Soss Ultralatch L2 User manual

1” Edge

Hole

21/8” Face Hole

Use 1” hole saw to drill door edge

2"deep. Hole must be drilled

parallel to the door face

and level.

It is very important that the bolt assembly is flush

in the mortise. If the door is beveled, ensure that

the bolt assembly is flush with the low

side of the bevel. The barrel of the bolt

must be parallel to the door face and

perpendicular to door edge. Trace with

pencil or utility knife to outline mortise.

Mortise edge of door to accept bolt assembly

and face plate.

Insert latch and tighten screws.

Drill door jamb using 1” hole saw 9/16" deep in door jamb on center line

of screws.

Locate screw holes on strike with

center line on jamb. Outline edges

and chisel 5/64" for A01 (ANSI) strike

plate and 1/16" deep for A02 and A03.

Predrill 11/64" pilot holes for A01 (ANSI)

or 1/8" pilot holes for A02 or A03

strike plates.

Install strike plate and

tighten screws.

Adjustable tang on A03 strike

plate permits bending to

eliminate loose fit between

door and stop.

Jamb

Door

Door Preparation

For new slab door, start at

least 36" above floor.

Fold and apply template to

high side of door bevel.

Ensure that template is level

and square.

Mark center hole on door face

through guide on template

for 23/8" or 23/4" backset.

Repeat on door edge for latch.

With template in place, transfer center line to door jamb.

UltraLatch® units are packed to a specific backset (23/8" or 23/4")

depending upon door thickness. Normally If your door is 13/8"

thick, you will have a 23/8" backset; if your door is 13/4" or thicker,

the backset is 23/4".

To determine position for strike plate,

ensure that center of hole is level with

center of 21/8" face hole on door.

To measure, insert end of

template against flat of latch

bolt and close door against stop.

Mark template from edge of jamb

and transfer lines around face of

jamb to locate strike opening.

Mark center line for screws and

1" hole, using dimensions shown

on chart at right.

Drill 21/8" hole through door face

as marked for lockset. Hole must

be drilled perpendicular to the door

face and level. Drill the 21/8" hole

first. To avoid splintering, stop when

pilot bit starts to exit opposite side.

Reverse drill to remove and

repeat on opposite side using

pilot hole as a guide.

•BoltAssembly:Includes2Mounting

Screws and 2 Face Plates 1" and 11/8"

•Unirose/ChassisAssembly:Includes

Mounting Hardware, Lock Trip Key

•2Handles:1Leftand1Right

•2RoseCovers

•StrikePlates:L1Modelwillinclude

11/8" x 23/4" and 11/4" x 21/4" Strike Plates

L2 and L3 Models will include 11/4" x 47/8",

11/8" x 23/4" and 11/4" x 21/4" Strike Plates

Tools needed to install

the SOSS® UltraLatch®

Handle

Right

Cover

Screw

Screws

Cover

Screw

Handle

Left

Pull Side

Unirose

Handle

Shaft

Spacers

(for 2"

doors only)

Bolt

Assembly

Handle

Shaft

Strike Plates

A01

(ANSI)

A02

A03

Push Side

Unirose

Unirose

Cover

Unirose

Cover

Spring

Optional UltraLatch®

Drill Guide (Part # LDG)

(Sold Separately)

Pivot Pin

Pivot Pin

Before installation, please check

carton contents:

•FlatScrewdriver •#2PhillipsScrewdriver

•TorpedoLevel •Hammer

•AdjustableSquare •ElectricDrill

•1”FlatWoodChisel •1/8", 11/64" and 9/32"DrillBits

•Pencil •SmallNeedleNosePliers

•UltraLatchDrillGuide •SafetyGogglesorGlasses

Several areas of this assembly have been factory

lubricated. Please DO NOT remove this lubrication.

DONOTremovetheLinear-Camshippingpinuntil

instructed to do so.

1

2

3

4

5

Installation Instructions

Models L1, L2, L3

Important Notes

Mark from

High Side of

DoorBevel

5

6

Important Notes

If you are prepping the door for a standard

round deadbolt, leave at least 8" between the

center of deadbolt and center of UltraLatch®

bolt to allow clearance for UltraLatch® handles.

If using any other type of deadbolt, measure

before placing hole to ensure that you have

enough clearance.

1

Mortise

5/32”

Deep

Door

5/64” Deep

for A01

1/16” Deep

for A02, A03

11/16” for�

13/8” Door

7/8” for

13/4” Door

1” x 9/16”

Jamb

A

B

B

A01 Strike

A=41/8”B=21/16”

A02 Strike

A=21/8”B=11/16”

A03 Strike

A=15/8”B= 13/16”

UltraLatch

Drill Guide

Ta pe Stop-Mark

Pull Side

If door is not plumb, use measurements as noted in #7a.

When level, tighten screws.

DO NOT USE POWER TOOLS

TO SECURE SCREWS

We recommend drilling the

push side of the door first.

Drill hole through Drill Guide

to the tape mark. Do not

drill completely through the

door. Remove drill guide and

Unirose, repeat procedure on

opposite side of door. Drilling

in two steps will prevent

splintering on the door.

When holes meet, go to

step 8.

Installation without Drill Guide

If not using Drill Guide, prepare 9/32"DrillBitbymarkingaStop-Mark

with tape to allow 1" max penetration for 13/8" door, 13/8" for 13/4"

door or 15/8" for 2" Door. Measurement should be made from tip of

drill to tape marker.

OpenChassisAssembly,removethe

3 screws from Pull Side Unirose.

As long as door is plumb, insert Pull

Side Unirose into the 2-1/8” hole.

Checkmeasurementsandmark

location of 9/32" hole with a pencil.

Remove Unirose and repeat

procedure on opposite side of door.

Carefullydrillhole,insuringthe

bit is perpendicular to the door

face. Do not drill completely

through the door. Drilling in two

steps will prevent splintering on

the door.

When holes meet, go to step 8.

Installation using Optional UltraLatch® Drill Guide

Prepare 9/32"DrillBitbymarkingaStop-Markwithtapetoallow2”

max penetration for 13/4" Door or 15/8" for 13/8" Door. Measurement

should be made from tip of drill to tape marker.

OpenChassisAssembly,removethe3screwsfromPullSideUnirose.

Invert Unirose to

avoid drilling into it

and place in the 21/8"

face hole on door.

Insert UltraLatch®

Drill Guide on other

side of door, attach

with 2 lower screws

to snug.

CheckwithTorpedo

Level only if door is

plumb – adjust

if necessary.

Determining Door Orientation

BeforeinstallingtheUnirose/ChassisAssemblyyoumust

determine if your door is a Right or Left hand door. This is

accomplished by noticing hinge location when facing the

Push side of the door. If the hinges are on the left, it's a left

hand door and if on the right, it's a right hand door. The

assembly is set at the factory for a left hand door.

Set Up for a Right Hand Door

Remove the 2 screws that secure the chassis to the Push

Uniroseusinga#2PhillipsScrewdriver.RotatetheChassis

180°sothattheLinearCamnowfacesthe3o'clock

position (as shown). Reinstall and tighten the screws at the

4 and 10 O'clock positions. If this is a 2" door installation

(L3) then you must also reinstall the Spacers between the

ChassisandUniroseatthe4and10o'clockpositions.

7

7a

DO NOT use power tools to secure screws.

DO NOT remove lubrication from internal parts.

DO NOT remove linear cam shipping pin until told to do so.

Important Notes

Pull Side

Unirose

Ta pe Stop-Mark

Ta pe Stop-Mark

If not using Drill Guide or Level

Manydoorsarebeveledontheedge.Besuretostartmeasurement

from the highest point of the bevel when using an adjustable square.

Prepare 9/32"DrillBitbymarkingaStop-Markwithtapetoallow1"

max. penetration for 13/8" door, 13/8" for 13/4" door or 15/8" for 2" Door.

Measurement should be made from tip of drill to tape marker.

Optionally, you can use an

adjustable square to determine

position for the Unirose. If your

backset is 23/4", set square to

223/64" from outside of door to

the top side of the Unirose.

Mark your drill hole with pencil,

repeat on other side.

If your door has a 23/8" backset,

the distance needed is 131/32".

Carefullydrillhole,insuringthebit

is perpendicular to the door face.

Do not drill completely through

the door. Drilling in two steps will

prevent splintering on the door.

When holes meet, go to step 8.

Left Hand Door Right Hand Door

Push

Side of

Door

Push

Side of

Door

The UltraLatch® requires a precisely located screw hole drilled perpendicular to the door face above the face hole. Follow instructions in 7 or 7a below

to locate this hole. We highly recommend the purchase of the optional UltraLatch® drill guide to ensure proper location of this hole.

Important Note

2

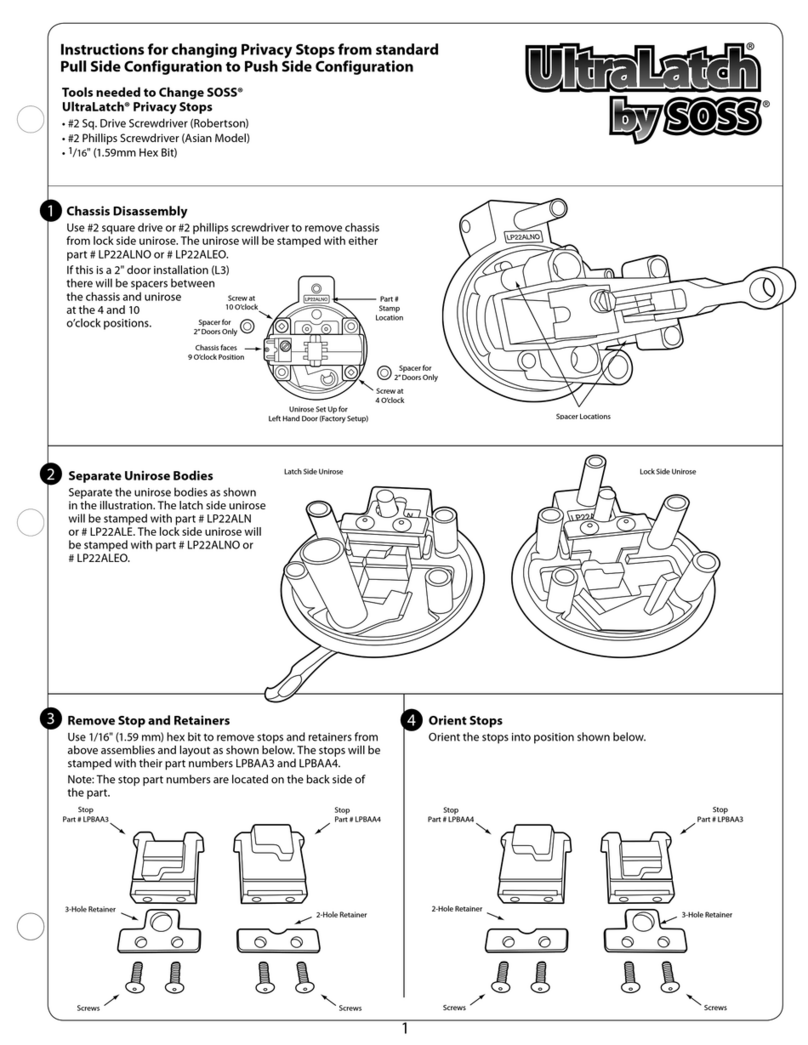

Screw at

10 O’clock

Screw at

10 O’clock

Spacer for �

2” Doors Only

Spacer for �

2” Doors Only

Chassisfaces

9 O’c lock Position

Chassisfaces

3 O’clock Position

Unirose Set Up for

Left Hand Door (Factory Setup)

Unirose Set Up for

Right Hand Door (ChassisRotated180°)

Screw at

4 O’clock

Screw at

4 O’clock

23/4”Backset=223/64”

23/8”Backset=131/32”

Measure

from high

side of door

bevel

Pull Side

Unirose

To save time, we recommend using 2 UltraLatch® Drill Guides.

Please refer to section 12 on page 4.

Ta pe Stop-Mark

UltraLatch

Drill Guide

Push Side

Invert Unirose

before drilling to

avoid damaging�

Unirose.

8 9

10

11

DonotactuatetheLinear-CambypushingitinorbyactuatingtheRacks.

TheLinearCammustbeintheforwardpositiontobeinstalled.

Ifbyaccidentyouhavedoneso,thenyoumustrepositiontheChassis

Spring as shown at right using needle nose pliers or tweezers.

Important Note

Install Bolt Assembly

Install bolt assembly through outside edge of

door. Tapered end of bolt should face the strike

plate in the jamb. Attach face plate (1" or 11/8"),

snap on to bolt assembly short shell. Attach

with screws.

Installation of Chassis Assembly

RemoveLinearCamShippingpin

with yellow flag

from Unirose

with needle

nose pliers.

Insert Push Side Unirose into door, slightly

depressing the linear cam to clear the 21/8" hole.

When Push Side is approximately 1/4" from face

of door, push bolt inwards to depress retention

clip, allowing linear cam to engage into slot

inbolt.ItshouldclickintoplacewiththeBolt

Assembly. Manually test to ensure bolt action

works freely.

Attach Pull Side Unirose

Secure with 3 screws to snug.

Testboltactionagain.Check

for level with Torpedo Level, if

correct, tighten the screws with

#2 Phillips screwdriver. If your

UltraLatch® is equipped with a

Privacy Lock, the lever will be

facing the right. Turn the locking

shaft on the Push side to the

right(Clockwise).(Totestthe

bolt, on the PULL SIDE of door,

push the rack, on the PUSH SIDE

of the door, pull rack to test).

RemovethefollowingfromyourHardwareBag:2eachoftheHandle

PivotScrews,2eachoftheHandleShaftand2eachoftheCoverScrews.

Install Handle Shafts into racks.

Make sure they are centered

on each side.

InstallRoseCovers

w/cover screws.

Install Handles

When installing handles, the

offset side of the handle must

face the hinge side of the door

(see diagram at right).

Install PUSH SIDE

Handle. Place

handle almost

flat sliding over

handle shaft.

Tip forward,

insert Pivot Pin

and tighten with

#2 Phillips

screwdriver.

Repeat procedure on

the PULL Side handle

Test to ensure system works freely.

Congratulations,yourinstallationiscomplete!

3

PinPin Retracted

Correct, Ready to InstallIncorrect, Not Ready to Install

ChassisAssembly

About the Privacy Lock

The Privacy Lock on the SOSS® UltraLatch® will secure your door from

the inside (Pull Side) of the room. Slide lever to the LEFT to activate.

Operating the Pull Side handle will disengage the Privacy Lock.

A Trip Key is provided. To deactivate the Privacy Lock from outside

ofdoor,insertTripKeyintosmallholeontheUniroseCover.ForLH

Doors pull slightly toward the hinge side of the door. For RH doors

push key toward the door jamb.

Foraddedsecurity,usetheSOSS®SingleCylinderDeadboltby

Medeco. (See separate installation instructions).

For Bifold Closet Doors

AdditionalToolsneeded:1/8" Drill bit

If installing UltraLatch® on bi-fold closet door,

please use the following procedure.

If other UltraLatch® handles are used in the room,

try to match height for consistency. Please follow

Door manufacturer's instructions for location of

the handles.

Determine the best distance from the door’s

edge to install the handle.

No 21/8" hole is necessary. Once your placement

isdetermined,placeClosetUniroseonfaceof

door, check for level, then mark for screw holes.

Pre-drill to 7/8" depth with 1/8" drill bit.

AttachClosetUnirosewiththeprovidedscrews.

Attach rose cover and handle as directed in

step 10 and 11 of basic instructions.

Tip:

Mark top hole at 12 o'clock. Drill pilot hole and attach with screw to snug,

check for level. Mark other screw holes with pencil. Loosen Unirose and

rotate 180°. Drill other pilot holes. Return Unirose to original position and

install remaining screws.

Part #: LPUXAY2 © Copyright 2011, Universal Industrial Products, Inc.

SOSS®

Door Hardware

BothhandlesmustbeinstalledbeforeactivatingthePrivacyLock.

Important Note

If Latch Disassembly from Door is Required.

Remove Pull Side handle, cover and Unirose by removing the three

screws. Depress spring clip while gently pulling on the Push Side

Unirose to free bolt to allow removal. While removing assembly,

depress clip from Pull Side, depress rack slightly to allow clearance for

the one inch hole.

Beforeattemptingtoreinstall,resettheChassisSpringasshownon

the top of page 3.

Using Two UltraLatch® Drill Guides

Prepare 9/32"DrillBitbymarkingaStopMarkwithtapetoallow2”

maximum penetration for 13/4" doors or 15/8" for 13/8" doors.

Measurement should be made from tip of drill bit to the tape marker.

Insert UltraLatch® Drill Guide into 21/8" hole on the Push Side of the

door, insert screws to align for second Drill Guide on Pull Side of door.

Tighten screws slightly, check with torpedo level to ensure that Drill

Guides are level. If both sides are level, tighten screws and recheck

for level. Adjust if necessary. Drill first hole from the Push-Side of the

door, then go to the Pull-Side and drill until the holes meet.

Depress

SpringClip to

FreeBolt

May be covered by one or more U.S. Patent Nos. D603,244; D600,531; D592,486; D584,594; and D502,641. U.S. and Int’l Patents Pending.

UltraLatch® is made in the U.S.A. of domestic and imported components.

Universal Industrial Products, Inc.

One Coreway Drive

Pioneer, OH, USA 43554-0628

Phone: (419) 737-2324 (800) 922-6957

FAX: (419) 737-2130

SOSS Asia Pte. Ltd.

#6 Third Chin Bee Road

Jurong, Singapore 618682

Phone: 656 261 3276

FAX: 626 261 5047

Email: [email protected]

4

Trip Key

12

Using 2 UltraLatch® Drill

Guides will save set-up time.

Ta pe Stop-Mark

UltraLatch

Drill Guide

UltraLatch

Drill Guide

Push Side

This manual suits for next models

2

Other Soss Door Lock manuals

Popular Door Lock manuals by other brands

Philips

Philips EasyKey Alpha user manual

iSecurity101

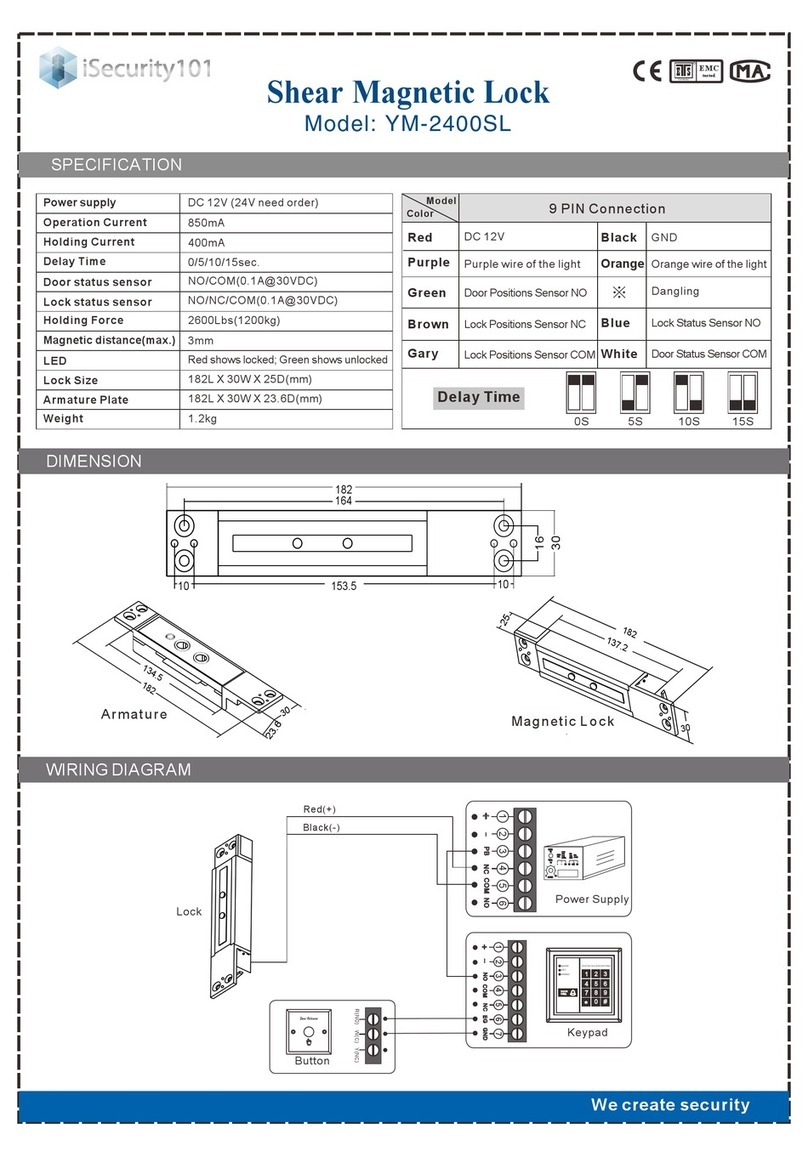

iSecurity101 YM-2400SL quick start guide

Major Manufacturing

Major Manufacturing HIT-41 SERIES instructions

Kaba

Kaba Saflok RT Series Rework Installation Sheet

Titon

Titon Overture DH Fixing and Operating Instructions

Schlage

Schlage Touch FE695 Lever installation instructions