5

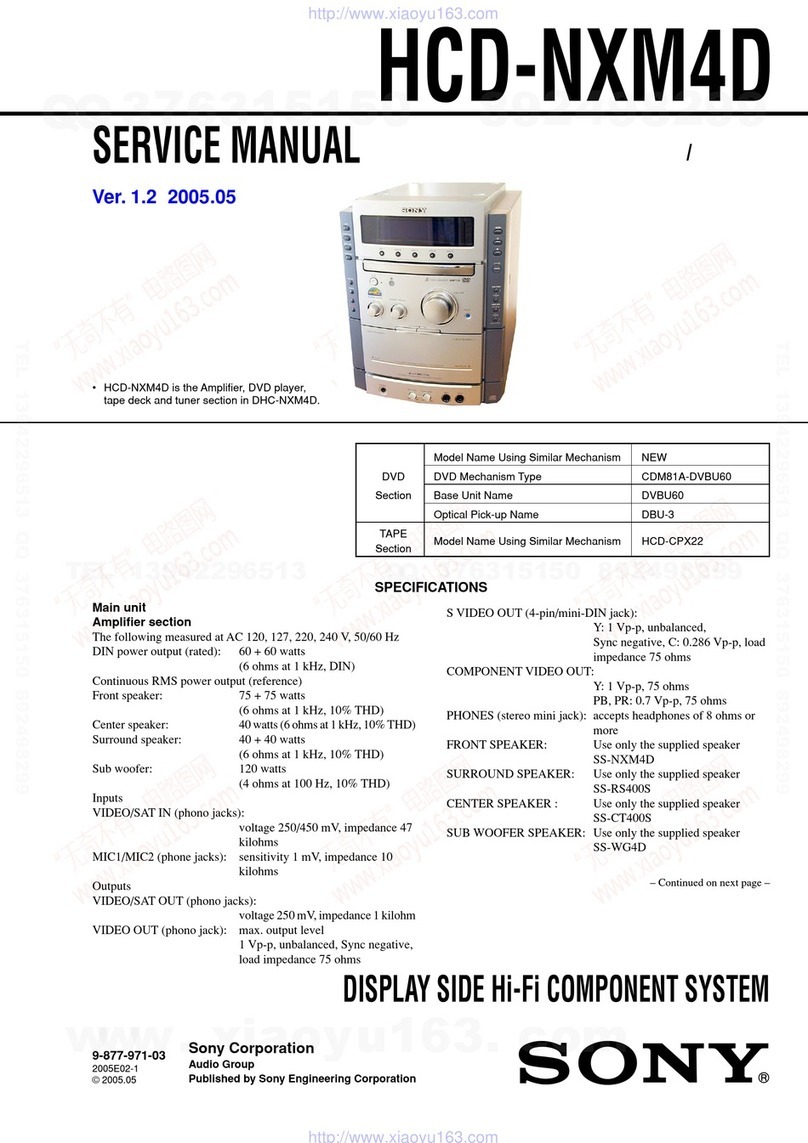

TABLE OF CONTENTS

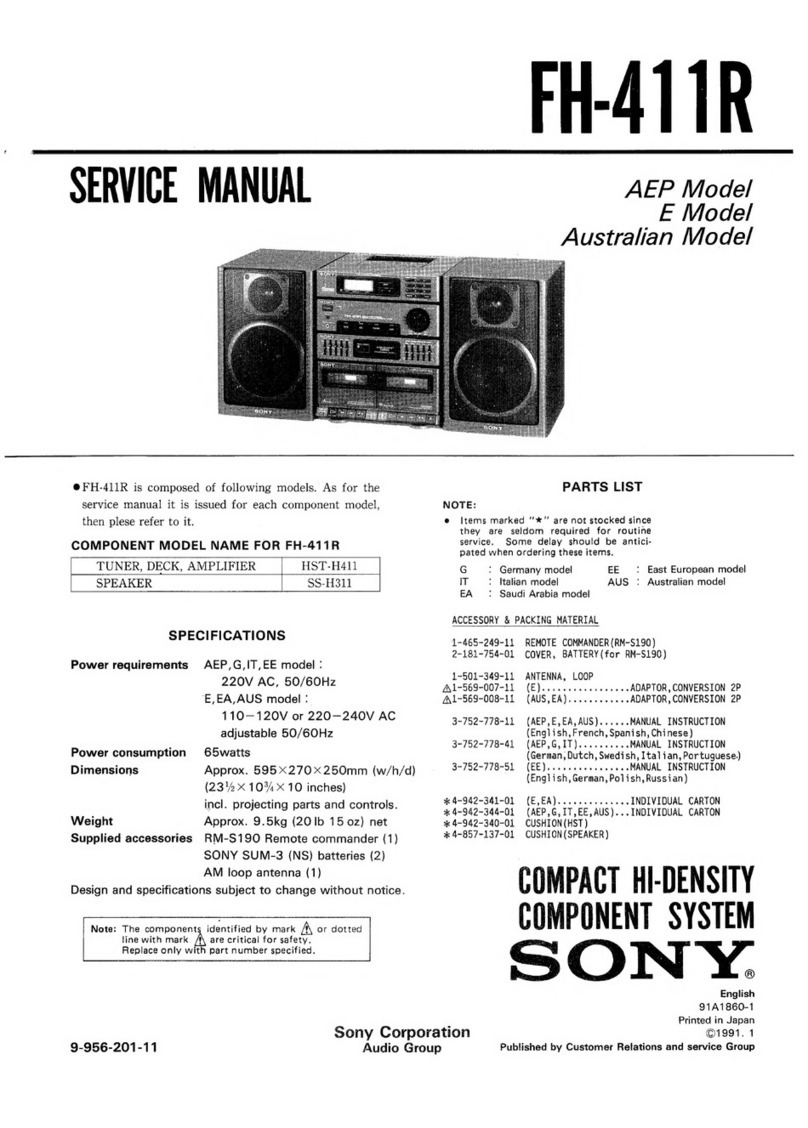

1. SERVICE NOTE

1-1. Service Position of CD Mechanism Deck........................... 6

1-2. Service Position of Amp Board........................................... 6

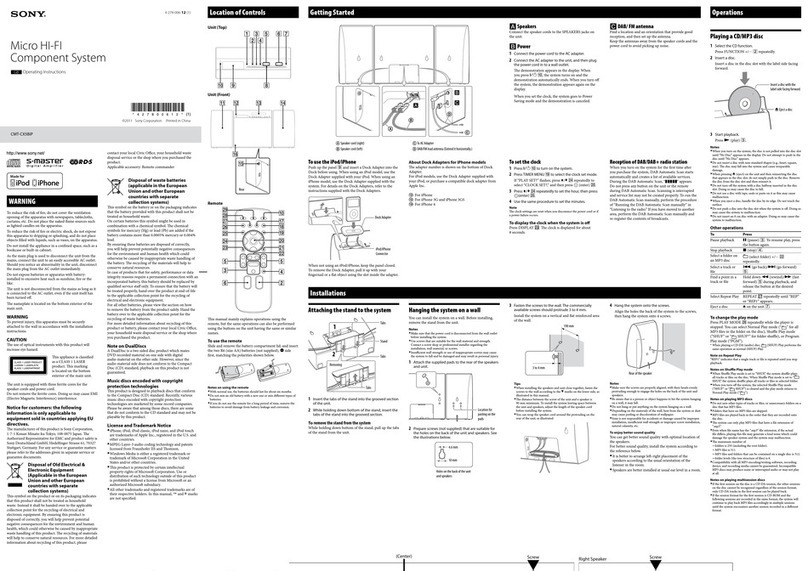

2. GENERAL

List of Button Locations and Reference Pages........................ 7

3. DISASSEMBLY

3-1. Case (Top) ......................................................................... 10

3-2. CD Door ............................................................................ 10

3-3. Front Panel Section ........................................................... 11

3-4. CD Mechanism Deck ........................................................ 11

3-5. Tape Mechanism Deck, Mic Board ................................... 12

3-6. Panel Board ....................................................................... 12

3-7. Back Panel Section, Sub Trans Board............................... 13

3-8. Trans Board ....................................................................... 13

3-9. Main Board ....................................................................... 14

3-10. Amp Board ........................................................................ 14

3-11. BD49 Board ...................................................................... 15

3-12. VCD Connect Board, VMP43GY Board .......................... 15

3-13. Driver Board, SW Board ................................................... 16

3-14. Optical Pick-up ................................................................. 16

3-15. Sensor Board ..................................................................... 17

3-16. Motor (TB) Board ............................................................. 17

3-17. Motor (LD) Board .............................................................18

4. TEST MODE ..................................................................... 19

5. ELECTRICAL ADJUSTMENTS................................. 23

6. DIAGRAMS

6-1. Circuit Boards Location .................................................... 25

6-2. Printed Wiring Board –CD Mechanism Section (1/2)– .... 28

6-3. Schematic Diagram –CD Mechanism Section (1/2)– ....... 29

6-4. Printed Wiring Boards –CD Mechanism Section (2/2)–... 30

6-5. Schematic Diagram –CD Mechanism Section (2/2)– ....... 31

6-6. Printed Wiring Board –VCD Connect Section–................ 32

6-7. Schematic Diagram –VCD Connect Section– .................. 32

6-8. Printed Wiring Board –VMP Section–.............................. 33

6-9. Schematic Diagram –VMP Section (1/2)–........................ 34

6-10. Schematic Diagram –VMP Section (2/2)–........................ 35

6-11. Schematic Diagram –Main Section (1/2)– ........................ 36

6-12. Schematic Diagram –Main Section (2/2)– ........................ 37

6-13. Printed Wiring Board –Main Section– ..............................38

6-14. Printed Wiring Boards –Panel Section– ............................ 39

6-15. Schematic Diagram –Panel Section (1/2)– ....................... 40

6-16. Schematic Diagram –Panel Section (2/2)– ....................... 41

6-17. Printed Wiring Boards –Jack Section–.............................. 42

6-18. Schematic Diagram –Jack Section– ..................................43

6-19. Printed Wiring Board

–Power Section (1/2) (HCD-RV22)– ................................ 44

6-20. Printed Wiring Boards

–Power Section (2/2) (HCD-RV22)– ................................ 45

6-21. Schematic Diagram –Power Section (HCD-RV22)– ........ 46

6-22. Schematic Diagram –Power Section (HCD-RV55)– ........ 47

6-23. Printed Wiring Board

–Power Section (1/2) (HCD-RV55)– ................................ 48

6-24. Printed Wiring Boards

–Power Section (2/2) (HCD-RV55)– ................................ 49

6-25. IC Block Diagrams............................................................ 50

7. EXPLODED VIEWS

7-1. Main Section ..................................................................... 60

7-2. Front Panel Section (1)...................................................... 61

7-3. Front Panel Section (2)...................................................... 62

7-4. Front Panel Section (3)...................................................... 63

7-5. Main Board Section .......................................................... 64

7-6. CD Mechanism Deck Section (1) ..................................... 65

7-7. CD Mechanism Deck Section (2) ..................................... 66

7-8. CD Mechanism Deck Section (3) ..................................... 67

7-9. Base Unit Section .............................................................. 68

8. ELECTRICAL PARTS LIST ........................................ 69

HCD-RV22/RV55