Southern States VM-1 Service manual

Type VM-1

Motor Operator

All Ratings

INSTRUCTION

INSTALLATION &

MANUAL

The Quality Name in High Voltage Switching

The Quality Name in High Voltage Switching

Safety Information

IMPROPER HANDLING, INSTALLATION, OPERATION OR MAINTENANCE OF THIS EQUIPMENT MAY

CAUSE IMMEDIATE HAZARDS WHICH WILL LIKELY RESULT IN SERIOUS PERSONNEL INJURY OR

DEATH.

The equipment covered by this publication must be handled, installed, operated and maintained by qualified

persons who have direct knowledge and experience dealing with the hazards involved and are thoroughly

trained in the handling, installation, operation and maintenance of high voltage transmission and distribution

equipment. These instructions are meant for only such Qualified Persons. They are not intended to be a

substitute for adequate training and experience in safety procedures for this type of equipment.

A Qualified Person is one who is trained in and has skills necessary:

to read and comprehend this instruction book –understanding that these instructions are general in

nature

to accept personal responsibility to prepare and maintain an intrinsically safe work environment and

maintain control of the work site to safeguard all persons present

to develop and implement a proper rigging, lifting, and installation plan along with all safety

precautions required to insure safe and proper lifting and installation of the equipment.

to distinguish between energized and non energized parts

to determine proper approach distances to energized parts

to properly work with and around energized or de-energized equipment that may be pressurized

with gas

for proper use of personal protective equipment, insulating and shielding materials, insulated tools

for working near energized and /or pressurized electrical equipment

to recognize and take necessary precautions for the unique and dynamic conditions of site and

specialized equipment to maintain a safe work environment during handling, installation, operation,

and maintenance of high voltage switching equipment

The instructions in this manual are general guidelines for this type of equipment and not specific to the

equipment supplied. Portions of it may not be applicable or may not have complete instructions for your

specific equipment.

If you do not understand any part of these instructions or need assistance, contact Southern States Service

Division at 770-946-4562 during normal business hours (8:00am –4:30pm EST, M-F) or 770-946-4565 after

normal business hours.

The Quality Name in High Voltage Switching

LIMITED WARRANTY

Southern States, LLC (“SSLLC”) warrants only to the Warranty Holder (hereinafter defined as the “End User”

or the “Immediate Purchaser”, as applicable, pursuant to the terms and conditions of this Limited Warranty as

set forth below), that the Product identified below will, upon shipment, be free of defects in workmanship and

material for the applicable Warranty Period. The “Warranty Period” is that period of time during which this

Limited Warranty is effective, and such period begins on the invoice date issued by SSLLC for the Product,

and continues until the earlier to occur of (1) the expiration of the Warranty Duration period, or (2) the Number

of Operations, both as specified in the table below. If the Product is both purchased and installed within the

United States or Canada, this Limited Warranty is granted to each end user of the Product who acquired the

Product for its own use during the Warranty Period (“End User”). In all other situations, this Limited Warranty

is granted only to the first purchaser of the Product (“Immediate Purchaser”) from SSLLC. No primary or

remote purchaser or owner of the Product who is not a Warranty Holder may claim any benefit under this

Limited Warranty, or any remedial promise included in this Limited Warranty. SSLLC shall, upon prompt

written notice from the Warranty Holder, correct a nonconforming Product by repair or replacement at the sole

discretion of SSLLC of the nonconforming Product or any part or component of a nonconforming Product

necessary in SSLLC’s discretion to make such Product conforming. Any transportation charges, labor for

removing, reinstalling the Product or part, and/or costs related to providing access to the Product shall be the

responsibility of the Warranty Holder. Correction in this manner will constitute the Warranty Holder’s exclusive

remedy and fulfillment of all SSLLC’s liabilities and responsibilities hereunder. SSLLC’s duty to perform under

this limited warranty may be delayed, at SSLLC’s sole option, until SSLLC has been paid in full for all products

purchased by the Warranty Holder. No such delay will extend the Warranty Period. If SSLLC does not make

such repair or replacement, SSLLC’s liability for damages on account of any claimed nonconformity will in no

event exceed the purchase price of the Product in question. This Limited Warranty does not apply to any

Product that has been disassembled, repaired, or altered by anyone other than SSLLC. This LimitedWarranty

will not apply to any Product that has been subjected to improper or abnormal use of the Product. SSLLC has

no responsibility to repair or replace any Product or component thereof manufactured by another party, but

SSLLC will assign, to the extent assignable, to the Warranty Holder any manufacturers’ warranty that applies

to products and components not manufactured by SSLLC.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES. THERE

ARE NO OTHER EXPRESS, IMPLIED, OR STATUTORY WARRANTIES. ALL IMPLIED

WARRANTIES WHICH MAY ARISE BY IMPLICATION OF LAW, OR APPLICATION OF COURSE OF

DEALING OR USAGE OF TRADE, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, NONINFRINGEMENT OR

OTHERWISE ARE EXPRESSLY EXCLUDED. SSLLC SHALL NOT BE LIABLE OR RESPONSIBLE

FOR ANY CONSEQUENTIAL, INCIDENTAL, INDIRECT, EXEMPLARY, SPECIAL, OR PUNITIVE

DAMAGES, EVEN IF SSLLC HAS BEEN ADVISED OF THE POSSIBILITY OF SAME. THE

WARRANTY HOLDER IS SOLELY RESPONSIBLE FOR THE SUITABILITY OF THE PRODUCT FOR

ANY PARTICULAR APPLICATION.

Product Purchased

Region

Product Installed

Region

Warranty Holder

Warranty Duration

U.S and Canada

U.S and Canada

End User

Five (5) Years

All Other Conditions

Immediate

Purchaser

Earlier of 1 year from

installation or 18 months

from shipment

Revised 7/14/15

The Quality Name in High Voltage Switching

TYPE VM-1

Installation and Adjustment Procedures

3

Chapter Page

Introduction ...........................................................................................................................................................3

Important...............................................................................................................................................................3

Unpacking: ............................................................................................................................................................4

Installation:............................................................................................................................................................5

Electrical Check-Out Procedure:...........................................................................................................................7

Adjusting Switch Operation to VM-1 Rotation:......................................................................................................8

Manual Operation:.................................................................................................................................................9

Electrical Operation:..............................................................................................................................................9

Changing Output Rotation: .................................................................................................................................10

Auxiliary Switch Adjustment:...............................................................................................................................11

Reverse Motor Rotation:.....................................................................................................................................14

Swing Handle Attachment:..................................................................................................................................14

Maintenance:.......................................................................................................................................................14

Figures Page

Figure 1 - Part Identification..................................................................................................................................4

Figure 2 - Decoupler .............................................................................................................................................6

Figure 3 - Decoupler Operation ............................................................................................................................7

Figure 4 - Manual Operation.................................................................................................................................9

Figure 5 - Re-Position Locking Plate Manually...................................................................................................10

Figure 6 - Rotate with Crank Handle to Desired Position...................................................................................10

Figure 7 - Auxiliary Switch ..................................................................................................................................12

Figure 8 - CCW –LS...........................................................................................................................................13

Figure 9 - CW –LS .............................................................................................................................................13

Figure 10 - Vertical Pipe Rotates CCW to Open. ...............................................................................................13

Figure 11 - Vertical Pipe Rotates CCW to Open. ...............................................................................................13

Figure 12 - Vertical Pipe Rotates to CW To Open..............................................................................................13

Figure 13 - Vertical Pipe Rotates CW to Open...................................................................................................13

Figure 14 - Swing Handle Attachment................................................................................................................14

Important

The information contained herein is general in nature and not intended for specific application purposes. It

does not relieve the user of responsibility to use sound practices in application, installation, operation, and

maintenance of the equipment purchased. Southern States reserves the right to make changes in the

specifications shown herein or to make improvements at any time without notice or obligations. Should a

conflict arise between the general information contained in this publication and the contents of drawings or

supplementary material, or both, the latter shall take precedence.

Installation and Adjustment Procedures

4

Unpacking:

Unpack the mechanism and check for damage. If damage is found, file a claim with the carrier immediately

and notify the factory.

Figure 1 - Part Identification

Storage:

If this equipment is to be stored prior to use:

1. Store the VM-1 mechanism in the upright position

2. The door should be latched closed

3. No part of the mechanism should be submerged

4. Indoor storage or covering with a tarp is not necessary, but preferred. As with all electrical

equipment, however, condensation is a consideration.

5. The heater should be energized if the mechanism is stored outdoors for an extended period (3+

months) or in a humid environment. Refer to wiring diagram drawing for heater connection.

Installation and Adjustment Procedures

5

Static brake

The static brake is an electro-mechanical mechanism comprised of a brake pad, brake arm, spring and solenoid.

The spring provides the mechanical force necessary to depress the brake and keep the motor operator from

turning. When the motor is energized, the brake solenoid, seen in Figure 1, depresses the spring thereby

releasing the brake and allowing the motor operator to function.

Dynamic brake

The dynamic brake is a strictly electrical device. A set of contacts runs parallel to the motor which is normally

closed. When the operator needs to be stopped, a short is induced across the motor operator which therefore

stops the operator from rotating.

Installation Note: Installation consists of mounting and adjusting the VM-1 Motor Mechanism to coordinate

with the switch operating controls. Sketches and dimensions contained in this manual are for illustration only.

Refer to unit assembly drawing and operating mechanism drawing for specific dimensions.

Application Note: The VM-1 Motor Mechanism is equipped with an adjustable rotation lock that provides

variable starting and stopping points on a rotational angle between 30° and 330°. Refer to section VIII for

adjustment of this lock.

Caution: Use manual operation for installation. Do not perform electrical operation until all

adjustments are complete. Keep away from moving parts. Keep away from electrical

components unless power has been disconnected.

Installation:

1. Mount the VM-1 Mechanism as shown on the Operating Mechanism Drawing or Mounting

Arrangement Drawing. Refer to Switch Installation Instructions for switch adjustment.

2. Attach the upper decoupler member to the vertical pipe in accordance with the instructions provided

for the decoupler type supplied.

3. Universal Decoupler (Not Common)

●Do not drive in the self-piercing set screws at this time.

●The vertical pipe should bottom out in the lower decoupler section for 1-1/2 inch pipe and in the

upper decoupler section for 2 inch pipe.

●Discard cap and hardware for the unused section.

●A clearance of ½ inch must be maintained between the upper and lower decoupler members. To

adjust, raise or lower the vertical pipe in the vertical bearing at the top of the pipe. The full pipe weight

must be supported by the vertical bearing.

●When required clearance is achieved, pierce the pipe with the set screw in the pipe collar above the

vertical bearing.

●It may be necessary to pre-drill all set screw holes, using the threaded drill guides if provided.

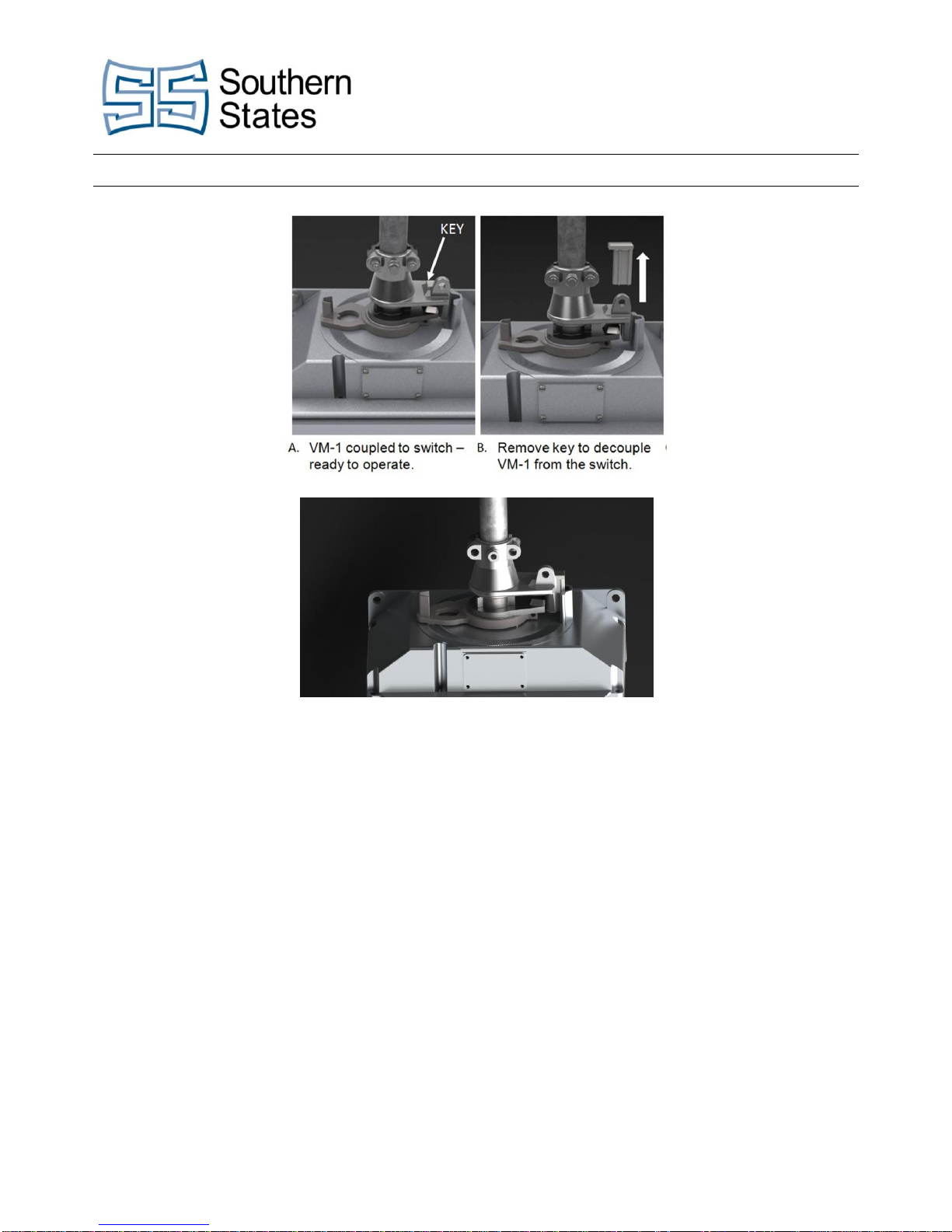

●Refer to Figures 2 and 3 for decoupler operation. Use the decoupler key to align the upper decoupler

member with the fixed rotation lock and tighten clamping bolts. Do not pierce the pipe with set screw

at this time.

Installation and Adjustment Procedures

6

4. Single Size Decoupler:

●Do not pierce the pipe with the self-piercing set screws at this time.

●The vertical pipe should bottom out in the upper decoupler member.

●A clearance of ½ inch must be maintained between the upper and lower decoupler members. To

adjust, raise or lower the vertical pipe in the vertical bearing. The vertical bearing must support the full

weight of the pipe.

●When required clearance is achieved, pierce the pipe with the set screw in the collar above the

vertical bearing. (Do not drive set screw into coupling yet)

●If heavy wall pipe is used it will be necessary to pre-drill all set screw holes, using the threaded drill

guides when provided.

●Refer to Figure 3 for decoupler operation. Use the decoupler key to align the upper decoupler

member with the fixed rotation lock. Tighten the clamping bolts. Do not pierce the pipe until proper

switch operation has been confirmed.

Figure 2 - Decoupler

Note : If the upper decoupler member rests upon the lower decoupler member, it is not adjusted properly. The

1/2 –inch gap must be present at installation to allow thermal expansion.

Installation and Adjustment Procedures

7

C. VM-1 Decoupled- Switch is locked out

Figure 3 - Decoupler Operation

Decoupler Operation: If decoupler key is hard to remove, use crank handle or swing

handle to back off torque load. The key should have

adequate clearance between the lower decoupler member

when the key is in the decoupled (locked out) position.

Electrical Check-Out Procedure:

1. Although electrical operation of the switch should not be attempted until later, the VM-1 mechanism

can be checked electrically now with the VM-1 decoupled from the switch

2. Decouple as shown in Figure 3 and connect the VM-1 mechanism for electrical operation as shown on

the wiring diagram drawing. Refer to Figure 1 for conduit entry into the cabinet.

3. Proper rotation is set at the factory, however adjustment may be required. Test each mechanism to

confirm rotation output agrees with the operating mechanism drawing. It is recommended the

decoupled VM-1 be hand cranked to the midpoint of rotation before the initial test operation. Use the

push buttons for testing operation.

4. OPEN and CLOSE push buttons (if supplied) initiate electrical operation.

Installation and Adjustment Procedures

8

5. STOP button (if supplied) overrides all other commands, sets the brake and halts mechanism

operation.

6. The motor fuses (or circuit breakers) must be in place for electrical operation.

7. In event of motor overload: (When Supplied)

The thermal overload relay will trip.

Remove cause of overload.

Allow motor to cool until it reaches normal operating temperature.

Reset the thermal overload relay by flipping the motor switch to the OFF position, and

then back to the ON position.

Use the OPEN and CLOSE push buttons to resume electrical operation.

8. If over or under rotation is observed, adjust the motor limit switches as directed in Auxiliary Switch

Adjustment: Page 11

Caution: Before performing any maintenance or adjustment inside the VM-1 housing, make

sure the circuits are de-energized.

Adjusting Switch Operation to VM-1 Rotation:

1. Adjust the switch operating mechanism to match the specified rotation of the VM-1 mechanism by

adapting the length of the adjustable arm at the top of the vertical pipe. Refer to the Operating

Mechanism drawing and switch installation instructions for this procedure.

2. Perform all trail operations manually. Refer to Figure 4.

3. Do not rotate the VM-1 past the open and/or close position locks. Over rotation can damage the switch

and operating mechanism.

4. The motor safety switch automatically disconnects the motor from the line voltage when the manual

crank handle is inserted.

5. Removal of the manual hand crank automatically reconnects the motor with the line voltage.

6. Refer to switch installation instructions for adjustment procedures of the operating mechanism. During

switch adjustments, use the position stops (if supplied) as reference points for fully open and fully

closed.

Installation and Adjustment Procedures

9

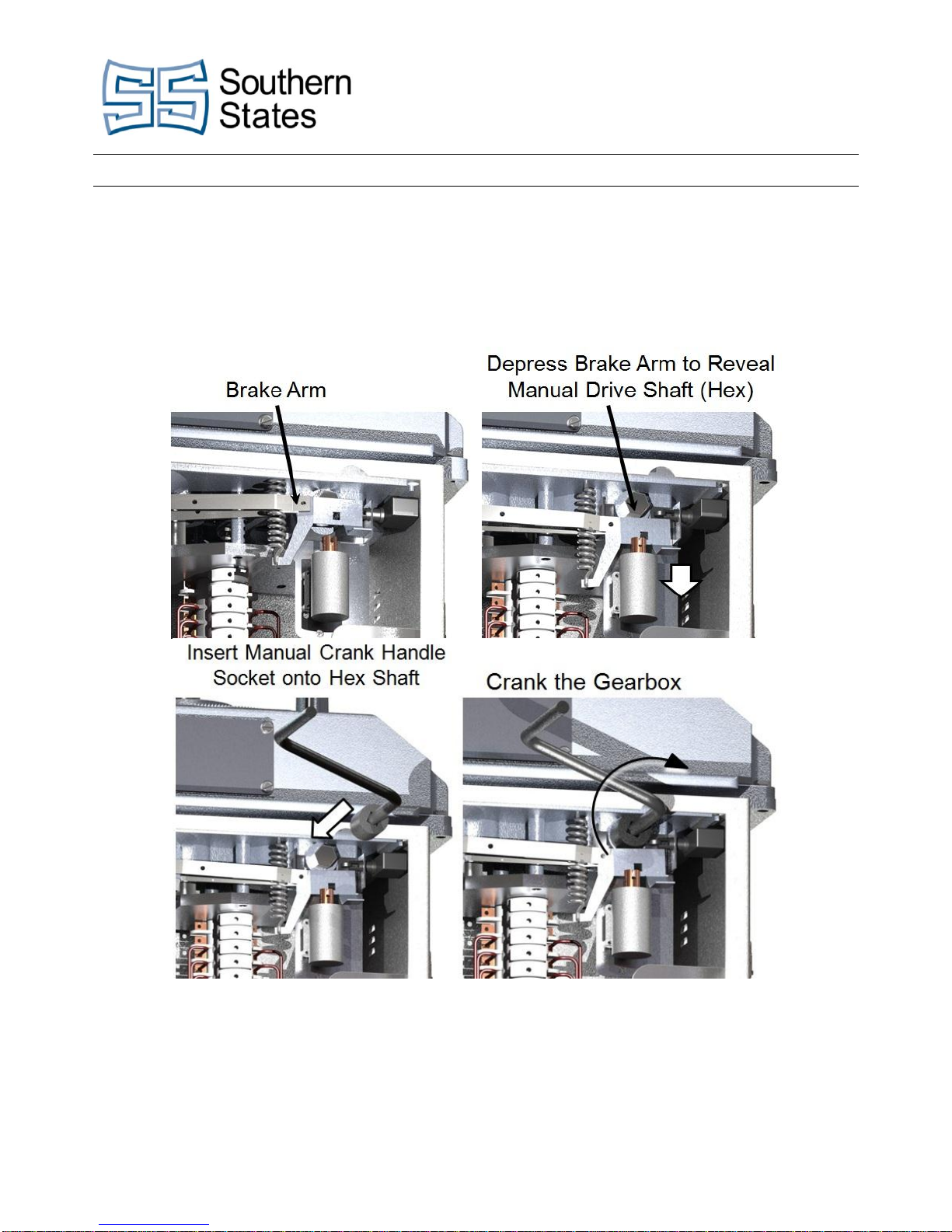

Manual Operation:

1. Depress brake arm.

2. Fit the socket on the hex head shaft.

3. Crank the gearbox manually.

Figure 4 - Manual Operation

Electrical Operation:

1. Complete adjustments of switch and operating mechanism.

2. MAKE SURE MANUAL ROTATION OF THE SWTICH MATCHES THE ELECTRICAL ROTATION OF

THE VM-1 MECHANISM.

3. Remove the manual operating handle and test electrical operation of the switch.

4. NOTE: The stop button when supplied will override all other commands.

Installation and Adjustment Procedures

10

Changing Output Rotation:

1. Two adjustments are required to change rotation of the VM-1 mechanism. The adjustable lock position

and the motor limit switch settings.

2. Loosen the adjustable lock plate and disengage-Refer to Figure 5.

3. Manually rotate the VM-1 mechanism to the desired position. (See Figure 6) Adjust the motor limit

switches to stop the motor at the new position as described in section IX. The limit switches are the

two top poles of the auxiliary switch. The motor switch and fuse switch should be in the OFF position.

4. To check degree of rotation, use cast-in rotation marks on top of the gearbox.

5. Decouple and check new rotation electrically.

6. Perform several trial operations to confirm limit switch setting is correct.

7. Rotate the adjustable lock plate to its new position and retighten.

8. If necessary, realign the pressure-sensitive open and close position indicators.

Special Application Note: To adjust the starting position, lock the upper decoupler member closed with the

clamping bolts loose and the vertical pipe free to rotate. Reposition vertical pipe to desired position. (the swing

handle socket may be used for this operation.) Tighten the clamping bolts and drive in the self-piercing set

screw after the desired starting position is achieved.

Important: The optional stop tangs(not shown) are for use as a reference point during manual operation and

are not intended to stop motor operation. Do not overdrive against these tangs.

Figure 5 - Re-Position Locking Plate

Manually

Figure 6 - Rotate with Crank Handle to

Desired Position

Installation and Adjustment Procedures

11

Auxiliary Switch Adjustment:

1. Each auxiliary switch contact is spring loaded.

2. A contact is opened and held open by a cam operating against a roller –Refer to Figure 8.

3. The Auxiliary switch is adjustable in infinite steps to open and close at any point in the line switch

operation.

4. To adjust the auxiliary switch, use a 3/32 inch Allen wrench, loosen the screw that holds the cam on

the can wheel. Do not loosen the screw more than required to allow cam movement.

5. Slide the cam around the cam wheel to desired position and retighten the screw.

6. In closed position, allow approximately ¼ inch clearance between the cam and cam roller –refer to

Figure 8

7. Retighten the cam wheel set screw firmly. Do not over tighten.

8. Perform several trial operations to make sure the setting is correct.

9. Each contact is adjusted independent of other contacts. Any contact may be made a Type A or Type B

by adjusting the switch as indicated on Figure 8, Figure 9, Figure 10, Figure 11, Figure 12 and Figure

13.

Installation and Adjustment Procedures

12

Figure 7 - Auxiliary Switch

6 mm

Installation and Adjustment Procedures

13

Procedure for Setting Auxiliary And Limit Switch Contacts

Factory Settings:

┤├ Closed in counter-clockwise limit position (CCW). (Figure 8)

┤├ Closed in clockwise limit position (CW). (Figure 9)

All Illustrations Shown From Above

Limit Switches

Figure 8 - CCW –LS

Set Mechanism (vertical pipe) in CCW limit position

and set as shown.

Figure 9 - CW –LS

Set mechanism (vertical pipe) in CW limit position

and set as shown.

Auxiliary Switches

Figure 10 - Vertical Pipe Rotates CCW to

Open.

1. Set mechanism in closed position and set

all ┤├ auxiliary switches as shown.

Figure 11 - Vertical Pipe Rotates CCW to

Open.

2. Set mechanism in open position and set all

┤├ auxiliary switches as shown.

Figure 12 - Vertical Pipe Rotates to CW

To Open.

1. Set mechanism in closed position and set

all ┤├ auxiliary switches as shown.

Figure 13 - Vertical Pipe Rotates CW to

Open.

2. Set mechanism to open position and set all

┤├ auxiliary switches as shown.

Maintenance

14

Reverse Motor Rotation:

1. Motor Mechanisms are factory wired to rotate in the direction indicated on the switch operating

mechanism drawing or customer’s order.

2. Refer to notes on the VM-1 wiring diagram should it become necessary to reverse rotation.

3. All auxiliary contacts must be readjusted after changing leads. Follow procedure described on 11.

Caution:When reversing rotation, always have the VM-1 decoupled from the switch. Leave it decoupled until

complete adjustment has been made. The motor fuses and heater fuses should be pulled during adjustment of

the auxiliary switch and overload toggle switch when provided placed in off position.

Swing Handle Attachment:

1. Attach swing handle socket as shown in Figure 14.

2. When supplied, the switch position indicator is attached to the vertical pipe, above the swing handle

socket, and aligned with indicator on the decoupler.

Note: Emergency switch operation can be performed with the Swing Handle. The Swing Handle can

also be used to provide chopping action under icing conditions or to relieve pressure when removing

the decoupler key.

Figure 14 - Swing Handle Attachment

Maintenance:

1. The VM-1 requires no maintenance under normal service conditions.

2. Should severe conditions exist:

a. Remove access plate from gear box.

b. Spray gears and shafts with a light coating of silicone lubricant every five years.

c. Apply a few drops of heavy oil (EP-type preferred) to the thrust washers supporting the center

and right-side shafts.

d. Re-seal access plate with “Permatex” (hardening grade) or equivalent.

Important: Do not use a fluid type lubricant on motor pinion due to possible seepage to the brake disc.

30 Georgia Avenue

Hampton, Georgia 30228

Phone: 770-946-4562

Fax: 770-946-8106

E-mail: support@southernstatesllc.com

http://www.southernstatesllc.com

©2015 Southern States, LLC

IB-501-VM1-Rev 1 100815 Printed U.S.A.

Table of contents

Popular Control Unit manuals by other brands

Image Engineering

Image Engineering iQ-LED V2 Setup instructions

Resol

Resol WMZ manual

Hudson Reed

Hudson Reed 1/2 NPT Instruction

WABCO

WABCO MICO ACV-DMN-LS Product Explanation, Operating Information, and Service Instructions

Bently Nevada

Bently Nevada 3500 Galvanic Isolator Interface manual

Burkert

Burkert 6213 EV operating instructions