Vollrath STOELTING U421-I2A User manual

Other Vollrath Commercial Food Equipment manuals

Vollrath

Vollrath JT4 User manual

Vollrath

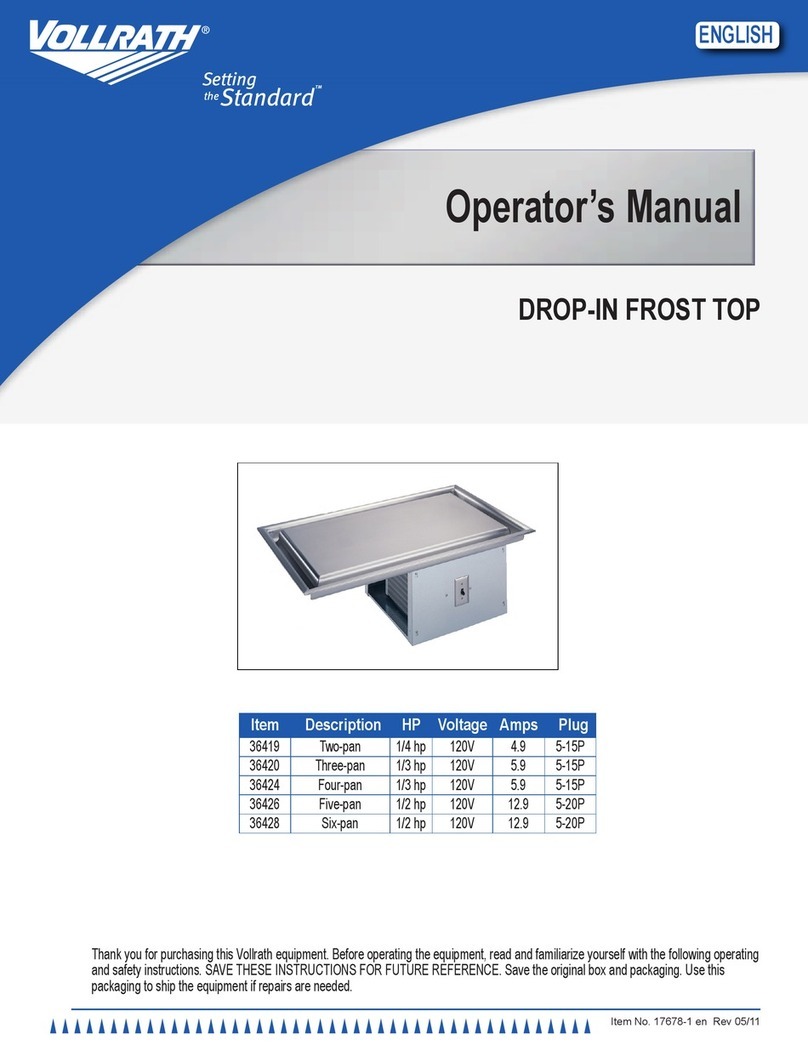

Vollrath 36419 User manual

Vollrath

Vollrath Cayenne TSI7001 User manual

Vollrath

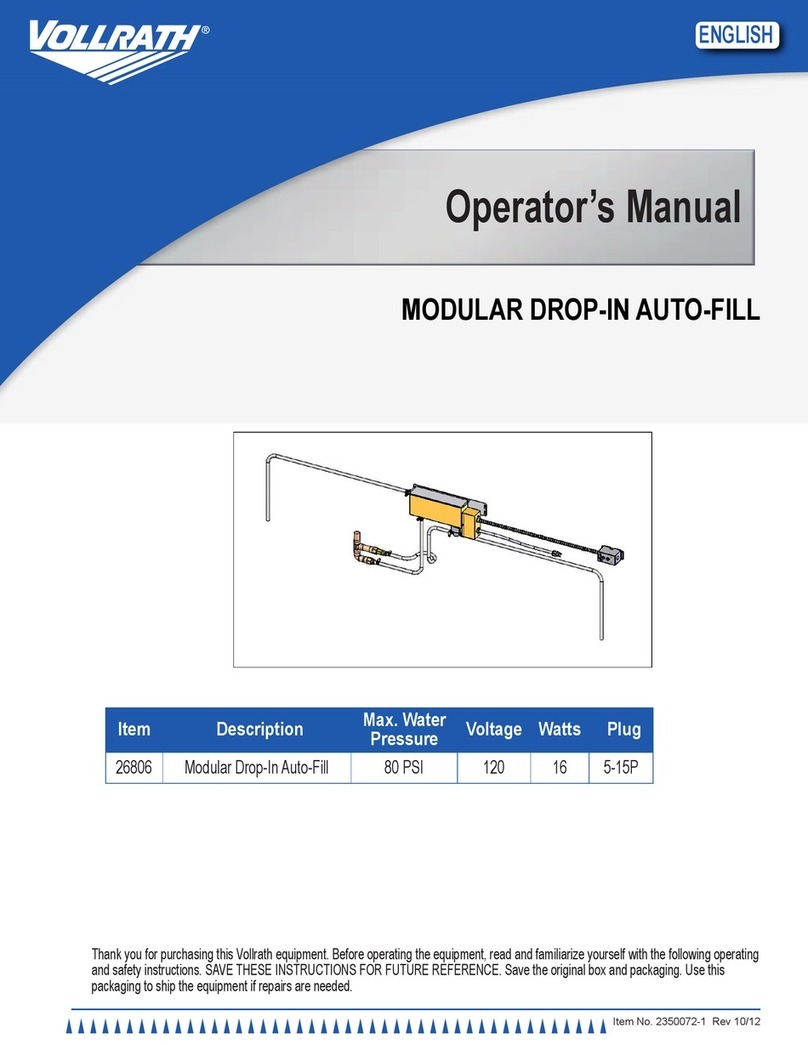

Vollrath 26806 User manual

Vollrath

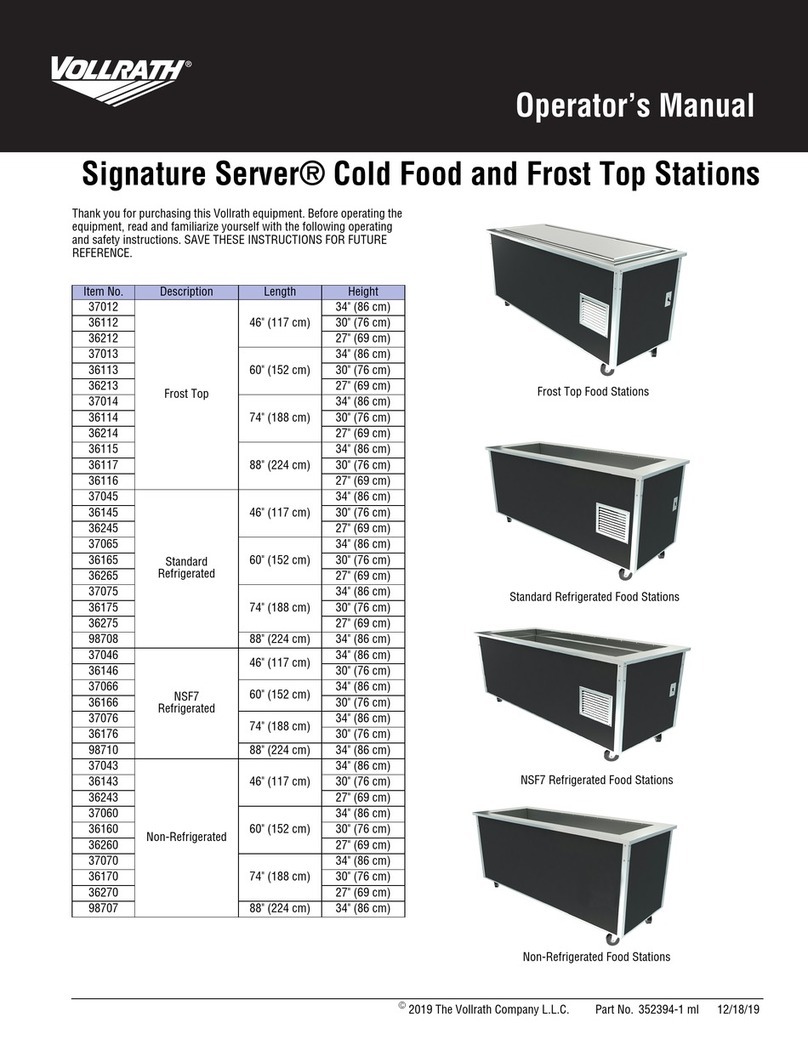

Vollrath Signature Server 37012 User manual

Vollrath

Vollrath KDC1418-4F-06 User manual

Vollrath

Vollrath Stoelting DQU411 Series User manual

Vollrath

Vollrath 38012 User manual

Vollrath

Vollrath STOELTING SU412 User manual

Vollrath

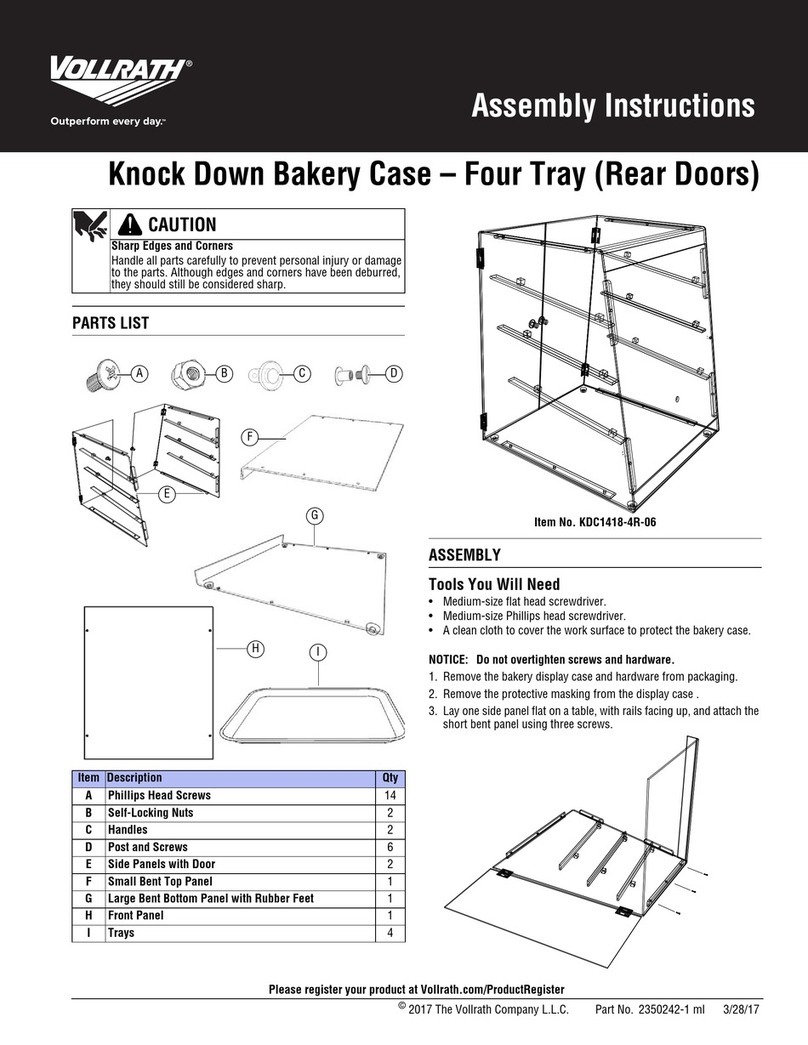

Vollrath KDC1418-4R-06 User manual

Vollrath

Vollrath Cayenne TSA7209 User manual

Vollrath

Vollrath 46670 User manual

Vollrath

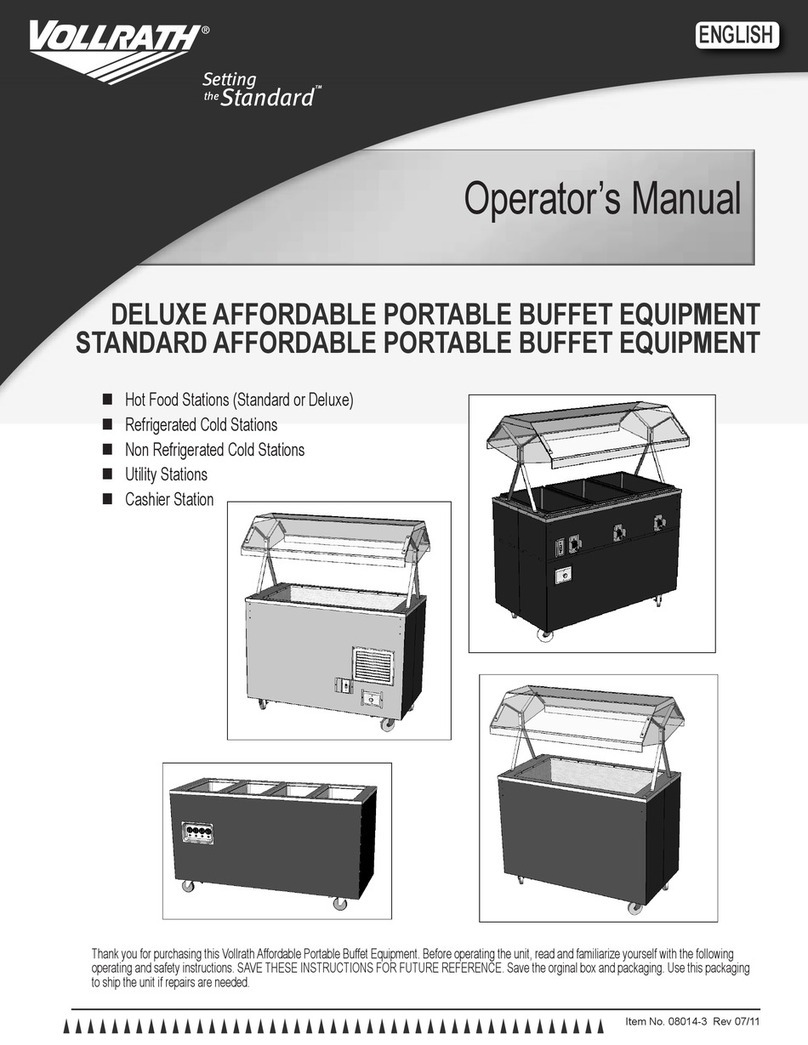

Vollrath DELUXE User manual

Vollrath

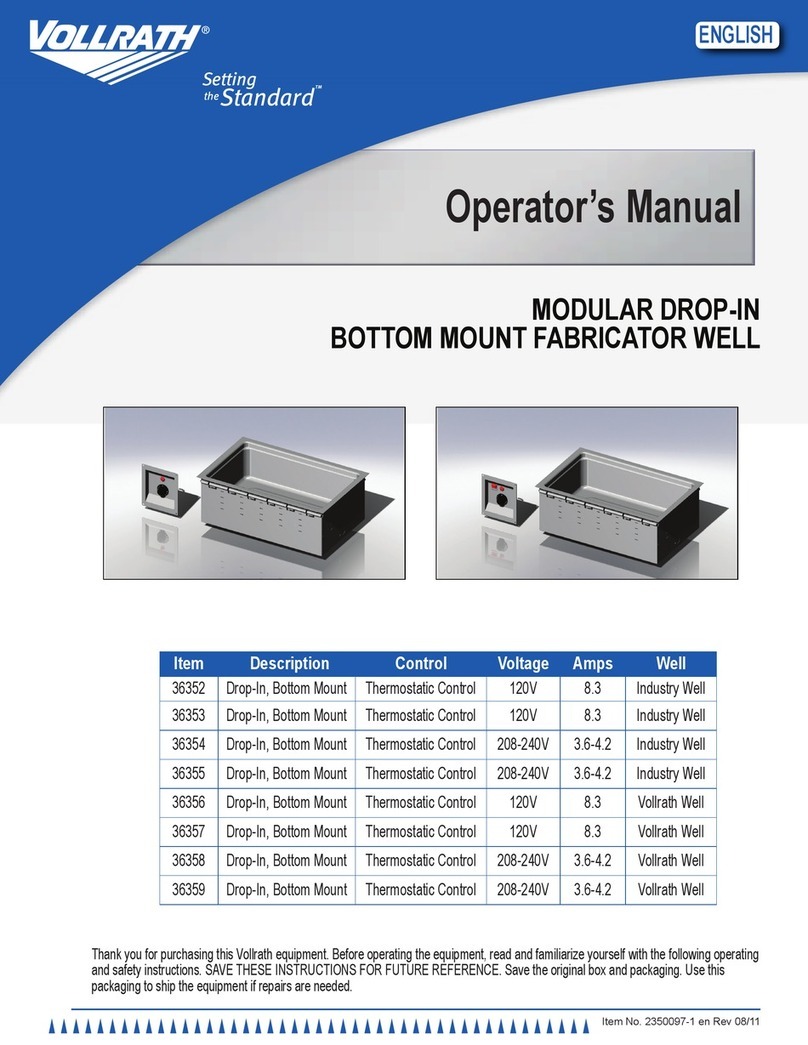

Vollrath 36352 User manual

Vollrath

Vollrath Cayenne BMA7103 User manual

Vollrath

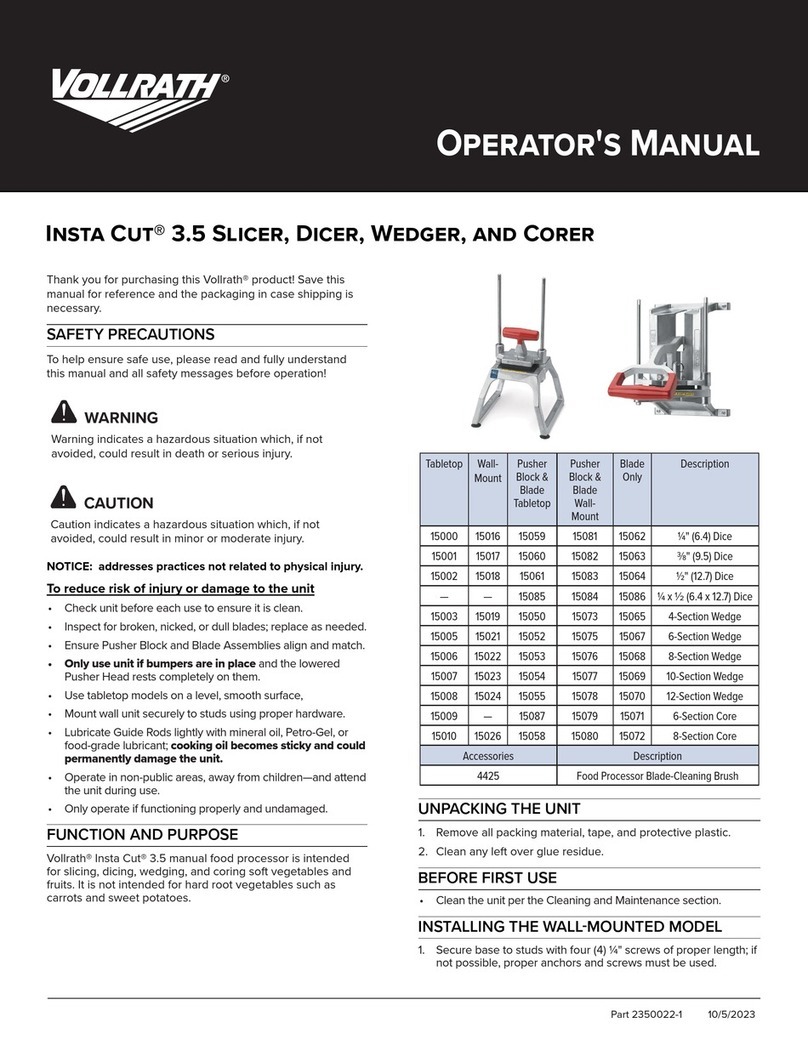

Vollrath Insta Cut 3.5 User manual

Vollrath

Vollrath Cayenne FMA7026 User manual

Vollrath

Vollrath 40868 User manual

Vollrath

Vollrath FAC-3 User manual

Vollrath

Vollrath Stoelting U412 Series User manual

Popular Commercial Food Equipment manuals by other brands

Blue Seal

Blue Seal EF30 Installation & operation manual

Tecfrigo

Tecfrigo Snelle 400 GS installation instructions

Follett

Follett PFT Series Operation and maintenance manual

MEFE

MEFE CAT 206 PTR User manual and maintenance

Premier

Premier 900cl Product manua

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Cambro

Cambro IBSD37 Setup guide and user manual