South Bend Tools SB1124F User manual

®

A Tradition of Excellence

South Bend Tools

© January, 2023 by South Bend Tools For Machines Mfd. Since 11/22 (V1.06.23)

MODEL SB1124F

9" X 48" 3 HP VARIABLE-SPEED

TURRET MILL W/DRO

OWNER'S MANUAL

***Keep for Future Reference***

Customer Service

We stand behind our machines. If you have any service questions, parts requests or general questions

about your purchase, feel free to contact us.

South Bend Tools

P.O. Box 2027

Bellingham, WA 98227

Phone: (360) 734-1540

Fax: (360) 676-1075 (International)

Fax: (360) 734-1639 (USA Only)

Email: [email protected]

Updates

For your convenience, any updates to this manual will be available to download free of charge

through our website at:

www.southbendtools.com

Scope of Manual

This manual helps the reader understand the machine, how to prepare it for operation, how to control

it during operation, and how to keep it in good working condition. We assume the reader has a basic

understanding of how to operate this type of machine, but that the reader is not familiar with the

controls and adjustments of this specific model. As with all machinery of this nature, learning the

nuances of operation is a process that happens through training and experience. If you are not an

experienced operator of this type of machinery, read through this entire manual, then learn more

from an experienced operator, schooling, or research before attempting operations. Following this

advice will help you avoid serious personal injury and get the best results from your work.

Manual Feedback

We've made every effort to be accurate when documenting this machine. However, errors sometimes

happen or the machine design changes after the documentation process—so

the manual may not

exactly match your machine.

If a difference between the manual and machine leaves you in doubt,

contact our

customer service for clarification.

We highly value customer feedback on our manuals. If you have a moment, please share your

experience using this manual. What did you like about it? Is there anything you would change to

make it better? Did it meet your expectations for clarity, professionalism, and ease-of-use?

South Bend Tools

C

/O Technical Documentation Manager

Table of Contents

INTRODUCTION...............................................................2

Left Front View Identification ............................2

Right Front View Identification .......................... 3

Description of Controls & Components ..............4

Product Specifications ......................................... 7

SAFETY............................................................................. 10

Understanding Risks of Machinery ..................10

Basic Machine Safety ........................................10

Additional Milling Machine Safety................... 12

PREPARATION .............................................................. 13

Preparation Overview........................................ 13

Required for Setup............................................. 13

Power Supply Requirements.............................14

Converting Voltage to 440V ..............................16

Unpacking ..........................................................17

Inventory ............................................................17

Cleaning & Protecting ....................................... 18

Location ..............................................................19

Lifting & Moving................................................20

Leveling & Mounting......................................... 21

Anchoring to Floor ............................................. 21

Assembly ............................................................22

Power Connection (220V) ..................................24

Power Connection (440V) ..................................24

Initial Lubrication .............................................25

Test Run .............................................................26

Spindle Break-In................................................ 29

Inspections & Adjustments ............................... 29

OPERATION....................................................................30

Operation Overview........................................... 30

Table Movement.................................................31

Head Movement .................................................33

Ram Movement ..................................................34

Spindle Speed..................................................... 35

Spindle Downfeed ..............................................38

Using Spindle Brake.......................................... 42

Loading/Unloading Tooling ...............................42

ACCESSORIES.............................................................. 44

MAINTENANCE ............................................................. 48

Maintenance Schedule....................................... 48

Cleaning & Protecting ....................................... 48

Lubrication......................................................... 50

Machine Storage ................................................54

SERVICE........................................................................... 55

Coolant Reservoir...............................................55

Tramming Spindle .............................................57

Adjusting Gibs....................................................59

Adjusting Leadscrew Backlash ......................... 60

TROUBLESHOOTING................................................. 62

ELECTRICAL................................................................... 65

Electrical Safety Instructions ...........................65

Electrical Overview............................................ 66

Electrical Cabinet ..............................................67

Electrical Cabinet Wiring Diagram (220V) ...... 68

Electrical Cabinet Wiring Diagram (440V) ...... 69

Control Panel .....................................................70

Main Motor Wiring Diagrams........................... 71

DRO Wiring Diagram ........................................ 72

Power Feed Wiring Diagram.............................72

Electrical Component Photos ............................ 73

PARTS................................................................................ 74

Belt Housing.......................................................74

Gearbox ..............................................................76

Headstock........................................................... 78

Column, Knee & Ram........................................81

Table ...................................................................84

One Shot Oiler ...................................................86

Coolant System ..................................................87

Electrical Cabinet ..............................................88

Control Box.........................................................89

Accessories .........................................................90

Machine Labels (Front) .....................................91

Machine Labels (Side) ....................................... 92

WARRANTY..................................................................... 93

-2-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F INTRODUCTION

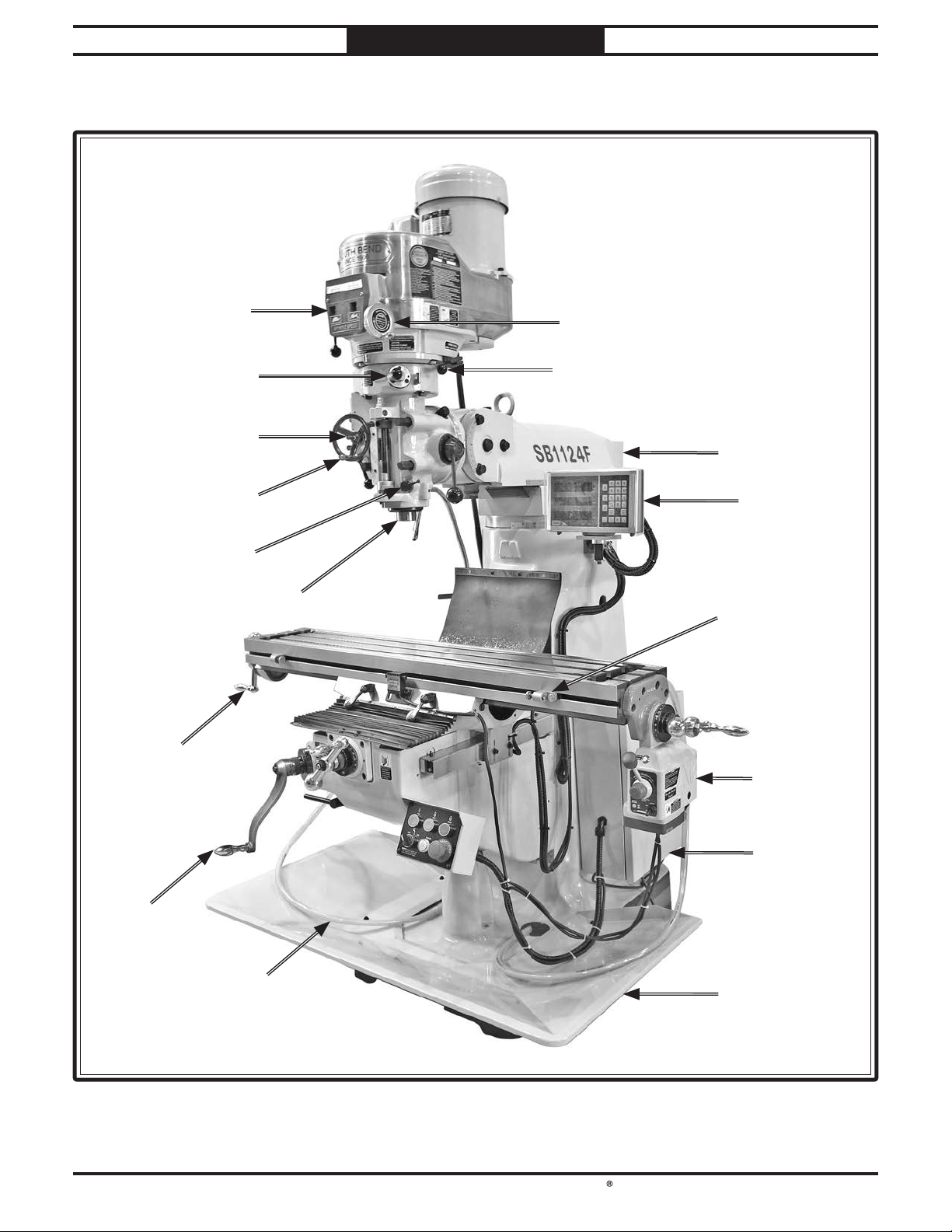

Left Front View Identification

Introduction

MotorMotor

Spindle Brake LeverSpindle Brake Lever

KneeKnee

X-Axis TableX-Axis Table

Lock (1 of 2)Lock (1 of 2)

Z-Axis TableZ-Axis Table

Lock (1 of 2)Lock (1 of 2)

Fine Downfeed Clutch LeverFine Downfeed Clutch Lever

Coolant ValveCoolant Valve

& Nozzle& Nozzle

One ShotOne Shot

OilerOiler

Y-Axis BallY-Axis Ball

HandleHandle

AdjustableAdjustable

Downfeed StopDownfeed Stop

9090°°Positive StopPositive Stop

Y-AxisY-Axis

TableTable

LockLock

Control PanelControl Panel

Auto DownfeedAuto Downfeed

Rate SelectorRate Selector

X-Axis LimitX-Axis Limit

SwitchSwitch

CoarseCoarse

DownfeedDownfeed

LeverLever

Knee CrankKnee Crank

Lock LeverLock Lever

High-RangeHigh-Range

Variable-SpeedVariable-Speed

IndicatorIndicator

Belt HousingBelt Housing

HeadstockHeadstock

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-3-

INTRODUCTION

Right Front View Identification

RamRam

X-Axis BallX-Axis Ball

Handle (1 of 2)Handle (1 of 2)

Quill and SpindleQuill and Spindle

DRODRO

Fine DownfeedFine Downfeed

HandwheelHandwheel

Splash PanSplash Pan

X-AxisX-Axis

Power FeedPower Feed

Quill LockQuill Lock

LeverLever

Variable-Speed HandwheelVariable-Speed Handwheel

Auto DownfeedAuto Downfeed

Direction PinDirection Pin

Coolant ReturnCoolant Return

HoseHose

Manual/PowerManual/Power

Downfeed SelectorDownfeed Selector

Spindle SpeedSpindle Speed

Range SelectorRange Selector

ElectricalElectrical

BoxBox

X-AxisX-Axis

Limit StopLimit Stop

(1 of 2)(1 of 2)

KneeKnee

CrankCrank

Low-RangeLow-Range

Variable-SpeedVariable-Speed

IndicatorIndicator

-4-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F INTRODUCTION

Description of Controls

& Components

Refer to Figures 1–6and the following

descriptions to become familiar with the basic

controls and components used to operate this

machine.

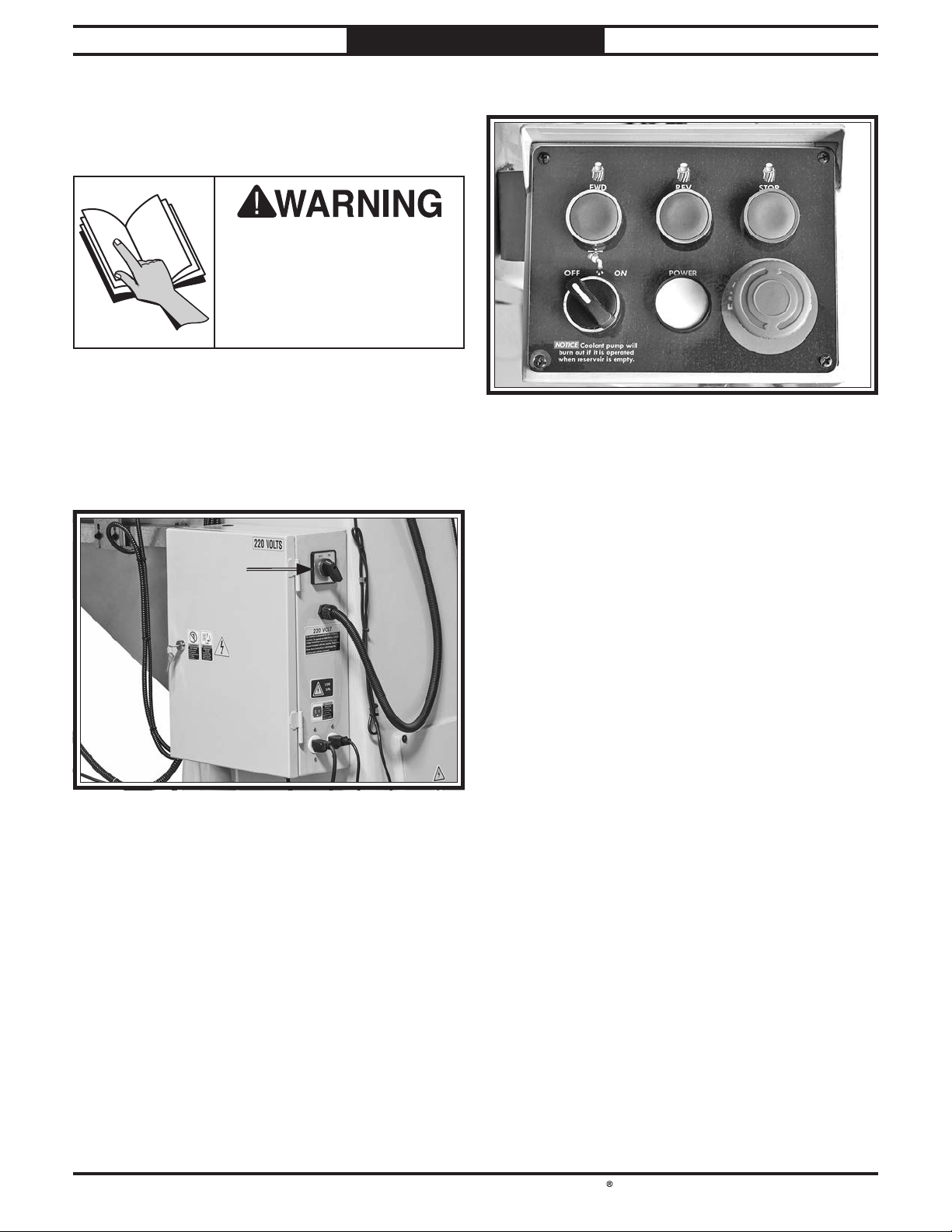

Master Power Switch

A. Master Power Switch: Turns incoming power

ON and OFF.

To reduce the risk of

serious injury when using

this machine, read and

understand this entire

manual before beginning any

operations.

Figure 1. Location of master power switch.Location of master power switch.

AA

Control Panel

B. FWD Button: Starts spindle forward rotation

(clockwise looking down on headstock).

C. REV Button: Starts spindle reverse

rotation (counterclockwise looking down on

headstock).

D. Stop Button: Stops spindle rotation.

E. Coolant Pump ON/OFF Switch: Turns

coolant pump ON and OFF.

F. POWER Light: Illuminates when power to

machine is enabled.

G. EMERGENCY STOP Button: Disables power

to control panel and stops all machine

functions when pressed. To reset, twist

button clockwise until it pops out.

Figure 2. Control panel.Control panel.

DD

EEFF

BBCC

GG

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-5-

INTRODUCTION

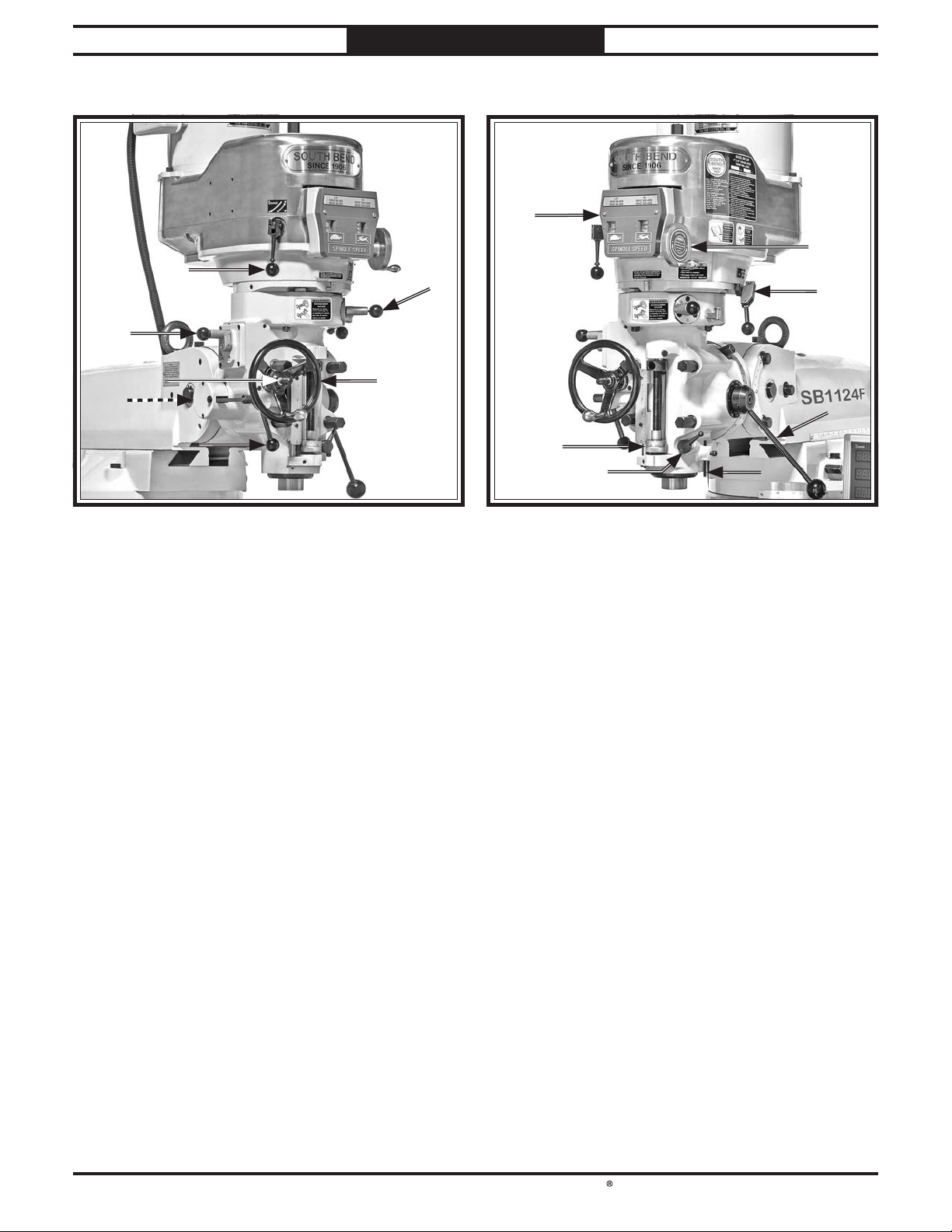

Headstock (Left)

H. Spindle Brake Lever: Quickly stops spindle

AFTER power to spindle is turned OFF.

I. Manual/Power Downfeed Selector: Selects

between manual and power downfeed.

J. Fine Downfeed Handwheel: Manually

controls slow spindle downfeed for fine Z-axis

control.

K. Fine/Auto Downfeed Clutch Lever: Engages

fine/auto-downfeed gears.

L. 90° Positive Stop: Stops headstock at 90°to

table following tilt procedure.

M. Auto-Downfeed Direction Pin: Starts, stops,

and reverses auto-downfeed direction.

N. Auto-Downfeed Rate Selector: Selects one of

the three auto-downfeed rates:

• 0.0015 in./rev.

• 0.003 in./rev.

• 0.006 in./rev.

O. Variable-Speed Indicators: Indicate spindle

speed in high and low ranges.

Headstock (Right)

P. Variable Speed Handwheel: Selects desired

spindle speed within high or low range.

Q. Spindle Speed Range Selector: Engages

back gear for low (60 RPM–500 RPM), and

disengages back gear for high (500 RPM–

4200 RPM) spindle speed ranges.

Note: When engaged, back gear reverses

spindle rotation, causing spindle FWD/REV

buttons to be reversed in low range.

R. Coarse Downfeed Lever: Quickly moves

quill downward manually and automatically

retracts spindle to top position when

released. Typically used for drilling

operations.

S. Dial Indicator Rod: Used to hold dial test

indicator when tramming spindle.

T. Quill Lock Lever: Locks quill in vertical

position.

U. Adjustable Downfeed Stop: Limits depth of

quill travel. Dial is graduated in increments

of 0.001". Typically used for repeat

operations.

Figure 3. Headstock controls (left).Headstock controls (left).

JJ

KK

LL

NN

MM

HHII

Figure 4. Headstock controls (right).Headstock controls (right).

PP

QQ

RR

TT

UU

SS

OO

-6-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F INTRODUCTION

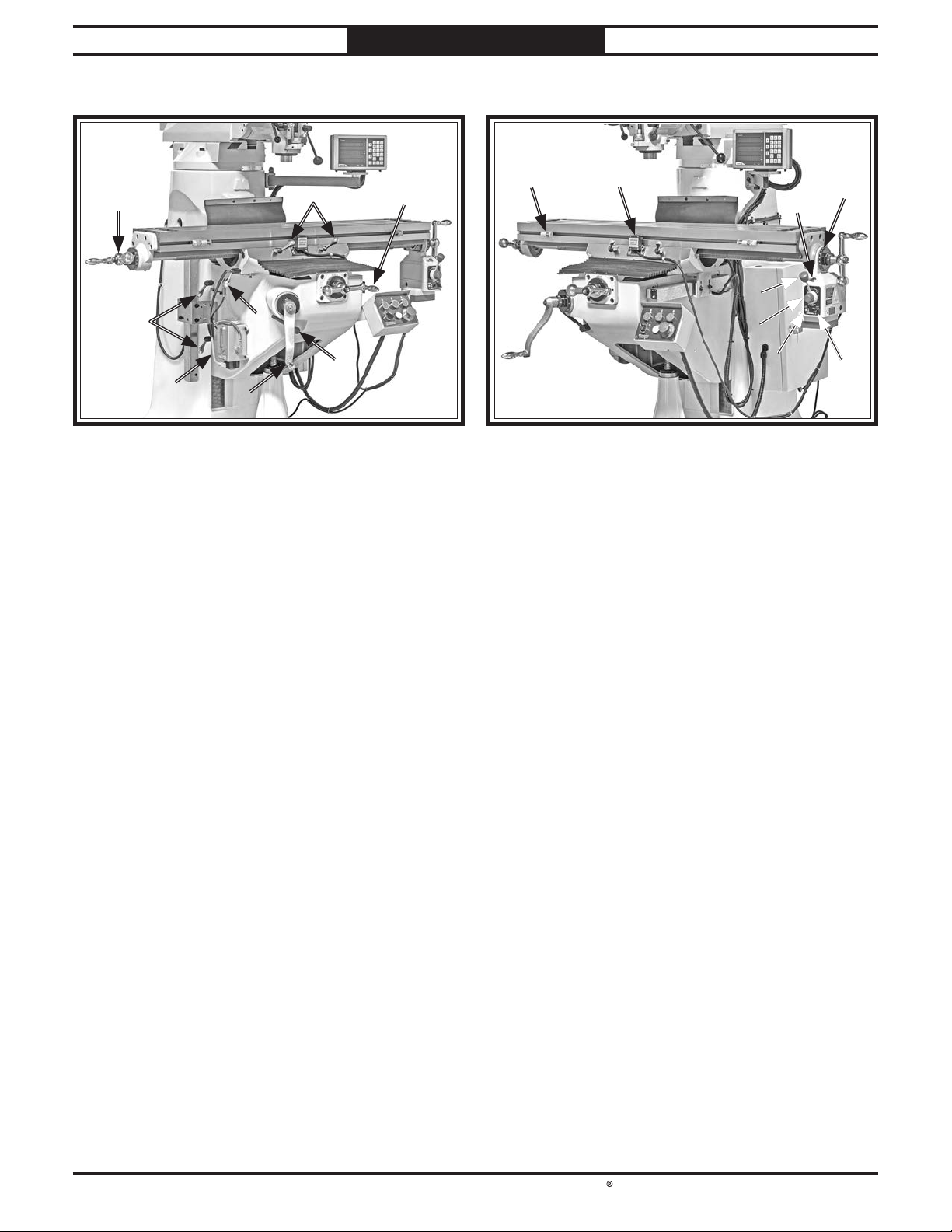

Table

V. X-Axis Table Locks: Tighten to prevent

X-axis table movement for increased rigidity

during operations where X-axis should not

move.

W. Y-Axis Ball Handle: Manually moves table

along Y-axis (front and back).

X. Knee Crank Lock Lever: Tightens to prevent

accidental movement of knee crank.

Y. Knee Crank: Manually moves table along

Z-axis (up and down).

Z. Y-Axis Table Lock: Tightens to prevent

Y-axis table movement for increased rigidity

during operations where Y-axis should not

move.

AA. One Shot Oiler: Lubricates X-, Y-, and Z-axis

table ways.

AB. Z-Axis Table Locks: Tighten to prevent Z-axis

table movement for increased rigidity during

operations where Z-axis should not move.

AC. X-Axis Ball Handle (1 of 2): Manually moves

table along X-axis (left and right).

AD. Limit Stop (1 of 2): Restricts table movement

by its positioning along front of table.

AE. Limit Switch: Stops table movement when

either of the switch side plungers are pressed

by limit stops.

AF. Rapid Traverse Button: When pressed, moves

table at full speed when already in motion.

AG. Graduated Index Ring: Displays distance of

table travel in 0.001" increments, with one

full revolution equal to 0.200" of table travel.

AH. Power Feed ON/OFF Switch: Turns power

feed ON and OFF.

AI. Reset Button: Resets internal circuit breaker

if unit is overloaded and shuts down.

AJ. Speed Dial: Controls speed of power feed.

Rotating dial increases/decreases speed.

AK. Direction Lever: Selects direction of table

movement. Middle position is neutral.

X-Axis Power Feed

Figure 5. Table controls.Table controls.

VVWW

YY

XX

AAAA

ZZ

ABAB

ACAC

Figure 6. X-Axis power feed controls.X-Axis power feed controls.

ADAD AEAE

AFAF AGAG

AJAJ

AIAI AHAH

AKAK

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-7-

INTRODUCTION

Product Specifications

Model SB1124F Page 1 of 3

Model SB1124F

9" x 48" 3 HP Variable‐Speed Turret Mill With

DRO

Product Dimensions

Weight........................................................................................................................................................... 2315 lbs.

Width (side-to-side) x Depth (front-to-back) x Height..................................................................... 64 x 57 x 84 in.

Footprint (Length x Width)....................................................................................................................... 24 x 36 in.

Space Required for Full Range of Movement (Width x Depth)............................................................... 95 x 63 in.

Shipping Dimensions

Type.......................................................................................................................................................... Wood Crate

Content.......................................................................................................................................................... Machine

Weight........................................................................................................................................................... 2625 lbs.

Length x Width x Height................................................................................................................... 66 x 59 x 77 in.

Electrical

Power Requirement.................................................................................................... 220V or 440V, 3-Phase, 60 hz

Prewired Voltage................................................................................................................................................ 220V

Full-Load Current Rating.............................................................................................. 9.6A at 220V, 4.8A at 440V

Minimum Circuit Size..................................................................................................... 15A at 220V, 15A at 440V

Connection Type.............................................................................. Cord at 220V, Permanent (Hardwire) at 440V

Power Cord Included.............................................................................................................................................. No

Recommended Power Cord............................................................................. "S"-Type, 4-wire, 14 AWG, 300 VAC

Plug Included.......................................................................................................................................................... No

Recommended Plug Type................................................................................................................... 15-20 for 220V

Switch Type....................................................................................... Control Panel w/Magnetic Switch Protection

Motors

Main

Horsepower............................................................................................................................................... 3 HP

Phase.................................................................................................................................................... 3-Phase

Amps........................................................................................................................... 8A at 220V, 4A at 440V

Speed................................................................................................................................................ 1720 RPM

Type........................................................................................................................................ TEFC Induction

Power Transfer .......................................................................................................................................... Belt

Bearings................................................................................................ Shielded & Permanently Lubricated

Coolant Pump

Horsepower............................................................................................................................................ 1/8 HP

Phase.................................................................................................................................................... 3-Phase

Amps.................................................................................................................. 0.4 A at 220V, 0.23A at 440V

Speed................................................................................................................................................ 3450 RPM

Type................................................................................................................................................... Induction

Power Transfer ............................................................................................................................ Direct Drive

Bearings.................................................................................................... Sealed & Permanently Lubricated

-8-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F INTRODUCTION

Model SB1124F Page 2 of 3

Longitudinal Power Feed

Horsepower.......................................................................................................................................... 1/10 HP

Phase............................................................................................................................................ Single-Phase

Amps.......................................................................................................................................................... 0.8A

Speed............................................................................................................................................. 0 - 160 RPM

Type................................................................................................................................................... Universal

Power Transfer ............................................................................................................................. Gear Drive

Bearings.................................................................................................... Sealed & Permanently Lubricated

Main Specifications

Operation Info

Spindle Travel.................................................................................................................................. 4-15/16 in.

Max Distance Spindle to Column........................................................................................................... 19 in.

Max Distance Spindle to Table......................................................................................................... 18-1/4 in.

Longitudinal Table Travel (X-Axis).................................................................................................. 30-1/4 in.

Cross Table Travel (Y-Axis).............................................................................................................. 11-1/4 in.

Vertical Table Travel (Z-Axis)................................................................................................................. 15 in.

Ram Travel............................................................................................................................................... 12 in.

Turret or Column Swivel (Left/Right)................................................................................................ 360 deg.

Head Tilt (Left/Right)...................................................................................................................... 0 - 90 deg.

Head Tilt (Front/Back)..................................................................................................................... 0 - 45 deg.

Drilling Capacity for Cast Iron................................................................................................................. 1 in.

Drilling Capacity for Steel...................................................................................................................... 3/4 in.

End Milling Capacity................................................................................................................................. 1 in.

Face Milling Capacity................................................................................................................................ 4 in.

Table Info

Table Length............................................................................................................................................ 48 in.

Table Width................................................................................................................................................ 9 in.

Table Thickness................................................................................................................................... 2-3/4 in.

Table Height (from Floor/Base)........................................................................................................ 42-1/2 in.

Table Weight Capacity......................................................................................................................... 400 lbs.

Number of T-Slots........................................................................................................................................... 3

T-Slot Size............................................................................................................................................... 5/8 in.

T-Slots Centers.................................................................................................................................... 2-1/2 in.

Number of Longitudinal Feeds.......................................................................................................... Variable

X-Axis Table Power Feed Rate.................................................................................................... 0 - 3.34 FPM

X/Y-Axis Travel per Handwheel Revolution..................................................................................... 0.200 in.

Z-Axis Travel per Handwheel Revolution......................................................................................... 0.100 in.

Spindle Info

Spindle Taper.............................................................................................................................................. R-8

Number of Vertical Spindle Speeds................................................................................................... Variable

Range of Vertical Spindle Speeds............................................................................................ 60 - 4200 RPM

Quill Diameter..................................................................................................................................... 3-3/8 in.

Quill Feed Rates.................................................................................................. 0.0015, 0.003, 0.006 in./rev.

Drawbar Thread Size............................................................................................................................ 7/16-20

Drawbar Length................................................................................................................................ 18-1/2 in.

Spindle Bearings....................................... Angular Contact P4 (ABEC-7) & Double-Shielded Ball Bearing

Construction

Spindle Housing/Quill.................................................................. Chrome-Plated & Precision-Ground Steel

Table.................................................................................................................... Precision-Ground Cast Iron

Head................................................................................................................................ Meehanite Cast Iron

Column/Base................................................................................................................... Meehanite Cast Iron

Paint Type/Finish.............................................................................................................................. Urethane

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-9-

INTRODUCTION

Model SB1124F Page 3 of 3

Other

Country of Origin ........................................................................................................................................... Taiwan

Warranty ........................................................................................................................................................ 2 Years

Approximate Assembly & Setup Time ......................................................................................................... 2 Hours

Serial Number Location .............................................................................................................................. ID Label

Sound Rating .................................................................................................................................................... 67 dB

Features

Fagor Digital Readout

High-Quality, Low-Vibration TEFC Spindle Motor

Auto-Downfeed Stop with Micro-Adjustable Stop

Variable-Speed Longitudinal Power Feed

Precision-Ground Table Surface

Chromed Steel Quill

Heavy-Duty Spindle Brake

Japanese Nachi Bearings

Table, Knee, and Ram are Equipped with Dual Locking Mechanisms

Meehanite Castings

Lever-Action, One-Shot Pump Lubrication System

Powered Recycling Coolant System

Included Accessories

10-Piece Hex Head Wrench Set (1.5 - 10mm)

Open-Ends Wrench 10/12mm

Combination Wrench 19mm

Combination Screwdriver

Oil Bottle

Spare Key Set (Assorted Sizes)

Toolbox

SAFETY

-10-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F SAFETY

Understanding Risks of Machinery

Operating all machinery and machining equipment can be dangerous or relatively safe depending

on how it is installed and maintained, and the operator's experience, common sense, risk awareness,

working conditions, and use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe use. This

responsibility includes proper installation in a safe environment, personnel training and usage

authorization, regular inspection and maintenance, manual availability and comprehension,

application of safety devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held liable for injury or property

damage from negligence, improper training, machine modifications, or misuse. Failure to read,

understand, and follow the manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are as follows:

Death or catastrophic

harm WILL occur.

Moderate injury or fire

MAY occur.

Death or catastrophic

harm COULD occur.

Machine or property

damage may occur.

Basic Machine Safety

Owner’s Manual: All machinery and machining

equipment presents serious injury hazards

to untrained users. To reduce the risk of

injury, anyone who uses THIS item MUST

read and understand this entire manual

before starting.

Personal Protective Equipment: Operating or

servicing this item may expose the user

to flying debris, dust, smoke, dangerous

chemicals, or loud noises. These hazards

can result in eye injury, blindness, long-

term respiratory damage, poisoning,

cancer, reproductive harm or hearing loss.

Reduce your risks from these hazards

by wearing approved eye protection,

respirator, gloves, or hearing protection.

Trained/Supervised Operators Only: Untrained

users can seriously injure themselves

or bystanders. Only allow trained and

properly supervised personnel to operate

this item. Make sure safe operation

instructions are clearly understood. If

electrically powered, use padlocks and

master switches, and remove start switch

keys to prevent unauthorized use or

accidental starting.

Guards/Covers: Accidental contact with

moving parts during operation may cause

severe entanglement, impact, cutting,

or crushing injuries. Reduce this risk by

keeping any included guards/covers/doors

installed, fully functional, and positioned

for maximum protection.

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-11-

SAFETY

Entanglement: Loose clothing, gloves, neckties,

jewelry or long hair may get caught in

moving parts, causing entanglement,

amputation, crushing, or strangulation.

Reduce this risk by removing/securing

these items so they cannot contact moving

parts.

Mental Alertness: Operating this item with

reduced mental alertness increases the

risk of accidental injury. Do not let a

temporary influence or distraction lead to a

permanent disability! Never operate when

under the influence of drugs/alcohol, when

tired, or otherwise distracted.

Safe Environment: Operating electrically

powered equipment in a wet environment

may result in electrocution; operating near

highly flammable materials may result in a

fire or explosion. Only operate this item in

a dry location that is free from flammable

materials.

Electrical Connection: With electrically

powered equipment, improper connections

to the power source may result in

electrocution or fire. Always adhere to all

electrical requirements and applicable

codes when connecting to the power source.

Have all work inspected by a qualified

electrician to minimize risk.

Disconnect Power: Adjusting or servicing

electrically powered equipment while it

is connected to the power source greatly

increases the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other tooling.

Secure Workpiece/Tooling: Loose workpieces,

cutting tools, or rotating spindles can

become dangerous projectiles if not

secured or if they hit another object during

operation. Reduce the risk of this hazard

by verifying that all fastening devices are

properly secured and items attached to

spindles have enough clearance to safely

rotate.

Chuck Keys or Adjusting Tools: Tools used to

adjust spindles, chucks, or any moving/

rotating parts will become dangerous

projectiles if left in place when the machine

is started. Reduce this risk by developing

the habit of always removing these tools

immediately after using them.

Work Area: Clutter and dark shadows increase

the risks of accidental injury. Only operate

this item in a clean, non-glaring, and well-

lighted work area.

Properly Functioning Equipment: Poorly

maintained, damaged, or malfunctioning

equipment has higher risks of causing

serious personal injury compared to

those that are properly maintained.

To reduce this risk, always maintain

this item to the highest standards and

promptly repair/service a damaged or

malfunctioning component. Always follow

the maintenance instructions included in

this documentation.

Unattended Operation: Electrically powered

equipment that is left unattended while

running cannot be controlled and is

dangerous to bystanders. Always turn the

power OFF before walking away.

Health Hazards: Certain cutting fluids and

lubricants, or dust/smoke created when

cutting, may contain chemicals known to

the State of California to cause cancer,

respiratory problems, birth defects,

or other reproductive harm. Minimize

exposure to these chemicals by wearing

approved personal protective equipment

and operating in a well ventilated area.

Difficult Operations: Attempting difficult

operations with which you are unfamiliar

increases the risk of injury. If you

experience difficulties performing the

intended operation, STOP! Seek an

alternative method to accomplish the

same task, ask a qualified expert how the

operation should be performed, or contact

our Technical Support for assistance.

-12-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F SAFETY

Additional Milling Machine Safety

Understanding Controls:

Make sure you

understand the function and proper use of all

controls before starting. This will help you

avoid making mistakes that result in serious

injury.

Avoiding Entanglement:

DO NOT wear loose

clothing, gloves, or jewelry, and tie back long

hair. Keep all guards in place and secure.

Always allow spindle to stop on its own. DO

NOT stop spindle using your hand or any

other object.

Wear Face Shield:

Always wear a face shield

in addition to safety glasses. This provides

more complete protection for your face than

safety glasses alone.

Use Correct Spindle Speed:

Follow

recommended speeds and feeds for each size

and type of cutting tool. This helps avoid tool

breakage during operation and ensures best

cutting results.

Inspect Cutting Tool:

Inspect cutting tools for

sharpness, chips, or cracks before each use.

Replace dull, chipped, or cracked cutting

tools immediately.

Properly Secure Cutter:

Firmly secure cutting

tool or drill bit so it does not fly out of

spindle during operation.

Power Disruption:

In the event of a local power

outage during operation, turn machine OFF

to avoid a possible sudden startup once

power is restored.

Clean Machine Safely: Metal chips or shavings

can be razor sharp. DO NOT clear chips

by hand or compressed air that can force

chips farther into machine—use a brush or

vacuum instead. Never clear chips while

spindle is turning.

Secure Workpiece To Table: Clamp workpiece

to table or secure in a vise mounted to

table, so workpiece cannot unexpectedly

shift or spin during operation. NEVER hold

workpiece by hand during operation.

Properly Maintain Machine: Keep machine

in proper working condition to help ensure

that it functions safely and all guards and

other components work as intended. Perform

routine inspections and all necessary

maintenance. Never operate machine with

damaged or worn parts that can break or

result in unexpected movement during

operation.

Disconnect Power First: To reduce risk of

electrocution or injury from unexpected

startup, make sure mill/drill is turned

OFF, disconnected from power, and that all

moving parts have come to a complete stop

before changing cutting tools or starting

any inspection, adjustment, or maintenance

procedure.

Remove Chuck Key & Spindle Tools: Always

remove chuck key, drawbar wrench, and

other tools used on the spindle immediately

after use. This will prevent them from being

thrown by the spindle upon startup.

You can be seriously injured or killed by getting clothing, jewelry, or long hair entangled with rotating

cutter/spindle. You can be severely cut or have fingers amputated from contact with rotating cutters.

You can be blinded or struck by broken cutting tools, metal chips, workpieces, or adjustment tools

thrown from the rotating spindle with great force. To reduce your risk of serious injury when operating

this machine, completely heed and understand the following:

PREPARATION

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-13-

PREPARATION

Preparation Overview Required for Setup

The items listed below are required to

successfully set up and prepare this machine for

operation.

For Lifting

• A forklift or other power lifting device rated

for the weight of the machine.

• Lifting straps w/safety hooks or chain (rated

for at least 3000 lbs.)

For Power Connection

• A power source that meets the minimum

circuit requirements for this machine. (Refer

to Power Supply Requirements on Page

14 for details.)

• A qualified electrician to ensure a safe and

code-compliant connection to the power

source.

• 14AWG power cord with 15-20 plug (for

220V connection).

For Assembly

• Cleaner/Degreaser

• Disposable Shop Rags/Gloves

• Phillips Head Screwdriver #2

•Precision Level 12"

• Thread-Sealing Tape or Pipe Sealant

• Two Assistants

• Safety Glasses for Each Person

The purpose of the preparation section is to help

you prepare your machine for operation. The list

below outlines the basic process. Specific steps

for each of these points will be covered in detail

later in this section.

The typical preparation process is as follows:

1. Unpack the machine and inventory the

contents of the box/crate.

2. Clean the machine and its components.

3. Identify an acceptable location for the

machine and move it to that location.

4. Level the machine and either bolt it to the

floor or place it on mounts.

5. Assemble the loose components and make

any necessary adjustments or inspections to

ensure the machine is ready for operation.

6. Connect the machine to the power source.

7. Test run the machine to make sure it

functions properly and is ready for operation.

Serious personal injury could occur if

you connect the machine to power before

completing the setup process. DO NOT

connect power until instructed to do so later

in this manual.

Like all machinery there is potential danger

when operating this machine. Accidents are

frequently caused by lack of familiarity or

failure to pay attention. Use this machine with

respect and caution to decrease the risk of

operator injury. If normal safety precautions are

overlooked or ignored, serious personal injury

may occur.

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your indi-

vidual working conditions. Use this and other

machinery with caution and respect. Failure to

do so may result in serious personal injury or

property damage.

-14-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F PREPARATION

Power Supply

Requirements

Electrocution or fire may

occur if machine is not

correctly grounded and

attached to the power

supply. Use a qualified

electrician to ensure a safe

power connection.

Before installing the machine, consider the

availability and proximity of the required power

supply circuit. If an existing circuit does not meet

the requirements for this machine, a new circuit

must be installed.

To minimize the risk of electrocution, fire,

or equipment damage, installation work and

electrical wiring must be done by a

n electrician

or qualified service personnel

in accordance with

applicable electrical codes and safety standards.

Availability

Note: The circuit requirements in this manual

are for

a dedicated circuit—where only one

machine will be running at a time. If this

machine will be connected to a shared circuit

where multiple machines will be running at

the same time, consult a qualified electrician to

ensure the circuit is properly sized.

The full-load current rating is the amperage

a machine draws at 100% of the rated output

power. On machines with multiple motors, this is

the amperage drawn by the largest motor or sum

of all motors and electrical devices that might

operate at one time during normal operations.

The full-load current is not the maximum

amount of amps that the machine will draw. If

the machine is overloaded, it will draw additional

amps beyond the full-load rating.

If the machine is overloaded for a sufficient

length of time, damage, overheating, or fire may

result—especially if connected to an undersized

circuit. To reduce the risk of these hazards,

avoid overloading the machine during operation

and make sure it is connected to a power supply

circuit that meets the requirements in the

following section.

Full-Load Current Rating

Full-Load Rating at 220V.................. 9.6 Amps

Full-Load Rating at 440V.................. 4.8 Amps

A power supply circuit includes all electrical

equipment between the main breaker box or fuse

panel in your building and the incoming power

connections inside the machine. This circuit

must be safely sized to handle the full-load

current that may be drawn from the machine for

an extended period of time. (If this machine is

connected to a circuit protected by fuses, use a

time delay fuse marked D.)

Circuit Information

For your own safety and protection of property,

consult an electrician if you are unsure about

wiring practices or applicable electrical codes.

Circuit Requirements for 440V

Nominal Voltage ............................... 440V/480V

Cycle .............................................................60 Hz

Phase ....................................................... 3-Phase

Circuit Rating....................................... 15 Amps

Connection ..... Hardwire with Locking Switch

This machine can be converted to operate on

a

440V power supply. To do this, follow the

Voltage Conversion

instructions included in

this

manual. The intended 440V circuit must

have a verified ground and meet the

following

requirements:

Circuit Requirements for 220V

This machine is prewired to operate on a power

supply circuit that has a verified ground and

meets the following requirements:

Nominal Voltage ........... 208V/220V/230V/240V

Cycle .............................................................60 Hz

Phase ....................................................... 3-Phase

Circuit Rating....................................... 15 Amps

Plug/Receptacle ............................ NEMA 15-20

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-15-

PREPARATION

Grounding Requirements

This machine must be grounded! In the event

of

certain types of malfunctions or breakdowns,

grounding provides a path of least resistance

for electric current

in order to reduce the risk of

electric shock.

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without

yellow stripes) is the equipment-grounding wire.

If repair or replacement of the power cord or

plug is necessary, do not connect the equipment-

grounding wire to a live (current carrying)

terminal.

Check with an electrician or qualified service

personnel if you do not understand these

grounding requirements, or if you are in doubt

about whether the tool is properly grounded.

If you ever notice that a cord or plug is

damaged or worn, disconnect it from power, and

immediately replace it with a new one.

FigureFigure 7. NEMA 15-20 plug and receptacle.. NEMA 15-20 plug and receptacle.

Grounding Pin

Current Carrying Blades

GROUNDED

15-20 RECEPTACLE

15-20

PLUG

For 220V operation: Use the plug type listed in

the

Circuit Requirements

for this voltage. The

listed plug (similar to the following figure) has

an equipment-grounding wire to safely ground

the machine.

The plug must only be inserted

into

a matching

receptacle (outlet) that is properly

installed and grounded in accordance with all

local codes and ordinances.

FigureFigure 8. Typical setup of a permanently connected. Typical setup of a permanently connected

machine.machine.

Power Source

LOCKING

DISCONNECT SWITCH

Machine

Conduit

Ground Ground

Conduit

For 440V operation: As specified in Circuit

Requirements

for 440V, the machine must be

hardwired to the power source, using a locking

switch as a disconnecting means (see below). The

machine must also be connected to a grounded

metal permanent wiring system; or to a system

having an equipment-grounding conductor. Due

to the complexity and high voltage involved, this

type of installation MUST be done by a qualified

electrician.

No adapter should be used with plug. If

plug does not fit available receptacle, or if

machine must be reconnected for use on a

different type of circuit, reconnection must

be performed by an electrician or qualified

service personnel, and it must comply with all

local codes and ordinances.

-16 -

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F PREPARATION

Converting Voltage

to 440V

The Model SB1124F is prewired to run on 220V

power, but it can be converted to 440V operation.

This conversion consists of: 1) Disconnecting the

machine from power, 2) rewiring the transformer

for 440V operation, 3) replacing the overload

relay, and 4) rewiring the motors for 440V

operation.

All wiring changes must be inspected by a

qualified electrician or service personnel before

the saw is connected to the power source. If,

at any time during this procedure you need

assistance, call Grizzly Tech Support at (570)

546-9663.

Phase Converters

DO NOT use a static phase converter to create

3-phase power—it can quickly decrease the

life of electrical components on this machine.

If you must use a phase converter, only use a

rotary phase converter. See the Model G5844 in

Accessories on Page 47.

Extension Cords (220V Only)

Minimum Gauge Size............................12 AWG

Maximum Length (Shorter is Better) ....50 ft.

We do not recommend using an extension cord

with this machine. If you must use one, only

use it if absolutely necessary and only on a

temporary basis.

Extension cords cause voltage drop, which may

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size gets smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine

must contain a ground wire, match the required

plug and receptacle listed in the

Circuit

Requirements

for the applicable voltage, and

meet the following requirements:

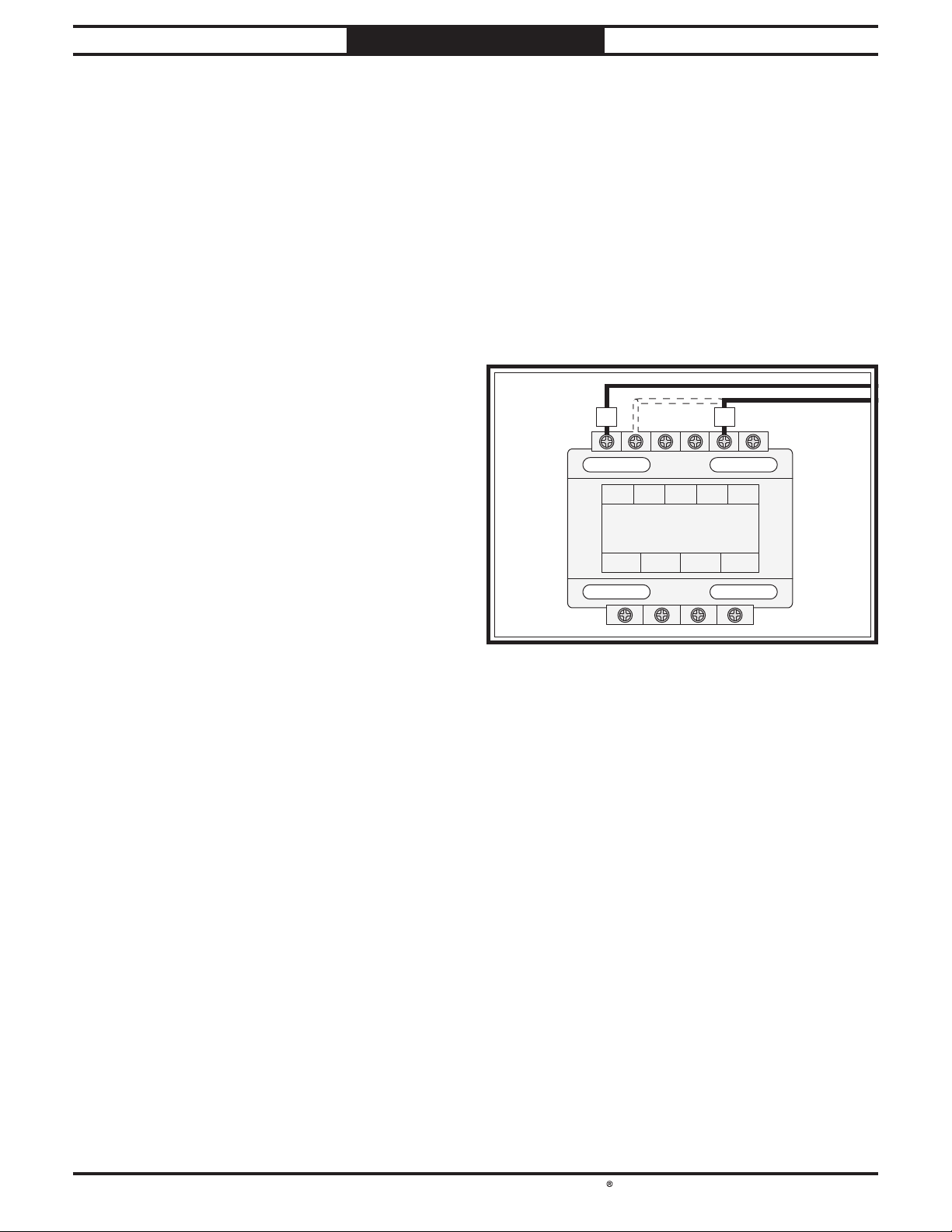

To convert SB1124F to 440V operation:

1. DISCONNECT MACHINE FROM POWER!

2. Open electrical cabinet and locate

transformer (see Figure 9).

3. Move "R" wire from 220V terminal to 440V

terminal (see Figure 9).

4. Remove overload relay and replace with

TECO RHU-10/4.8K1 overload relay (refer

to wiring diagrams on Pages 68–69). Set

amperage dial to 4.8A.

5. Close electrical cabinet.

6. Remove motor junction box covers on main

and coolant motors.

7. Rewire main motor and coolant pump for

440V operation (refer to wiring diagrams on

Page 71).

Note: If the diagram included on the motor

conflicts with the one in this manual, the

motor may have changed since the manual

was printed. Use the diagram provided on

the motor.

8. Install junction box covers on main and

coolant motors.

0V 220V 380V 400V 440V

110V 0V 24V 0V

Transformer

LCE

LCPIC-TBSM-100400

TR

FigureFigure 9. Moving "R" wire to 440V terminal.. Moving "R" wire to 440V terminal.

Items Needed Qty

Phillips Head Screwdriver #2...............................1

Hex Wrench 8mm .................................................1

TECO Overload Relay RHU-10/4.8K1 .................1

South Bend Tools

For Machines Mfd. Since 11/22 Model SB1124F

-17-

PREPARATION

Unpacking

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at

(360) 734-1540 for advice. You may

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

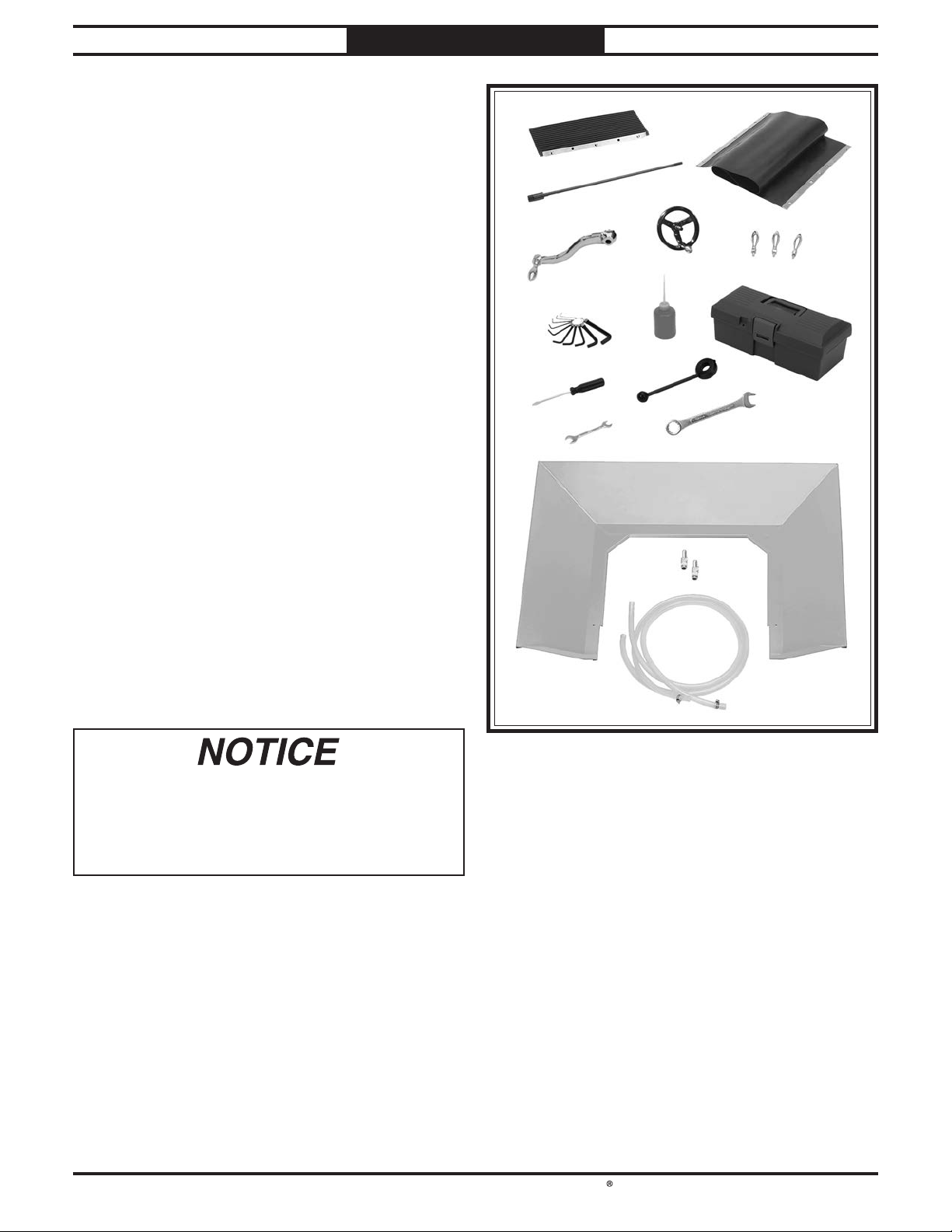

Inventory

If you cannot find an item on this list, carefully

check around/inside the machine and

packaging materials. Often, these items get

lost in packing materials while unpacking or

they are pre-installed at the factory.

Inventory (Figure 10) Qty

A. Front Way Cover............................................ 1

B. Rear Way Cover ............................................. 1

C. Drawbar 7⁄16"-20 x 18

1⁄2"..................................1

D. Knee Crank ....................................................1

E. Fine Downfeed Handwheel............................1

F. Revolving Handles .........................................3

G. Hex Wrench 10-Pc. Set 1.5–10mm................ 1

H. Oil Bottle ........................................................1

I. Tool Box ..........................................................1

J. Combination Screwdriver..............................1

K. Coarse Downfeed Lever .................................1

L. Open-End Wrench 10/12mm .........................1

M. Combo Wrench 19mm.................................... 1

N. Splash Pan......................................................1

O. Coolant Return Hose Pipe Fittings...............2

P. Coolant Return Hoses w/Clamps .................. 2

Q. Spare Key Set (Not Shown) ........................... 1

FigureFigure 10. Inventory.. Inventory.

AA

BB

CC

DD

EE

FF

GGHH

II

JJKK

LLMM

NN

OO

PP

-18-

For Machines Mfd. Since 11/22

South Bend Tools

Model SB1124F PREPARATION

The unpainted surfaces are coated

at the factory

with a heavy-duty rust preventative that

prevents corrosion during shipment and

storage.

The benefit of this rust preventative is that it

works very well. The downside is that it

can be

time-consuming

to thoroughly remove.

Be patient and do a careful job when

cleaning

and removing the rust preventative

. The time

you spend doing this will reward you with

smooth

-sliding parts and a better appreciation

for the proper care of

the unpainted surfaces.

Although there are many ways to successfully

remove the rust preventative, the

following

process works well in most situations

.

Before cleaning, gather the following:

• Disposable

rags

• Cleaner/degreaser

(certain citrus-based

degreasers work extremely well and they

have non-toxic fumes)

• Safety glasses & disposable gloves

Note:

Automotive degreasers, mineral spirits, or

WD•40 can be used to remove rust preventative.

Before using these products, though, test them

on an inconspicuous area of a painted surface to

make sure they will not damage it.

Basic steps for removing rust preventative:

1. Put on safety glasses and disposable gloves.

2. Coat all surfaces that have rust preventative

with a liberal amount of your cleaner or

degreaser and let them soak for a few

minutes.

3. Wipe off the surfaces. If your cleaner or

degreaser is effective, the rust preventative

will wipe off easily.

Note: To clean off thick coats of rust

preventative on flat surfaces, such as beds

or tables, use a PLASTIC paint scraper to

scrape off the majority of the coating before

wiping it off with your rag. (Do not use a

metal scraper or it may scratch the surface.)

4. Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a

quality metal protectant or light oil to

prevent rust.

GAS

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used for

cleaning. Avoid using these

products to remove rust

preventative.

Many cleaning solvents are

toxic if inhaled. Minimize

your risk by only using

these products in a well

ventilated area.

Avoid chlorine-based solvents, such as

acetone or brake parts cleaner that may

damage painted surfaces. Always follow the

manufacturer’s instructions when using any

type of cleaning product.

Order online at

www.grizzly.com

OR

Call 1-800-523-477

7

T23692—Orange Power Degreaser

A great product for removing the waxy shipping

grease from the non-painted parts of the

machine during clean up.

Cleaning & Protecting

FigureFigure 11.. T23692 Orange Power Degreaser.

Table of contents

Other South Bend Tools Lathe manuals

Popular Lathe manuals by other brands

Maggi

Maggi BORING SYSTEM 35 ORIGINAL USE AND MAINTENANCE MANUAL

Elem Garden Technic

Elem Garden Technic SBE2201-2L Original instructions

Roland

Roland MODELA MDX-50 user manual

Hafco Metalmaster

Hafco Metalmaster TM-1740G instruction manual

woodmizer

woodmizer Sawmill LT20 AC MH Series Safety, Setup, Operation & Maintenance Manual

Southbend

Southbend SB1307 instruction sheet