Spartan O'Brien User manual

O’Brien Root Cutter

Owner’s Manual

SPARTAN TOOL L.L.C.

8 0 0 . 4 3 5 . 3 8 6 6

www.spartantool.com

Record the Serial Number of your

O’Brien Root Cutter

and give the number to the factory

when ording parts.

Serial Number ..............................................

SPSP

SPSP

SPARTART

ARTART

ARTANAN

ANAN

AN

44247500 10-170-12 © 2012 Spartan Tool LLC

Page 2

Table of Contents

Technical Data .................................................................................................... 3

Warnings............................................................................................................ 3-4

Operating Instructions ........................................................................................ 5

Proper Orifice Selection ...................................................................................... 5

Cutter Blade Selection......................................................................................... 6

Skid Mounting ...................................................................................................... 7

Attachment of Cutters .......................................................................................... 7

O’Brien Root Cutter Operation ....................................................................... 8-9

O’Brien Root Cutter Parts List .................................................................... 10-11

Optional Accessories ........................................................................................12

Page 3

Technical Data

NOTE: The correct root cutter model must be selected for proper operation.

OPERATING PRESSURES ------ 2000 PSI

FLOW RATE REQUIRED --------- 35 - 60 GPM

HOSE FITTING REQUIRED ----- 3/4” or 1” hose

WEIGHT ------------------------------- 19 lbs.

PIPE SIZES --------------------------- 6” to 20”

INCLUDED SKIDS SIZES -------- 6”, 8”, 10”, 12”, and 15”

Do not start root cutter unless it is contained inside the drain line! Severe injury will result

from contact with cutter blades.

—Drain and sewer cleaning can be dangerous. Always read the safety precautions and operators

manual before using the equipment.

—When operating any high velocity water jetter with root cutter, always wear safety goggles, rubber

boots, rubber gloves, and rain coat. A full face shield is recommended.

—Insure that the hose and root cutter has been placed in the pipe a minimum of 3’ before engaging

the water pressure to prevent the root cutter form coming out of the pipe and causing injury.

—Always shut the water pressure off before pulling the root cutter out of the pipe. Mark the hose a

minimum of 3’ from the root cutter to insure the hose is not accidentally pulled out of the pipe while

still under pressure. Shut off the water pressure when the hose mark is encountered.

“California Prop. 65: This product may contain an extremely small amount of lead in the coating. Lead

is a material known to the State of California to cause cancer or reproductive toxicity.”

Warnings

Page 4

Warnings

WARNING: Read the “Owner’s Manual” thoroughly before using any Spartan tool

products. Drain/Sewer cleaning can be dangerous if proper

procedures are not followed. Know the proper operation, correct

applications and the limitations of all Spartan Tool products before

use.

Safety must always be the operator’s prime concern. The operator must read and understand this

manual and all safety signs on the machine before operating the equipment. Failure to follow these

safety precautions could result in property damage and/or personal injury or death. This safety

summary describes basic safety measures which apply to the use and maintenance of the machine.

Further safety measures are described in other sections throughout this manual.

The precautions listed in this manual and on the equipment are not all-inclusive. The operator must be

satisfied that the use of any procedure, method, tool or part not specifically recommended by Spartan

Tool is safe for personnel, and will not damage or make the equipment unsafe.

Safety decals have been placed at operating points on the equipment to remind operators to observe

safety precautions. All standard decals and their proper locations are documented in a later section of

this manual. These decals must be visible at all times. Check these decals on a regular basis and

during machine set-up prior to the first operation. Replace damaged or unreadable decals.

Remember, your ability as a professional operator is critical to ensuring your safety and that of your co-

workers.

The following safety alert symbols are used throughout this manual:

DANGER: Indicates immediate hazards which WILL

result in severe personal injury or death.

WARNING: Indicates hazards or unsafe practices

which COULD result in severe personal

injury or death.

CAUTION: Indicates hazards or unsafe practices

which COULD result in minor personal

injury, or machine damage.

NOTE: Indicates special features or operation

of the machine.

Page 5

Operating Instructions

WARNING

Follow all safety and operating instructions provided with your high pressure water jet unit as well

as applicable local and OSHA standards. Always wear goggles, gloves and other safety attire.

Proper Orifice Selection

The O’Brien root cutter is supplied with two special bypass orifice grease fittings. One style must be

selected and screwed into the jet head for proper root cutter operation (see fig. 1). The orifice fittings

are color coded for easy identification. One black for 1” hose units and one plain for 3/4” hose units.

The 3/4” root cutter orifice is designed for units having flow capacities of 30-35 GPM (113.6 - 132.5

LPM) and the 1” root cutter orifice (black) is designed for units having flow capacities of 45-60 GPM

(170.3 - 227.1 LPM). These flows require operating pressure of 1200 PSI (80.5 bars) to 2000 PSI

(140 bars). The 3/4” root cutter hose requires the use of the reducing bushing (furnished) to be screwed

into the jet nozzle to accept a 3/4” hose fitting. After selection of the proper fitting(s) are made, screw

fitting(s) into jet nozzle tight (NOTE: Use thread lock if available).

DANGER

In no case should pressures greater that 2000 PSI (140 bars) be

applied to the root cutter unit. Damage to equipment or personal

injury including death could result.

Fig. 1

By-Pass Orifice Grease Fitting

Plain 3/4” Unit

Black 1” Unit

Page 6

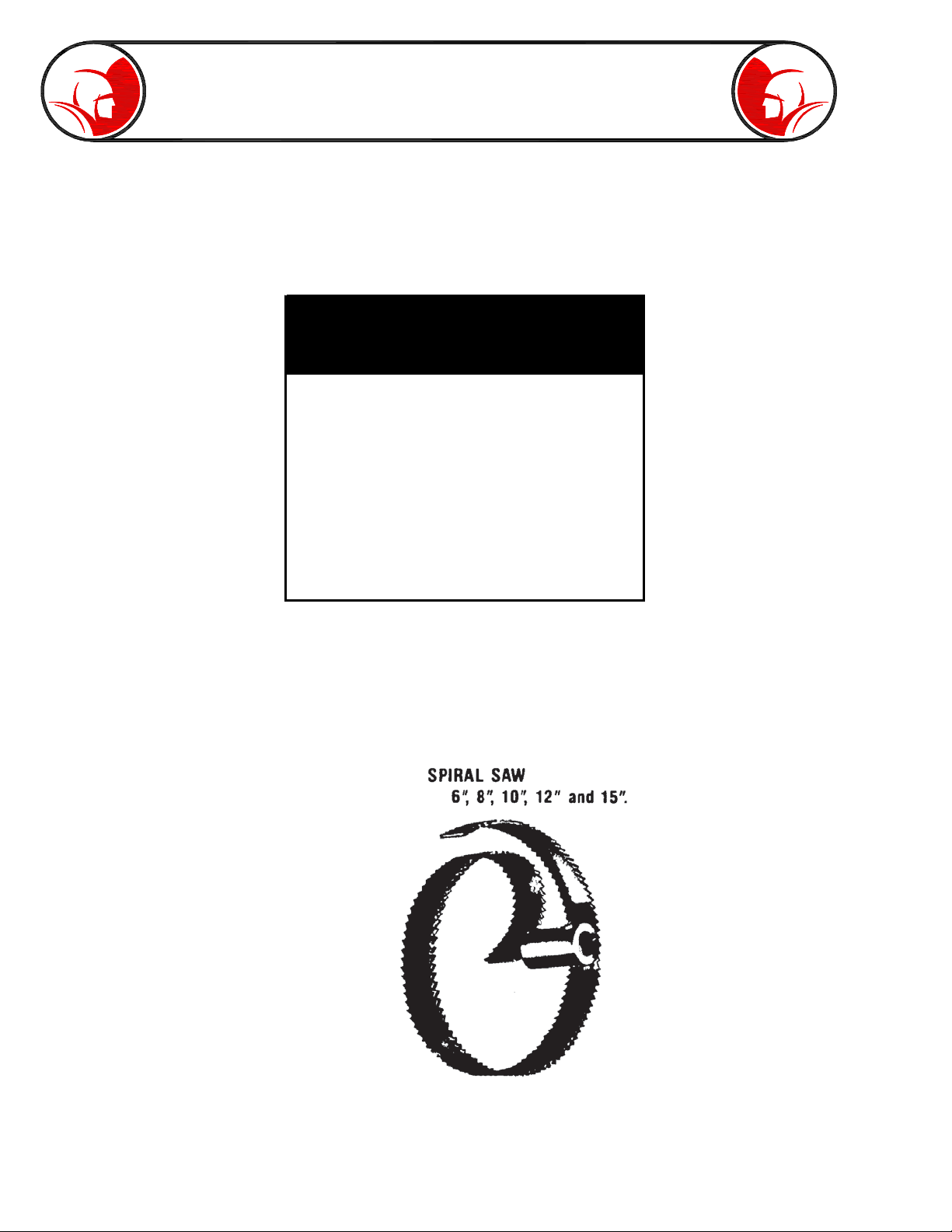

Cutter Blade Selection

Saw blades for the O’Brien root cutter are available in 6”, 8”, 10”, 12” and 15” sizes. Saw blades allow

about 1/2” clearance in the pipeline and skid assemblies are designed smaller than the cutter blades

to allow unit to pass through opening cut by the saw blade. The 6” cutter assembly with 6” blade at-

tached is designed for straight or gentle sweeping lines and will not traverse elbows. The following

indicates the size cutter and skid to be used in pipe cleaning applications.

Proper skid and cutter should be attached to root cutter before the high pressure hose is attached to

the unit. Always keep engine off while attaching root cutter assembly to hose or while root cutter is

attached and out of pipe. The rotating cutter blade and high pressure water jet discharge are poten-

tially dangerous and could cause sever injury and/or death.

Fig. 2

Pipe

Size

Skid

Size

Cutter

Size

4" none 4"

6" 6" 6"

8" 6" 6"

10" 8" 8"

12" 10" 10"

15" 12" 12"

18" to 21" 15" 15"

Page 7

Attachment of Cutters

CAUTION: Wear protective gloves when handling root cutter

blades.

All cutter units for O’Brien root cutters are attached to the motor shaft by means of a woodriff key

and a bolt and nut arrangement. The hub of the cutter must be slid over the key on the shaft which

drives the cutter. Align cross hole in hub with hole through shaft and insert bolt through hub and

secure with lock washer and nut. This prevents cutter pulling off when withdrawing unit.

CAUTION: Do not try to drive cutters without drive key or by use of

bolt and nut only, as cutter could become loose and

lost in line or cause tile damage.

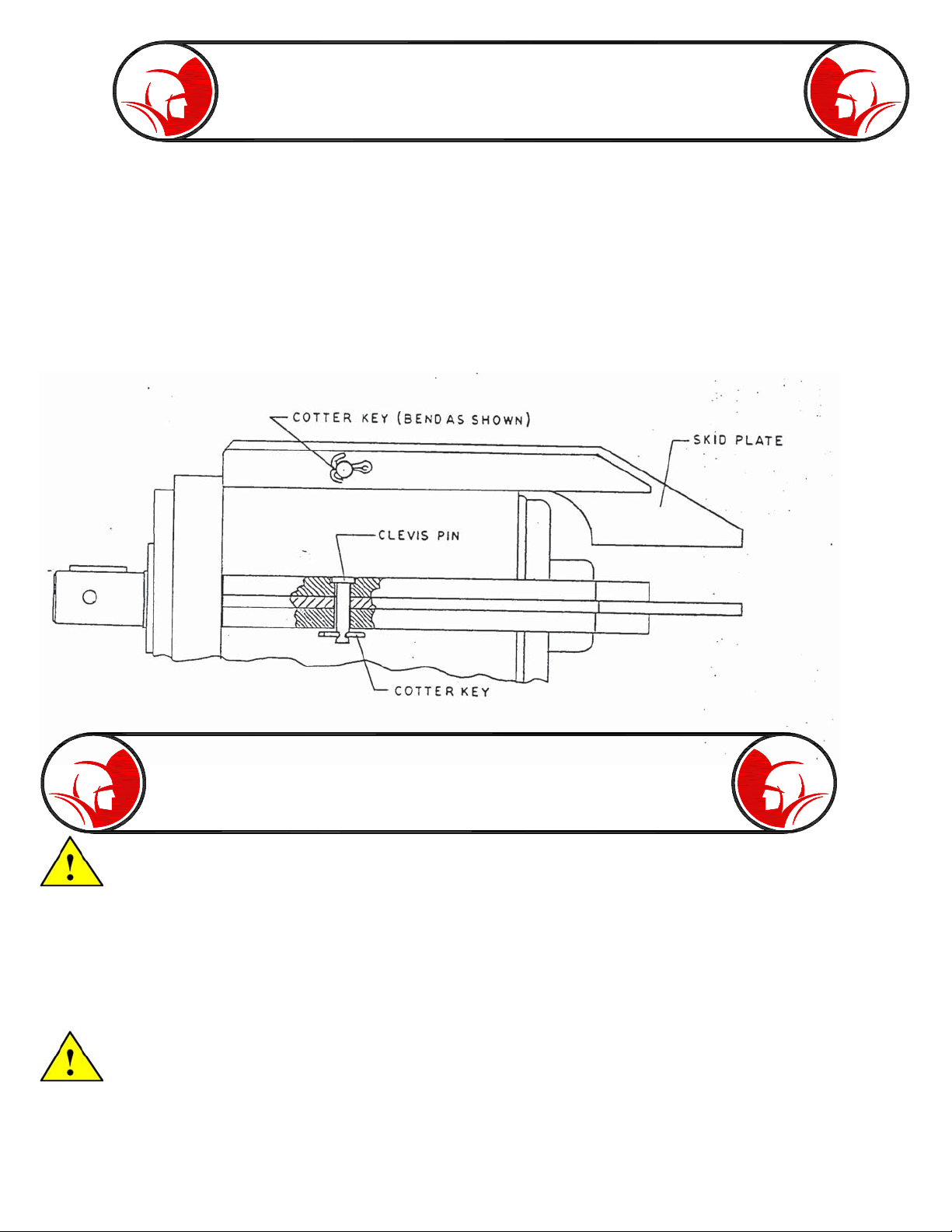

Skid Mounting

The O’Brien root cutter offers in a unique design, the mounting of plate runners to the body shell of the

root cutter by means of four removable pins which are locked in place by cotter keys (fig. 3). The main

motor need never be removed from the body shell to change skid sizes. By attaching the skid plates in

this manner, the hose end of the plates are projected downward and rearward to offer a large angle

projection over twice that of conventional skid units, thus offering greater protection to root cutter removal

in the event an offset or dropped line is encountered. Skid plates are stamped with pipe size of pipe

for easy selection. NOTE: Do not intermix skid plates on body shell. To simplify skid plate removal and

change, the snipping off of the end of the cotter key is recommended to remove same. Use only new

cotter keys for assembly (extra keys provided). As these are standard cotter keys, they may be

purchased locally for replacement.

Fig. 3

Page 8

O’Brien Root Cutter Operation

After assembly of your O’Brien root cutter with skid and cutter blade as outlined in previous sections,

attach the high pressure hose. NOTE: If tubular tiger tail hose guide is used, slide it over the hose

before attaching hose to root cutter. Attach placement tool and lower root cutter unit into manhole and

position it at the pipe entrance with cutter blade facing in the direction of travel. NOTE: If possible,

cutting should always be done against the flow to allow debris to be carried back to the working manhole.

Start jet unit engine and turn on water pressure momentarily to allow root cutter to enter line several

feet. Turn off pressure and position hose guide/guard at pipe entrance. Tie safety rope to jet or clamp

in place, avoiding trip area. Mark hose top of manhole entrance with white waterproof tape.

Begin cleaning operation by running engine at low RPM. Back off or reduce output pressure at

regulator if unit is so equipped, and increase throttle setting on jet unit to operate at full RPM.

Adjust pressure regulator for maximum pressure (never exceeding 2000 psi). Feed root cutter

hose slowly into pipe allowing cutter to cut obstructions and to avoid jamming blade. Jamming of

cutter into obstruction could cause cutter and shaft to lock in the obstruction and the body of the

motor to rotate in the pipe, causing jet hose twist and damage. When hose is in the pipe, it should

be tight against the hose guide to avoid slack. Slacking of the hose indicates the root cutter has

encountered an obstruction. Immediately pull back on the hose by hand. Gradually feed root cutter

hose forward by hand allowing cutter to cut into and through obstruction. Use care to keep your body

well balanced and maintain stable footing when performing the above.

If root cutter does not penetrate blockage after several minutes, you may have encountered a

lateral or a collapsed pipe and should consider other options. Continued operation without penetration

can damage root cutter and/or blade or cause root cutter to lockup in pipe. After penetration is

made through a blockage, no slack should be felt or seen at hose. Continue feeding root cutter

slowly a few feet up pipe and if no slack is seen or felt on the hose, you are through blockage. For

every 2 to 3 feet of blockage, pull root cutter back to manhole to clear pipeline of debris. The

marking of white tape on the hose will indicate the root cutter distance of exit from the line. Do not

pull unit all the way into manhole at this time, but reduce water pressure and flow to root cutter to

prevent debris from washing into another pipe and clogging. If debris is not excessive, root cutter

may be allowed to advance further into pipeline as outlined above and the procedure continued

until complete line is cleaned. However, if debris is excessive with first run, pull root cutter toward

pipe entrance after turning down pressure to allow debris to build up in bottom of manhole. Turn off

water pressure and engine.

DANGER: Failure to turn off engine could result in inadvertent

activation of root cutter, resulting in serious bodily

injury.

Page 9

Remove root cutter from manhole by hand, lifting with the hose. Remove debris from root cutter and

blade. Clean debris from manhole. If entrance into manhole is required, observe NIOSHA safety

rules. After cleaning of debris from first run, root cutter can be reinserted into line and following outline

as above, continue procedure until complete pipe is clean.

When job is complete, retrieve root cutter as outlined. Remove root cutter from hose. If root cutter will

not be used within a 6 hour period, remove cutter blade and with special grease coupler (supplied)

attached to grease gun, pump a light weight grease into the orifice grease fitting. Motor shaft will be

turned by the grease as this is done. When grease can be seen at hose connection, greasing is

complete and root cutter can be stored. In freezing conditions, keep root cutter motor unit warm or

service with grease immediately. As grease may become thick in extreme cold, and if warming is not

possible, service root cutter motor with S.A.E. #10 motor oil. This is done in the following manner.

Place “T” wrench provided on motor shaft, orient root cutter motor so shaft is pointing down, pour oil

into hose connection at jet nozzle a little at a time while turning motor shaft in a clockwise direction as

viewed from hose connection end. When oil is forced out of orifice grease fitting, oiling is complete.

O’Brien Root Cutter Operation

Page 10

44247601 - O’Brien RootCutter

with 6” Saw

44247602 - O’Brien RootCutter

with 8” Saw

Item Req'd Part # Description

1 44247200 O'Brien Root Cutter Only

2 1 44247300 Tool Box w/ Decal

3 1 41579000 W rench, RootCutter 'T'

4 1 44234400 Hanger Hood

5 1 44247400 Vial w/ Parts

6 1 44249100 Decal Set

7 4 44246500 Skid Plate - 6"

8 4 44246600 Skid Plate - 8"

9 4 44246700 Skid Plate - 10"

10 4 44246800 Skid Plate - 12"

11 4 44246900 Skid Plate - 15"

12 1 41306603 6" Spiral Saw

13 1 41006000 Reducer Bushing, 1" to 3/4"

14 1 04381900 Caplug, 3/4" NPT

15 1 77742600 Bushing Reducer 3/4 x 1/2

Item Req'd Part # Description

1 44247200 O'Brien Root Cutter Only

2 1 44247300 Tool Box w/ Decal

3 1 41579000 W rench, Rootcutter "T"

4 1 44234400 Hanger Hood

5 1 44247400 Vial w/ P arts

6 1 44249100 Decal Set

7 4 44246500 Skid Plate - 6"

8 4 44246600 Skid Plate - 8"

9 4 44246700 Skid Plate - 10"

10 4 44246800 Skid Plate - 12"

11 4 44246900 Skid Plate - 15"

12 1 41306604 8" S piral Saw

13 1 41006000 Reducer Bushing, 1" to 3/4"

14 1 04381900 Caplug, 3/4" NPT

15 1 77742600 Bushing Reducer 3/4 x 1/2

Page 11

3

14

5

4

2

6

7

8

910

13

12

1

11

44247603 - O’Brien RootCutter

with 10” Saw

Item Req'd Part # Description

1 44247200 O'Brien Root Cutter Only

2 1 44247300 Tool Box w/ Decal

3 1 41579000 W rench, Rootcutter 'T'

4 1 44234400 Hanger Hood

5 1 44247400 Vial w/ Parts

6 1 44249100 Decal Set

7 4 44246500 Skid Plate - 6"

8 4 44246600 Skid Plate - 8"

9 4 44246700 Skid Plate - 10"

10 4 44246800 Skid Plate - 12"

11 4 44246900 Skid Plate - 15"

12 1 41306605 10" Spiral Saw

13 1 41006000 Reducer Bushing, 1" to 3/4"

14 1 04381900 Caplug, 3/4" NPT

15 1 77742600 Bushing Reducer 3/4 x 1/2

Page 12

2

3

4

5

6

1

Optional Accessories

Item Part # Description

1 41306602 4" Spiral Saw

2 41306603 6" Spiral Saw

3 41306604 8" Spiral Saw

4 41306605 10" Spiral Saw

5 41306606 12" Spiral Saw

6 41306607 15" Spiral Saw

Page 13

Spartan Tool warrants its equipment to free from defects in material and workmanship for one year from

the date of purchase. To obtain warranty service, a purchaser should notify Spartan Tool in writing, at the

address provided below, within the warranty period, and Spartan Tool will direct where to take or send

the equipment for service. If the defect is covered by the warranty, Spartan Tool will repair or replace, at

its option, the defective equipment, without charge for labor or materials. (Freight and insurance are the

purchaser’s responsibility.)

This warranty is limited to the original retail purchaser and is not transferable. Spartan Tool assumes no

responsibility for damage due to accident, neglect, abuse, tampering or misuse, nor damage from

repairs or alterations by others. This warranty does not cover damage to the equipment resulting from

the use of replacement parts other than Spartan Tool parts.

Spartan Tool’s sole obligation and the original retail purchaser’s exclusive remedy under this warranty

shall be for repair or replacement as described above. ALL OTHER WARRANTIES, WHETHER

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO

EVENT SHALL SPARTAN TOOL BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

SPARTAN TOOL L.L.C.

MENDOTA, ILLINOIS 61342

Spartan Tool L.L.C. reserves the right to make changes at any time, without notice, to specifications and

models and also discontinue models. The right is also reserved to change specifications or parts at any

time without incurring any obligation to equip same on models manufactured prior to the date of change.

SPARTAN TOOL L.L.C.

1506 W. Division Street

Mendota, IL 61342

800.435.3866 Fax 888.876.2371

www.spartantool.com

ONE YEAR WARRANTY

Table of contents

Other Spartan Cutter manuals

Popular Cutter manuals by other brands

Alpha tools

Alpha tools A-MF 1300 Original operating instructions

EIBENSTOCK

EIBENSTOCK ERC 300 Original instructions

Fortum Proffesional

Fortum Proffesional 4770840 Translation of the original user manual

Metabo

Metabo SSE 18 LTX BL Original instructions

tattered lace

tattered lace Crossover instruction manual

RED ROOSTER

RED ROOSTER RRI-8004 manual