Southbend SB1231 User manual

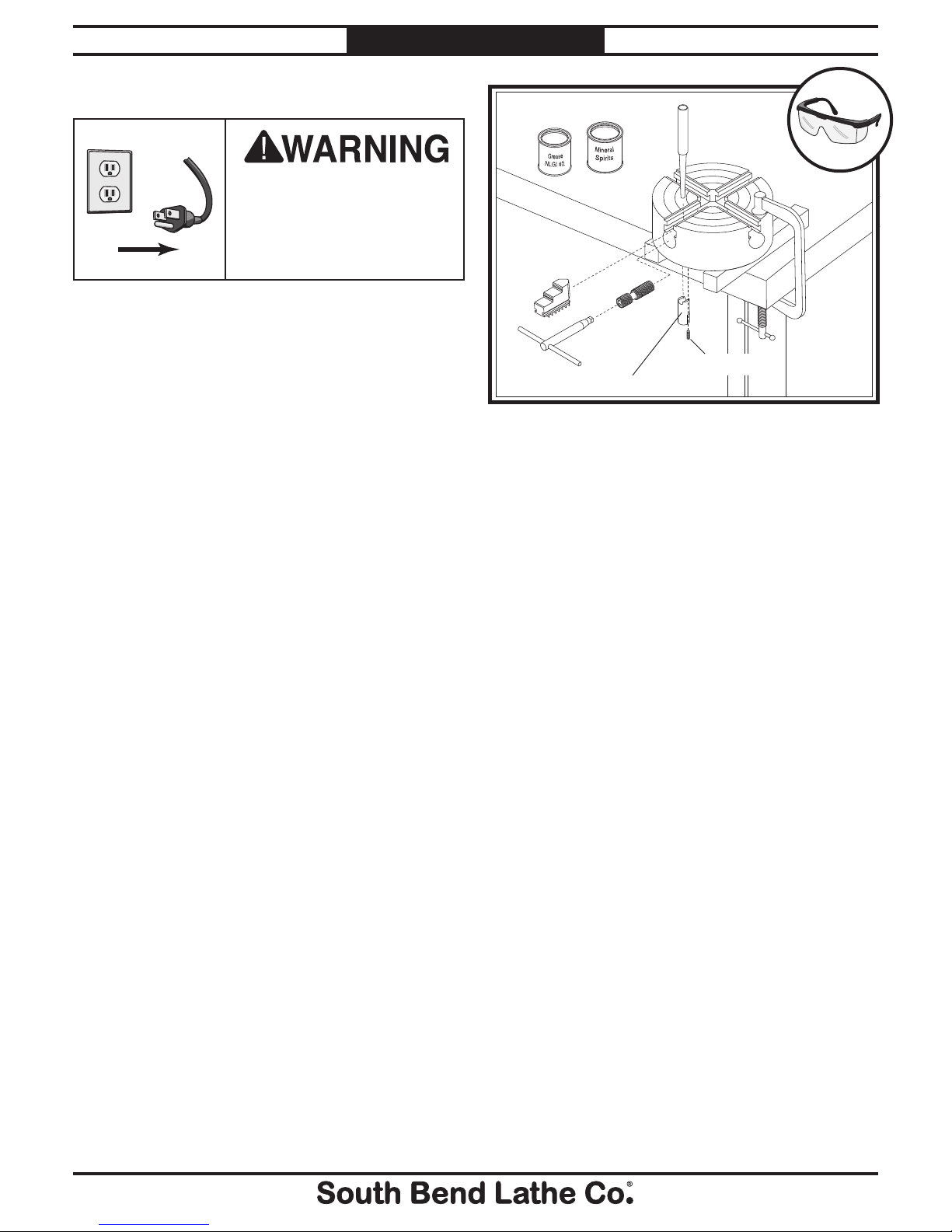

Chucks are heavy! Get assistance when

installing or removing the chuck from the

lathe. Wear heavy duty leather boots for

foot and toe protection, and keep hands and

fingers away from all pinch points. Ignoring

this warning can lead to a severe crushing

injury or finger amputation!

Specifications

•OD Clamping...... 0.69"–10.04" (17.5–255mm)

•ID Clamping.......... 3.74"–10.83" (95–275mm)

•Chuck Bore Diameter ................2.56" (65mm)

•Chuck Outer Diameter ..........11.81" (300mm)

•Maximum Speed ...........................2500 RPM*

•Mounting Type ......................... D1-8 Camlock

• Construction..................Fine-GrainCast-Iron

• ChuckWeight......................................... 80lbs

• ChuckShippingWeight......................... 85lbs

•Country of Origin ................................ Taiwan

* ThemaximumspeedlistedaboveisONLY

possiblewiththechuckjawsandthe

workpieceincompleterotationalsymmetry.

Theworkpieceweightmustbewithinthe

limitsofthelathe,andtheworkpiecemass

mustbeofequaldensitythroughoutto

preventcentrifugalimbalanceorradial

runout—evenifatailstockorothersupport

isusedforadditionalsupport.

Instruction Sheet

PHONE: (360) 734-1540 • www.southbendlathe.com

MODEL SB1231

12" 4-JAW INDEPENDENT CHUCK

Copyright © October, 2010 by South Bend Lathe Co.

WARNING: No portion of this manual may be reproduced without written approval.

#CR13310 Printed in Taiwan

Figure 1. Features.

Introduction

TheModelSB1231usesadirectmountD1-8

camlocksystemwherethecamlockstudsare

directlythreadedintotothechuckbodyinstead

of being threaded into a backing plate that

isboltedtothechuck.Withoutusingaback

platetomountthechuck,thechuckjawsare

positionedclosertotheheadstockwhichgives

alongerdistancebetweenthejawsandthe

tailstock.Anotherbenefitisthatthedistance

betweenthejawsandtheoutboardspindlenose

isreduced,soifaspidersupportisusedonthe

outboardspindle,shortgunbarrelsandother

shorterworkpiecescanbeheldatbothends.

Manufactured

with high-tech

German CNC

machinery

Fine-grain cast

iron body

Hardened steel jaws

for durability and

extreme clamping

force and grip

Independent jaw

screws for each

reversible jaw

Direct

camlock

spindle

mounting

Jaw screw

retaining pin

with lock screws

Safety

•Chuck Key Safety:Achuckkeyleftinthe

chuckcanbecomeadangerousprojectile

whenthespindleisstarted.Alwaysremove

thechuckkeyafterusingit.Developahabit

of not taking your hand off of a chuck key

unlessitisawayfromthemachine.

•Disconnect Power: Disconnectthelathe

frompowerbeforeinstallingandremoving

the chuck or doing any maintenance or

adjustments.Accidentallathestartupcan

causesevereinjuryordeath.

•Secure Clamping: Athrownworkpiece

maycausesevereinjuryorevendeath.

Whenswappingthechuckjawpositions,

keep in mind that maximum gripping

forceisattainedatfulljawandjawscrew

engagement. Ifonlyoneispartiallyengaged,

overallclampingforceisreduced.

•Speed Rates: Operating the lathe where

maximumchuckspeedisexceeded,orattoo

highofaspeedforanunbalancedworkpiece,

cancausetheworkpiecetobethrownfrom

thechuck.Alwaysusetheappropriatefeed

andspeedrates.Athrownworkpiecemay

causesevereinjuryorevendeath.

•Large Chucks: Largechucksareveryheavy

anddifficulttograsp,whichcanleadto

crushedfingersorhandsifmishandled.

Getassistancewheninstallingorremoving

largechuckstoreducethisrisk.Protectyour

handsandtheprecisiongroundwaysby

usingachuckcradleorpieceofplywoodover

thewaysofthelathewhenservicingchucks.

•Safe Clearances: Oftenchuckjawswill

protrudepastthediameterofthechuckand

cancontactacoolantnozzle,tooling,tool

post,orsaddle.Beforestartingthespindle,

makesuretheworkpieceandchuckjaws

haveadequateclearancebyrotatingthenby

handthroughitsentirerangeofmotionby

hand.

•Stopping Lathe By Hand: Stopping the

spindlebyputtingyourhandonthe

workpieceorchuckcreatesanextremerisk

ofentanglement,impact,crushing,friction,

orcuttinghazards.Neverattempttoslow

orstopthelathechuckbyusingyourhand.

Allowthespindletocometoastoponits

ownorusethebrake(ifequipped).

•Long Stock Safety: Longstockcanwhip

violentlyifnotproperlysupported,causing

seriousimpactinjuryanddamagetothe

lathe.Reducethisriskbysupportingany

stockthatextendsfromthechuck/headstock

morethanthreetimesitsowndiameter.

Alwaysturnlongstockatslowspeeds.

-2-

Mfg.Since5/10

Model SB1231 INSTRUCTIONS

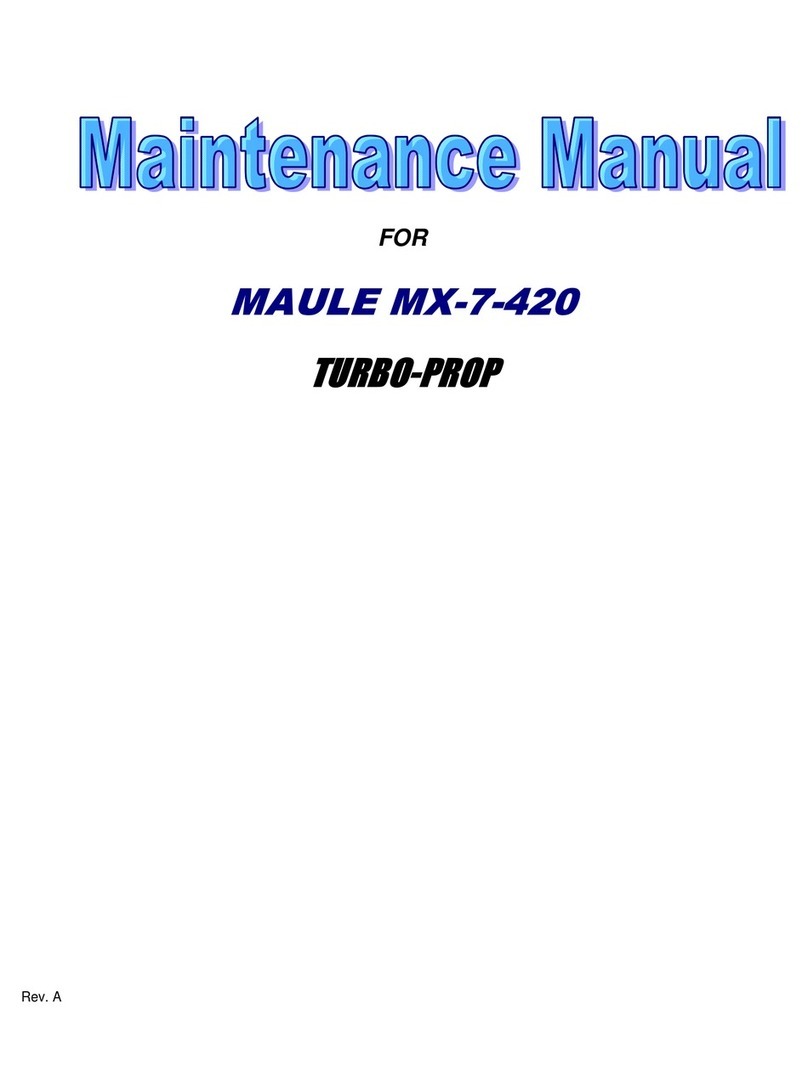

Camlock Stud Installation

Thecamlockstudsthatareshippedwiththis

chuckmaybepre-installedfromthefactory.

IfsoskipthissectionandcompleteChuck

Installation and Removal on Page 4;

otherwise,installthecamlockstudsasoutlined

below:

1. Oilandthreadeachcamstudintothechuck

untilthealignmentgrooveisushwiththe

chucksurface,asshowninFigure 2.

2. Installandtightenthelockingcapscrew

foreachstud,makingsurethatthecamlock

studscanslightlyrotatebackandforth.

Figure 2. Camlock stud installation.

Figure 3. Camlock stud adjustment.

Camlock Stud Adjustment

Ifthecamlockstudshavebeenpre-installedat

thefactory,orifyouareinstallingthemforthe

rsttime,slightmachiningdifferencesbetween

thelathespindleandchuckcancauseoneor

morecamlockstolockattheincorrectlocation.

If any cam line stopsoutsideofa “V” mark when

allofthecamlockshavebeentightened, remove

thechuckandadjusttheheightoftheoffending

stud one full turn up or down asillustrated

below.Afterallcamlocksoperatecorrectly,

stampalignmentmarksinthechuckandspindle

toensurethatthechuckcanbere-installedin

thesamepositionafterbeingremoved.

Camlock Stud

Must Slightly

Rotate Back/Forth

Cap Screw

Installed & Tight

Initial Adjustment:

Camlock Stud Alignment

Groove is Flush with Chuck

Surface

Alignment Marks

Spindle Line

CORRECT

The Camlock Mark

Stops Between the

“V” Marks.

To Correct:

Turn Stud One Turn In

To Correct:

Turn Stud One Turn Out

INCORRECT

The Camlock Mark

Stops Before the

“V” Marks.

INCORRECT

The Camlock Mark

Stops After the

“V” Marks.

Mfg.Since5/10 Model SB1231

-3-

INSTRUCTIONS

6. Withthehelpofanotherperson,orwiththe

helpofachuckcradle,alignthechuckwith

thespindlesothestudsandcamlockbores

arealignedcorrectly,andcarefullyslidethe

chuckontothelathespindle.Neverrestthe

chuckonitslowerstuds,asshowninFigure

5,androllorpushthetopofthechuckinto

placeonthespindle.Thisisabadpractice

thatmaydamagethestudsandcamlock

bores.

Do not install the chuck without having

the camlock cap screws in place or fully

tightened. Otherwise, the camlock studs may

turn with the camlocks on release, resulting in

the chuck being permanently locked onto the

spindle.

Figure 5. Typical alignment of studs and camlock

bores.

3. Cleanawaydebrisandoilysubstancesfrom

thematingsurfacesofthespindleandthe

chucktoensurethebestfitpossible.

4. Inspectandmakesurethatallcamlock

studsareundamaged,clean,andlightly

oiled.

5. Makesurethatthecamlockstudretaining

capscrewsaresnug,butstillallowthestuds

toberotatedbackandforthslightlybyhand.

Thisfree-playiscriticaltoensurethatthe

camlockstightenandlockwiththestuds

completely,andwillreleasewithoutbinding.

—Ifaproblemisfoundwiththecamlock

lockingorrelease,removetheoffending

studandcleanitwithmineralspirits.

Compareitwithagoodstudforany

inconsistencies,andreplaceitifaproblem

isfound.Inspectthebore,capscrew,seat

depth,andthreadswithothersthatare

knowntobecorrect.Chaseallthreads,

andremoveanyburrsordingsintheseat.

Dryouttheborewithcompressedairand

lightly re-lubricate with a drop or two of

machine oil or way oil.

Figure 4.Wooden chuck support cradle.

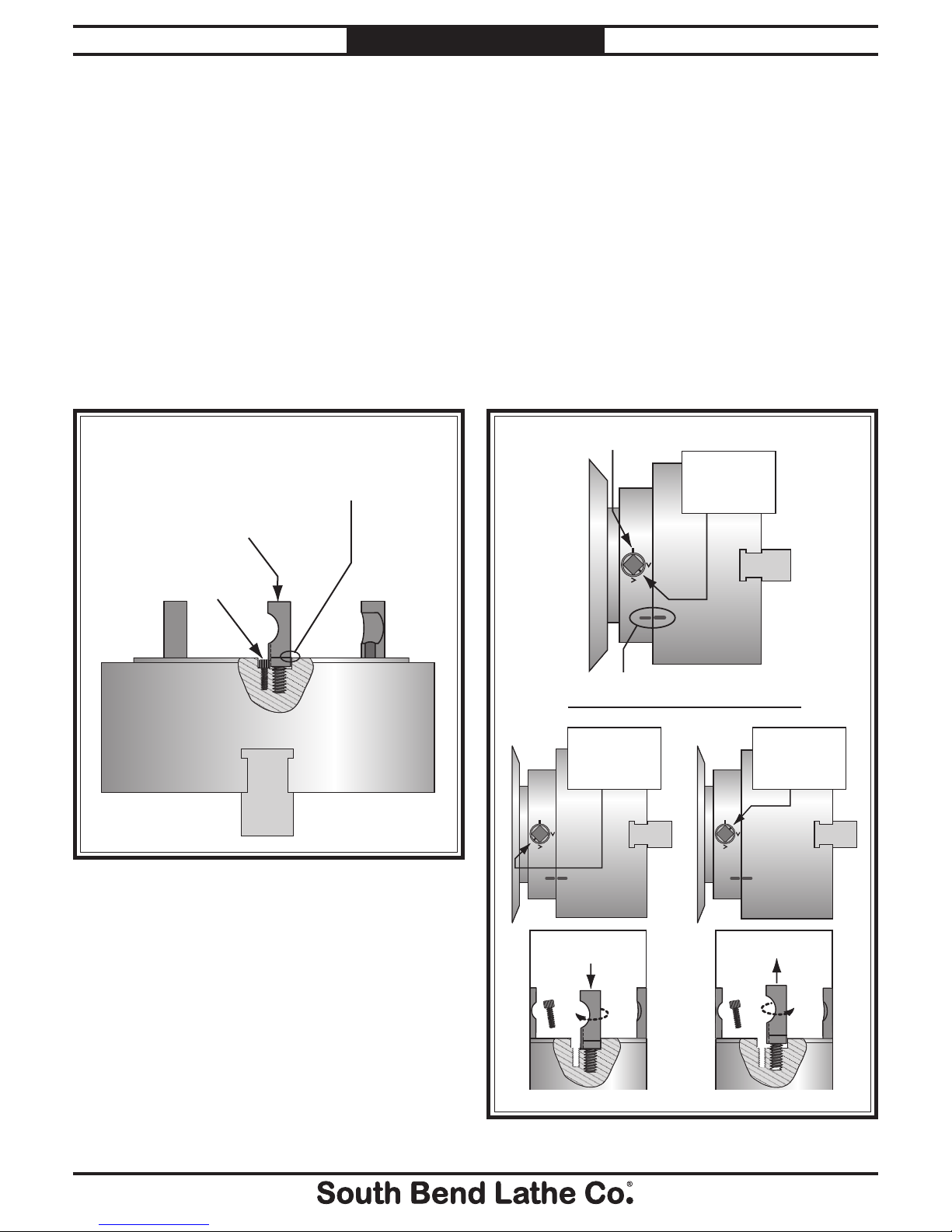

Before turning the lathe

ON, make sure the chuck

key is removed! A thrown

chuck key can cause

serious injury or death to

the operator or bystanders.

1. DISCONNECTLATHEFROMPOWER!

2. Layachuckcradle(seeFigure 4) or

plywoodunderthechuckandoverthe

bedwaytoprotecttheprecisionground

surfacesfromdamageandreducetheriskof

fingersgettingpinched.

Chuck Installation and Removal

INCORRECTCORRECT

-4-

Mfg.Since5/10

Model SB1231 INSTRUCTIONS

7. Tightencamlocksinastarpatterntodraw

thechuckinevenlyandreducethechance

ofmisalignment.Makesuretotighten

camlocksinanincrementalmannerto

ensurethatonecamlockdoesnotgetfully

tightenedbeforetheothers(i.e.,snugthe

camlocksonthefirstpass,thenmoderately

tightenonthenextpass,thenfullytighten

onthethirdpass).

Asyoutightenthecamlocks,thechuck

willseatwiththespindlenose.Whenfully

tightened,thecamlinewillfallbetweenthe

two"V"marksonthespindlenose,asshown

in Figure 6.

Figure 6. Camlock is fully tightened with the camlock

line positioned between the "V" marks.

— Ifthecamisfullytightened,butthecam

line ispositionedoutsideofthe“V”marks,

removethechuckandadjusttheheightof

the offending camlock stud,asoutlinedin

Camlock Stud Adjustment on Page 3.

8. Wheninstallationiscompleteandyouare

satisedwiththeresults,lightlystampaset

ofalignmentmarksonthechuckandspindle.

Note: Alignmentmarksensurethatthe

chuckcanbere-installedinthecorrect

positioneverytimeforconsistentchuckand

spindlealignment.Italsoallowsforthesame

camlocksandstudstooperatetogetherfor

consistentlockingandunlocking.

Cam line is between

the "V" marks

PINCH HAZARD! Protect your hands and the

precision ground bedways with plywood or a

chuck cradle when removing the lathe chuck!

The heavy weight of a falling chuck can cause

serious injury.

To remove the chuck:

1. DISCONNECTLATHEFROMPOWER!

2. Layachuckcradleorplywoodunderthe

chuckandoverthebedwaytoprotectthe

precisiongroundsurfacesfromdamageand

reducetheriskoffingersgettingpinched.

3. Loosenthecamlocksbyturningthekey

counterclockwiseapproximatelyone-thirdof

aturnuntilthemarkonthecamlockaligns

withthespindlemarkonthespindlenose

(seeFigure 7).Ifthestuddoesnotfreely

releasefromthecamlock,wigglethecamlock

untilitstudreleases.

Note:Camlockscanbecomeverytight.Acheater

pipemaybeusedtoaddleveragewhen

loosening.

Figure 7. Camlock is fully loosened when the camlock

line is aligned with the spindle mark.

Cam line is

aligned with the

spindle mark

Mfg.Since5/10 Model SB1231

-5-

INSTRUCTIONS

CAUTION: During the next step, the

chuck may come off suddenly, so it

is important that you are ready to

support its weight with a chuck cradle

to prevent crushing your fingers or

dropping the chuck.

4. Usingadeadblowhammerorother

softmallet,lightlytaparoundtheouter

circumference of the chuck body to break the

chuckfreefromthecamlocksandthespindle

nosetaper.

5. Usearockingmotiontocarefullyremovethe

chuckfromthespindle.

—Ifthechuckdoesnotimmediatelycome

off,rotatethechuckapproximately60˚

andtapagain.Makesureallthemarks

onthecamsandspindleareinproper

alignmentforremoval.

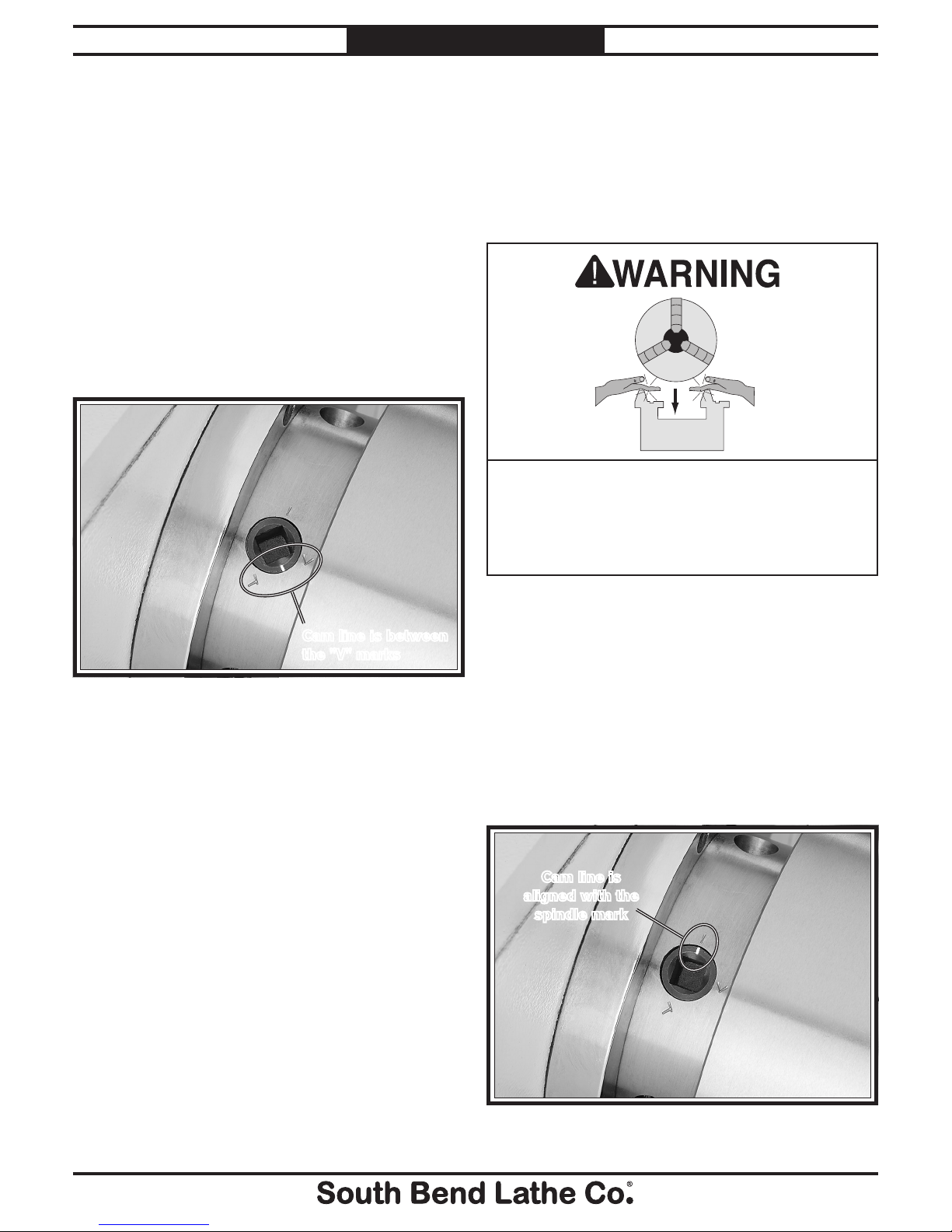

Operation

Non-cylindricalpartscanbeheldandbrought

intothespindlecenterlineforfacingorboring

Theotherbenetisthatthemajorityof

workpiecescanbepositionedoutofthespindle

rotationaxisifabore(seeFigure 9)orastep

needstobecutintoaworkpieceonanoutlying

edge.Forthebestgrippossibleonodd-shaped

workpieces,oneormorejawscanalsoberotated

180°tograbmoresurfaceareaforclamping.

Ifallfourjawscannotbeusedtoholdthe

workpiece,youmustusefaceplatetoreducethe

riskofaworkpiecebeingthrown.

To clamp a workpiece in the chuck:

1. DISCONNECTLATHEFROMPOWER!

2. Installacenterinthetailstock.

3. Retracteachjawand place the workpiece

flatagainstthechuckface.

4. Slidethetailstockforward,sothetipofthe

deadcenterappliesenoughpressureagainst

theworkpiecetoholditinplace,andthen

lockthetailstockinposition.

5. Moveeachjawuntilitmakeslightcontact

with the workpiece.

Figure 8. Tightening sequence.

7. Aftertheworkpieceisheldinplaceby

thejaws,turnthechuckbyhandandpay

attention to the workpiece alignment.

—Iftheworkpieceisnotcorrectlyaligned

foryouroperation,turnthechuckand

makefineadjustmentsbyslightly

looseningonejawandtighteningthe

opposingjawuntiltheworkpieceis

correctlyaligned(seeFigure 9 for an

example).

1

2

3

4

Hole to be

bored into

workpiece

Figure 9. Non-concentric workpiece correctly clamped

in the 4-jaw chuck.

6. FollowingthesequenceshowninFigure 8,

tighteneachjawinsmallincrementstomove

theworkpieceintotherequiredposition.

Checkfrequentlytomakesuretheintended

centerpointoftheworkpiecehasnot

wanderedawayfromthespindlecenterline

whilethejawsarebeingtightened.

-6-

Mfg.Since5/10

Model SB1231 INSTRUCTIONS

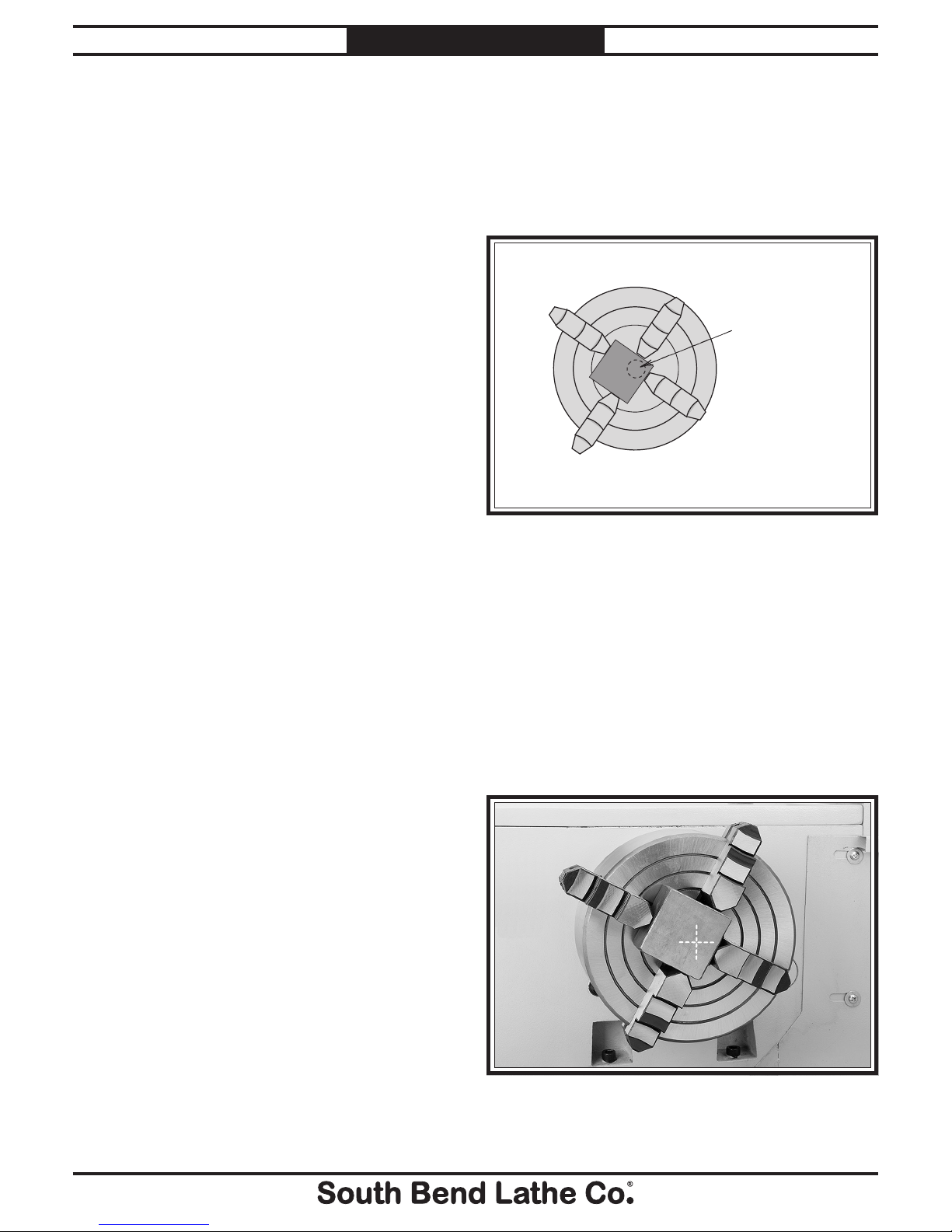

Jaw screw retaining pin

Set screw

a

Figure 10. Chuck sequence of disassembly.

Care & Maintenance

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

b. Backthejawsoutofthechuck

c. Removethefoursetscrews.

d. Putonsafetyglasses,anduseahammer

anddriftpunchtotapouteachjawscrew

retaining pin.

e. Slidethejawscrewsoutoftheirbores.

4. Usingmineralspirits,cleananddryall

parts.Inspectandxallbores,teeth,pins,

andmatingsurfacesforwear,burrs,galling,

rust,orcracks.

5. Withoutchangingthedimensionofanypart,

useawirebrush,emerycloth,ordressing

stonestoremoveallrust,burrs,oranyhigh

spotscausedbygalling.

6. CoatallpartswithanyautomotiveNLGI#2

grease,andcarefullyre-assemblethechuck

inthereverseordershowninFigure 10.

7. Rotatethechuckkeyclockwiseuntilthe

leadthreadofeachjawscrewisseenjust

enteringthejawguide,theninserteach

numberedjawintoitsnumberedslot.

8. Oneatatime,holdeachjawagainstitsjaw

screw,androtatethechuckkeyclockwiseto

engagethejawscrewwiththejaw,thenfully

threadthejawintothechuck.

9. Alignandre-installthechuck.

Foroptimumperformancefromyourchuck,

followthemaintenanceschedulebelow.Never

hammeronthechuck,jaws,oraworkpiecethat

isclampedinthechuck;andneversubjectthe

chucktoabrasives,ame,orwater.

Daily:

• Check/correctloosemountingbolts.

•Keep the chuck clean and oiled.

•Useavacuum,rag,orbrushtocleanthe

chuckafteruse. Neveruseairpressureto

cleanchipsawayfromachuck.

• Avoidleavingthechuckclampedona

workpiece,unloadthechuckjawsdaily.

• Makesurethechuckkeyisremovedfrom

thechuckwhennotinuse.

Ifthechuckeverbecomesstifftooperate,

itmayhavebeencontaminatedwithmetal

chipsorabrasivesfromincorrectorinfrequent

maintenanceintervals.Ifthisisthecase,the

chuckmustbedisassembled,cleaned,andre-

lubricated.

To disassemble the chuck for a full cleaning

and lubrication service:

1. DISCONNECTLATHEFROMPOWER!

2. Verifythatchuckalignmentmarksare

presentsothechuckcanbere-installedin

thesameposition,andremovethechuck.

Stampthemarksiftheydonotexist.

3. Leavingthecamlockstudsinplace,

disassemblethechuckinthesequencelisted

belowandshowninFigure 10.

a. Placeasetofwoodenblocksunderthe

chucksothecamlockstudsdonotreston

thetable,andclampthechucktothe

tableasshowninFigure 10.

b

c

d

e

d

Mfg.Since5/10 Model SB1231

-7-

INSTRUCTIONS

Troubleshooting

Symptom Possible Cause Possible Solution

Thechuckhas

hardspotsorbinds

completely.

1. Jawisinapoorpositionfor

clamping.

1. Re-installjawsformaximumengagementwithjaw

slotandjawscrew.

2. Lackoflubrication,rust,burr,or

metalshavingsinsideofchuck.

2. Disassemble,de-burr,clean,andlubricatechuck.

3. Brokentoothonthejaworthejaw

screw.

3. Disassemblechuckandrepair/replacebrokenpart.

Theworkpieceslips

inthejaws.

1. Incorrectjaworworkpiececlamping

position.

1. Re-installjawsformaximumengagementwithjaw

slotandjawscrew.

2. Chuckisbindingbeforefull

clampingforceisachieved,orajaw

orjawscrewisbinding.

2. Chuckisloadedupwithcontaminants.Disassemble

andservicechuck.Loosenandretightenthechuck

keyseveraltimestodistributelubricant.

3. Cuttingoverload. 3. Reduce cutting depth or feed rate.

Clamping accuracy

ispoor.

1. Workpieceimproperlyclampedor

workpieceismisaligned.

1. Removejaws,clean,de-burr,andre-install;verify

accuracyandrecalibratetest/dialindicator.

2. Chuckloose;mountingisoff-center,

orisimproperlyseated.

2. Removechuck,cleanandde-burrmounting;adjust

camlockstuds,andre-installchuck.

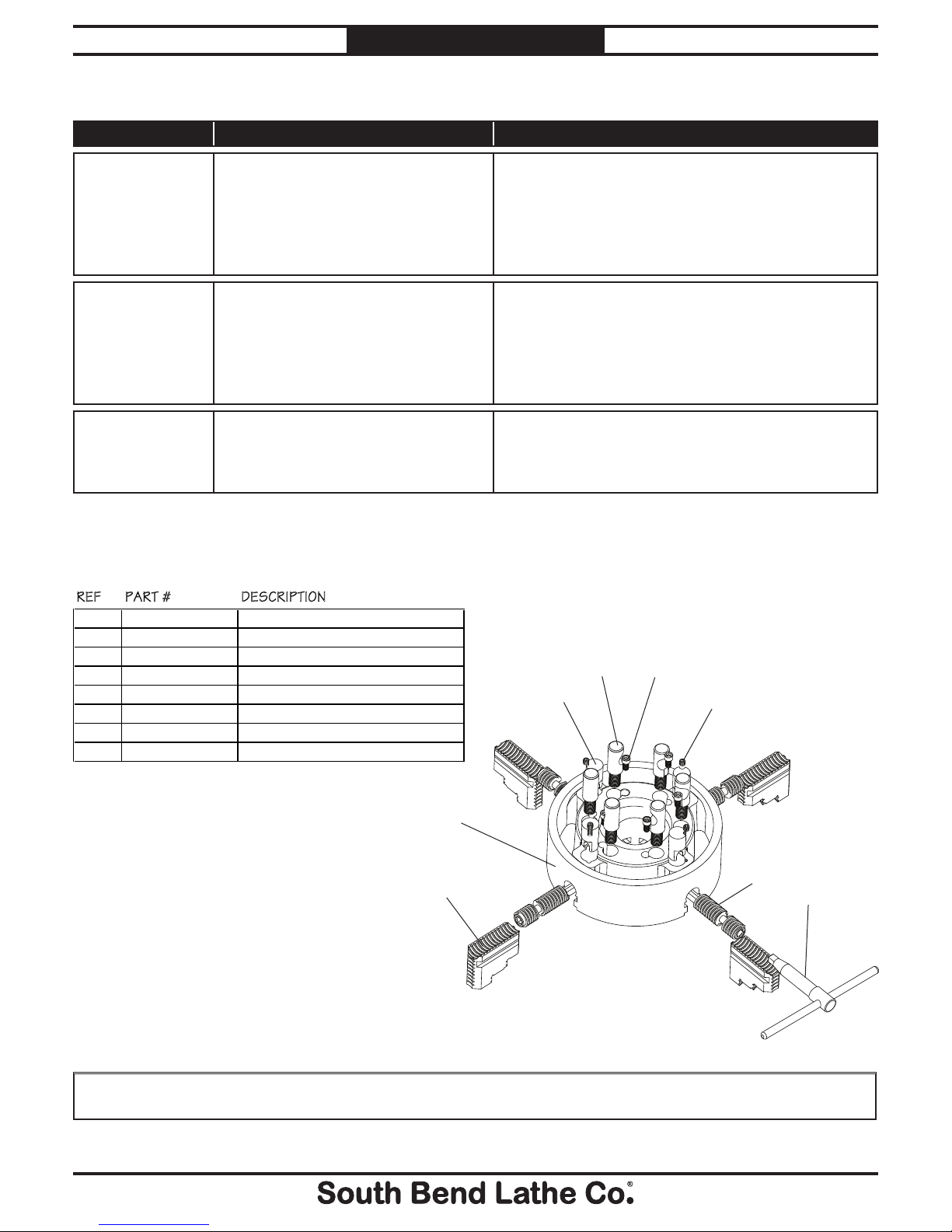

Parts List

Please Note: We included this parts breakdown for service purposes only. Since many of the parts shown are machined to

each individual chuck, they may not be available as replacement items.

Parts Diagram

REF PART # DESCRIPTION

1 PSB1231001 REVERSIBLE CHUCK JAW

2 PSB1231002 CHUCK BODY

3 PSB1231003 JAW SCREW

4 PSB1231004 JAW SCREW PIN

5 PSS02 SET SCREW 5/16-18 X 3/8

6 PSB1231006 CHUCK KEY

7 PSB1231007 D1-8 CAMLOCK STUD

8 PCAP09 CAP SCREW 5/16-18 x 5/8

6

3

2

1

5

8

7

4

If you need help with your new chuck,

contact us at:

PHONE: (360) 734-1540

FAX: (360) 676-1075 (International)

FAX: (360) 734-1639 (USA Only)

EMAIL: [email protected]

-8-

Mfg.Since5/10

Model SB1231 INSTRUCTIONS

Table of contents

Other Southbend Tools manuals