2

HCD-CP333

TABLE OF CONTENTS

General

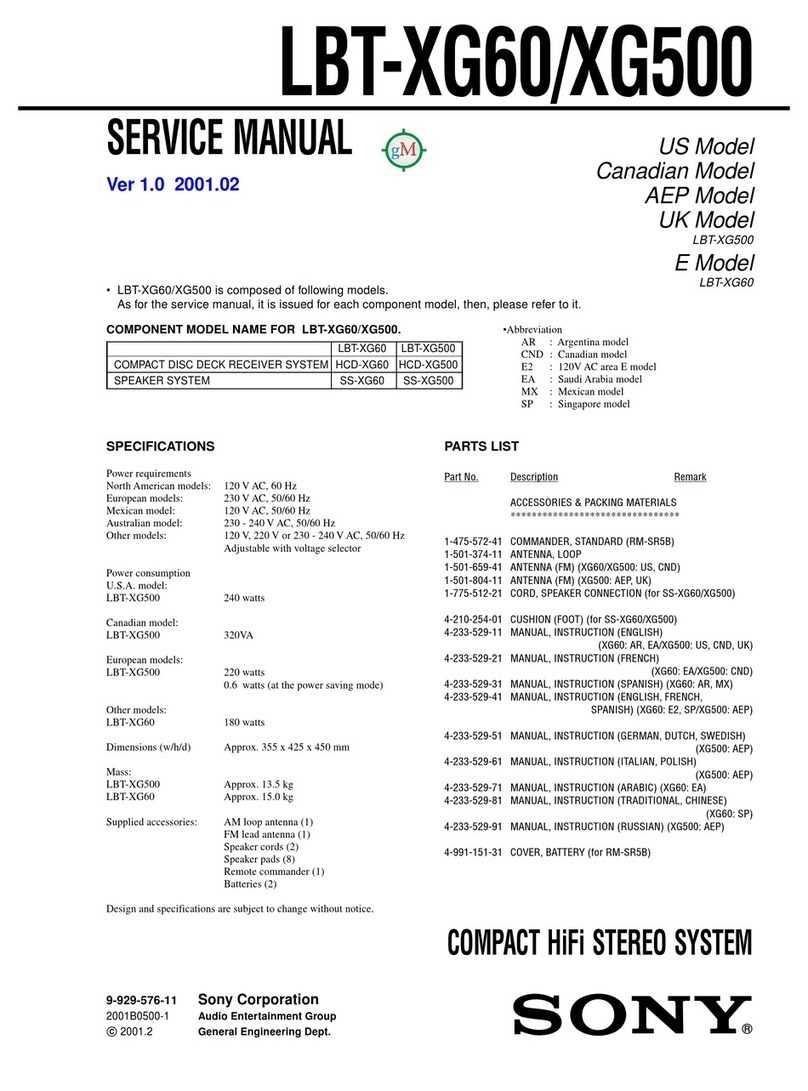

Power requirements

North American model: 120 V AC, 60 Hz

European model: 230 V AC, 50/60 Hz

Other models: 110 - 120 V or 220 -

240 V AC , 50/60 Hz

Adjustable with voltage

selector

Power consumption

European model 70 W

0.4 W (at the power

saving mode)

Other models: 70 W

Dimensions (w/h/d) Approx. 225 ×273 ×

385 mm incl. projecting

parts and controls

Mass Approx. 7.3 kg

AM tuner section

Tuning range

North American model: 530 - 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 - 1,710 kHz

(with the tuning interval

set at 9 kHz)

European model: 531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 - 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

Antenna AM loop antenna, external

antenna terminal

Intermediate frequency 450 kHz

•Design and specifications are subject to change without notice.

1. SERVICING NOTES························································· 4

2. GENERAL············································································ 5

3. DISASSEMBLY·································································· 7

3-1. Cover (Upper) ································································· 8

3-2. Front Panel Section························································· 8

3-3. Tape Mechanism Deck-1 ················································ 9

3-4. Tape Mechanism Deck-2 ················································ 9

3-5. LED Board, CONTROL Board ···································· 10

3-6. Back Panel SubAssy, JACK Board ······························ 10

3-7. MAIN Board ································································· 11

3-8. POWER Board······························································ 11

3-9. CD Mechanism Deck (CDM63K-K6BD44) ················ 12

3-10.CD Board ······································································ 12

3-11.Base Unit (BU-K6BD44) ············································· 13

3-12.Tray Assy ······································································ 13

3-13.Silder (Loading)···························································· 14

3-14.TRAY SENSOR Board, MOTOR Board······················ 14

3-15.IN OUT SW Board ······················································· 15

3-16.Stocker Assy ································································· 15

3-17.CD Base Unit Assy, DISC SENSOR Board ················· 16

4.TEST MODE······································································ 17

5. ELECTRICAL ADJUSTMENTS································· 18

6. DIAGRAMS ······································································· 20

6-1. Note For Printed Wiring BoardsAnd Schematic

Diagrams······································································· 20

6-2. Block Diagrams ···························································· 21

6-3. Circuit Boards Location················································ 23

6-4. Printed Wiring Board – CD Board – ··························· 24

6-5. Schematic Diagram - CD Board -································· 25

6-6. Printed Wiring Board – TC Board – ····························· 26

6-7. Schematic Diagram – TC Board –································ 27

6-8. Printed Wiring Board – MAIN Board – ······················· 28

6-9. Schematic Diagram – MAIN Board (1/3) – ················· 29

6-10.Schematic Diagram – MAIN Board (2/3) – ················· 30

6-11.Schematic Diagram – MAIN Board (3/3) – ················· 31

6-12.Printed Wiring Board – CONTROL Section – ············· 32

6-13.Schematic Diagram – CONTROL Section – ················ 33

6-14.Printed Wiring Board – DRIVER Section – ················· 34

6-15.Schematic Diagram – DRIVER Section –···················· 35

6-16.Printed Wiring Board – POWER Board – ···················· 36

6-17.Schematic Diagram – POWER Board – ······················· 37

6-18.Printed Wiring Board – LCD Section – ························ 38

6-19.Schematic Diagram – LCD Section –··························· 38

6-20.IC Pin Function Description ·········································39

6-21.IC Block Diagrams ······················································· 41

7. EXPLODEDVIEWS························································ 44

7-1. Cover Section································································ 44

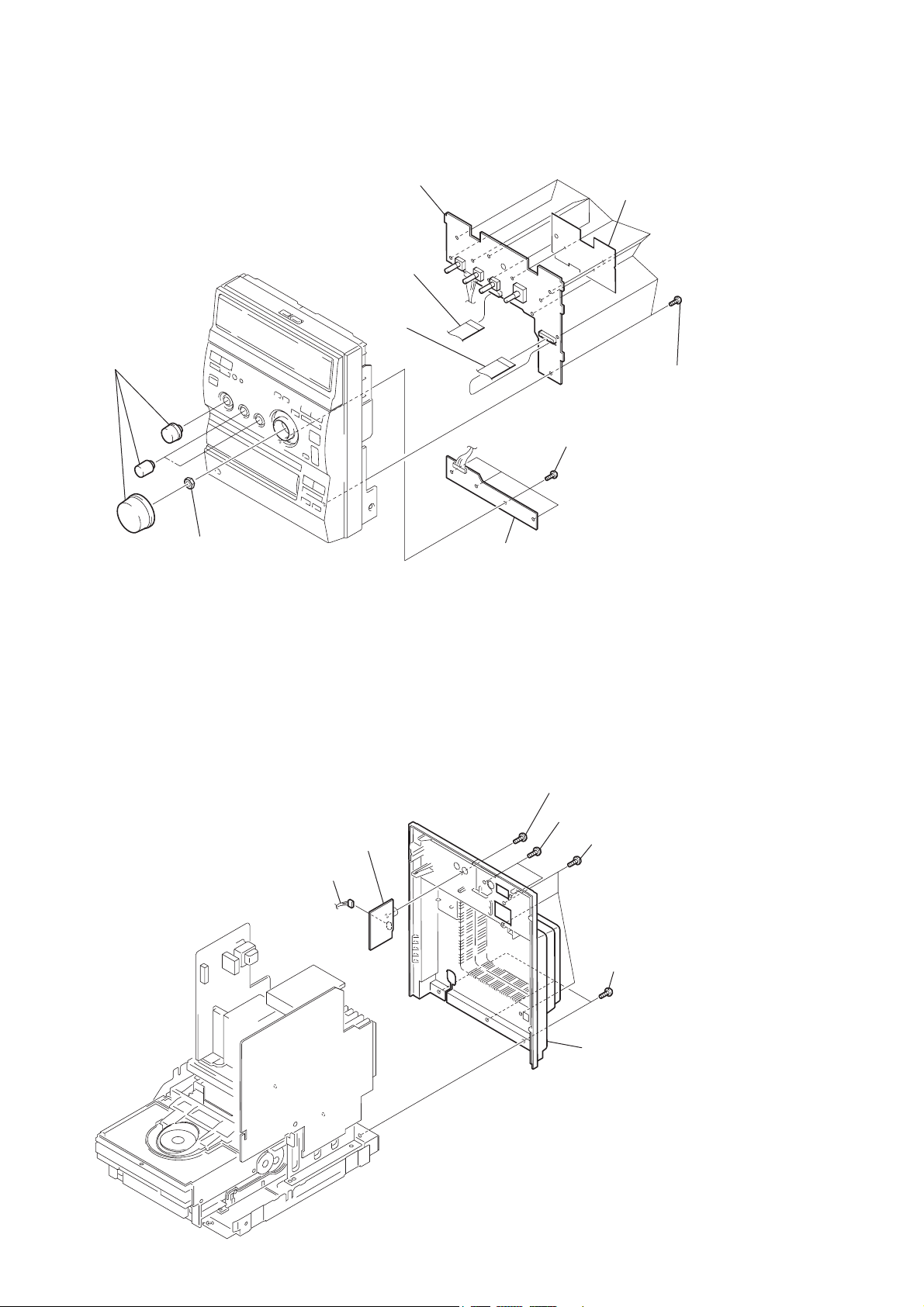

7-2. Front Panel Section······················································· 45

7-3. Chassis Section ····························································· 46

7-4. CD Mechanism Deck-1 ················································ 47

7-5. CD Mechanism Deck-2 ················································ 48

7-6. KSM-213D ··································································· 49

8. ELECTRICAL PARTS LIST········································· 50

Ver 1.1 2003.11