : center click

VOR switch (S402) : OFF

0 dB=0.775 V

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

frequency

counter

test tape

WS-48A

(3 kHz, 0 dB) 16 Ω

EAR jack (J102)

set +

–

TestTape

Regulation Level

input level Mic –60dBs

output level earphone 16Ω, –20dBs

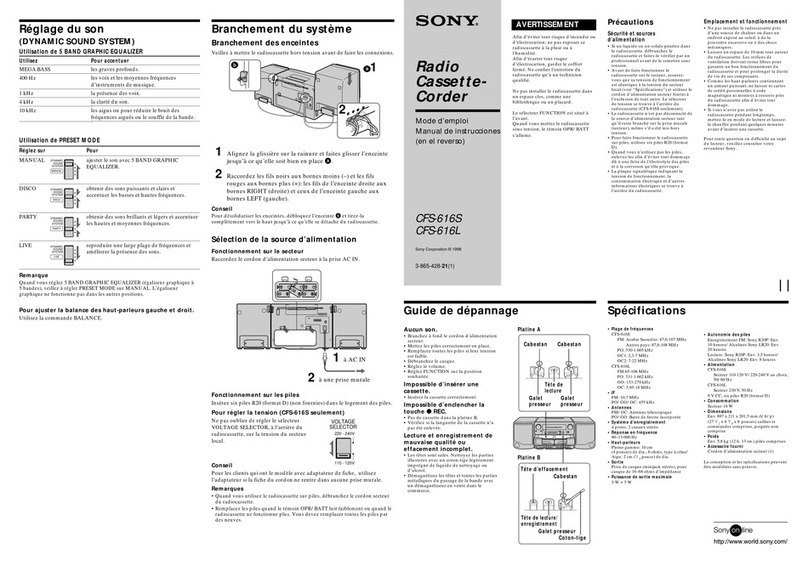

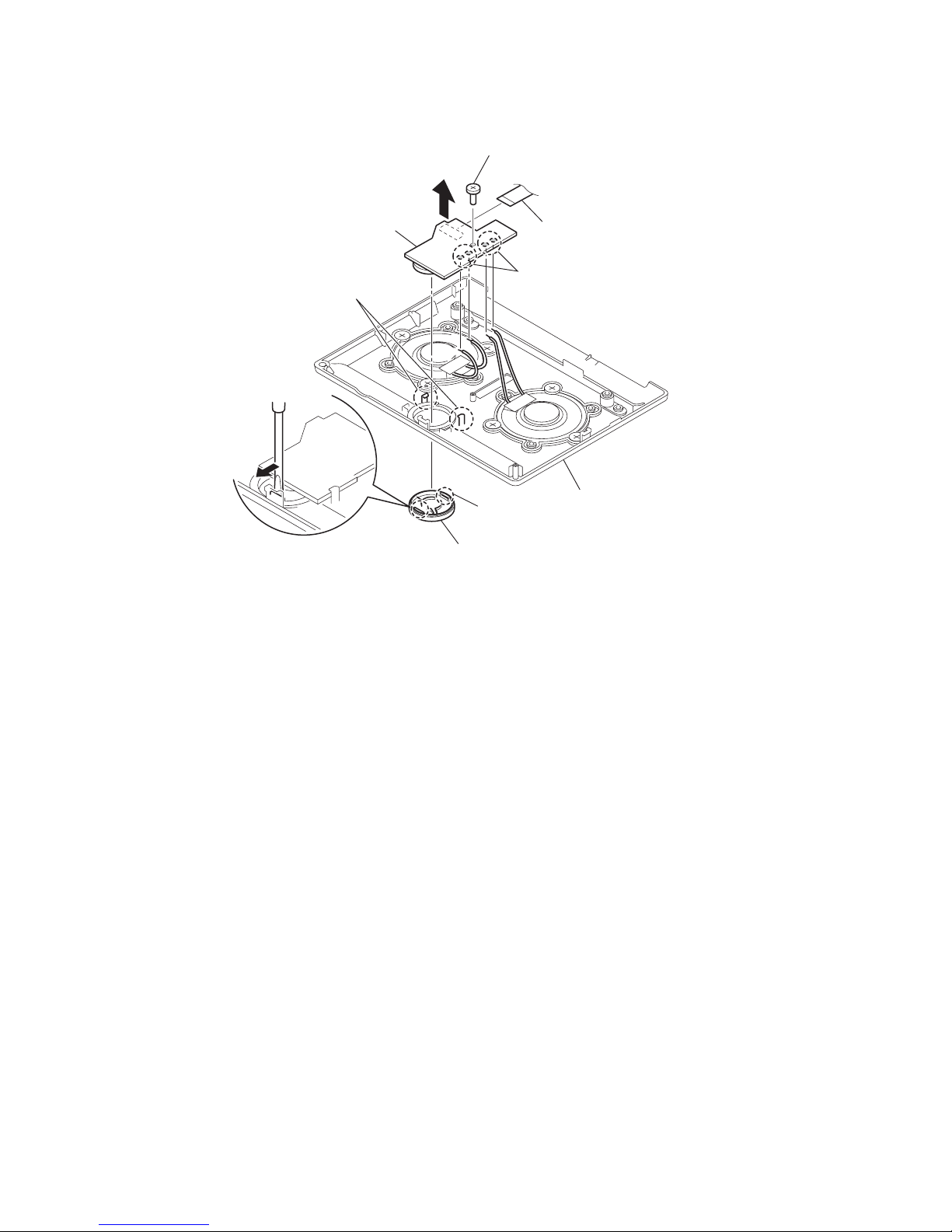

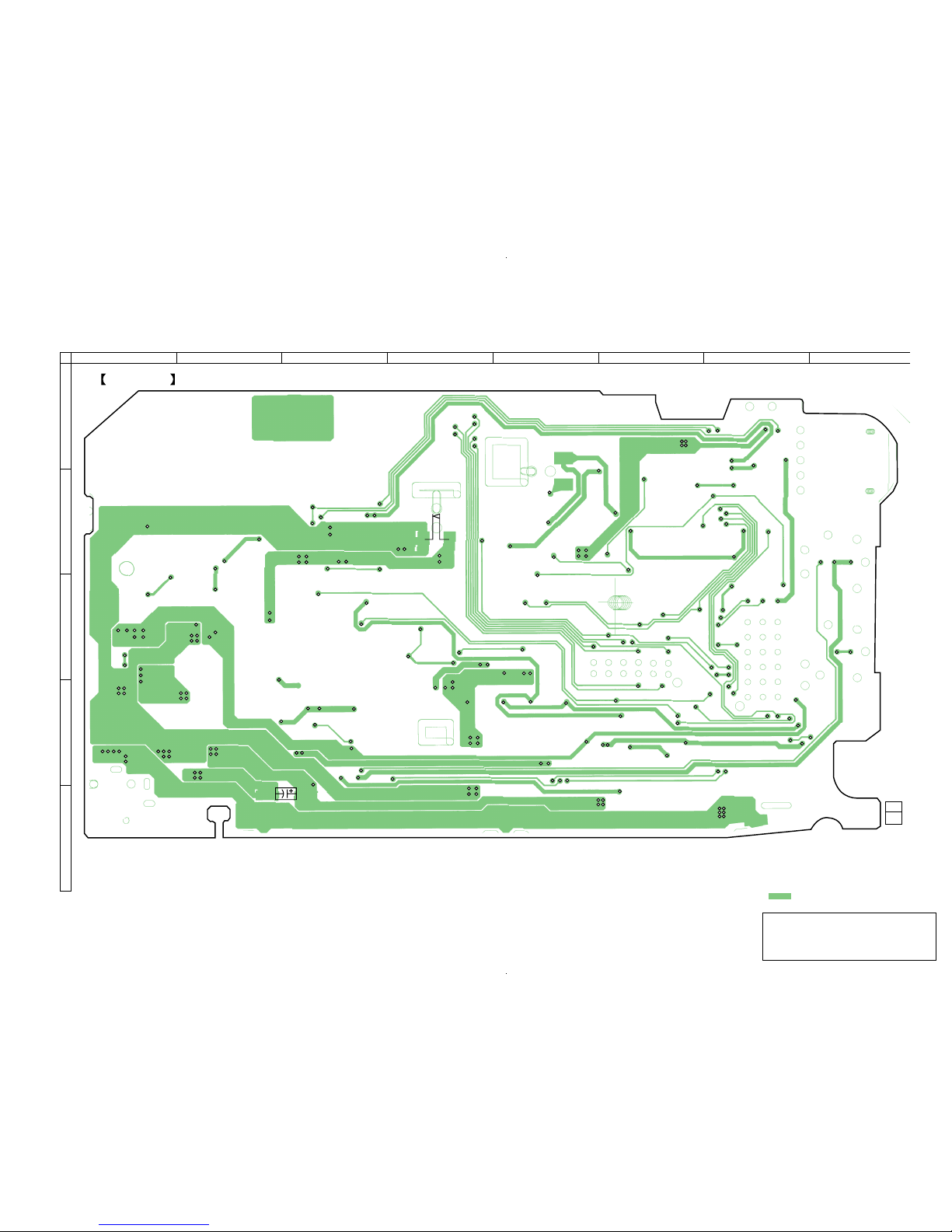

Adjustment Location:

– MAIN BOARD (Conductor Side) –

IC601

10

11

RV602

RV601

Tape Speed Adjustmen