– 2 –

TABLE OF CONTENTS

1. SERVICING NOTES.............................................. 3

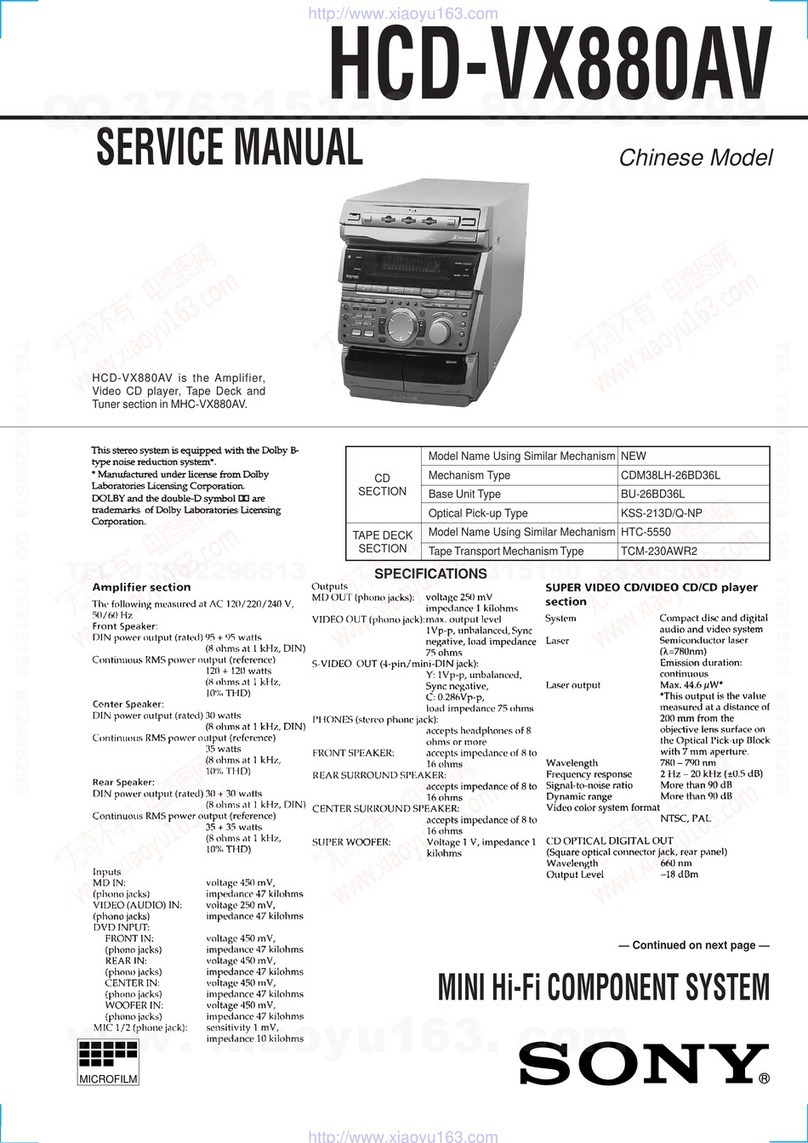

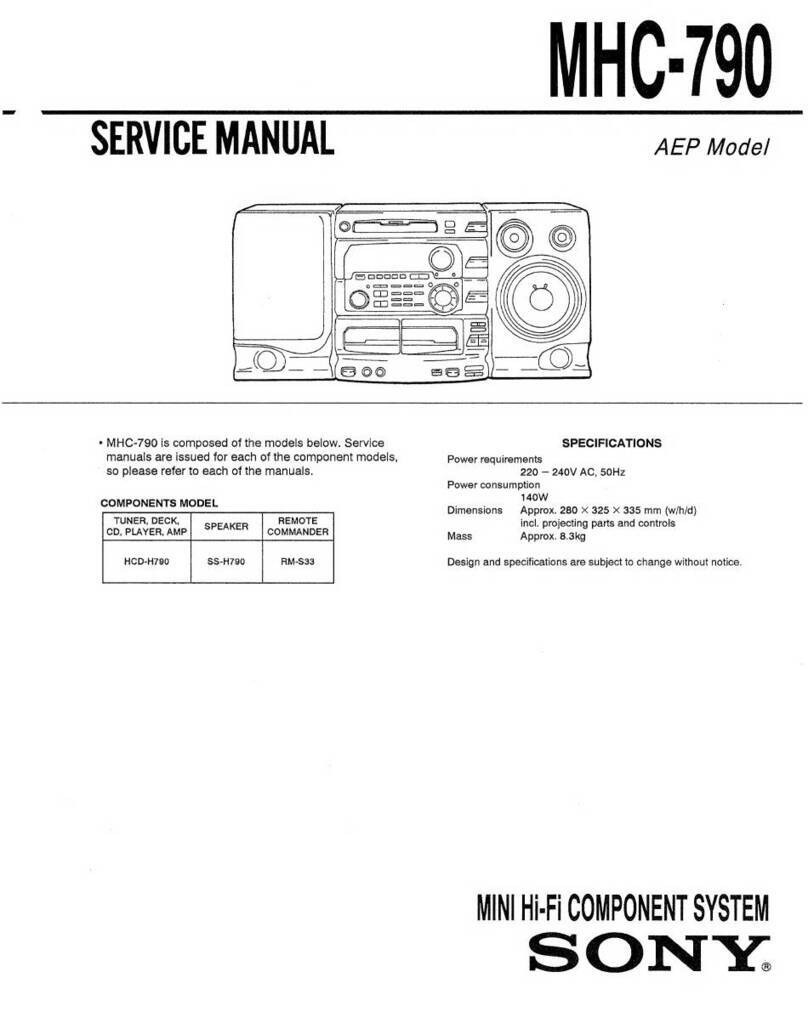

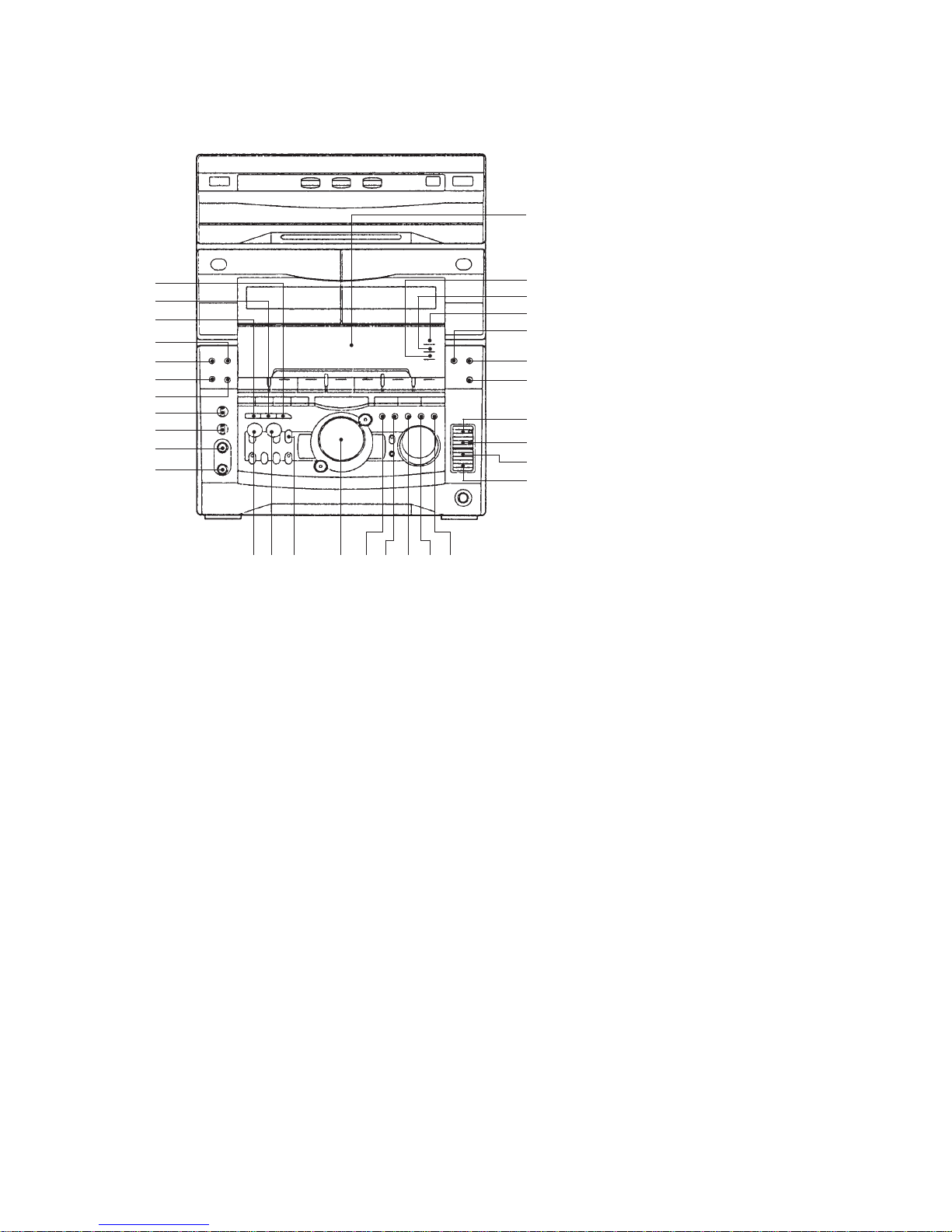

2. GENERAL .................................................................. 6

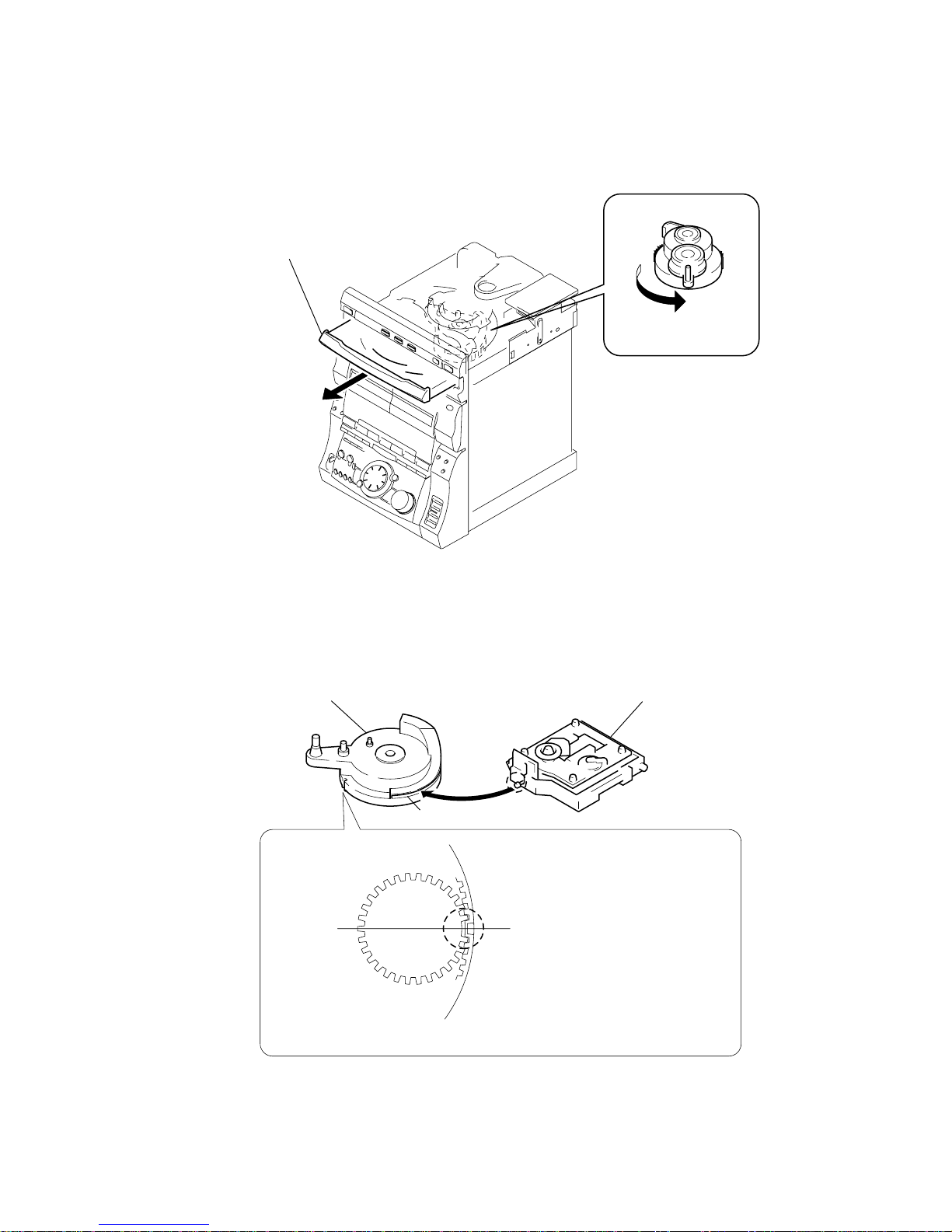

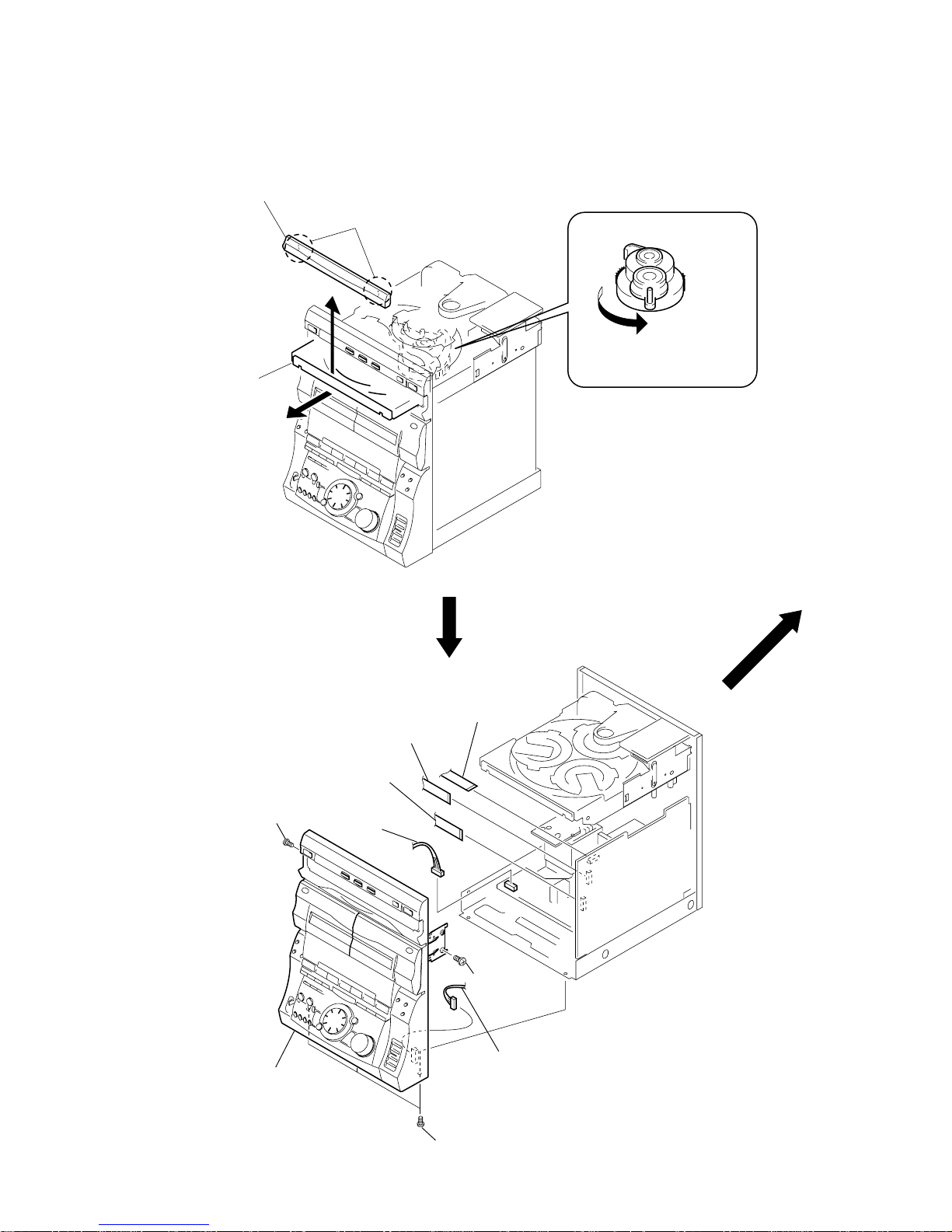

3. DISASSEMBLY ........................................................ 10

4. TEST MODE............................................................. 13

5. MECHANICAL ADJUSTMENTS...................... 16

6. ELECTRICAL ADJUSTMENTS

DECK Section................................................................ 16

CD Section ..................................................................... 19

VIDEO Section .............................................................. 21

7. DIAGRAMS

7-1. Block Diagram – SERVO Section –............................. 23

7-2. Block Diagram – AUDIO/VIDEO CD Section – ........ 25

7-3. Block Diagram – TAPE DECK Section – .................... 27

7-4. Block Diagram – MAIN Section (1/2) –...................... 29

7-5. Block Diagram – MAIN Section (2/2) –...................... 31

7-6. Block Diagram – DISPLAY/KEY CONTROL/

POWER SUPPLY Section – .......................................... 33

7-7. Note for Printed Wiring Boards and

Schematic Diagrams ...................................................... 36

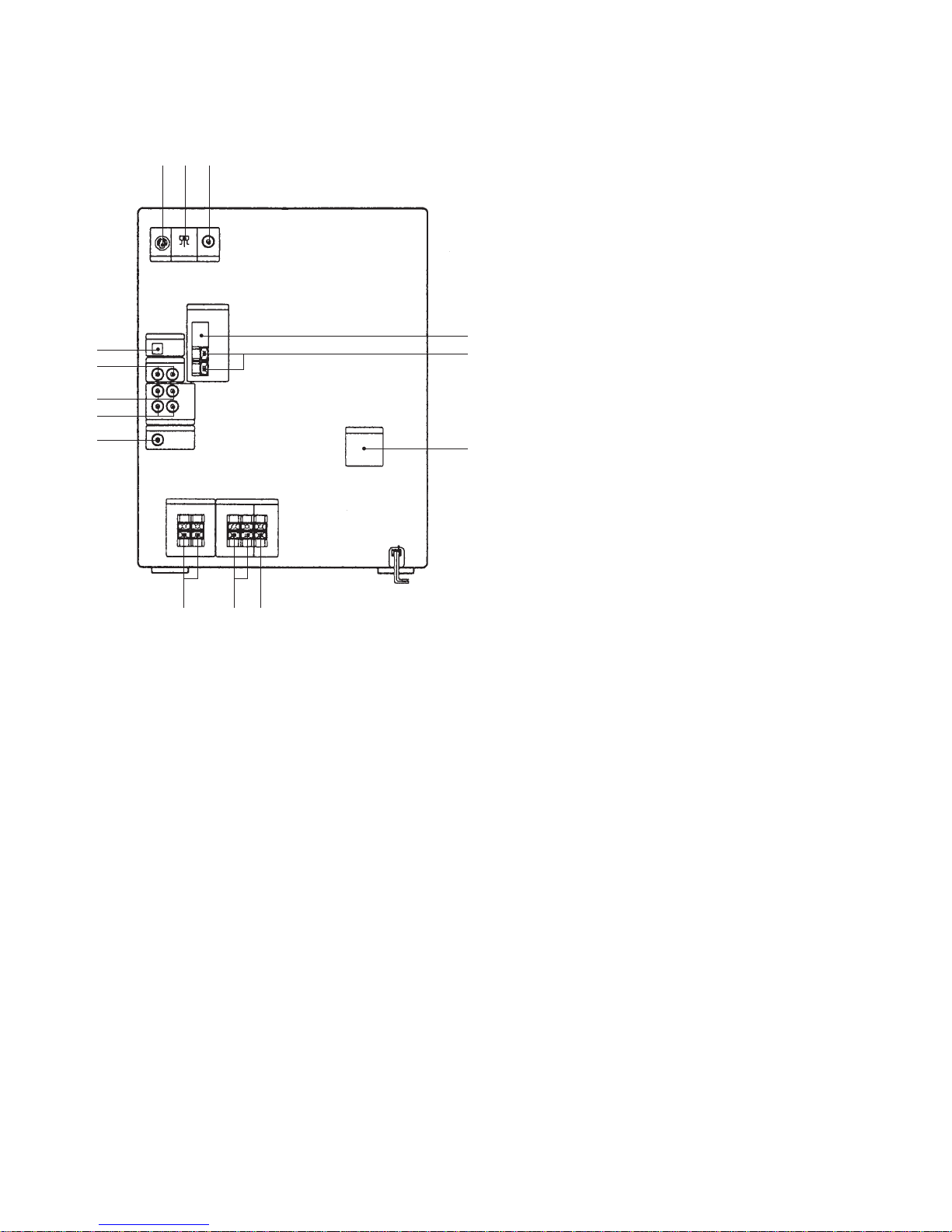

7-8. Printed Wiring Board – BD Section – .......................... 37

7-9. Schematic Diagram – BD Section –............................ 39

7-10. Printed Wiring Board – VIDEO Section – ................... 41

7-11. Schematic Diagram – VIDEO Section (1/2) – ............ 43

7-12. Schematic Diagram – VIDEO Section (2/2) –............ 45

7-13. Printed Wiring Boards – CD MOTOR Section –......... 47

7-14. Schematic Diagram – CD MOTOR Section – ............ 49

7-15. Printed Wiring Board – TAPE DECK Section –.......... 51

7-16. Schematic Diagram – TAPE DECK Section –............ 53

7-17. Printed Wiring Board – LEAF SW Section – .............. 55

7-18. Schematic Diagram – LEAF SW Section – ................ 55

7-19. Printed Wiring Board – MAIN Section –..................... 57

7-20. Schematic Diagram – MAIN Section (1/4) –.............. 59

7-21. Schematic Diagram – MAIN Section (2/4) –............... 61

7-22. Schematic Diagram – MAIN Section (3/4) –............... 63

7-23. Schematic Diagram – MAIN Section (4/4) –............... 65

7-24. Printed Wiring Board – PANEL Section – ................... 67

7-25. Schematic Diagram – PANEL Section – ...................... 69

7-26. Printed Wiring Boards – DISPLAY Section – ............. 71

7-27. Schematic Diagram – DISPLAY Section –................. 73

7-28. Schematic Diagram

– MIC/HEADPHONE Section – ................................... 75

7-29. Printed Wiring Boards

– MIC/HEADPHONE Section – ................................... 76

7-30. Printed Wiring Board – POWER AMP Section – ........ 77

7-31. Schematic Diagram – POWER AMP Section – ........... 79

7-32. Schematic Diagram

– TRANSFORMER Section –....................................... 81

7-33. Printed Wiring Board

– TRANSFORMER Section –....................................... 83

7-34. Printed Wiring Board – SURROUND Section – ......... 84

7-35. Schematic Diagram – SURROUND Section – ............ 85

7-36. IC Pin Function Description .......................................... 94

8. EXPLODED VIEWS............................................... 106

9. ELECTRICAL PARTS LIST .............................. 114