6

1. Technical Data

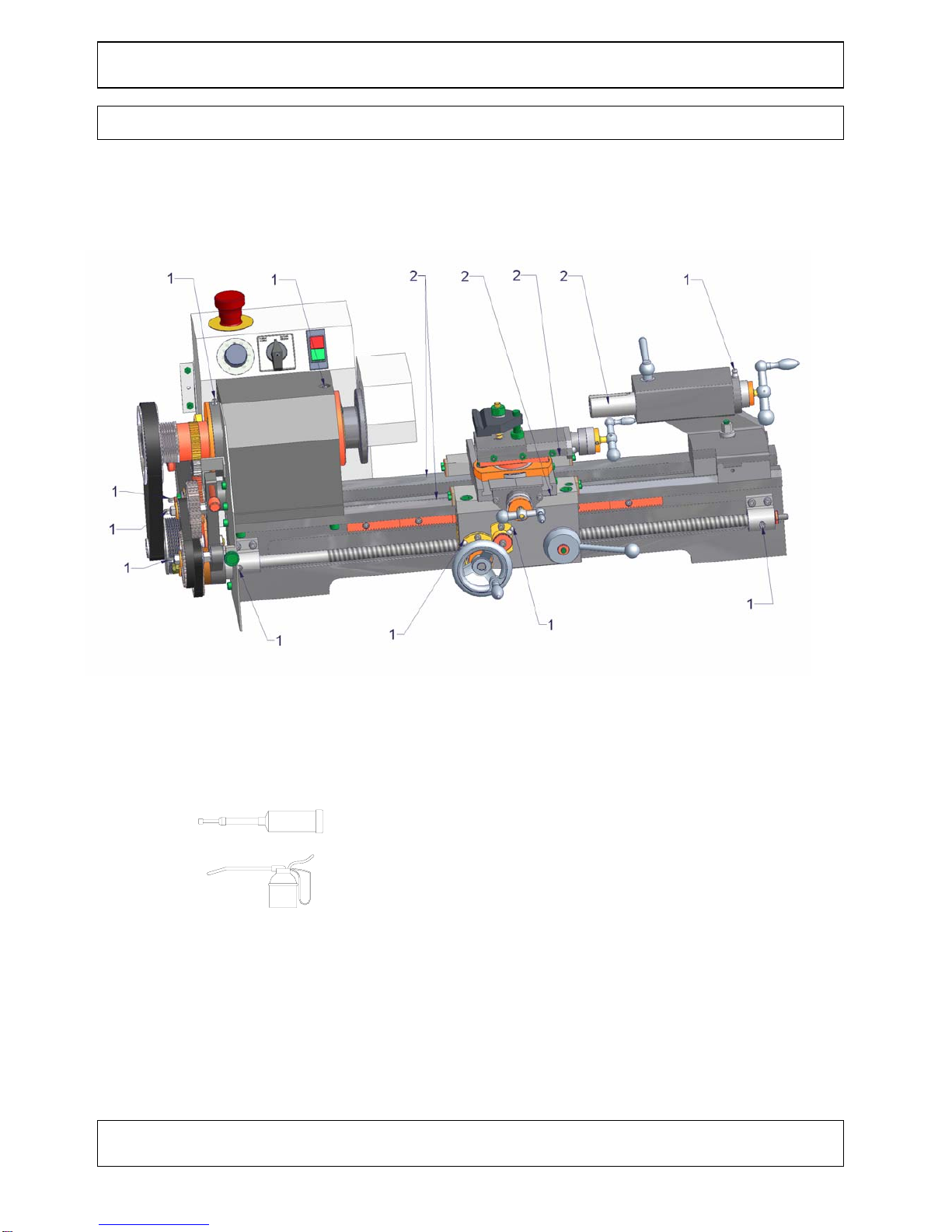

Working range

Centre distance.......................................................... 350 mm

Centre height.............................................................. 100 mm

Largest turning diameter over bed.............................. 200 mm

Largest turning diameter over slide............................ 120 mm

Work spindle

Drive output................................................................ 1,4 Kw, 220V, 50Hz

Infinetely variable spindle speed................................. 45 – 2300

Spindle bore............................................................... 20 mm

Cone in spindle nose Cone 3

Cross table

Cross table range of displacement............................. 100 mm

Turning carriage´s range of displacement.................. 50 mm

Turning carriage´s range of displacement.................. 360°

Max. height of turning tools ........................................ 16 mm

Guideways

Longitudinal support................................................... Dovetail guide and adjustment rails

Cross support............................................................. Dovetail guide and adjustment rails

Chips and dirt stripper ................................................ Protection of the guides

Tailstock

Tail spindle´s range of displacement.......................... 45 mm

Tail spindle´s hole bore .............................................. Cone 2

Lateral displacement of the tailstock

to both sides...............................................................

± 10 mm

Screw cutting attachment

Advance..................................................................... 0,085 and 0,16 mm/min

Thread pitch ...............................................................

- metric....................................................................... 0,4 - 3,0 mm

- inch .......................................................................... 10 - 32 thead per inch

Noise values according DIN 45635 - part 1

Emission data

No-load running LpA = 63 dB(A)

Load running LpA = 67 dB(A)

- Subject to technical alterations -