Sorotec COMPACT 0605 User manual

SOROTEC GmbH

Withig 12

77836 Rheinmünster

Tel.: +49 (0) 7227-994255-0

Fax: +49 (0) 7227-994255-9

E-Mail: [email protected]

Web: www.sorotec.de

Assembly instructions

CNC portal milling machine kit

Basic-Line

Version 2.3.3

MPF.BLxxxx.01.B

Page 1/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Technical specications

Basic-Line 0605 0607 1005 1007

Travel X: 650 mm

Y: 530 mm

Z: 140 mm

X: 650 mm

Y: 730 mm

Z: 140 mm

X: 1050 mm

Y: 530 mm

Z: 140 mm

X: 1050 mm

Y: 730 mm

Z: 140 mm

Clearance

under portal

180 mm 180 mm 180 mm 180 mm

Clamping area X: 840 mm

Y: 530 mm

X: 840 mm

Y: 730 mm

X: 1240 mm

Y: 530 mm

X: 1240 mm

Y: 730 mm

Outer dimensions L: 950 mm

B: 790 mm

H: 820 mm

L: 950 mm

B: 990 mm

H: 820 mm

L: 1350 mm

B: 790 mm

H: 820 mm

L: 1350 mm

B: 990 mm

H: 820 mm

Ball screw spindles

Tolerance class T07

X: 16 x 10 mm

Y: 16 x 10 mm

Z: 16 x 5 mm

X: 16 x 10 mm

Y: 16 x 10 mm

Z: 16 x 5 mm

X: 16 x 10 mm

Y: 16 x 10 mm

Z: 16 x 5 mm

X: 16 x 10 mm

Y: 16 x 10 mm

Z: 16 x 5 mm

Weight without

accessories

approx. 46 kg approx. 52 kg approx. 50 kg approx. 57 kg

© 2023 Sorotec GmbH

Reproduction, duplication or translation, also in extracts, without the written approval of

Sorotec GmbH is not permitted. All rights under the Copyright Act remain the

Sorotec GmbH expressly reserved.

Technical changes reserved.

Made in Germany.

Page 2/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Introduction

Congratulations on the purchase of our kit for a

Basic-Line CNC portal milling machine. We recom-

mend reading through these instructions completely

before assembly and then assembling the kit step by

step as described.

Required tools

The following tools and aids must or should be avai-

lable during assembly:

• Common hand tools, such as Allen keys,

screwdrivers, plastic hammers, etc.

• Work surface as at as possible in the size of

the base frame

• Flat or stop angle, at least

• 300 mm long in tolerance class 1 or better

• Dial indicator with stand / holder

• Torque wrench from 6 Nm up to

• at least 25 Nm1)

1) In order to avoid warping due to screws tightened

unevenly, the use of a torque wrench for load-bearing

screws M5 to M8 is recommended. By observing the

prescribed tightening torque also prevents unwanted

loosening during later operation of the machine.

Optional accessories

The fully assembled machine can be supplemented

and adapted to your requirements with optional ac-

cessories. In the Sorotec shop you will nd:

• Performance Kit 2)

• Milling spindles

• Electrical installation kit

• Control electronics

• Control software

• T-slot plate

• Vacuum table

• Minimum quantity lubrication

Caution!

Only carry out the work if you are familiar with the

necessary actions and suitable tools are available.

Sorotec GmbH assumes no liability for damage to

property or personal injury occurring during assem-

bly or operation of the CNC portal milling machine!

General information

Please assemble the kit as carefully and precisely

as possible - the accuracy of the nished machine

does not only depend on the quality of the delivered

components, but also to a high degree on the correct

assembly and exact alignment. Before assembly, all

components must be checked for burrs and rewor-

ked if necessary.

2) recommended for processing non-ferrous metals

Infosheet Measure Screws

SOROTEC GmbH Tel.: +49 (0) 7 7-994 55-0

Withig 1 Fax: +49 (0) 7 7-994 55-9

77836 Rheinmünster E-Mail: sorotec@sorotec.de Version 1.0 Juli 0 0

Dimensions

Screw sizes are always given in the form of "diameter x length". In the case of metric screws, the diameter is

given by an M. Wood, sheet metal or plastic screws are not specially marked in the dimensioning. The unit of

measurement mm is usually not specified.

Examples:

M4 x 40 - metric screw with M4 thread and 40 mm length

3 x 5 - wood screw 3 mm in diameter and 5 mm in length

Web: www.sorotec.de

Diameter

Measurements are always made with the vernier caliper and on the

outside of the thread. To prevent the cutting edges of the measuring

jaws from slipping into the thread grooves, the screw is placed

lengthways between the jaws.

Length

Everything that disappears in the material is part of the

length of a screw. This means that measurements are taken

- ideally with the depth gauge of the caliper - from the

underside of the screw head to the end of the screw. Any

parts without a thread are also part of the length.

Exception countersunk screw

Because the head of the countersunk screw disappears

into the material, the head height here is part of the

length. So the length is measured over everything. But

really: Only with the countersunk screw!

Page 3/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Scope of delivery

Illustration Description Number

End plate Y on the left

BL.FT.007.01 1

End plate Y on the right

BL.FT.008.01 1

Stop plate Z

BL.FT.013.01 1

Drive X:

xed bearing 4F

CL.ZAN.FL16.H

Ball screw 4S

see page 6

Recirc. ball nut 4K

readily mounted on ball screw

oating bearing 4L

BL.FT.017.01 and

AL.ZAN.LA6000RS

1

1

1

1

Drive Y:

xed bearing 5F

CL.ZAN.FL16.H

Ball screw 5S

see page 6

Recirc. ball nut 5K

readily mounted on ball screw

oating bearing 5L

CL.ZAN.LL16.H

1

1

1

1

Drive Z:

xed bearing 6F

CL.ZAN.FL16.H

Ball screw 6S

ZAN.NTS.KGS1605.0270.M

Recirc. ball nut 6K

readily mounted on ball screw

1

1

1

Stieners Z:

left 7L / right 7R

BL.FT.022.01

2

1

2

3

4

5

6

7

Illustration Description Number

Base plate Z

BL.FT.012.01 1

Flange bracket X

BL.FT.018.01 1

Flange bracket Y

BL.FT.019.01 1

Flange bracket Z

BL.FT.020.01 1

Flange plate

BL.FT.016.01 1

Device base

(self-adhesive)

AL.EZB.0109

7

Claw clutch

MZK.080.100.V25 3

Carriage

ZFW.NTS.HGH20CA

5

(7)

Linear rail X

see page 6 2

8

9

10

11

12

13

14

15

16

Page 4/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Illustration Description Number

Linear rail Y

see page 6 2

Linear rail Z

(300 mm lg.)

BL.ZFS.HGR20R.0300

1

Motor ange Z

BL.FT.011.01 1

Plate Z

BL.FT.010.01 1

Portal beam

(preassembled)

see page 6

1

Portal beam

see page 6 1

Portal cheek:

left 23L BL.FT.005.01

right 23R BL.FT.004.01

1

1

Prole 10 45 x 90 light

see page 6

3

(4)

Prole 10 45 x 90

heavy (819 mm lg.)

see page 6

2

17

18

19

20

21

22

23

24

25

Illustration Description Number

Prole 5 20 x 20

BL.PR.0520201N.0372 2

Reference switch

with shim

EZB.T1 / AL.IS.001

3

Switch carrier X

CL.FT.013.01 1

Switch carrier Y

BL.FT.021.01 1

Sled Y

BL.FT.009.01 1

Face plate in the back

see page 6 1

Front plate

see page 6 1

Angle 20 x 20

BL.PR.W.052020

including cover

5

Angle 40 x 40

AL.PR.WS.084040

including cover

6

26

27

28

29

31

32

33

34

35

Page 5/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Illustration Description Number

Angle 45 x 45

AL.PR.WS.104545

8

(12)

Drag chain holder

CL.FT.032.01 1

Tapered grease nipple

M6 x 1

ZB.HI.SN008

2

Grease nipple 90°

M6 x 1

ZB.HI.SN003

3

Cylinder head screw DIN 912

M3 x 14 A1 MED.SMZ8.8V.03.014

M3 x 16 A2 MED.SMZ8.8V.03.016

M4 x 16 B1 MED.SMZ8.8V.04.016

M4 x 20 B2 MED.SMZ8.8V.04.020

M4 x 25 B3 MED.SMZ8.8V.04.025

M5 x 12 C1 MED.SMZ8.8V.05.012

M5 x 14 C2 MED.SMZ8.8V.05.014

M5 x 16 C3 MED.SMZ8.8V.05.016

M5 x 18 C4 MED.SMZ8.8V.05.018

M5 x 20 C5 MED.SMZ8.8V.05.020

M5 x 22 C6 MED.SMZ8.8V.05.022

M5 x 25 C7 MED.SMZ8.8V.05.025

M6 x 14 D1 MED.SMZ8.8V.06.014

M6 x 35 D2 MED.SMZ8.8V.06.035

M6 x 50 D3 MED.SMZ8.8V.06.050

Sliding block 5 M5

3D.PR.NS.05M5S

Hammer nut

Slot 8 M5 G1 AL.PR.HM.08M5.017

Slot 8 M6 G2 AL.PR.HM.08M6.017

Slot 10 M5 H1 AL.PR.HM.10M5.030

Slot 10 M6 H2 AL.PR.HM.10M6.030

Slot 10 M8 H3 AL.PR.HM.10M8.030

36

37

SN

SM

F1

Illustration Description Number

Hammer screw

Slot 10 M8 x 20 J

enclosed with angle

Flat headed screw ISO 7380

M5 x 8 K1 MED.SMF10.9.05.008

M5 x 20 K2 MED.SMF10.9.05.020

M6 x 16 K3 MED.SMF10.9.06.016

M6 x 25 K4 MED.SMF10.9.06.025

M8 x 16 K5 MED.SMF10.9.08.016

M12 x 30 K6 MED.SMF10.9.12.030

Mounting bracket

drag chain

CL.PR.BW.604020

1

Cylinder head screw DIN 6912

M5 x 10 L1 MED.SMZNK8.8V.05.010

M5 x 16 L2 MED.SMZNK8.8V.05.016

M6 x 40 M1 MED.SMZNK8.8V.06.040

M8 x 20 N1 MED.SMZNK8.8V.08.020

Nut DIN 934

M3 OMED.SMU0.8V.03

M4 PMED.SMU0.8V.04

Flange nut DIN 6923

M8 Q

enclosed with angle

Washer DIN 125

3,2 UMED.SUS.V.03

8,4 XMED.SUS.V.08

Dowel pin hard DIN 6325

5 x 18 mm Z

AL.ZS.05.18

38

Page 6/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Order numbers of size-dependent parts

Maschine

Bezeichnung BL 0605 BL 0607 BL 1005 BL 1007

4S Ball screw X ZAN.NTS.KGS1610.0800.M ZAN.NTS.KGS1610.0800.M ZAN.NTS.KGS1610.1200.M ZAN.NTS.KGS1610.1200.M

5S Ball screw Y ZAN.NTS.KGS1610.0650.M ZAN.NTS.KGS1610.0850.M ZAN.NTS.KGS1610.0650.M ZAN.NTS.KGS1610.0850.M

16 Linear rail X BL.ZFS.HGR20R.0817.BL BL.ZFS.HGR20R.0817.BL BL.ZFS.HGR20R.1217.BL BL.ZFS.HGR20R.1217.BL

17 Linear rail Y BL.ZFS.HGR20R.0622.BL BL.ZFS.HGR20R.0822.BL BL.ZFS.HGR20R.0622.BL BL.ZFS.HGR20R.0822.BL

21 Portal beam BL.FT.023.01 BL.FT.028.01 BL.FT.023.01 BL.FT.028.01

22 Portal beam BL.FT.003.01 BL.FT.024.01 BL.FT.003.01 BL.FT.024.01

24 Prole 10 45 x 90 light BL.PR.104590L.0395 BL.PR.104590L.0595 BL.PR.104590L.0395 BL.PR.104590L.0595

25 Prole 10 45 x 90

heavy

BL.PR.104590S.0819 BL.PR.104590S.0819 BL.PR.104590S.1219 BL.PR.104590S.1219

32 Face plate back BL.FT.001.01 BL.FT.025.01 BL.FT.001.01 BL.FT.025.01

33 Face plate front BL.FT.002.01 BL.FT.026.01 BL.FT.002.01 BL.FT.026.01

Infosheet spindle bearings

SOROTEC GmbH Tel.: +49 (0) 7227 994255 0

Withig 12 Fax: +49 (0) 7227 994255 9

77836 Rheinmünster E Mail: sorotec@sorotec.de Version 1.0 März 2023

Floating bearings are not "loose bearings"

When storing a shaft in a machine, the thermal linear expansion must always be taken into account in the

design. In the case of a ball screw made of high alloy steel, for example, with a length of 0.1 ... 0.2 mm per

meter per 10 Kelvin temperature difference, this is quite considerable the additional tenths have to go

somewhere.

If the roller bearings were to be firmly connected at the ends both to the shaft and to the surrounding housing,

considerable axial stress would quickly arise as a result of thermal expansion. The bearings would be severely

overloaded and would wear out after a short time; Gradually louder, grinding rolling noises are the alarm signal

for bearing damage at the end.

Web: www.sorotec.de

Conflicting requirements

For this reason, the fit between the bearing seat on the shaft and

the inner ring of the bearing as well as that between the outer ring

and the bore in the housing is very tight on the fixed bearing.

Great forces may be required for assembly (plastic hammer, if

necessary driving sleeve for the inner ring), the use of heat and/or

cold to expand or shrink the components can also be helpful. In

any case, use oil!

At the floating bearing, a firm clamping should only guarantee the

guidance of the shaft radially (so that it does not "slack around"),

but it should be movable in the longitudinal direction to allow

thermal expansion without the build up of tension forces. The

mobility can take place either between the shaft and the inner ring

of the bearing or between the outer ring and the housing seat.

The bearing must not jam in one of the seats. However, the seat

must not be too loose either: even before any disruptive radial

mobility comes into play, one of the rings could begin to "wander"

and gradually wear down the seat on the shaft or in the housing.

Compromise: tight but not clamped

In practice, a workable compromise is usually reached by sliding the floating bearing tightly onto the end of the

shaft, but without using much force. How large the force may be is at the discretion of the machine builder. The

span of justifiable handling ranges from energetic pressing by hand (but without hammer blows) to pushing it onto

the “sucking” seat.

Important to know: Standard parts such as bearings also have tolerances. With the problem discussed here, a few

thousandths of a millimeter can make a big difference one bearing is jammed, the next can be easily pushed on.

If possible, trying out several bearings can lead to success. Otherwise it has to be reworked. This is also normal

and commonplace in mechanical engineering.

Regrind bearing seat

If necessary, use a piece of abrasive fleece to make the loose bearing seat of the ball screw sufficiently free to

move. Alternatively, you can also use very fine grain sandpaper. Make sure you work evenly all around. Try

frequently to slide the bearing onto the oiled seat. If the inner ring is tight without binding, the floating bearing is

installed correctly.

Fixed bearing (above) and floating

bearing in a Sorotec Alu-Line

Attention!

If you have to pull of a bearing that accidentally stuck by

gripping the outer ring, it is likely badly damaged and should

no longer be used.

Page 7/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Preparatory work

Preparing angles for surface

mounting

When installing an angle 34 or 35 on a component

without fastening grooves, the centering tabs on the

angle must be removed before installation (see Figu-

re 1). This can be done by breaking o with a screw-

driver or ling / sanding.

Fig. 1: Centering tabs on mounting bracket

35

34

Pre-assembly of the ball screws,

spindle nuts and bearing units

Caution!

The pre-assembled recirculating ball nuts must not

be turned o the ball screws!

The ball nuts and ball screwsare sensitive and must

be handled with care!

Install the grease nipple

(all drives):

Equip all ball nuts with 90° angled grease nipples

(see picture 2). Do not fully tighten the grease nipples

to be able to align them later.

Fig 2: Bore and thread for grease nipples

Page 8/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

Mount the xed bearings

• Push the rst bushing onto the ball screw.

Place the xed bearing unit on the ball screw.

• Push the second bushing onto the ball screw.

• Screw the shaft nut onto the ball screw.

Attention: The collar of the shaft nut in the

direction of the xed bearing block.

• To adjust the axial play, tighten the shaft nut

until the ball screw can only be turned with

diculty in the xed bearing unit. Then carefully

loosen the shaft nut a little (approx. 5 °) until the

ball screw can easily be turned again.

• Screw the stud bolts into the threaded holes in

the shaft nut and tighten.

• X drive only: screw the xed bearing 4F to the

ange plate 12 ; Tighten the screws D2 slightly.

• Align the rear edges of the xed bearing and

ange plate in parallel and tighten the screws.

Fig. 3: Mounting xed bearings

Fig. 4: Fixed bearing on X-drive

Install oating bearing X drive

• Press the roller bearing into the housing.

Note:

In order not to damage the rolling bearing when in-

stalling it in the housing, only push / hit on the bearing

outer ring. Use a suitable drive sleeve (tube) and oil

the outer bearing ring before assembly!

• Place the oating bearing on the ball screw.

Install oating bearing Y drive

• Place the oating bearing unit on the ball

screw and attach the circlip to the end of the ball

screw.

Fig. 5: Rolling bearing assembly with drive sleeve

Fig 6: Floating bearing assembly

4L

Page 9/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

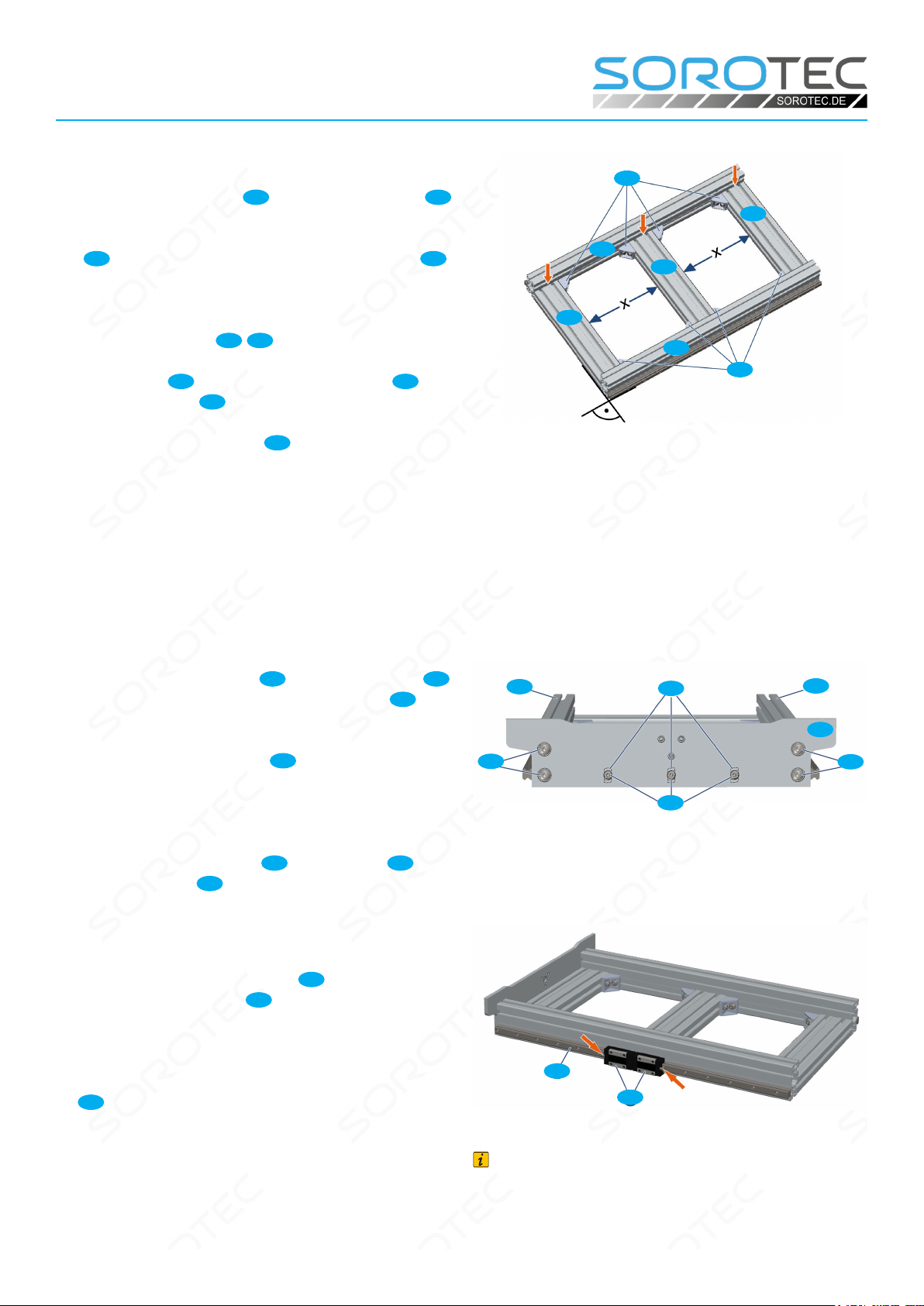

Assembly X axis

and base frame

Note:

The following illustrations show the Basic-Line 0605

kit. The Basic-Line 1005 is installed analogously.

Fig. 7: Completely assembled base frame

• Screw the linear guide 16 to the prole 25 ;

The lower edge of the linear guide must lie along

the milled stop edge of the prole over its entire

length (see Figure 8).

• Tighten the screws evenly outwards in the

middle. Tightening torque: 6 Nm

• Repeat steps with a second prole and a

second linear guide.

Note:

The sealing plugs for the holes in the guide rails pre-

vent the accumulation of dirt and chips, which could

otherwise damage the sealing lips of the carriages.

• Insert the sealing plugs into the holes in the

guide rails. Make sure they sit ush.

Fig. 8: Linear guides on the stop edge (arrow)

16

H1

C4

Note:

The further assembly of the base frame is carried out

lying on its back, as shown in Figure 9. Fig. 9: Base frame in supine position

Page 10/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

The base frame must be mounted in such a way that

there is an air gap of approx. 0.5 mm between the

end faces of the proles 24 and the long prole 25

for aligning the base frame (see red arrows in Figure

10). On the opposite side, the end faces of the pro-

les 24 must be in contact with the long prole 25 .

The base frame should be installed as stress-free as

possible.

• Lay out proles 24 /25 as shown on a at

work surface and loosely screw them together

with angles 36 . Use the hammer screws J

and ange nuts Qfor this.

• Move the inner prole 24 or inner proles

(1005) so that equally long elds (x) are created.

• Tighten the screws one after the other from an

outside corner (tightening torque: 25 Nm). Always

check the perpendicularity and parallelism of the

base frame and correct if necessary.

Fig. 10: Assembly of the base frame

36

36

25

24

24

24

25

• Fit three front screws K5 on the front plate 33

and loosely screw on three hammer nuts H3 on

the inside.

• Position the front plate 33 at the front,

threading the hammer nuts into the T-groove of

the prole. Tighten the screws slightly to turn the

hammer nuts 90° in the T-slot

• Screw front end plate 33 with proles 25 ;

Tighten screws K6 slightly.

• Tighten all front panel mounting screws.

Fig. 11: Mounting end plate on frame proles

K5

25

25

K6

33

K6

H3

• Push one or two carriages 15 on each side

onto the linear guides 16 . Please note:

smoothed, bare surfaces on the long sides of the

carriage point down towards the work surface.

• Load the carriage with straight grease nipples

SN so that they point outwards.

Fig. 12: Lubricating nipples on the carriage point outwards

Note:

The illustration shows the assembly with the Per-

formance Kit, i.e. with two carriages per side on the

guide of the X axis.

16

15

Page 11/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Equip the rear faceplate 32 with three screws

N2 and loosel screw on three hammer nuts H3

on the inside.

• Position the rear end plate, threading hammer

nuts into the T-slot of the prole. Tighten the

screws slightly to turn the hammer nuts in the

T-slot by 90°.

• Screw the rear face plate to the proles with

at-head screws K6 ; Tighten screws slightly.

• Tighten all rear face plate mounting screws.

Fig. 13: Assembly of the rear face plate

32

H3

K6 K6

K5

25 25

• Place the pre-assembled X drive 4in the

base frame as shown in Figure 14.

• Screw the oating bearing to the front face

plate with socket head screws D1 ; Tighten

screws slightly.

• Insert two hammer nuts H2 in the groove of

the prole, turn them 90 ° and slide them under

the mounting holes of the xed bearing.

• Screw the xed bearing to the prole using

socket head screws D3 ; Tighten screws slightly.

• Insert four hammer nuts H1 in the grooves of

the prole, turn them 90° and slide them under

the mounting holes of the ange plate 12 .

• Screw the ange plate to the prole using

socket head screws C3 ; Tighten screws slightly.

Note:

The fastening screws C3 , D1 and D3 of the bearing

units 4L / 4F are not tightened until aligning.

For the following reference switch assembly, if ne-

cessary, observe the additional instructions for as-

sembly „Electrical installation kit“.

Fig. 14: Assembly of the X drive

D3

D3

H2

4F

4

12

C3

33

D1

4L

C3

Page 12/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Equip switch carrier X 28 with screws K5 and

washers Xand loosely screw on two hammer

nuts H3 on the inside.

• Position switch carrier X as shown on the

xed bearing side of the base frame, threading

hammer nuts into the T-slot of the prole.

• Tighten the screws, turning the hammer nut

through 90° in the T-slot.

• Place the shim between the reference switch

and switch carrier X and screw on the reference

switch. Fig. 15: Assembly of the X reference switch

27

U

K5

28

H3

X

X

A1

Assembly of Y-axis / portal

Note:

The following illustration shows the assembly without

a performance kit, i.e. with one carriage per side on

the X axis.

Fig. 16: Fully assembled portal with Y axis

Page 13/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Drive in dowel pins Zinto the portal cheeks

23L /23R until they protrude approximately 3 ... 4

mm on the inside.

• Place the portal cheeks with the cylinder pins on

the carriages 15 and screw them in with cylin-

der screws Z. Tightening torque: 6 Nm.

Remove pins after assembly.

Fig. 17: Assembly of the portal cheeks

23L 23R

C3 C3

Z15 Z

15

• Load the linear rails 17 from above with

cylinder screws C4 and screw on the hammer

nuts G1 from below.

Fig. 18: Assembly of the Y linear guides

17

21

17

• Place the linear rails on the proles of the

portal beam in such a way that the lower edges

of the linear guides marked with arrows in Figure

18 (detail) point to the milled stop edges.

• Align the linear rails in the center of the proles

and turn the screws slightly in order to turn the

hammer nuts by 90° in the T-slot.

• Screw the linear rails to the proles; continue

to watch the lower edges of the linear guides

matching the milled stop edges of the proles

over their entire length. Tightening torque: 6 Nm

• Insert the sealing plugs into the holes in the

guide rails. Make sure they sit ush.

• Load four angles 35 with one screw K4 each

and loosely screw on a hammer nut G2 at the

back.

• Insert the hammer nuts through the elongated

holes on the back of the gantry beam into

the prole and screw the brackets (Fig. 19,

magnifying glass above); Tighten the screws

slightly so that the angles can just be shifted.

• Screw two angles 35 with at-head screws

K3 and hammer nuts G2 to the lower prole of

the gantry beam 21 (Fig. 19, magnifying glass

below); Tighten the screws slightly so that the

angles can just be moved on the prole.

• Place the portal beam on the two portal cheeks

as shown and screw all angles to the portal

cheeks with at-head screws K3 and hammer

nuts G2 ; Tighten screws slightly. Fig. 19: Connection of portal beams and cheeks

K5

G2

21

23

K5

K4

G2

23

35

K3

35

Page 14/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Insert the portal beam 22 as shown in Figure

20 in the recesses in the portal cheeks and

mount with cylinder screws D1 ; Tighten screws

slightly

• Degrease the adhesive surfaces and stick a

device foot 13 on the portal cheeks at the front

and rear.

Fig. 20: Installation of girder portal beam

D1

D1

13

13

13

13

22

• Before aligning the X axis (Figure 21), check

that the following screw connections are not yet

tight, but are only slightly tightened:

D1 Connections portal girder / portal cheeks

K5 Connections angle / portal cheeks

K4 Connections angle / portal beam

K3 Connections angle / prole

• If necessary, loosen screw connections and

fasten slightly.

• Move the portal several times from one end of

the base frame to the other end, gradually

tightening the screws in the following order:

D1 Connections portal girder / portal cheeks

K5 Connections angle / portal cheeks

K4 Connections angle / portal beam

K3 Connections angle / prole

Fig. 21: Align the X axis

D1

K3

K5

K4

K5

K3

K5

To adjust the parallelism of the base frame, some

screw connections are loosened on the side with the

air gap (see Fig. 10 and Fig. 22) so that the width of

the base frame can be shifted slightly.

• Loosen screw connections somewhat.

• Move the portal several times from one end

of the base frame to the other end and gradually

tighten the loosened screws again.

• Check whether the portal can be easily moved

over the entire travel path over the base frame

after all screws have been tightened. Fig. 22: Setting the parallelism of the basic frame

Page 15/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Tighten the lubricating nipple of the

recirculating ball nut 4K so that it faces the rear

face plate.

• Mount the ball nut on the ange bracket X 9

using socket head screws C5 ; Tighten screws

slightly.

• Move the portal until the ange bracket X is

above the portal beam.

• Screw ange bracket X to the gantry beam

using socket head screws C7 ; Tighten screws

slightly.

Fig. 23: Mounting ange bracket

C7

C7

4K

C5

22

• Move the portal as far forward as possible by

turning the ball screw 4S .

• Tighten the xing screws D2 of the oating

bearing. Tightening torque: 10 Nm

• Tighten the xing screws C5 of the ball nut on

the ange bracket X (see Figure 23). Tightening

torque: 6 Nm

Fig. 24: Tighten oating bearing X-axis

4S

D2

• Carefully tighten the fastening screws C7 of

the ange bracket X on the gantry beam (see

Fig. 23).

• Move the portal backwards by turning the ball

screw so that the xing screws 4F of the xed

bearing are just accessible.

• Tighten the xing screws D3 of the xed

bearing. Tightening torque: 10 Nm

• Befestigungsschrauben der Flanschplatte 12

festziehen. Schraubenanzugsdrehmo-ment: 6

Nm Tighten the fastening screws C3 of the

ange plate C5 . Tightening torque: 6 Nm

Fig. 25: Festziehen Festlager und Flanschplatte X-Achse

D3

C3

4S

4F

12

C3

• Drive the dowel pins Zinto the Y slide 31

ush to the back.

Fig. 26: Dowel pins in sledge

31

Z

Page 16/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Push one carriage 15 each onto the linear

rails 17 ; Please note the following:

- smoothed, bare surface on the long sides of

the carriage point upwards

- Grease nipples point to the left

(see picture 27)

• Place the slide Y 31 with the cylinder pins Z

on the upper carriage and screw them in with

cylinder screws C1 . Tightening torque: 6 Nm

• Screw carriage Y to the lower carriage; Tighten

screws slightly.

• Slide carriage Y back and forth on the linear

rails several times as far as possible; gradually

tighten the fastening screws of the lower

carriage. Tightening torque: 6 Nm

Fig. 27: Location of the grease nipples on the Y carriage

15

31

17

17

21

Z

• Guide the pre-assembled Y drive 5behind the

Y carriage as shown in Figure 28. Screw the

oating bearing 5L with 2 and the xed bearing

5F with 4 cylinder screws M1 to the portal

beam; Tighten screws slightly.

• Tighten the 90° lubrication nipple on the

recircula-ting ball nut 5K facing the opening.

• Mount the ball nut on the ange bracket Y 10

using pan head screws K2 ; Tighten screws

slightly.

• Slide the slide Y to the screw connection with

the ange bracket Y.

• Screw slide Y and ange bracket Y with socket

head screws C1 ; Tighten screws slightly

• Move the slide Y to the xed bearing by turning

the ball screw 5S until the xing screws of the

xed bearing are just accessible.

Fig. 28: Assembly of ange bracket and Y-slide

5S

M1 M1

21

31

M1

5F

K2

5K 10

C1

5L M1

Page 17/26

Assembly instructions

Basic-Line kit

www.sorotec.de V 2.3.3

• Tighten the xing screws of the xed bearing.

Tightening torque: 10 Nm

• Tighten the xing screws of the ball nut on the

ange bracket Y. Tightening torque: 6 Nm

• Carefully tighten the fastening screws of the

ange bracket Y.

• Move the slide Y to the oating bearing by

turning the ball screw until the fastening screws

of the oating bearing are just accessible.

• Tighten the xing screws of the oating

bearing. Tightening torque: 10 Nm

• Degrease the adhesive surfaces on the xed

bearing and oating bearing and stick on the

device feet 13 .

• Screw the right end plate Y 2to the gantry

beam using cylinder screws N1 .

• Screw the left end plate Y 1with cylinder

screws N1 on the portal beam.

Note:

The switch bracket Y 29 is mounted on the outside

left on the prole of the portal beam.

When installing the reference switch, observe the ad-

ditional instructions for the „Electrical installation kit“.

• Equip switch carrier Y 29 with two cylinder

head screws C2 and loosely screw on hammer

nuts G1 at the bottom.

• Position switch carrier Y, threading hammer

nuts into the T-slot of the prole. Tighten the

screws slightly to turn the hammer nuts in the

T-slot by 90°.

• Place the shim between the reference switch

27 and switch carrier Y and screw the reference

switch to the switch carrier Y using cylinder head

screws A2 and a washer U.

Fig. 29: Stick on the device feet as a buer

Fig. 30: Assembly of the right end plate

Fig. 31: Assembly of the left end plate

Fig. 32: Installation of Y reference switch

13

5F 13 5L

2N1

21

1

N1 21

G1

U

C2

A2

27

This manual suits for next models

3

Table of contents

Other Sorotec Power Tools manuals