— 3 —

p

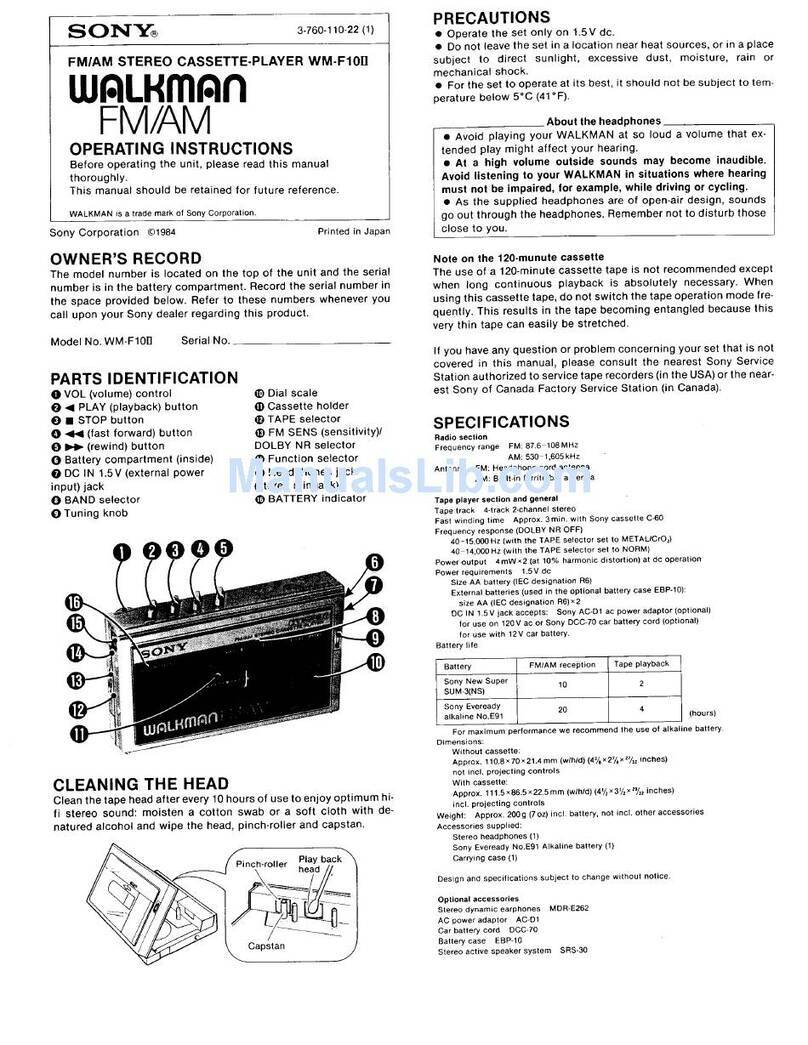

(S3) ENTER

(S10) BAND

(S8)

MENU

(S6)

R43

(SIDE A)

Q15

(SIDE A)

PH1

(SIDE A)

SET

(S7)

(S1)

FWD

←

STOP

→

REV

Battery terminal

’

Battery terminal

‘

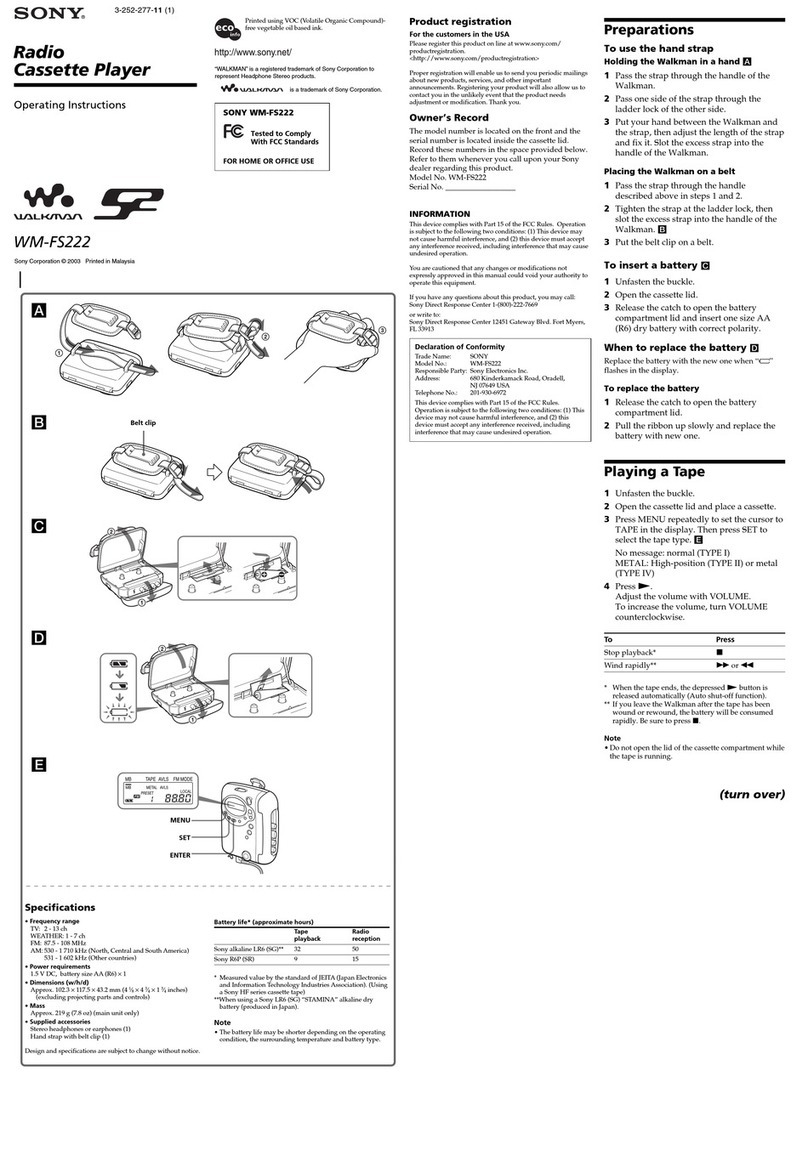

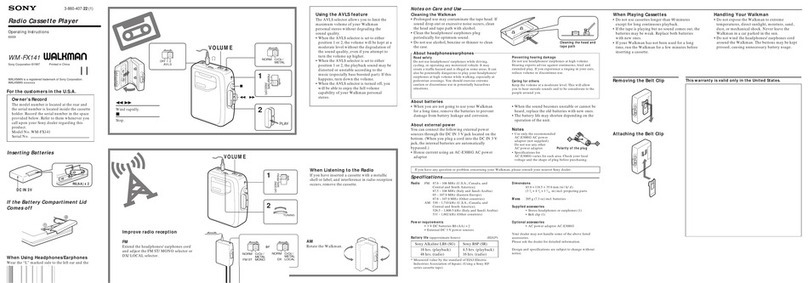

Square-wave

(sine wave)

10 Hz, -3.5 dB

AF OSC

Plunger (PM901)

Short

R TUME

SWITCH

(S901-2)

TAPE DETECT

SWITCH

(S901-1)

FF AMS

(S4)

REW AMS

(S5)

œ

REPEAT

(S9) M601

M

SECTION 1

SERVISE NOTE

[Service Mode]

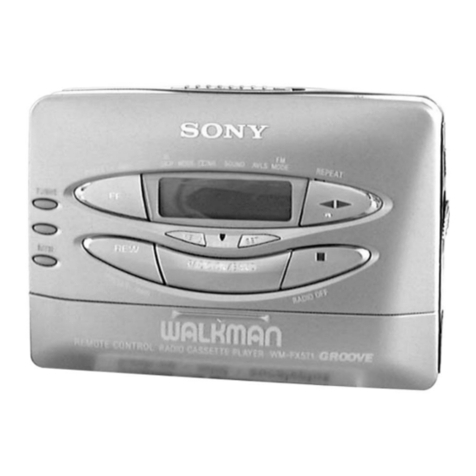

The service mode enables to operate the mechanism ofWM-FX671

while the MAIN board is opened.

Rotation of the idler gear (A) (S side) is detected using the photo-

reflector (PH1) in the WM-FX671. PH1 is located on the MAIN

board, therefore the rotation of the idler gear (A) (S side) cannot be

detected by PH1 when the MAIN board is removed. As a result, the

motor cannot be controlled and cannot run correctly.

To repair the machine after the MAIN board is removed while the

main power is turned on, follow the procedures as described below.

1. Setting

1) Removethe cabinets referringto section“3. DISASSEMBLY”.

Open the MAIN board.

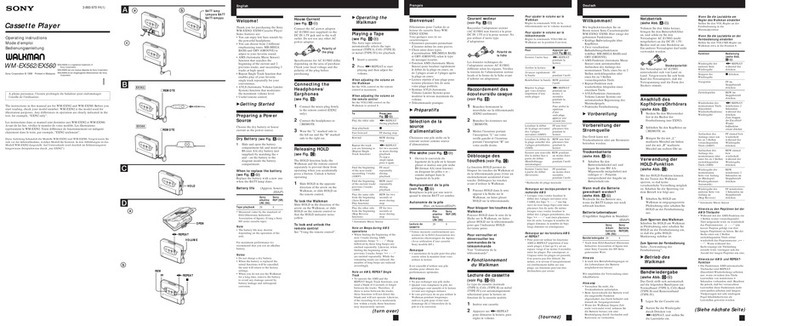

2) Connect the motor (M601) and the plunger solenoid (PM901)

tothe MAIN board usingthe jumperwires. When theextension

jig (1-769-143-11) (10 wires as a set) is used, they can be

connected easily.

3) Short the TAPE DETECT switch (S901-2), R TUME switch

(S901-1).

4) Connect an AF oscillator to resistor (R43).

5) Connect DC 1.3V from external regulated power supply to ‘

and ’terminals of the battery.

2. PRE-SET status

The PLAY, FF and REW modes can be entered only from the PRE-

SET status.

1) Check that the slider (NR) is in the center position (S1), and

the FWD/REV switch is also in the center position. When

these switches are not in the center position, set them to the

PRE-SET status as follows.

2) Move the FWD/REV switch (S1) to the same position as the

slider (NR) is set.

3) The slider (NR) can be moved when the main power of the

regulated power supply is turned OFF once then back ON.

Move the FWD/REV switch (S1) to the center position in

synchronism with the timing when the slider (NR) is moved.

3. FF, REW modes

1) Check that the PRE-SET status is set.

2) Connect square wave or sine wave to resistor (R43). (See

illustration below.)

3) Press the pswitch (S3) to enter the STOP mode.

4) Press the FF AMS switch (S4) and the REW AMS switch

(S5).

4. PLAY mode

1) Check that the PRE-SET status is set.

2) Connect square wave or sine wave to resistor (R43). (See

illustration below.)

3) Press the pswitch (S3) to enter the stop mode.

4) When the 9(REPEAT switch (S9) of the MAIN board is

pressed, the slider (N/R) moves once to the F side then moves

to the R side. When the FWD/REV switch (S1) is pressed in

the synchronism with the above timing, the machine can enter

the PLAY (R side) mode. Press the 9(REPEAT switch

(S9) again, and move the FWD/REV switch (S1) in the

synchronism with the motion of slider (NR). It enables the

machine to enter into the PLAY (F side) mode.

Note 1: When you fail to enter the PLAY mode, re-start from step

1) PRE-SET status.

Note 2: Regarding the 9(REPEAT (S9), p(S3),

FF AMS (S4), and REW AMS (S5) switches, use these

switches of the remote control unit as much as possible.

Note 3: If a headphones are used, the beep sound shows the timing

of the FWD/REV switch (S1).

– MAIN BOARD (SIDE B) —