4

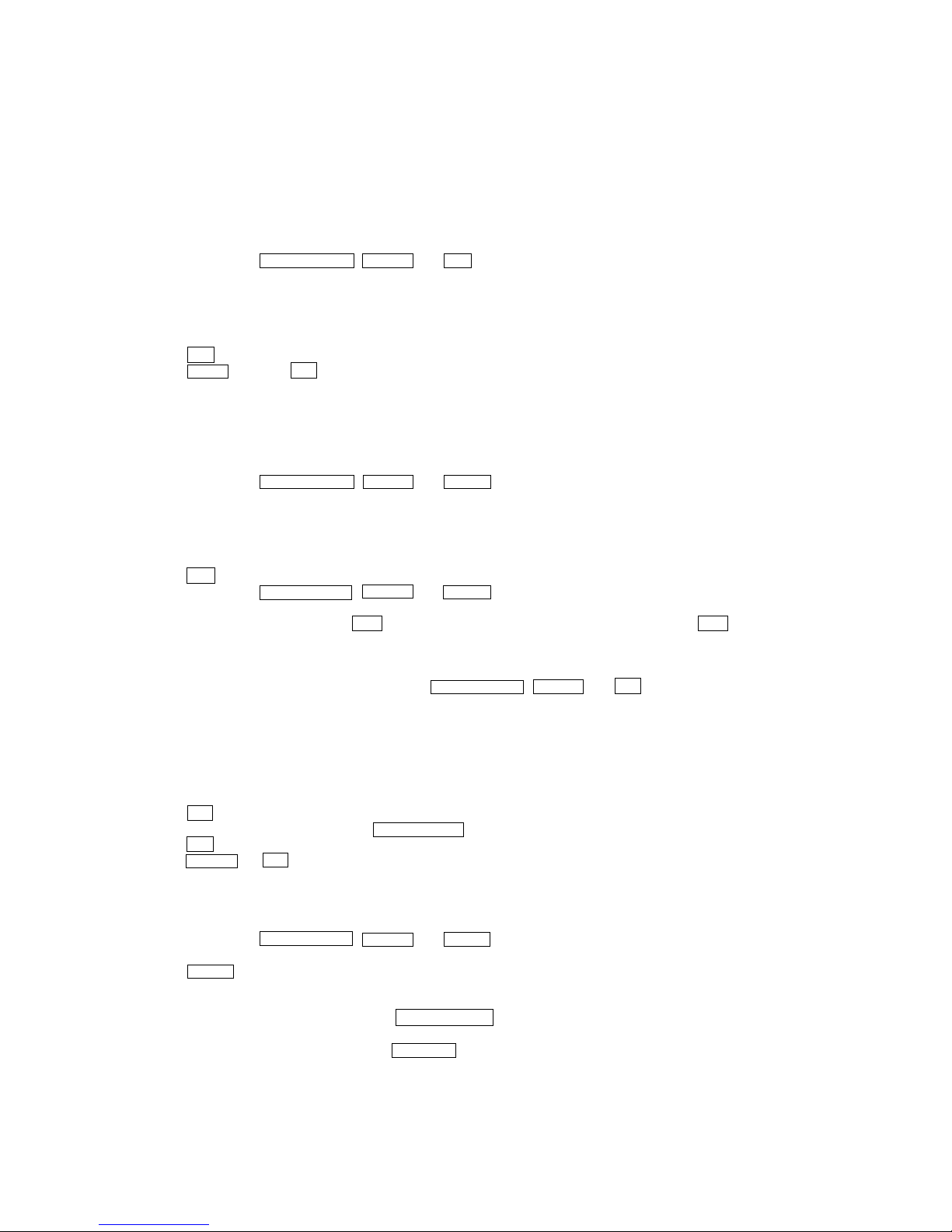

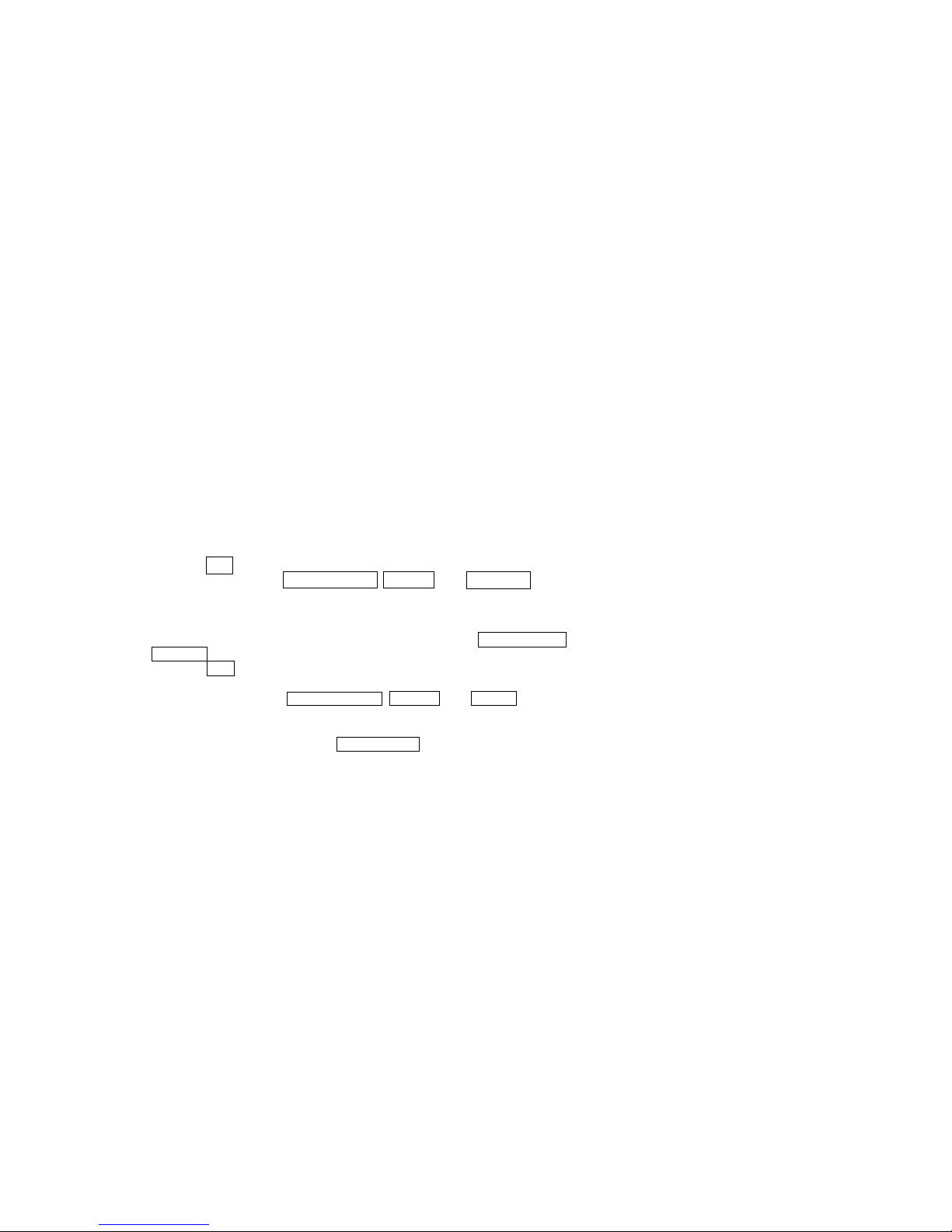

8. EXPLODEDVIEWS

8-1. Case and Back Panel Section .............................................. 66

8-2. Front Panel Section 1 .......................................................... 67

8-3. Front Panel Section 2 .......................................................... 68

8-4. Chassis Section ................................................................... 69

8-5. TC Mechanism Section 1 (TCM230PWR12) ..................... 70

8-6. TC Mechanism Section 2 (TCM230PWR12) ..................... 71

8-7. CD Mechanism Section (CDM37L-5BD34L) .................... 72

8-8. Base Unit Section (BU-5BD34L) ....................................... 73

9. ELECTRICAL PARTS LIST ........................................ 74

1. SERVICING NOTE .......................................................... 5

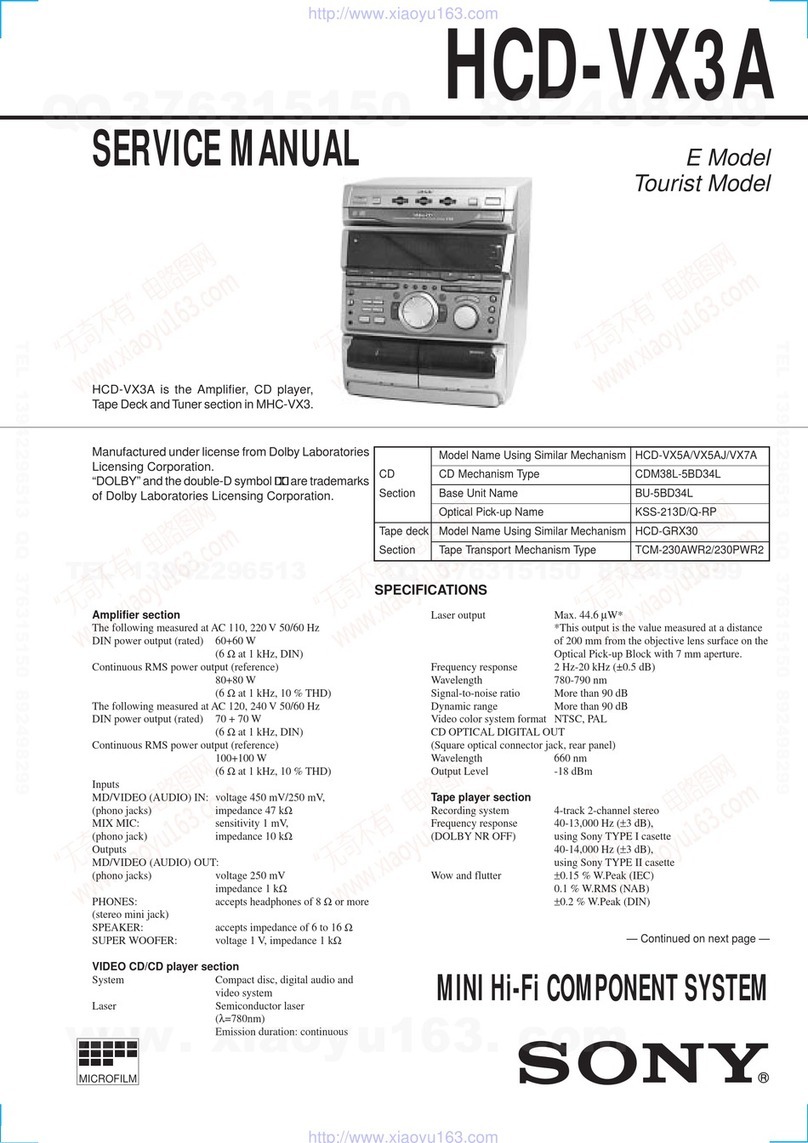

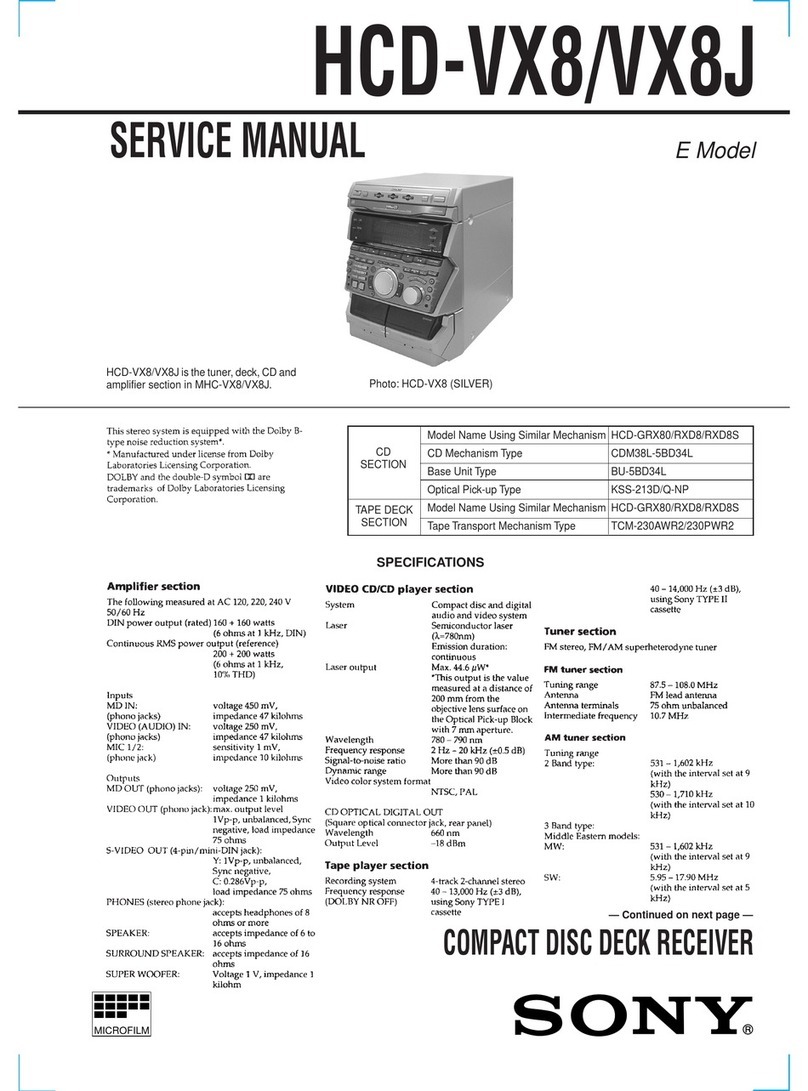

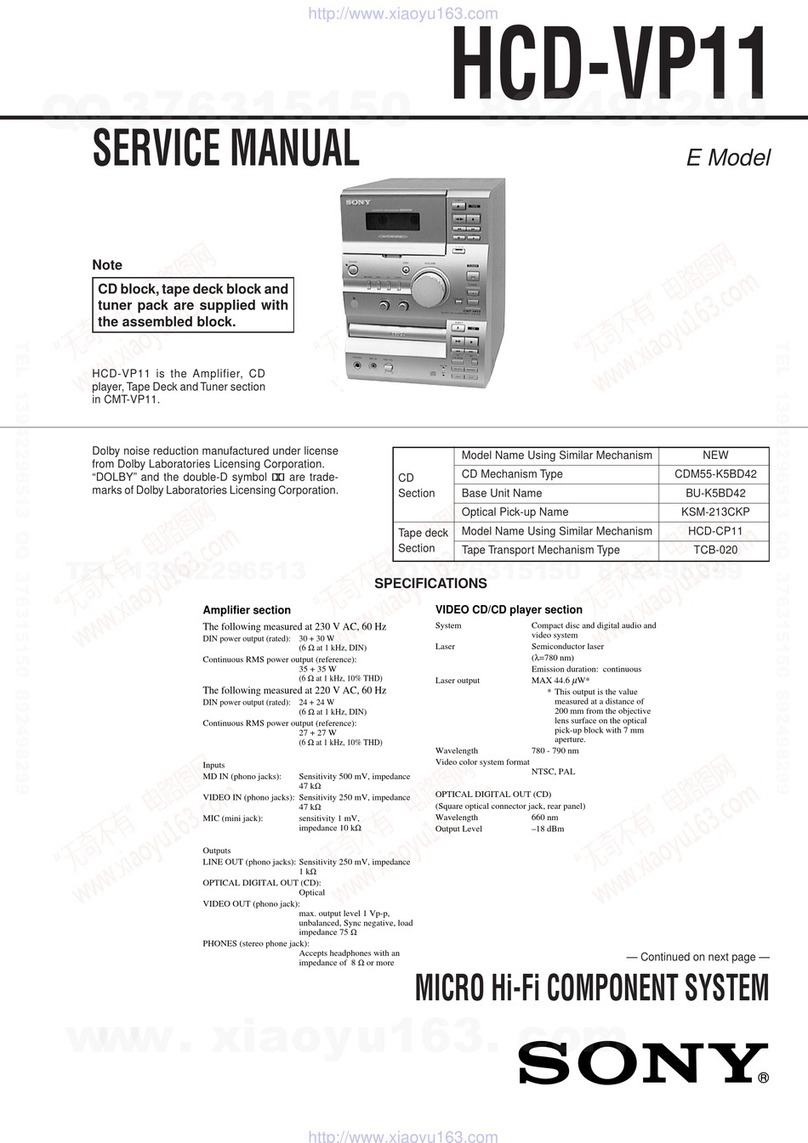

2. GENERAL ....................................................................9

3. DISASSEMBLY

3-1. Front Panel and Video Board .............................................. 11

3-2. Main Board ......................................................................... 11

3-3. Sub Panel ............................................................................ 12

3-4. CD LID Assembly .............................................................. 12

3-5. Tape Mechanism Deck and Cassette LID ........................... 12

3-6. CD Mechanism Deck .......................................................... 13

3-7. Base Unit............................................................................. 13

3-8. Disc Table ........................................................................... 13

4.TEST MODE ..............................................................14

5. MECHANICAL ADJUSTMENTS ..........................15

6. ELECTRICAL ADJUSTMENTS ............................... 15

7. DIAGRAMS

7-1. Circuit Boards Location ...................................................... 19

7-2. Block Diagrams

•BD Section ....................................................................... 20

•Deck Section .................................................................... 21

•Main (1/2) Section ........................................................... 22

•Main (2/2) Section ........................................................... 23

•Video Section ................................................................... 24

•Power Section .................................................................. 25

•Display Section ................................................................ 26

7-3. Printed Wiring Board –BD Section –................................. 28

7-4. Schematic Diagram –BD Section –................................... 29

7-5. Schematic Diagram –Deck Section –................................. 30

7-6. Printed Wiring Board –Deck Section –.............................. 31

7-7. Printed Wiring Board –Video Section –............................. 32

7-8. Schematic Diagram –Video (1/3) Section –....................... 33

7-9. Schematic Diagram –Video (2/3) Section –....................... 34

7-10. Schematic Diagram –Video (3/3) Section –..................... 35

7-11. Printed Wiring Board –Main Section –............................ 36

7-12. Schematic Diagram –Main (1/3) Section –...................... 37

7-13. Schematic Diagram –Main (2/3) Section –...................... 38

7-14. Schematic Diagram –Main (3/3) Section –...................... 39

7-15. Printed Wiring Board –Power Section –......................... 40

7-16. Schematic Diagram –Power Section –............................ 41

7-17. Printed Wiring Board –Panel FL Section –..................... 42

7-18. Schematic Diagram –Panel FL Section –........................ 43

7-19. Printed Wiring Board –Panel VR Section –.................... 44

7-20. Schematic Diagram –Panel VR Section –....................... 45

7-21. Printed Wiring Board –TC Panel Section –..................... 46

7-22. Schematic Diagram –TC Panel Section –....................... 47

7-23. Printed Wiring Board –CD Panel Section –.................... 48

7-24. Schematic Diagram –CD Panel Section –....................... 49

7-25. Printed Wiring Board –CD Motor Section –................... 50

7-26. Schematic Diagram –CD Motor Section –...................... 51

7-27. Schematic Diagram –Trans Section –............................. 52

7-28. Printed Wiring Board –Trans Section –........................... 53

7-29. Schematic Diagram –Leaf SW Section –........................ 53

7-30. Printed Wiring Board –Leaf SW Section –..................... 53

7-31. IC Block Diagrams ........................................................... 54

7-32. IC Pin Functions ............................................................... 56

TABLE OF CONTENTS