4

TABLE OF CONTENTS

6-15. Schematic Diagram Deck Section ································ 40

6-16. Printed Wiring Board Deck Section ·····························41

6-17. Printed Wiring Board Power Section ··························· 42

6-18. Schematic Diagram Power (1/2) Section ····················· 43

6-19. Schematic Diagram Power (2/2) Section ····················· 44

6-20. Schematic Diagram Surround Section ························· 45

6-21. Printed Wiring Board Surround Section······················· 45

6-22. Schematic Diagram FL Section···································· 46

6-23. Printed Wiring Board FL Section ·································47

6-24. Schematic Diagram Panel VR Section ························· 48

6-25. Printed Wiring Board Panel VR Section ······················ 49

6-26. Schematic Diagram TC Panel Section ························· 50

6-27. Printed Wiring Board TC Panel Section······················· 51

6-28. Schematic Diagram CD Panel Section ························· 52

6-29. Printed Wiring Board CD Panel Section ······················ 53

6-30. Schematic Diagram CD Motor Section ························ 54

6-31. Printed Wiring Board CD Motor Section ····················· 55

6-32. Schematic Diagram Jack Section ································· 56

6-33. Printed Wiring Board Jack Section ······························ 57

6-34. Schematic Diagram Trans Section ······························· 58

6-35. Printed Wiring Board Trans Section····························· 59

6-36. Schematic Diagram Leaf SW Section ·························· 59

6-37. Printed Wiring Board Leaf SW Section ······················· 59

6-38. IC Block Diagrams ··························································· 60

6-39. IC Pin Functions ······························································· 61

7. EXPLODEDVIEWS

7-1. Case and Back Panel Section ··········································· 69

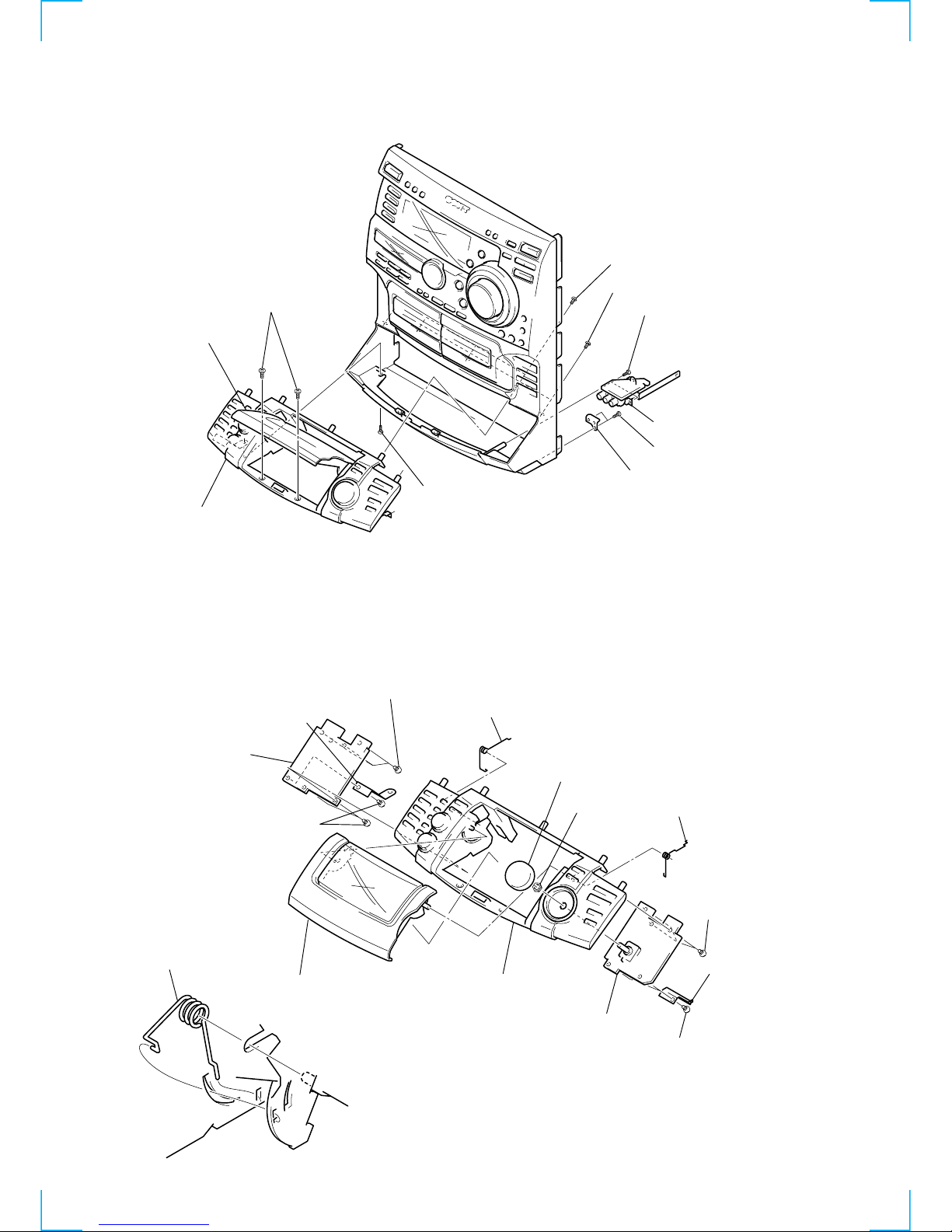

7-2. Front Panel Section 1 ······················································· 70

7-3. Front Panel Section 2 ······················································· 71

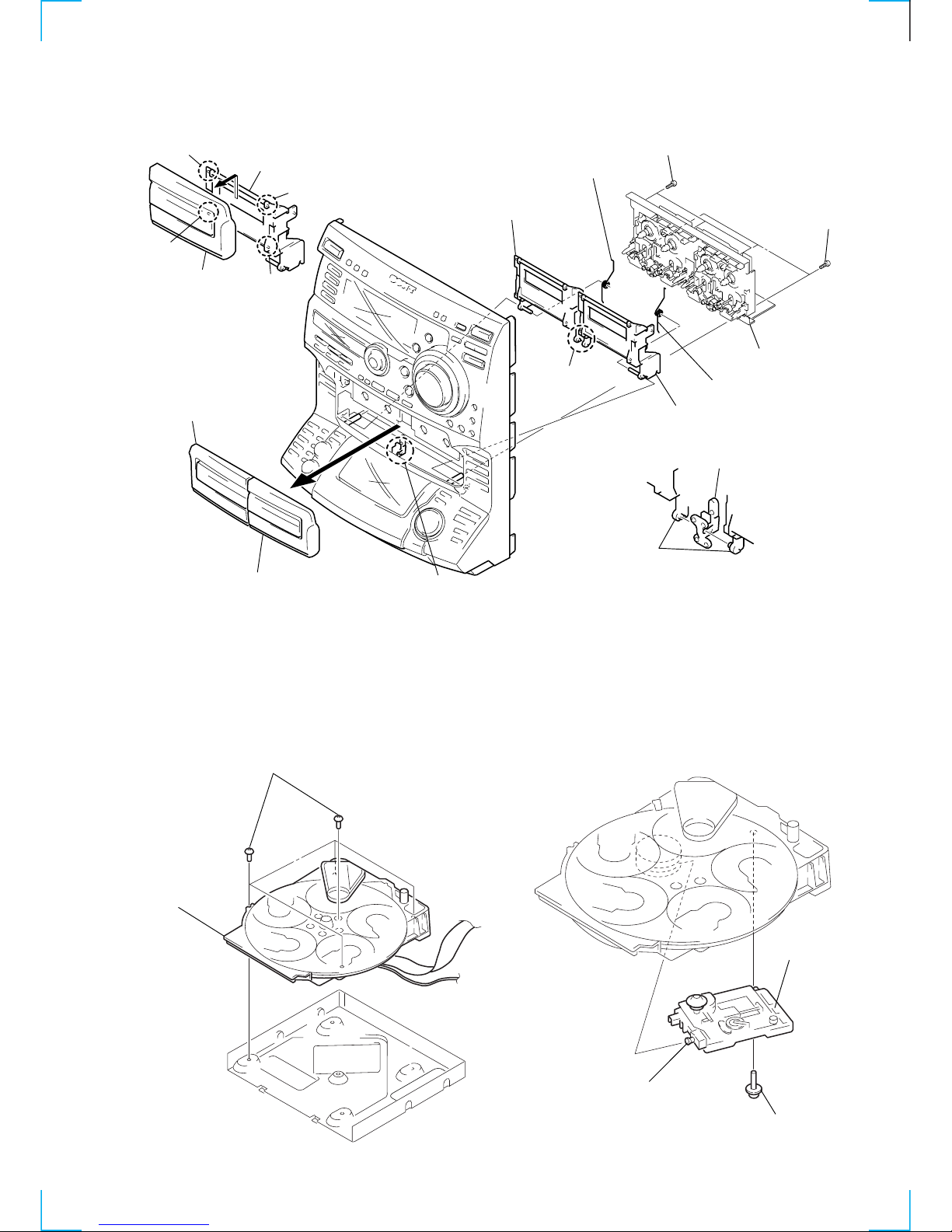

7-4. Chassis Section ································································· 72

7-5. TC Mechanism Section 1 (TCM230AWR2/230PWR2) ·· 73

7-6. TC Mechanism Section 2 (TCM230AWR2/230PWR2) ·· 74

7-7. CD Mechanism Section (CDM37M-5BD32L) ················ 75

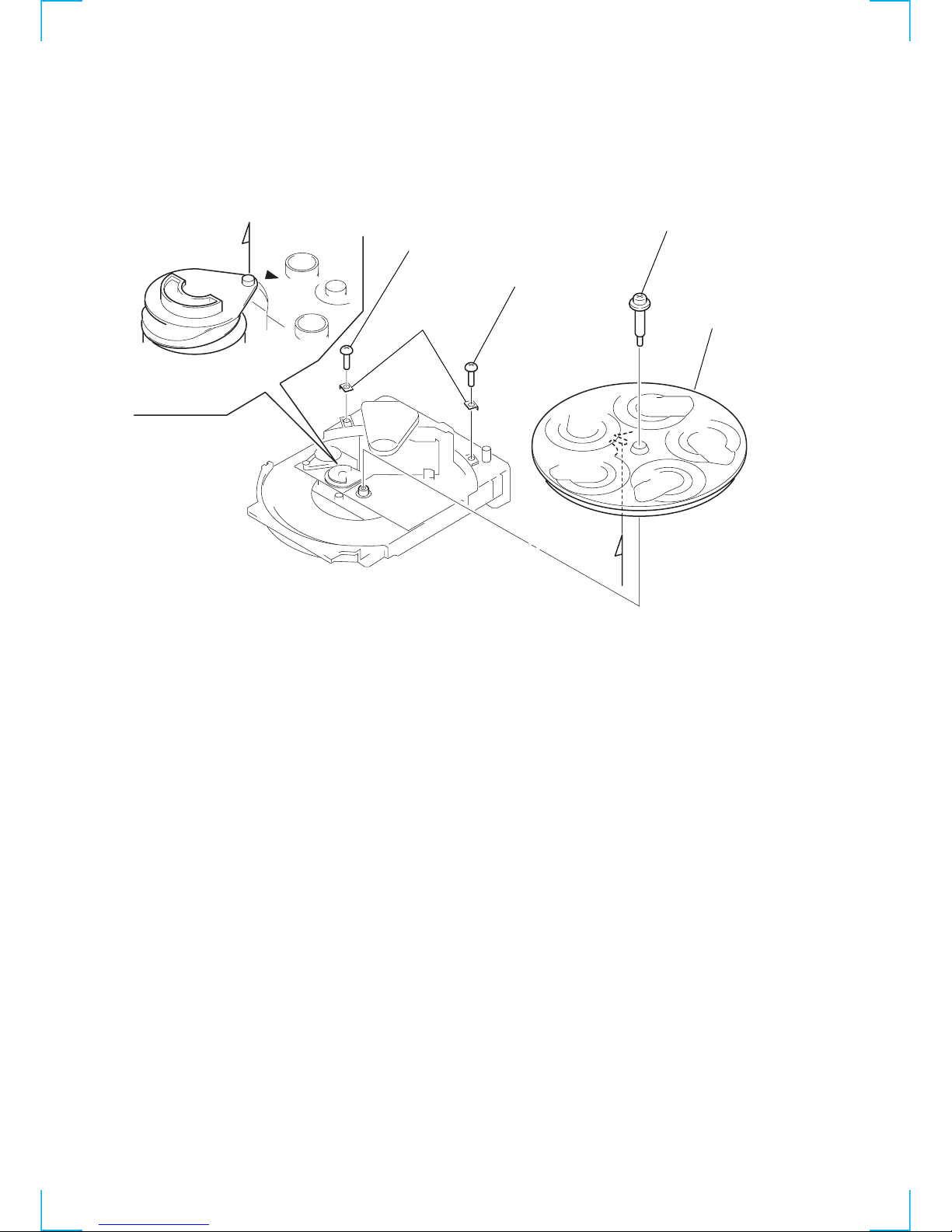

7-8. Base Unit Section (BU-5BD32L)····································· 76

8. ELECTRICAL PARTS LIST······································· 77

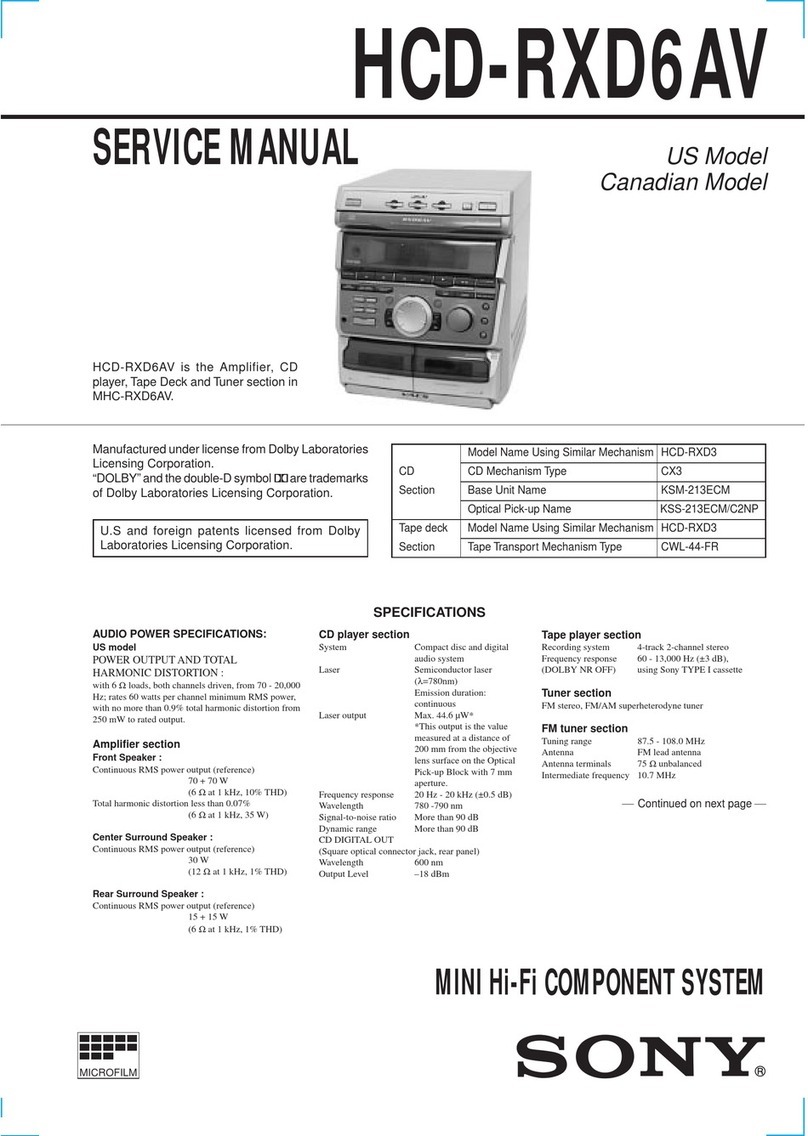

1. GENERAL ·········································································· 5

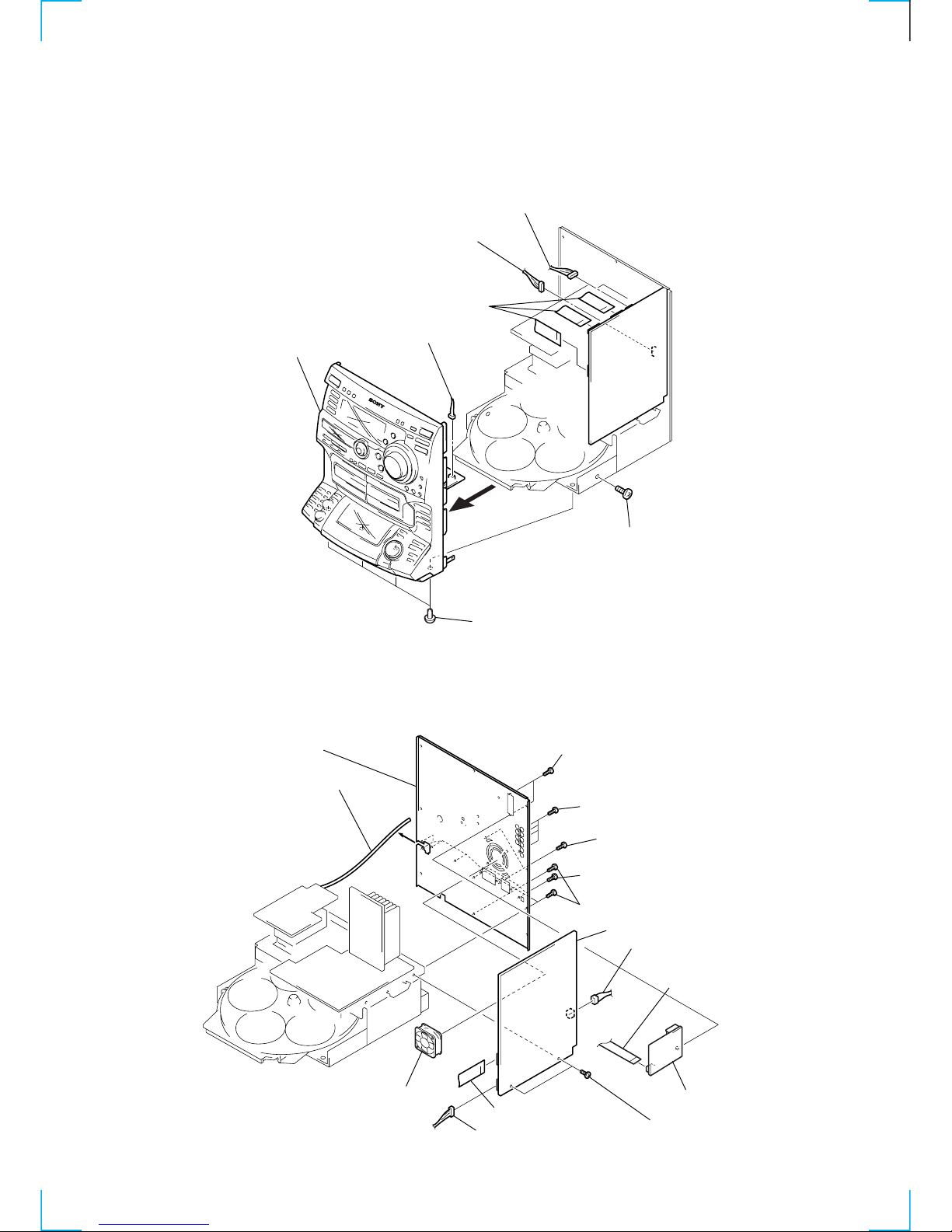

2. DISASSEMBLY

2-1. Front Panel ········································································· 7

2-2. Main Board ········································································· 7

2-3. Sub Panel ············································································ 8

2-4. CD-L/CD-R Board and CD Lid Assembly························· 8

2-5. Tape Mechanism Deck and Cassette Lid····························9

2-6. CD Mechanism Deck ························································· 9

2-7. Base Unit ············································································ 9

2-8. Disc Table ········································································· 10

3. SERVICE MODE ···························································· 11

4. MECHANICAL ADJUSTMENTS ····························· 15

5. ELECTRICAL ADJUSTMENTS ······························· 15

6. DIAGRAMS

6-1. Circuit Boards Location ··················································· 19

6-2. Block Diagrams

BD Section ······································································· 20

Video Section ··································································· 21

Deck Section····································································· 22

Main (1/2) Section···························································· 23

Main (2/2) Section···························································· 24

Power Section ··································································· 25

Display Section································································· 26

6-3. Printed Wiring Board BD Section ································ 28

6-4. Schematic Diagram BD Section··································· 29

6-5. Printed Wiring Board Video Section ···························· 30

6-6. Schematic Diagram Video (1/3) Section ······················ 31

6-7. Schematic Diagram Video (2/3) Section ······················ 32

6-8. Schematic Diagram Video (3/3) Section ······················ 33

6-9. Printed Wiring Board Main Section ····························· 34

6-10. Schematic Diagram Main (1/5) Section ······················· 35

6-11. Schematic Diagram Main (2/5) Section ······················· 36

6-12. Schematic Diagram Main (3/5) Section ······················· 37

6-13. Schematic Diagram Main (4/5) Section ······················· 38

6-14. Schematic Diagram Main (5/5) Section ······················· 39