— 4 —

CPD-2403

1.5 k

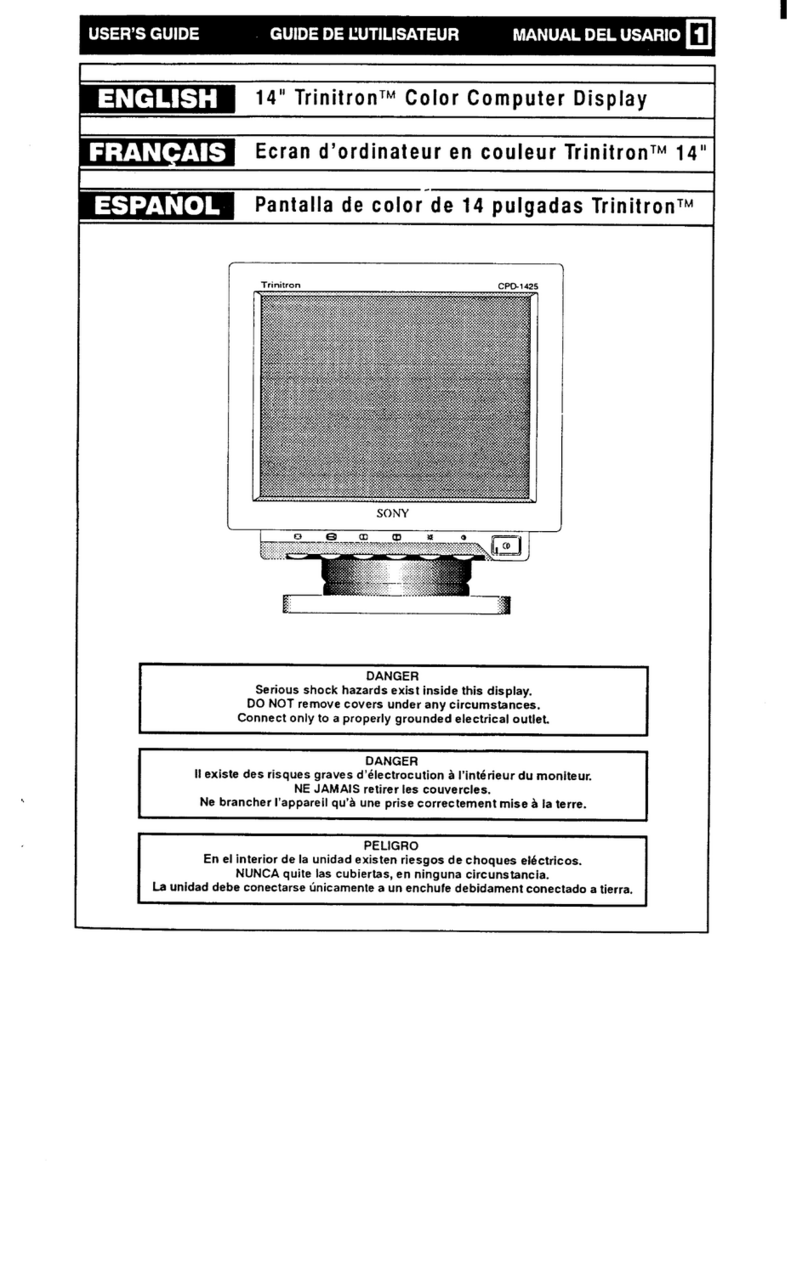

Ω

0.15 µF AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:

Leakage Test

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part

having a return to chassis, must not exceed 0.5 mA (500

microampere).Leakagecurrentcanbe measured byany one of

three methods.

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN WHICHTHE

DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENTWARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ONTHE

SCHEMATIC DIAGRAMS, EXPLODEDVIEWS AND INTHE PARTS

LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE

CRITICAL FOR SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOWTHESE PROCEDURESWHENEVER CRITICAL

COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA BOBINE DE

DEMAGNETISATION EST ENLEVEE.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNETRAME ET PAR UNE

MARQUE SUR LES SCHEMAS DE PRINCIPE, LES VUES

EXPLOSEES ET LES LISTES DE PIECES SONT D'UNE

IMPORTANCE CRITIQUE POUR LA SECURITE DU

FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST

INDIQUE DANS LE PRESENT MANUEL OU DANS DES

SUPPLEMENTS PUBLIES PAR SONY. LES REGLAGES DE

CIRCUIT DONT L'IMPORTANCE EST CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS LE

PRESENT MANUEL. SUIVRE CES PROCEDURES LORS DE

CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU

LORSQU'UN MAUVAIS FONTIONNEMENT SUSPECTE.

1. Check the area of your repair for unsoldered or poorly-

soldered connections. Check the entire board surface

for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground

straps,and mounting hardwarehave been replaced.Be

absolutely certain that you have replaced all the

insulators.

4. Look for unauthorized replacement parts, particularly

transistors,thatwereinstalledduring a previous repair.

Point them out to the customer and recommend their

replacement.

5. Lookforparts which, though functioning, showobvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord to

the customer.

7. Checkthe B+ and HV to see if theyare specified values.

Makesureyourinstrumentsare accurate;be suspicious

of your HV meter if sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized"

knobs, screws, and all other exposed metal parts for

AC Leakage. Check leakage as described below.

1. A commercial leakage tester, such as the Simpson 229 or

RCAWT-540A.Follow the manufacturers'instructions to use

these instructions.

2. Abattery-operatedACmilliammeter.TheDataPrecision245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of

a VOM or battery-operated AC voltmeter. The "limit"

indicationis0.75V, so analog meters musthavean accurate

lowvoltagescale.The Simpson's 250 andSanwaSH-63Trd

are examples of passive VOMs that are suitable. Nearly

all battery operated digital multimeters that have a 2V AC

range are suitable. (See Figure A)

Figure A