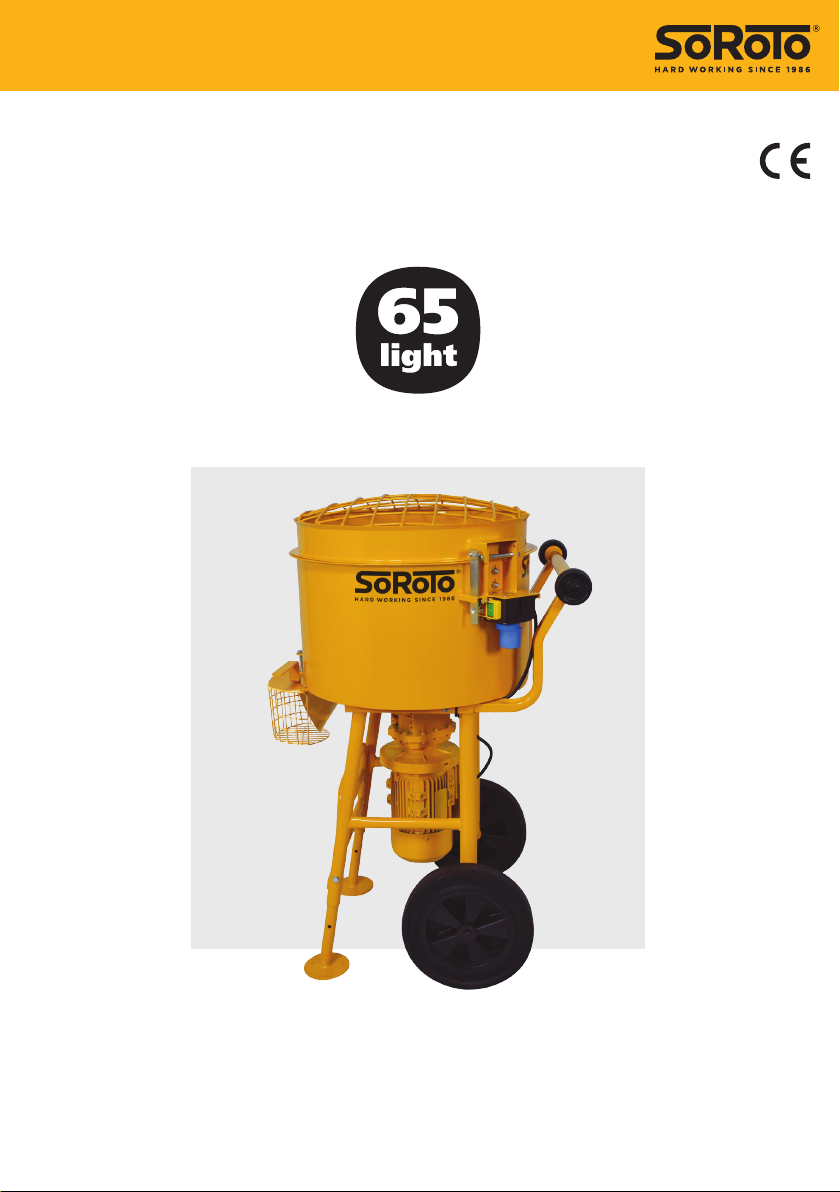

SoRoTo 65 light User manual

MANUAL

FORCED ACTION MIXER GB-12.12.18

MODEL 65-LIGHT

Mixing capacity:

65 litres

English

GB / 2 3 / GB

TABLE OF CONTENTS

SoRoTo 65-Light forced action mixer.........................p. 3

Before use............................................................................p. 3

Product description .......................................................p. 3

Mixer arms ...........................................................................p. 4

Technical data ....................................................................p. 4

General safety precautions..........................................p. 4

Operating the SoRoTo 65-Light

forced action mixer .........................................................p. 5

Application ..........................................................................p. 5

Maintenance and cleaning ...........................................p. 6

Transport ..............................................................................p. 7

Environment / disposal .................................................p. 7

Contact details ..................................................................p. 8

Special features.................................................................p. 9

Spare part list — 65-Light ............................................p. 10

EU Declaration of Conformity.........................................p. 12

MANUAL APPLIES TO

SoRoTo 65-Light

BEFORE USE

We encourage you to study this manual and the safety precautions be-

fore operating the forced action mixer.

Please note the warning signs below as they appear throughout the

manual and indicate the following,

Risk of personal injury or damages to the machine unless the safety in-

structions are observed.

Dangerous level of electric voltage.

Before starting the SoRoTo 65-Light mixer, we recommend that:

• The telescopic legs are adjusted for the right height — in order to

achieve the ergonomically best possible work position.

• The telescopic legs are adjustable for various heights.

• The easiest way for adjusting the legs is to lay down the mixer, so it

rests on all four wheels. The legs are released and locked with the fit-

ted lock splits/bolts.

NOTE!

The safety grid must be fitted onto the mixer in front of the mixer gate.

PRODUCT DESCRIPTION

• The SoRoTo 65-Light mixer is ideal for mixing most of the materials

used in the building industry, where high demands are imposed on

the quality of the mix.

• The 65-Light is designed for the workman who has fewer and short-

term masonry jobs, for the choosy self builder who wishes to ease

the work load, or the end user who is accustomed to a cement mixer

but wishes to upgrade their mixer to a forced action mixer.

GB / 4 5 / GB

NOTE!

65-Light is not designed for mixing stony materials. This can damage

both the mixer arms and the gear-motor.

MIXER ARMS

SoRoTo 65-Light Forced Action Mixer comes with a complete set of

mixer arms with three mixers arms. This ensures a homogeneous mix of

the materials used.

The mixer arms should be placed over the triangular shaft and the bolt

tightened.

TECHNICAL DATA

SoRoTo 65-Light Forced Action Mixer

Motor 230V/0,75 kW

RPM 30 RPM

Drum capacity 67 L

Mixing capacity 65 L

Height 110-124 cm

Width/length 64/67 cm

Weight 69 kg

SAFETY

Please store this manual in a safe place so that the information herin is

readily available.

Make sure to include this manual if you hand over the mixer to another

person.

This manual is also available to download digitally via our website:

www.soroto.com.

The manufacturer shall not be liable and shall not be liable in the event of

any work injury or damage to the machine which may occur due to breach

of the safety instructions of this manual.

Safe use of the machine is possible only when the operating instructions

and safety rules have been carefully read and the instructions carefully

followed.

AVOID ELECTRICAL SHOCK AND DAMAGE

• Always use the correct voltage. The voltage on the current

must be consistent with the information provided in the

instructions.

• Before connecting the power, the mixing arms must be bolted in

place and the grid lid closed. The mixer must not be put into opera

tion before the safety grid in front of the chute is securely mounted.

• When using an extension cable, please observe the following: Never

use a cable longer than max. 10 m. Always use a cable with a mini-

mum dimension of 1 mm. Never use the cable when it is rolled up.

Always roll it out completely, to avoid damaging the cable and the

motor.

GENERAL SAFETY PRECAUTIONS

• Always keep children and unauthorized persons away and at a safe

distance, when the mixer is in use.

• Always follow the instructions of the mixer manufacturer.

OPERATING THE SOROTO 65-LIGHT FORCED ACTION MIXER

In order to open the grid lid, pull out the black spring lock, which sits at

the hinge - on the back of the mixer. The built-in locking function can be

switched o by pulling out the spring lock and turning it.

APPLICATION

Before connecting the power, tighten the mixing arms with the supplied

machine bolt.

NOTE!

As a safety precaution - the motor can only run when the lid is closed.

GB / 6 7 / GB

It is recommended that the machine run while filling material - in order to

not cause damage to the gear-motor.

Pour the desired material into the mixing drum and add liquid a little at a

time. The black spring lock at the hinge ensures that the lid stays locked

while the machine is running.

The forced mixer is started by pressing the green START button located

on the mounted switch.

A zero voltage release is fitted in the motor protection. In the event of

a power failure or power cut, the forced mixer should subsequently be

restarted.

Also, for safety reasons, the engine cannot start if the lid is not closed.

To restart the mixer, press the green START button.

NOTE!

Never put your hand or any object into the machine when the power is

connected.

When the material has reached the desired consistency and the mixing

motion is finished, the mixing drum is emptied by opening the mixer gate.

The drum should be emptied right after mixing. Please observe that the

material may set in the mixing drum, if left for too long.

MAINTENANCE AND CLEANING

Before cleaning the machine, make sure to switch o the power to the

mixer.

Open the lid by pulling the black spring lock and remove the mixer arms.

First remove the bolt and then remove the mixer arms from the shaft.

Wash the mixer arms and the entire mixing drum using water.

When cleaning has ended, place the mixer arms onto the axle and close

the grid lid.

NOTE!

Prevent water from accessing the electrical parts.

NOTE!

The safety grid should be in front of the output gate at all times. If the

machine is jammed, e.g. by larger stones, ensure that the plug is discon-

nected from the protective motor switch, before removing the obstruc-

tion. Do not put your fingers or any object through the mixer gate.

TRANSPORT

During transport of the SoRoTo® 65-Light Forced Action Mixer it is

recommended that the mixer is placed on the four wheels, and the lid is

closed and locked with the rubber strap.

NOTE!

The spring-loaded lock must be activated before putting down the mixer.

ENVIRONMENT

• Environmental hazardous waste must always be disposed of in ac

cordance with any applicable legislation in the field in your country.

• Please take care of the environment.

GB / 8 9 / GB

PRODUCTION/WAREHOUSE

Fabriksparken 11

DK-2600 Glostrup

Tel. +45 3672 7800

teknik@soroto.dk

SALES/ADMIN

Fabriksparken 13

DK-2600 Glostrup

Tel. +45 3672 7500

soroto@soroto.dk

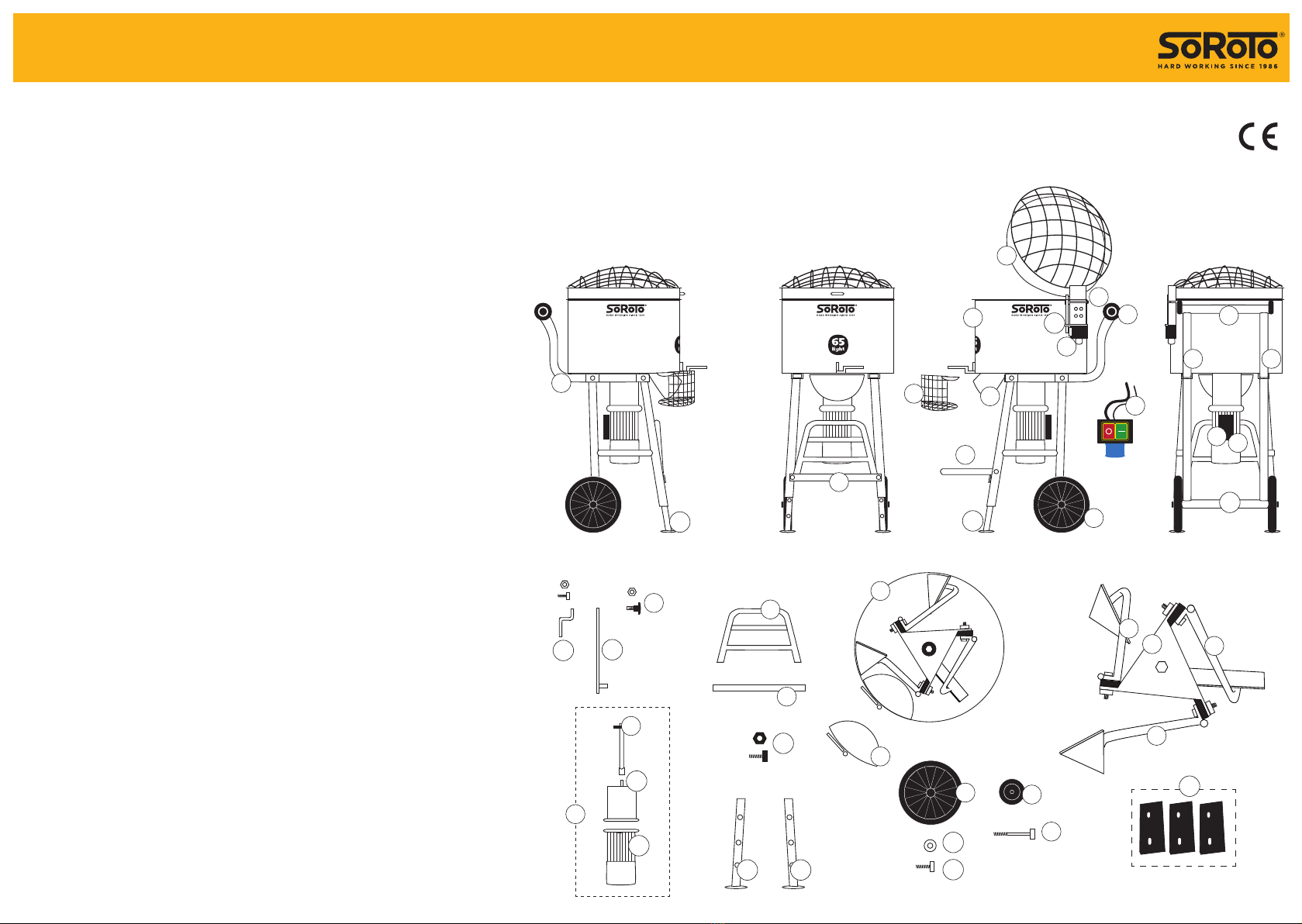

INCLUDING

Mixer arms with steel blades

and cross joints

INCLUDING

Telescopic legs for setting the

right working height

INCLUDING

User friendly start-stop and

safety switch

INCLUDING

Small loading wheels for easy

on-/unloading

INCLUDING

Puncture-free wheels lockx

with bolt and washer

INCLUDING

Cross-bar makes the mixer

easy to push

POS.NO. DESCRIPTION ART.NO.

2 Grid lid (hinge 90 mm) ............................................................... 65.002

2 A Spring lock for grid lid ................................................................ 65.002A

3 Mixer drum incl. mixer gate, complete ................................. 65.003

4 Frame, complete w/wheels etc. .............................................. 65.004

4 B Bucket stand ................................................................................... 65.004B

4 F Frame, front part — below bucket stand ............................. 65.004F

4 L Frame, front part — left side .................................................... 65.004L

4 R Frame, front part — right side ................................................. 65.004R

4 T Frame, top/rear part .................................................................... 65.004T

5 Loading wheel (1 pc.), 80 mm, excl. bolt ............................. 65.005

5 B Bolt (1 pc.) for 80 mm loading wheel ................................... 65.005B

6 Wheel (1 pc.), 300 mm, excl. bolt ........................................... 65.006

6 B Bolt (1 pc.) for 300 mm wheel ................................................. 65.006B

6 W Washer (1 pc.) for 300 mm wheel .......................................... 65.006W

7 Mixer gate incl. bolt. .................................................................... 65.007

8 Switch 8.0 Amp. w/thermal circuit breaker........................ 65.008

8 K1 Piece for safety switch — a straight metal piece ............ 65.008K1

8 K2 Metal hinge for fitting the safety switch .............................. 65.008K2

9 Mixer arm (1 pc.), Side ................................................................. 65.009

10 Mixer arm (1 pc.), Side-base ..................................................... 65.010

11 Mixer arm (1 pc.), Rake ............................................................... 65.011

12 Drive shaft ....................................................................................... 65.012

13 Gear motor 0,75 kW, 30 RPM, 230V ..................................... 65.013

13 G - Gear wo/motor ........................................................................... 65.013G

13 M - Motor wo/gear ............................................................................ 65.013M

14 Starting capacitor 125 µF ........................................................... 65.014

15 Operating capacitor 25 µF ........................................................ 65.015

17 B Telescopic leg (1 pc.), rear ......................................................... 65.017B

17 L Telescopic leg (1 pc.), front — left side ................................. 65.017L

17 R Telescopic leg (1 pc.), front — right side .............................. 65.017R

17 SB Bolt and nut (1 set) for telescopic leg (1 pc.) ..................... 65.017SB

19 Safety grid by the mixer gate .................................................. 65.019

22 Mixer arms, 3 pcs, incl. cross joint .......................................... 65.022

Mixer arms, 3 pcs, excl. cross joint ......................................... 65.022A

30 Discharge chute, incl. nuts ........................................................ 65.030

44 Cross joint for mixer arms, wo/rubber, incl. bolts ............ 65.044

44 R Replacement set for cross joint, rubber .............................. 65.044R

3

8

4T

4F

4F

2A

4L 4R

4

6

30

19

22

9

10

11

44

4B

4B

5

5

6

5B

2

6B

17SB

6W

17L17R

17R 17L

17B

13G

8K2 8K1

8K1

13M

12

7

15

14

44R

2A

13

8

SPARE PART LIST - 65 LIGHT, 230V

GB-29.11.18

Fabriksparken 11-13, DK 2600 Glostrup, tel. +45 36 72 75 00, www.soroto.com

EU DECLARATION OF CONFORMITY

ANNEX II.A OF THE MACHINERY DIRECTIVE

Manufacturer: SoRoTo A/S

Address: Fabriksparken 11-13, 2600 Glostrup, DENMARK

Product: Forced Action Mixers

Model: 65-light

Manufactured: From 2015 and onwards

We hereby declare that the SoRoTo® Forced Action Mixers are manu-

factured in conformity with the stipulation containted in COUNCIL

DIRECTIVE No. 2006/42/EC on the approximation of the laws of

member states on machine, including subsequent modifications, with

special regard to Annex I of the directive on important safety and

health requirements in connection with the design and manufacture

of machines.

Furthermore, we declare that the SoRoTo® Forced Action Mixers are

manufactured in conformity with the following harmonised standard,

EN 12151:2007

13.06.2019

Glostrup, DENMARK

________________________

Hans Terney Rasmussen

CEO

Original

Table of contents

Other SoRoTo Mixer manuals

Popular Mixer manuals by other brands

Electrolux

Electrolux EASYCOMPACT ESTM5 AR Series Instruction book

Kitchen Living

Kitchen Living HM925 User guide manual

Isoplam

Isoplam PLAM MIX 120 manual

MECNOSUD

MECNOSUD IM Series operating manual

cam

cam SX50 Installation operating and maintenance istructions

KitchenAid

KitchenAid ACCOLADE 400 Instructions and recipes