!WARNING

This manual is intended for qualified service personnel

only.

To reduce the risk of electric shock, fire or injury, do not

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

Refer all servicing to qualified service personnel. The material contained in this manual consists of

information that is the property of Sony Corporation and

is intended solely for use by the purchasers of the

equipment described in this manual.

Sony Corporation expressly prohibits the duplication of

any portion of this manual or the use thereof for any

purpose other than the operation or maintenance of the

equipment described in this manual without the express

written permission of Sony Corporation.

Le matériel contenu dans ce manuel consiste en

informations qui sont la propriété de Sony Corporation et

sont destinées exclusivement à l’usage des acquéreurs

de l’équipement décrit dans ce manuel.

Sony Corporation interdit formellement la copie de

quelque partie que ce soit de ce manuel ou son emploi

pour tout autre but que des opérations ou entretiens de

l’équipement à moins d’une permission écrite de Sony

Corporation.

Das in dieser Anleitung enthaltene Material besteht aus

informationen, die Eigentum der Sony Corporation sind,

und ausschließlich zum Gebrauch durch den Käufer der

in dieser Anleitung beschriebenen Ausrüstung bestimmt

sind.

Die Sony Corporation untersagt ausdrücklich die

Vervielfältigung jeglicher Teile dieser Anleitung oder den

Gebrauch derselben für irgendeinen anderen Zweck als

die Bedienung oder Wartung der in dieser Anleitung

beschriebenen Ausrüstung ohne ausdrückliche

schriftliche Erlaubnis der Sony Corporation.

TableofContents

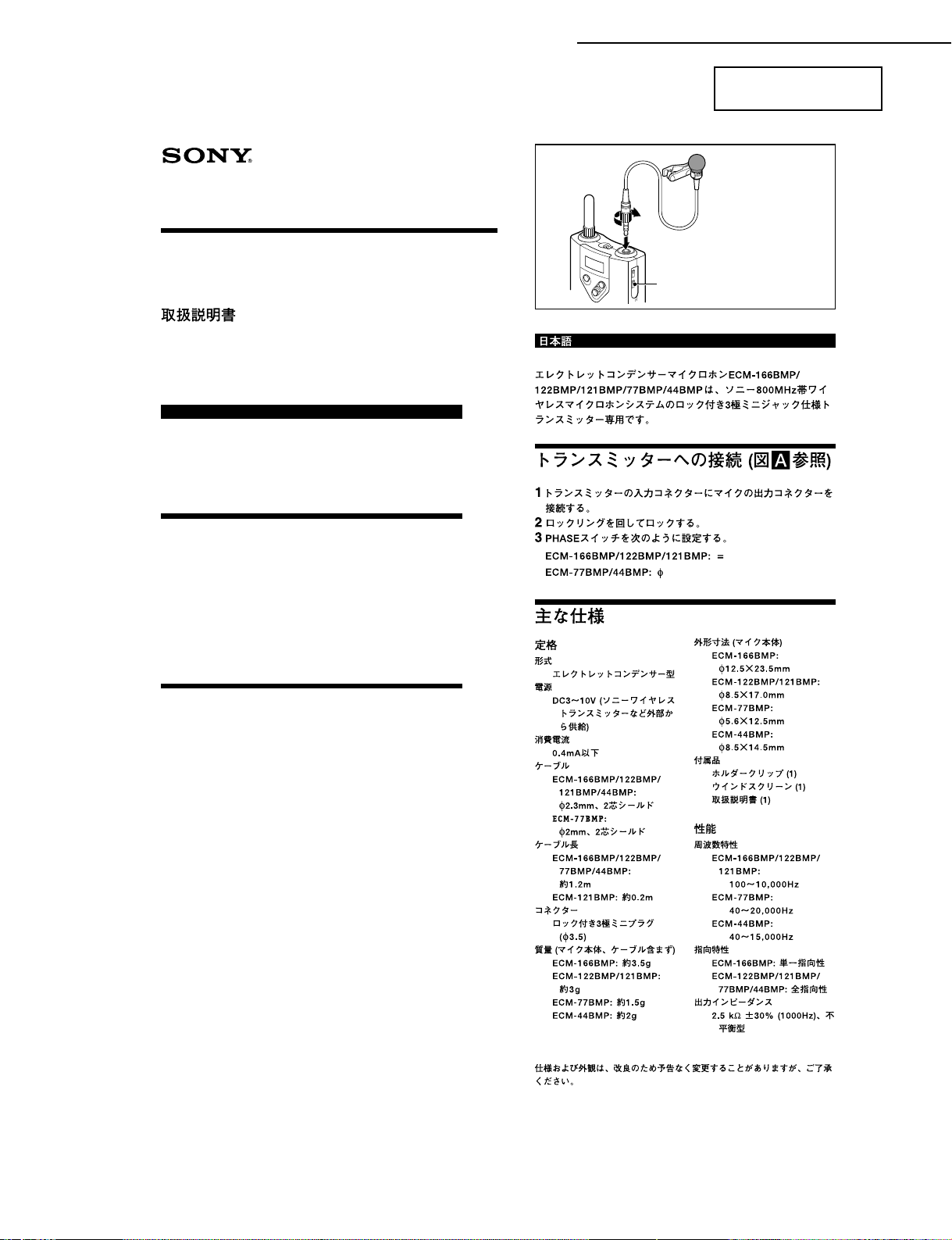

1.OPERATION.............................................1

2.ECM-44BMP............................................2

3.ECM-77BMP............................................3

4.ECM-166BMP.........................................4

Appendix(ECM-77LM)............................5

Appendix(ECM-77BC).............................8

Appendix(ECM-77B).............................18