Sony TRINITRON PVM-8020 User manual

Other Sony Monitor manuals

Sony

Sony Trinitron CPD-120VS User manual

Sony

Sony SDM-S75N User manual

Sony

Sony XV-M30 User manual

Sony

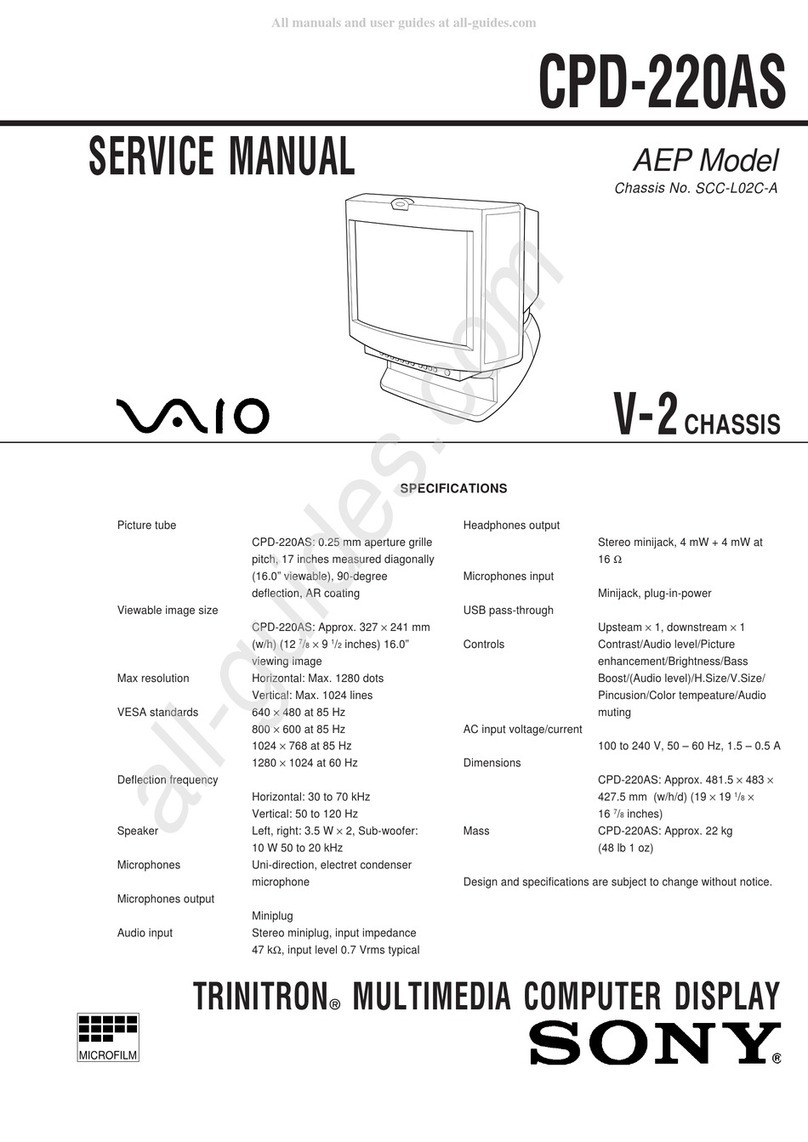

Sony TRINITRON VAIO CDP-220AS User manual

Sony

Sony FWD-50PX1 (English: pgs. 52-97) User manual

Sony

Sony Trinitron CPD-17SF2 User manual

Sony

Sony Multiscan SDM-N50 User manual

Sony

Sony KLH-W32 User manual

Sony

Sony Multiscan CPD-420GS User manual

Sony

Sony SDM-X202 User manual

Sony

Sony Trinitron HMD-A230 User manual

Sony

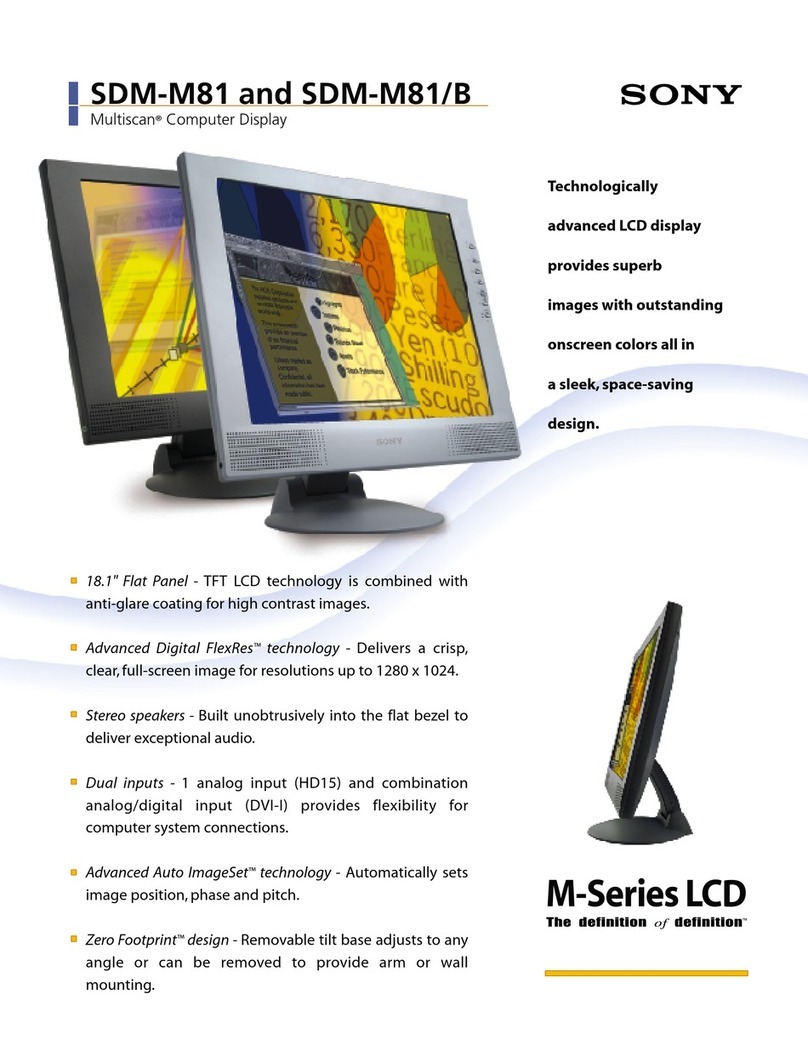

Sony Multiscan SDM-M81 User manual

Sony

Sony LMD2451MD User manual

Sony

Sony PVM-1444QM User manual

Sony

Sony CPD-17F03T User manual

Sony

Sony Multiscan300sf CPD-300SFT5 User manual

Sony

Sony PVM-740 User manual

Sony

Sony PFM-500A2W User manual

Sony

Sony CPD-100ES User manual

Sony

Sony GDM-90W01T User manual