Spears TRUE UNION 2000 Series User manual

SSI #49 6/13/2014 SPECIFICATION SUBMITTAL INFORMATION

THE FOLLOWING INFORMATION IS CORRECT AS NOTED BY THE FOLLOWING

INFORMATION FROM THE LISTED DATA SOURCES.

SUBMITTED BY MISCOWATER

27101 BURBANK STE B

FOOTHILL RANCH, CA 92610

PHONE 949-458-5555

RICK BARTON

REFERENCE ORANGE COUNTY SANITATION DISTRICT

SLUDGE DEWATERING AND ODOR CONTROL AT PLANT NO. 1

W. M. Lyles JOB T-1113 MISCO JOB 0222VB

GRANT GOURLEY 714-962-6828

PROJECT P1-101

10598 Garfield Ave

FOUTAIN VALLEY, CA 92708

SCOPE SUPPLY OF PVC MOV BALL VALVES FOR IW SERVICE

TYPE PLASTIC FULL PORT MODULATING

REFERENCE SPECIFICATION 15106.2.4

SUBMITTING "OR EQUAL " TO THE NAMED MANUFACTURERS

MANUFACTURER SPEARS MANUFACTURING

15852 OLDEN STREET

SYLMAR,CA 91392

818-364-1611

VALVE

SPEC COMPARISON ITEM DESCRIPTION OF ITEM

15106.A..2.4.A.1 CONFORMS PVC BODY; BALL; STEM; ENDS

15106.A..2.4.A.2 CONFORMS UNION/FLANGED AS REQUIRED

15106.A..2.4.B.1 CONFORMS FLANGES ASME16.5 CL 150 AS REQUIRD

15106.A..2.4.B.2 CONFORMS RATING OF PVC AS REQUIRED

15106.A..2.4.B.3 CONFORMS BALL FULL PORT WITH TFE SEAT

15106.A..2.4.B.4 CLARIFICATION BODYBALL SEALS ARE TFE TFE HAS NO ENERGIZING FEATURE;

STEM BEARING IS TFE RESILIENT SEAT IS REQUIRED FOR SEALS

O-RING SEALS AND STEM RESILIENT SEAT IS REQUIRED FOR SEALS

ALTERNATE SEALS ARE MEDIA COMPATIBLE VITON

15106.A..2.4.B.5 CONFORMS FULL PORT

15106.A..2.4.B.6 CONFORMS NA

15106.C CONFORMS LIMITORQUE QX

15106.D EQUAL SPEARS MANUFACTURING

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 1 of 148

NAMED MANUFACTURERS - SIZE RANGE DIFFICIENT

NOTE VALVES ARE PREVIOUSLY APPROVED ON 15106-004-A

TFE HAS NO MEMORY AND IS NOT RECOMMENDED FOR BODY SEALS

VITON IS RECOMMENDED AND COMPATABLE WITH ALL SERVICES LISTED

MANUFACTURER SPEARS MANUFACTURING

15852 OLDEN STREET

SYLMAR,CA 91392

818-364-1611

SIZE MODEL NUMBER ENDS

6" 1833-060 FLANGED ENDS

VALVE TAG # PID LOCATION DESCRIPTION AND SERVICE

15LFV742 15L-NP-325 IW SERVICE BALL VALVE WITH ELECTRIC MOTOR OPERATOR -MODULATING

CONTROL ANALOG WITH ANALOG FEEDBACK

15LFV747 15L-NP-325 IW SERVICE BALL VALVE WITH ELECTRIC MOTOR OPERATOR -MODULATING

CONTROL ANALOG WITH ANALOG FEEDBACK

15MFV822 15M-NP-302 IW SERVICE BALL VALVE WITH ELECTRIC MOTOR OPERATOR -MODULATING

CONTROL ANALOG WITH ANALOG FEEDBACK

15MFV827 15M-NP-302 IW SERVICE BALL VALVE WITH ELECTRIC MOTOR OPERATOR -MODULATING

CONTROL ANALOG WITH ANALOG FEEDBACK

ACTUATOR MANUFACTURER FLOWSERVE FLOW CONTROL

LIMITORQUE CORPORATION

5114 Woodall Road

Lynchburg, VA 24506-1318

Phone: 434-528-4400

ACTUATOR MODEL LIMITORQUE QX1-XP-FA10-WD-QX-030110-10000 MODUTRONIC APT 120 REL 1-8

120 VOLT CONTROL WITH HANDWHEEL OVERRIDE

AND INTEGRAL LOCAL CONTROL STATION

CONTROL AT THE ACTUATOR - LOCAL CONTROL PANEL ON THE ACTUATOR IN "LOCAL"

AT THE REMOTE HAND STATION IN "LOCAL"

AT THE ACTUATOR - MANUAL OVERRIDE WITH THE ACTUATOR IN "OFF"

OR NO POWER

DISCRETE CONTROL FROM THE PLC IN "REMOTE"

Special function of monitor relay Output contacts set for “actuator alarm AA” and “Break at valve alarm bA”

VALVE TORQUE REQUIRED 61 FTLBS AT 150 PSI

ACTUATOR RATED TORQUE 100 FTLBS

SAFETY FACTOR >1.5

SPEED RANGE 5-20 SECONDS SET AT 5 SECONDS

TURNS FOR FULL CYCLE 90 DEGREES

POSITION INDICATION VISUAL AND MECHANICAL

VOLTAGE 120/60

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 2 of 148

FAIL ON LOSS OF POWER LAST POSITION

WIRING DIAGRAMS WD-QX-030110-10000 MODUTRONIC APT 120 REL 1-8 120 CONTROL

ENCLOSURE RATING XP- NEMA 4X; IP68;

DISCONNECT REMOTE MOUNTED WITH EXTRA CONTACT EIM 84550- WITH EXTRA CONTACT

REMOTE HAND STAION NONE

DOCUMENENT SUPPLIED VALVE CATALOG

ACTUATOR CATALOG

VALVE SHOP DRAWINGS

ACTUATOR SHOP DRAWING

INSTRUCTION MANUAL ACTUATOR

INSTRUCTION MANUAL VALVE

VALVE PARTS LIST

ACTUATOR (NO PARTS LIST INCLUDED)

MAINTENANCE INSTRUCTIONS

WARRANTY TWO YEARS FROM DATE OF DATE OF THE FINAL ACCEPTANCE BY THE AGENCY

ASSEMBLY: FACTORY INSTALLED

CYCLE TESTING: MISCOWATER, 27101 BURBANK STE B, FOOTHILL RANCH, CA 92610

FIELD START-UP PERFORMED BY MISCO AS REQUIRED

VALVE IDENTIFICATION STAINLESS STEEL NAMEPLATES ATTACHED TO THE VALVE PER

17075 316 SS TWO HOLE NAMEPLATE WITH SS WIRE

TAG NUMBER

SIZE

TYPE OF VALVE

PID DRAWING

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 3 of 148

Section 15106

BALL VALVES

PART 1 - GENERAL

7+(5(48,5(0(17

$ 7KH&2175$&725VKDOOIXUQLVKDQG LQVWDOOEDOOYDOYHVFRPSOHWHDQGRSHUDEOHDV

VKRZQ DQG VSHFLILHG KHUHLQ LQFOXGLQJ HSR[\ FRDWLQJ DSSXUWHQDQFHV RSHUDWRUV DQG

DFFHVVRULHVLQDFFRUGDQFHZLWKWKHUHTXLUHPHQWVRIWKH&RQWUDFW'RFXPHQWV

5(/$7(':25.63(&,),('(/6(:+(5(

$ 7KH UHTXLUHPHQWV RI WKH IROORZLQJ VHFWLRQV DQG GLYLVLRQV DSSO\WRWKH:RUNRIWKLV

VHFWLRQ 2WKHU VHFWLRQV DQG GLYLVLRQV RI WKH 6SHFLILFDWLRQV QRW UHIHUHQFHG EHORZ VKDOO

DOVRDSSO\WRWKHH[WHQWUHTXLUHGIRUSURSHUSHUIRUPDQFHRIWKLV:RUN

6HFWLRQ3URWHFWLYH&RDWLQJ

6HFWLRQ9DOYHV*HQHUDO

6HFWLRQ9DOYH2SHUDWRUV

5()(5(1&(63(&,),&$7,216&2'(6$1'67$1'$5'6

$ $OO:RUNVSHFLILHGKHUHLQVKDOOFRQIRUPWRRUH[FHHG WKHDSSOLFDEOHUHTXLUHPHQWVRI

WKH UHIHUHQFHG SRUWLRQV RI WKH IROORZLQJ SXEOLFDWLRQV WR WKH H[WHQW WKDW WKH SURYLVLRQV

WKHUHRIDUHQRWLQFRQIOLFWZLWKRWKHUSURYLVLRQVRIWKHVH6SHFLILFDWLRQV

% &RPSO\ ZLWK WKH DSSOLFDEOH HGLWLRQV RI WKH IROORZLQJ FRGHV UHJXODWLRQV DQG

VWDQGDUGV

,QGXVWU\6WDQGDUGV

$60(% 3LSH )ODQJHV DQG )ODQJHG )LWWLQJV 136 WKURXJK

1360HWULF,QFK6WDQGDUG

$::$& %DOO 9DOYHV ,QFKHV WKURXJK ,QFKHV

0LOOLPHWHUVWKURXJK0LOOLPHWHUV

& &RPSO\ ZLWK WKH DSSOLFDEOH UHIHUHQFH 6SHFLILFDWLRQV DV GLUHFWHGLQWKH*HQHUDO

5HTXLUHPHQWVDQG$GGLWLRQDO*HQHUDO5HTXLUHPHQWV

&2175$&72568%0,77$/6

$ 6XEPLWWDOV VKDOO EH PDGH LQ DFFRUGDQFH ZLWK WKH *HQHUDO 5HTXLUHPHQWV $GGLWLRQDO

*HQHUDO5HTXLUHPHQWVDQGDVVSHFLILHGKHUHLQ

% 6XEPLWWDOVVKDOOEHPDGHLQDFFRUGDQFH6HFWLRQ9DOYHV*HQHUDO

48$/,7<$6685$1&(

$ *HQHUDO

&RPSO\ZLWKWKHWHVWLQJSURFHGXUHVVSHFLILHGLQWKHUHIHUHQFHVWDQGDUGV

D $OO YDOYHV LQFKHV DQG ODUJHU VKDOO EH WHVWHG LQ DFFRUGDQFHZLWK

PDQXIDFWXUHUVUHFRPPHQGDWLRQDQGDSSOLFDEOH$::$VSHFLILFDWLRQV

:$55$17<

$ *XDUDQWHHV DQG :DUUDQW\ VKDOO EH IXUQLVKHG LQ DFFRUGDQFH ZLWK ³:DUUDQW\´

&2175$&725¶V *XDUDQWHH RI WKH *HQHUDO &RQGLWLRQV DQG 6HFWLRQ 9DOYHV

*HQHUDO

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 4 of 148

NA

PART 2 - PRODUCTS

%$//9$/9(6,1&+(6$1'/$5*(5

$ &RQVWUXFWLRQ8QOHVVRWKHUZLVHVSHFLILHGDOOEDOOYDOYHVVKDOOEHLQDFFRUGDQFHZLWK

$::$&ZLWKFDVWLURQ$670RUGXFWLOHLURQLQWHJUDOVXSSRUWOHJVRULQWHJUDOSDGV

IODQJHGHQGVDFFHSWDEOHIRUYHORFLWLHVXSWRISVWHPSHUDWXUHVXSWRGHJUHHV)

DQG GHVLJQ SUHVVXUHV WR SRXQGV SHU LQFK 7KH EDOOV VKDOO EH RI FDVW LURQ $670

$GXFWLOHLURQ$670$VKDIWRUWUXQQLRQPRXQWHGZLWKWLJKWVKXWRIIEL

GLUHFWLRQDOO\GRXEOHVHDWDQGIXOOERUHSHU7DEOHRI$::$&6KDIWSDFNLQJVKDOO

EHVHOIDGMXVWLQJDQGZHDUFRPSHQVDWLQJ0DQXDOO\DGMXVWDEOHSXOOGRZQSDFNLQJJODQGV

DUHQRWDFFHSWDEOH7KHYDOYHVVKDOOEH]HUROHDNSHUR[LGHFXUHG(3'0UXEEHURUPHWDO

VHDWHGZLWKWKHVHDWUHWDLQHGLQWKHERG\DQGRXWRIWKHIORZVWUHDP6HDWVUHWDLQHGZLWK

KDUGZDUHVKDOOQRWWDSGLUHFWO\LQWRWKHYDOYHRUEDOODQGVKDOOXVHVWDLQOHVVVWHHOLQVHUWVWR

UHWDLQ WKH VHDW IDVWHQHUV 6KDIWV WDSHU SLQV VKDOO EH PHFKDQLFDOO\ ORFN IDVWHQHG WR WKH

EDOOURWRU DQGVKDOOEHVWDLQOHVVVWHHORUQLFNHOFRSSHUDOOR\0RQHOVKDIWVZLWKQRWOHVV

WKDQRQHJUHDVHSDFNHGWKUXVWEHDULQJ$::$3URRIRI 'HVLJQ+\GURVWDWLFOHDN

WHVWVDQGIDFWRU\OHDNWHVWFHUWLILFDWLRQVKDOOEHSURYLGHGELGLUHFWLRQDOO\)HUURXVVXUIDFHV

RIYDOYHVLQFKHVDQGODUJHU ZKLFK ZLOOEHLQ FRQWDFWZLWK ZDWHUVKDOOEHDPLQHFXUHG

HSR[\ FRDWHG DV VSHFLILHG LQ 6\VWHP 1R 6HFWLRQ 3URWHFWLYH &RDWLQJ

0DQXIDFWXUHUVKDOOKDYHDPLQLPXPRI\HDUVSURYHQH[SHULHQFHEXLOGLQJ$::$&

EDOOYDOYHV

% 2SHUDWRUV 8QOHVV RWKHUZLVH VSHFLILHG RU VKRZQ DOO EDOO YDOYHV VKDOO KDYH PDQXDO

$::$ RSHUDWRUV ZLWK KDQGZKHHO SRVLWLRQ LQGLFDWRU DQG LQFKVTXDUH RSHUDWLQJ QXW

2SHUDWRUV IRU EXULHG YDOYHV DQG IRU SRZHURSHUDWHG YDOYHV VKDOO EH LQDFFRUGDQFH ZLWK

SURYLVLRQVRI6HFWLRQ9DOYH2SHUDWRUV

& 0DQXIDFWXUHUV2U(TXDO

+HQU\3UDWW&RPSDQ\

$3&2

:LOODPHWWH9DOYH,QF

%$//9$/9(6,1&+(6$1'60$//(5

$ *HQHUDO5HTXLUHPHQWV

8QOHVVRWKHUZLVHVSHFLILHGRUVKRZQJHQHUDOSXUSRVHEDOOYDOYHVLQVL]HVXSWR

LQFKHVVKDOOKDYHPDQXDORSHUDWRUVZLWKVWDLQOHVVVWHHOOHYHUDQGQXWRUKDQGZKHHO

)RU RWKHU RSHUDWRU UHTXLUHPHQWV VHH 6HFWLRQ 9DOYH 2SHUDWRUV)HUURXV

VXUIDFHV RI LQFK YDOYHV ZKLFK ZLOO EH LQ FRQWDFW ZLWK ZDWHUVKDOOEH DPLQH FXUHG

HSR[\FRDWHGDVVSHFLILHGLQ6\VWHP1R6HFWLRQ3URWHFWLYH&RDWLQJ$OO

EDOOYDOYHVVKDOOEHRIEHVWFRPPHUFLDOTXDOLW\KHDY\GXW\FRQVWUXFWLRQ

%DOO YDOYHVLQFRSSHUOLQHVVKDOO EHEURQ]H ERG\ZLWKVROGHUHQGV9DOYHVVKDOO

FRPSO\ZLWK7LWOH$%QROHDGUXOH

%DOOYDOYHVVKDOOEHWRSHQWU\YDOYHVQRWUHTXLULQJGLVPDQWOLQJRISLSLQJIRUUHSDLU

DQGVKDOOEHDFFHSWDEOHIRURSHUDWLQJLQDWHPSHUDWXUHUDQJHIURP GHJUHHV)WR

GHJUHHV)

9DOYHVVKDOOEHQRQOXEULFDWHGDQGFDSDEOHRIVHDOLQJLQHLWKHUIORZGLUHFWLRQ

% %RG\$OOEDOOYDOYHVXSWRDQGLQFOXGLQJLQFKHVLQVL]H VKDOO KDYH 7\SH

VWDLQOHVVVWHHOWZRRUWKUHHSLHFHERGLHVZLWKVFUHZHGHQGVIRUDSUHVVXUHUDWLQJRIQRW

OHVVWKDQSRXQGVSHULQFK:2*9DOYHVRIWRLQFKHVLQVL]HVKDOOKDYHEURQ]H

IRUJHG EUDVV RU VWHHO ZLWK WZR RU WKUHHSLHFH ERGLHV DQG IODQJHG HQGV IRU D SUHVVXUH

UDWLQJRISRXQGVSHULQFK

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 5 of 148

& %DOOV7KHEDOOVVKDOOEH7\SHVWDLQOHVVVWHHOZLWKIXOORSHQLQJV

' 6WHPV7KHYDOYHVWHPVVKDOOEHRIWKHEORZRXWSURRIGHVLJQRI7\SHVWDLQOHVV

VWHHO RU RWKHU DFFHSWDEOH FRQVWUXFWLRQ 7KH VWHP SDFNLQJ VKDOO EH PDQXDOO\ DGMXVWDEOH

ZKLOHWKHYDOYHLVXQGHUSUHVVXUH

( 6WHP 6HDOV 6WHP VHDOV VKDOO EH SRO\WHWUDIOXRURHWK\OHQH 7HIORQ 7)( 37)( RU

IOXRURHODVWRPHU9LWRQ

) 6HDWV7KHYDOYHVHDWVVKDOOEHRI7HIORQ7)( RU37)(IRUELGLUHFWLRQDOVHUYLFH

DQGHDV\UHSODFHPHQW

* 0DQXIDFWXUHUV2U(TXDO

$SSROOR&RQEUDFR

-DPHVEXU\&RUSRUDWLRQ

-HQNLQV%URV

/XQNHQKHLPHU)ORZ&RQWURO

:P3RZHOO&RPSDQ\

:RUFHVWHU&RQWUROV

+LOOV0F&DQQD6HDO7RS(QWU\

67$,1/(6667((/%$//9$/9(6)25,167580(17$,53,3,1*

$ 7ZR LQFK DQG VPDOOHU EDOO YDOYHV LQVWDOOHG LQ VWDLQOHVV VWHHO SLSLQJ VKDOO EH RI 7\SH

VWDLQOHVVVWHHOFRQVWUXFWLRQZLWKWZRSLHFHHQGHQWU\ERG\VWDLQOHVVVWHHOEDOO7HIORQ

RU 9LWRQ VWHP VHDO UHLQIRUFHG 7HIORQ VHDWV DQG WKUXVW ZDVKHU D UHPRYDEOH RSHUDWLQJ

OHYHU DQGWKUHDGHGHQGV (DFK EDOO YDOYH LQ JDXJH LVRODWLRQVHUYLFHVKDOO EHIXUQLVKHG

ZLWKDURXQGKDQGOH9DOYHVVKDOOEHUDWHGQRWOHVVWKDQSRXQGVSHULQFKQRQVKRFN

FROG ZDWHU RLO JDV :2* DQG VKDOO EH GULS WLJKW LQ ERWK GLUHFWLRQV 9DOYHV VKDOO EH

&RQEUDFR,QGXVWULHV³$SROORVHULHV´RU1HOHV-DPHVEXU\³6HULHV´2U(TXDO

3/$67,&%$//9$/9(6

$ *HQHUDO5HTXLUHPHQWV

3ODVWLF EDOO YDOYHV IRU FKHPLFDO VHUYLFHV VKDOO EH PDGH RI SRO\YLQ\O FKORULGH

39& FKORULQDWHG SRO\YLQ\O FKORULGH &39& 7HIORQ 37)( RU SRO\YLQ\OLGHQH

IOXRULGH 39') DV UHFRPPHQGHG E\ WKH PDQXIDFWXUHU IRU LQGLFDWHGVHUYLFHVKRZQ

RQ WKH 3LSH 6FKHGXOH $OO YDOYHV VKDOO KDYH PDQXDO RSHUDWRUV XQOHVV RWKHUZLVH

VSHFLILHGRUVKRZQ

9DOYHVVKDOOKDYHWUXHXQLRQW\SHHQGFRQQHFWLRQV 6L]HV LQFKHVDQGJUHDWHU

VKDOOEHIODQJHG

% &RQVWUXFWLRQ

$OOSODVWLFEDOOYDOYHVVKDOOKDYHXQLRQHQGVRUIODQJHGHQGVFRQIRUPLQJWR$60(

%FODVVIRUHDV\UHPRYDO

9DOYHV VKDOO EH DFFHSWDEOH IRU D PD[LPXP ZRUNLQJ QRQVKRFN SUHVVXUH RI

SRXQGV SHU LQFK DW GHJUHHV ) IRU &39& ZLWK GHFUHDVLQJ UDWLQJV IRU KLJKHU

WHPSHUDWXUHVDQGRWKHUSODVWLFV

%DOOVVKDOOKDYHIXOOVL]HSRUWVDQG7HIORQVHDWV

$OOERG\VHDOVXQLRQ2ULQJVHDOVDQGVWHPVHDOVVKDOOEH7HIORQ

9DOYHVVKDOOEHIXUQLVKHGZLWKZUHQFKW\SHPDQXDORSHUDWRUKDQGOHV

:KHUHYDOYHVDUHXVHGIRUVRGLXPK\SRFKORULWHDLQFKGLDPHWHUKROHVKDOO

EHSURYLGHGLQWKHGRZQVWUHDPVLGHRIWKHEDOO

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 6 of 148

&

%

D

OO

V

7K

H

ED

OO

V

VK

D

OO

EH

7

\

SHVWDLQOHVVVWHHOZLWK

I

XOORSHQLQ

J

V

'

6

WHPV7KHYDOYHVWHPVVKDOOEHR

I

WKHEORZRXWSURR

I

GHVL

J

QR

I

7

\

SHVWDLQOHVV

V

W

HH

ORU RWKHU DFFHSWDEOH FRQVWUXFWLRQ 7KH VWHP SDFNLQ

J

VKDOO EH PDQXDOO

\

DG

M

XVWDEOH

ZKLOHWKHYDOYHLVXQGHUSUHVVXU

H

(

6

WHP

6

HDOV

6

WHP VHDOV VKDOO EH SRO

\

WHWUD

I

OXRURHWK

\

OHQH

7H

I

ORQ 7)(

37)(

RU

I

OXRURHODVWRPHU

9

LWRQ

)

6

HDWV7K

H

Y

D

OY

H

VHD

W

V

V

K

D

OO

EH

RI

7

HI

O

RQ

7)(

RU

37)(

I

RUE

L

G

LU

HF

WL

R

Q

D

O

VH

UYL

FH

DQGHDV

\

UHSODFHPHQW

*

0

DQX

I

DFWXUHUV

2

U(TXDO

$SSROOR

&

RQEUDFR

-

DPHVEXU

\

&

RUSRUDWLRQ

-

HQNLQV%URV

/XQNHQKHLPHU)ORZ

&

RQWURO

:P3RZHOO

&

RPSDQ

\

:RUFHVWHU

&

RQWUROV

+

LOO

V

0

F

&

DQQD

6

HDO7RS(QWU

\

6

7$,1/(

66

6

7((/%$/

/

9

$/9(

6

)

2

5,1

6

75

8

0(17$,53,3,1

*

$ 7ZR LQFK DQG VPDOOHU EDOO YDOYHV LQVWDOOHG LQ VWDLQOHVV VWHHO SLSLQ

J

VKDOO EH R

I

7

\

SH

VWDLQOHVVVWHHOFRQVWUXFWLRQZLWKWZ

R

S

LHFHHQGHQWU

\

ERG

\

VWDLQOHVVVWHHOEDOO7H

I

ORQ

RU 9LWRQ VWHP VHDO UHLQ

I

RUFHG 7H

I

ORQ VHDWV DQG WKUXVW ZDVKHU D UHPRYDEOH RSHUDWLQ

J

OHYHU DQGWKUHDGHGHQGV (DFK EDOO YDOYH LQ

J

DX

J

HLVRODW

L

R

Q

VH

UYL

FH

V

K

D

OO

EH

IX

UQL

V

K

HG

ZLWKDURXQGKDQGOH9DOYHVVKDOOEHUDWHGQRWOHVVWKDQSRXQGVSHULQFKQRQVKRFN

F

ROG ZDWHU RLO

J

DV

:

2*

DQGVKDOOEHGULSWL

J

KW LQ ERWK GLUHFWLRQV 9DOYHV VKDOO EH

&

RQEUDFR,QGXVWULHV

³

$SROOR

VHULHV

´

RU1HOHV

-

DPHVEXU

\

³6

HULHV´

2

U(TXDO

SEE THE NOTES

NA

& 3ODVWLFEDOOYDOYHVVKDOOEHIXUQLVKHGZLWKHOHFWULFPRWRUDFWXDWRUVZKHUHLQGLFDWHGRQ

WKH3ODQV7KHHOHFWULFDFWXDWRUVKDOOEHYROWVLQJOHSKDVHXQOHVVRWKHUZLVHLQGLFDWHG

RQ WKH 3ODQV $OO DFWXDWRUV VKDOO EH FRUURVLRQ UHVLVWDQW 1(0$ VXLWDEOH IRU D &ODVV

'LYLVLRQ JURXS & ' HQYLURQPHQW XQOHVV RWKHUZLVH LQGLFDWHG RQ WKH 3ODQV 7KH YDOYH

DQGDFWXDWRUVKDOOEHIDFWRU\DVVHPEOHGDQGVXSSOLHGE\WKHYDOYHPDQXIDFWXUHU

' 0DQXIDFWXUHUV2U(TXDO

$6$+,$PHULFD,QF

*HRUJ)LVFKHU3LSLQJ6\VWHPV,QF

1,%&2,QF&KHPWURO

+D\ZDUG,QGXVWULDO3URGXFWV,QF

PART 3 - EXECUTION

*(1(5$/

$ $OOYDOYHVLQVWDOOHGLQSODVWLFSLSHOLQHVVKDOOEHLQGHSHQGHQWO\VXSSRUWHGVRDVQRWWR

FDXVHXQGXHVWUHVVRURWKHUZLVHGDPDJHSLSLQJ

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 7 of 148

SPEARS MFR

10

Sample Engineering Specification

All thermoplastic ball valves shall be True Union 2000 Industrial type

manufactured to ASTM F 1970 and constructed from PVC Type I, ASTM

D 1784 Cell Classification 12454 or CPVC Type IV, ASTM D1784 Cell

Classification 23447. All O-rings shall be EPDM or Viton

®

. All valves shall

have Safe-T-Shear

®

stem with double O-ring stem seals. All valve handles

shall be polypropylene with built-in lockout mechanism. All valve union nuts

shall have Buttress threads. All seal carriers shall be Safe-T-Blocked

®

. All

valve components shall be replaceable. All valves shall be certified by NSF

International for use in potable water service. All 1/2" through 2" valves shall

be pressure rated to 235 psi, all 2-1/2" through 6", 8" Venturied and all flanged

valves shall be pressure rated to 150 psi for water at 73° F.

•Chemical & Corrosion Resistant PVC or

CPVC Construction

• Also Available in Spears®LXT™ High Purity,

Low Extractable PVC Material

• Interchangeable with all True Union 2000

Valves Mates with Union 2000 Pipe Unions

• High Impact Polypropylene Handle

• Built-in Handle Lockout

• Schedule 80 Full-Bore Design

• Strong, Buttress Thread Union Nuts

• Spears®Double O-ring Safe-T-Shear®

Stem Design

• EPDM or Viton®O-rings

• Spears®Safe-T-Blocked®Seal Carrier

• Self Adjusting PTFE Floating Seat Design

• Fully Serviceable, Replaceable Components

• Sizes 1/2" - 2" pressure rated to 235 psi @

73°F. Sizes 2-1/2" - 6", 8" Venturied and all

Flanged to 150 psi @ 73°F.

• NSF Certified for Potable Water use

• Suitable for Vacuum Service

• Assembled with Silicone-Free

, Water

Soluble Lubricants

• Manufactured to ASTM F 1970

Optional Vented Ball Valves

Same valve with special ball vent design for

sodium hypochlorite (bleach) and other chemical

applications where entrapped fluids may form

caustic crystalline residues and pressure build up

from gases developed. Valve has a 1/8” vent hole

in ball to equalize internal fluid pressures. Install

valve with ball vent on the pressure (upstream)

side when in closed position.

Optional Accessories*

•

Retro-Fit End Connector Sets for Valve

Replacement

• Split-Nut Repair Kits for Union Nut Replacement

• Supplemental End Connectors

• Round Safety Handles

• Handle Lockout Ring

• Stem Extension Kits

• Square Operator Nuts

• Multi Mount Valve/Actuation

Mounting Kits

TRUE UNION 2000 INDUSTRIAL BALL VALVES

Quick-View Valve Selection Chart

1) For CPVC, add the letter "C" following the size code of part number listed (e.g.,1829-005C, 1821-005CSR)

2) For Special Ball Vent Design, add the letter "V" before the dash separator (e.g.,1829V-005, 1821V-005CSR)

3) 8" Venturied Valves are 6" ball valves fitted with 6x8 end connector adapters.

* See “BALL VALVE ACCESSORIES” section for details of

individual products.

Valve

Size

O-ring

Material

PVC Part Number 1Pressure

Rating

Socket Threaded SR Threaded Flanged Spigot

1/2 EPDM 1829-005 included 1821-005SR 1823-005 1827-005

235 psi

Non-Shock

Water

@ 73° F

(Flanged

150 psi

Non-Shock)

Water

@ 73° F

Viton®1839-005 included 1831-005SR 1833-005 1837-005

3/4 EPDM 1829-007 included 1821-007SR 1823-007 1827-007

Viton®1839-007 included 1831-007SR 1833-007 1837-007

1EPDM 1829-010 included 1821-010SR 1823-010 1827-010

Viton®1839-010 included 1831-010SR 1833-010 1837-010

1-1/4 EPDM 1829-012 included 1821-012SR 1823-012 1827-012

Viton®1839-012 included 1831-012SR 1833-012 1837-012

1-1/2 EPDM 1829-015 included 1821-015SR 1823-015 1827-015

Viton®1839-015 included 1831-015SR 1833-015 1837-015

2EPDM 1829-020 included 1821-020SR 1823-020 1827-020

Viton®1839-020 included 1831-020SR 1833-020 1837-020

2-1/2 EPDM 1822-025 1821-025 1821-025SR 1823-025 1827-025

150 psi

Non-Shock

Water

@ 73° F

Viton®1832-025 1831-025 1831-025SR 1833-025 1837-025

3EPDM 1822-030 1821-030 1821-030SR 1823-030 1827-030

Viton®1832-030 1831-030 1831-030SR 1833-030 1837-030

4EPDM 1822-040 1821-040 1821-040SR 1823-040 1827-040

Viton®1832-040 1831-040 1831-040SR 1833-040 1837-040

6EPDM 1822-060 1821-060 1821-060SR 1823-060 1827-060

Viton®1832-060 1831-060 1831-060SR 1833-060 1837-060

83EPDM 1822-080 — — 1823-080 —

Viton®1832-080 — — 1833-080 —

Features – PVC, CPVC

This multi-featured, space saving quarter-turn shutoff valve is designed to meet the

demands of today's industrial and chemical processing applications. PVC and CPVC

valves are available in IPS sizes 1/2" through 6" with socket/regular thread, SR (Special

Reinforced) thread, flanged or spigot end connectors and 8" Venturied valve with socket or

flanged ends. Also available in metric socket and BSP thread sizes 1/2" through 2".

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 8 of 148

11

TRUE UNION 2000 INDUSTRIAL BALL VALVES

Replacement Parts

Dimensions, Weights, Operating Torque & CvValues

Temperature Pressure Rating

NOTE: 1) Flanged Valves have a base pressure rating of 150 psi.

No. Component Qty. Material

1 Seal Carrier 1 PVC/CPVC

2 Seat 2 PTFE

3 Body 1 PVC/CPVC

4 Carrier O-ring 1 EPDM/Viton®

5 Stem 1 PVC/CPVC

6 Stem Bearing 1 PP

7 Handle 1 PP

8 Stem O-ring 2 EPDM/Viton®

9 Handle Lock 1 PP

10 Ball 1 PVC/CPVC

11 Union Nut 2 PVC/CPVC

12 End Connector O-ring 2 EPDM/Viton®

13 End Connector 2 PVC/CPVC

System Operating

Temperature °F (°C)

100

(38)

110

(43)

120

(49)

130

(54)

140

(60)

150

(66)

160

(71)

170

(77)

180

(82)

190

(88)

200

(93)

210

(99)

Valve

Pressure

Rating

psi

(Mpa)

1/2” - 2”

PVC 235

(1.62)

211

(1.45)

150

(1.03)

75

(.52)

50

(.34)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

CPVC 235

(1.62)

219

(1.51)

170

(1.17)

145

(1.00)

130

(.90)

110

(.76)

90

(.62)

80

(.55)

70

(.48)

60

(.41)

50

(.34)

-0-

(-0-)

2-1/2” - 8”

PVC 150

(1.03)

135

(.93)

110

(.76)

75

(.52)

50

(.34)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

-0-

(-0-)

CPVC 150

(1.03)

140

(.97)

130

(.90)

120

(.83)

110

(.76)

100

(.70)

90

(.62)

80

(.55)

70

(.48)

60

(.41)

50

(.34)

-0-

(-0-)

NOT FOR USE WITH COMPRESSED AIR OR GASES

Nominal

Size

Dimensions Reference (inches, ± 1/16) Approx. Wt. (Lbs.) Oper.2

Torque

(in. lbs.)

Cv3Values

A

B1C

DEFG

PVC CPVC Soc/Thd Flanged Spigot

Soc/Thd Spigot Socket Thread Spigot

1/2 1-7/8 2-3/8 2-7/8 4-3/16 3-3/16 4-5/8 2-9/16 2-13/16 3-1/2 2-31/32 .36 .38 16 29 18 27

3/4 2-1/4 2-3/4 3-1/4 4-3/4 4-1/4 5-1/4 2-7/8 3-3/8 3-7/8 3-5/16 .56 .58 17 63 39 57

1 2-1/2 2-7/8 3-1/2 5-1/8 4-11/16 5-3/4 3-1/8 3-7/16 4-1/2 3-5/8 .74 .77 22 120 73 108

1-1/4 3-1/16 3-1/4 3-13/16 5-3/4 5-3/16 6-5/16 3-5/8 3-7/8 4-5/8 3-31/32 1.13 1.19 28 243 151 223

1-1/2 3-1/2 3-1/2 4 6-1/4 5-7/16 6-3/4 4 4-3/16 5 4-3/8 1.54 1.60 61 357 223 333

2 4-1/4 4-3/4 5-3/16 7-3/4 6-3/4 8-1/4 4-1/2 5-1/8 6 5-1/4 2.72 2.85 77 599 395 571

2-1/2 5-3/8 6-7/8 7-13/16 10-7/16 9-11/16 11-3/8 5-1/8 6-1/4 7-1/2 6 7.42 7.70 132 856 579 734

3 6-3/16 7 7-13/16 10-11/16 9-7/8 11-9/16 5-7/8 7-5/8 7-1/2 6-13/16 7.46 7.81 132 1416 974 1322

4 7-5/8 7-5/16 8-1/4 11-7/8 10-1/4 12-3/4 6-3/4 9-3/16 9 7-1/2 12.35 12.48 396 2865 1952 2672

6 11-5/8 11-1/16 13 17-1/16 15-3/4 18-1/2 8-1/8 14-5/16 11-1/4 10-3/16 37.53 40.55 732 6638 4824 6149

8411-5/8 23-3/16 --- 31-7/8 --- --- 8-1/8 14-5/16 13-1/2 17-13/16 50.84 55.92 732 N/A N/A N/A

1: Valve Lay Length

2: Torque required at valve maximum internal pressure rating, 5ft/sec. Flow velocity; due to adjustment differences during installation, actual valves may vary.

3: Gallons per minute at 1 psi pressure drop. Valves calculated from laying length, based on derivative of Hazen-Williams equation with surface roughness factor of C=150.

4: 8" Venturied Valves are 6" ball valves fitted with 6x8 end connector adapters.

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 9 of 148

81

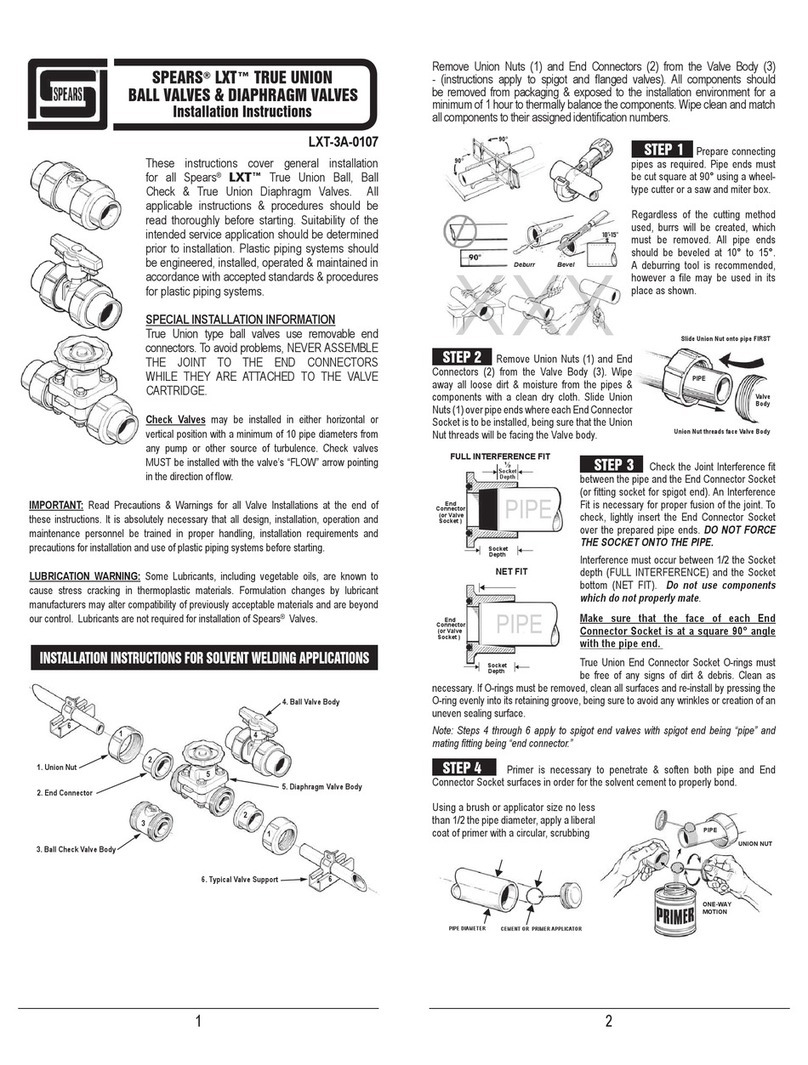

GENERAL INSTALLATION

Ease of installation and maintenance is one of the major advantages of using thermoplastic valves. As with any product, certain

procedures must be followed for successful installation, service and long life. This section specifies individual installation and

maintenance service instructions for Spears valves. All applicable instructions and procedures should be read thoroughly

before starting. Suitability of the intended service application should be determined prior to installation. Please review

“Material Considerations in Application and System Design”, in the “MATERIALS” section of this manual for

important additional considerations related to valve installations.

Plastic piping systems should be engineered, installed, operated and maintained in accordance with accepted standards and

procedures for plastic piping systems. It is absolutely necessary that all design, installation, operation and maintenance

personnel be trained in proper handling, installation requirements and precautions for installation and use of plastic piping

systems before starting.

Individual valve installation instructions specific to each product type are packaged with product. The following sections of

this manual contain safety precautions and procedures for making solvent cement, threaded or flanged joints.

Precautions & Warnings for All Valve, Strainer & Accessories Installations

CAUTION: The system shall be designed and

installed so as not to pull the valve in any direction.

Valve and strainers must be supported with

conventional piping system support devices.

Typical Valve Support Example

CAUTION: All valve connectors and connecting pipe

should be inspected for any breaking, chipping, gouging or

other visible damage before proceeding. All joining

components must be clean and dry. All valves and pipe

shall be removed from their packaging or containers and

exposed to the environment for a minimum of one hour in

order to thermally balance all components. Installation

temperatures should be between 40°F and 110°F.

CAUTION: All valves with fixed socket end connectors

in the body must be installed in the open position to aid in

evaporation of solvent vapors which can attack internal

components. WARNING: TAKE EXTRA CARE THAT NO

PRIMER OR SOLVENT CEMENT IS ALLOWED TO

COME IN CONTACT WITH THE BALL OR OTHER

INTERNAL VALVE COMPONENTS.

CAUTION: Threaded pipe connections require

application of a quality grade thread sealant to seal joint

assembly. Sealant should be applied to male pipe threads.

WARNING: SOME PIPE JOINT COMPOUNDS OR

TEFLON®PASTES MAY CONTAIN SUBSTANCES THAT

COULD CAUSE STRESS CRACKING IN

THERMOPLASTIC MATERIALS. Spears Manufacturing

Company recommends the use of Spears BLUE 75TM

thread sealant which has been tested for compatibility with

Spears products. Please follow the sealant manufacturers’

application / installation instructions. Choice of an

appropriate thread sealant other than those listed above is

at the discretion of the installer.

CAUTION: BEFORE THE VALVE IS CYCLED, all

dirt, sand, grit or other material shall be flushed from the

system. This is to prevent scarring of internal

components; e.g., ball, cup, wedge, seats, etc.

WARNING: Some Lubricants, including

vegetable oils, are known to cause stress cracking

in thermoplastic materials. Commercially available

pipe gasket lubricants suitable for PVC and CPVC

should be used where lubrication is needed for

installation or maintenance service (Seacord Ease-On

or equivalent). These water-soluble lubricants can be

mixed with water where "a mild soap and water

solution" is specified to be used. Choice of lubricant is

at the discretion of the installer.

WARNING: DO NOT USE COMPRESSED AIR OR

GAS TO TEST ANY PVC OR CPVC THERMOPLASTIC

PIPING PRODUCT OR SYSTEM, AND DO NOT USE

DEVICES PROPELLED BY COMPRESSED AIR OR GAS

TO CLEAR SYSTEMS. THESE PRACTICES MAY

RESULTIN EXPLOSIVE FRAGMENTATION OF

SYSTEM PIPING AND COMPONENTS CAUSING

SERIOUS OR FATAL BODILYINJURY. All air must be

bled from the system during initial fluid fill. Pressure testing

of the system should not be made until all solvent cement

joints have properly cured. Initial pressure testing should be

made at approximately 10% of the system hydrostatic

pressure rating to identify potential problems, prior to testing

at higher pressures.

WARNING: Systems should not be operated or flushed

out at flow velocities greater than 5 feet per second.

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 10 of 148

Section 15101

VALVE OPERATORS

PART 1 - GENERAL

7+(5(48,5(0(17

$ 7KLV VHFWLRQ LQFOXGHV UHTXLUHPHQWV IRU SRZHU RSHUDWHG DFWXDWRUV DQG SRZHU JDWH

RSHUDWRUV7KHDFWXDWRUUHTXLUHPHQWVDUHVKRZQRQ'UDZLQJV7KH&2175$&725VKDOO

IXUQLVK DQG LQVWDOO WKH YDOYH DFWXDWRUV VKRZQ RQ WKH 'UDZLQJV FRPSOHWH DQG RSHUDEOH

LQFOXGLQJ DOO FRQWUROV PRWRUV JHDUV HWF LQ DFFRUGDQFH ZLWK WKH UHTXLUHPHQWV RI WKH

&RQWUDFW 'RFXPHQWV $Q DFWXDWRU VFKHGXOH LV SURYLGHG IRU UHIHUHQFH RQO\ WKH

&2175$&725VKDOOREWDLQWKHFRXQWRIDFWXDWRUVIURPWKH'UDZLQJV

% $FWXDWRUV DQG WKHLU DSSXUWHQDQFHV VKDOO EH VXLWDEOH IRU WKH LQWHQGHG RSHUDWLQJ

FRQGLWLRQVDQGVXLWDEOHIRUWKHUHTXLUHPHQWVRIRSHUDWLQJWKHLUUHVSHFWLYHYDOYHVRUJDWHV

& 7KH DFWXDWRU PDQXIDFWXUHU VKDOO KDYH DW OHDVW ILYH \HDUV RI H[SHULHQFH LQ WKH

SURGXFWLRQRIVLPLODUYDOYHDFWXDWRUV

5(/$7(':25.63(&,),('(/6(:+(5(

$ 7KH UHTXLUHPHQWV RI WKH IROORZLQJ VHFWLRQV DQG GLYLVLRQV DSSO\ WR WKH :RUN RI WKLV

VHFWLRQ 2WKHU VHFWLRQV DQG GLYLVLRQV RI WKH 6SHFLILFDWLRQV QRW UHIHUHQFHG EHORZ VKDOO

DOVRDSSO\WRWKHH[WHQWUHTXLUHGIRUSURSHUSHUIRUPDQFHRIWKLV:RUN

6HFWLRQ&RPPLVVLRQLQJ

6HFWLRQ7UDLQLQJRI2&6'3HUVRQQHO

6HFWLRQ3URWHFWLYH&RDWLQJV

6HFWLRQ9DOYHV*HQHUDO

6HFWLRQ(OHFWULF0RWRUV

6HFWLRQ&RQWURO6WUDWHJ\

6HFWLRQ3URFHVV,QVWUXPHQWDWLRQDQG&RQWURO

5()(5(1&(63(&,),&$7,216&2'(6$1'67$1'$5'6

$ $OO:RUNVSHFLILHGKHUHLQVKDOOFRQIRUPWRRUH[FHHGWKHDSSOLFDEOH UHTXLUHPHQWV RI

WKH UHIHUHQFHG SRUWLRQV RI WKH IROORZLQJ SXEOLFDWLRQV WR WKH H[WHQW WKDW WKH SURYLVLRQV

WKHUHRIDUHQRWLQFRQIOLFWZLWKRWKHUSURYLVLRQVRIWKHVH6SHFLILFDWLRQV

% &RPSO\ ZLWK WKH DSSOLFDEOH HGLWLRQV RI WKH IROORZLQJ FRGHV UHJXODWLRQV DQG

VWDQGDUGV

&&5 &DOLIRUQLD &RGH RI 5HJXODWLRQV 7LWOH IRU (OHFWULFDO

6DIHW\2UGHUV

$::$& $PHULFDQ:DWHU:RUNV$VVRFLDWLRQ

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 11 of 148

$16, $PHULFDQ1DWLRQDO6WDQGDUGV,QVWLWXWH

$60( $PHULFDQ6RFLHW\RI0HFKDQLFDO(QJLQHHUV

,6$ ,QVWUXPHQW6RFLHW\RI$PHULFD

)&&3DUW

1)3$ 1DWLRQDO(OHFWULFDO&RGHODWHVWYHUVLRQ

1)3$ (OHFWULFDO6WDQGDUGIRU(OHFWULFDO0DFKLQHU\

&2175$&72568%0,77$/6

$ 6XEPLWWDOV VKDOO EH PDGH LQ DFFRUGDQFH ZLWK WKH *HQHUDO 5HTXLUHPHQWV DQG

$GGLWLRQDO*HQHUDO5HTXLUHPHQWV

% 2&6'VKDOOEHSURYLGHGDOLVWRIUHIHUHQFHVRIH[LVWLQJDFWXDWRULQVWDOODWLRQVLQFOXGLQJ

WKHFRQWDFWSHUVRQ¶VQDPHDQGSKRQHQXPEHUDQGVKDOOVXEPLWHYLGHQFHRIVDWLVIDFWRU\

RSHUDWLRQLQDWOHDVWILYHPXQLFLSDOZDVWHZDWHULQVWDOODWLRQVRIVLPLODUVFRSHDQGXVDJH

& 0RWRUDQGJHDUW\SHLQIRUPDWLRQ

' 'HVLJQ'DWD

6XEPLWRSHUDWLQJWKUXVWDQGWRUTXHFDOFXODWLRQVIRUHDFKJDWHVL]HDQGRSHUDWLQJ

KHDG

6XEPLWGDWDWRVXEVWDQWLDWHPRWRUKRUVHSRZHUDQGRSHUDWLQJWLPHV

6XEPLWGDWDYHULI\LQJDFWXDWRUVWDOOWRUTXHZLOOEHQRPRUHWKDQSHUFHQWRIWKH

GULYHVWHP¶VVKHDUVWUHQJWKWRUTXHFDSDFLW\DQGWKUXVWFDSDFLW\

6XEPLW SURSRVHG DFWXDWRU FRQILJXUDWLRQ DQG GLPHQVLRQV IRU HDFK GLIIHUHQW

DFWXDWRUW\SH

( 6KRS'UDZLQJV:LULQJ'LDJUDPVDQG3URGXFW'DWD

) 0DQXIDFWXUHU¶V3XEOLVKHG,QVWUXFWLRQV

* 2SHUDWLQJDQG0DLQWHQDQFH0DQXDOV

+ :DUUDQW\

)RUHOHFWULFSKDVHDFWXDWRUVRQO\FHUWLILHGFRSLHVRISURRIRIGHVLJQ WHVW

UHSRUWV DV VHW IRUWK LQ $::$ & 6HFWLRQ WRJHWKHU ZLWK DIILGDYLWV RI

FRPSOLDQFH DV LQGLFDWHG LQ $::$ & 6HFWLRQ VKDOO EH VXEPLWWHG WR 2&6'

EHIRUHWKHDFWXDWRUVDUHVKLSSHG

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 12 of 148

PLASTIC VALVE VOLTAGE IS 120/60

$ZULWWHQPDQXIDFWXUHU¶V ZDUUDQW\VKDOO EHSURYLGHGIRUWKH HTXLSPHQWVSHFLILHG

LQWKLVVHFWLRQ:DUUDQW\RQWKHYDOYHDFWXDWRUVVKDOOEHIRUDPLQLPXPSHULRGRIWZR

\HDUV IURP WKH GDWH RI RSHUDWLRQDO VWDUWXS DQG 2&6' DFFHSWDQFH 6XFK

ZDUUDQWLHV VKDOO FRYHU DOO GHIHFWV RU IDLOXUHV LQ PDWHULDOV RU ZRUNPDQVKLS WKDW RFFXU

DVWKHUHVXOWRIQRUPDORSHUDWLRQDQGVHUYLFH7KHPDQXIDFWXUHUVKDOOEHUHVSRQVLEOH

IRUDOOUHSODFHPHQWRUUHSDLUFRVWVRIPDWHULDOVODERUIRUUHPRYDODW2&6'¶VVLWHDQG

UHLQVWDOODWLRQ DW 2&6'¶V VLWH :DUUDQW\ ZRUN UHODWHG WR VWDQGDUG LWHPV VKDOO EH

FRPSOHWHGZLWKLQFDOHQGDUGD\V7KLVZDUUDQW\WLPHIUDPHVKDOOVWDUWIURPWKHGDWH

RIQRWLILFDWLRQE\2&6'WRWKH&2175$&725

$Q DEVROXWH HQFRGHU VKDOO EH XVHG WR VHQVH YDOYH SRVLWLRQ LQ ERWK PRWRU DQG

KDQGZKHHORSHUDWLRQDQGVKDOOQRWUHTXLUHEDWWHU\EDFNXS

>5HYLVHG$GGQ1R@

, Configuration/Programming Submittal

All equipment, devices and/or instruments that requires configuration or

programming. The submitted program shall be in native format and shall be

provided with the associated relevant software. For record purposes each

individual file shall be saved separately with filename as tag number in the

native format and submitted.

48$/,7<$6685$1&(

$ $OO LQWHUQDO ZLULQJ RI PRWRU DFWXDWRUV VKDOO EH LQGLYLGXDOO\ LGHQWLILHG ZLWK D XQLTXH

QXPEHU 7KH DVVLJQHG LQWHUQDO ZLULQJ QXPEHU VKDOO PDWFK WKH PDQXIDFWXUHU¶V

GRFXPHQWDWLRQ

% ,W LV WKH UHVSRQVLELOLW\ RI WKH &2175$&725 WR FRRUGLQDWH WKH UHTXLUHPHQWV RI WKLV

VHFWLRQZLWKWKRVHLQYROYLQJERWKHOHFWULFDODQGLQVWUXPHQWDWLRQVSHFLILFDWLRQV

& $OO DGMXVWPHQWV FDOLEUDWLRQ DQGRU WHVWLQJ VKDOO EH GRQH LQ WKH SUHVHQFH RI

(1*,1((5RU,163(&725

' ,QWHJUDWLRQ RI WKH YDOYH DQG DFWXDWRU VKDOO EH WKH UHVSRQVLELOLW\ RI WKH YDOYH

PDQXIDFWXUHU5HIHUHQFH6HFWLRQ9DOYHV*HQHUDO

( 7KHSURGXFWVXSSOLHGIRUHDFKW\SHRIDFWXDWRUVKDOODOOEHRIWKHVDPHPRGHOQXPEHU

IURPWKHVDPHPDQXIDFWXUHU

) $OO DFWXDWRUV RI WKH VDPH PRGHO QXPEHU VKDOO KDYH LGHQWLFDO LQWHUQDO ZLULQJ FRORUV

PDUNLQJDQGURXWLQJ

PART 2 - PRODUCTS

*(1(5$/5(48,5(0(176±$//$&78$7256

$ $OO DFWXDWRUV VKDOO EH VXSSOLHG ZLWK UHPRWH FRQWUROV LI WKH YDOYH DQG DFWXDWRU

DVVHPEO\ LV PRXQWHG LQ D GHILQHG ³FRQILQHG VSDFH´ LI LQWHJUDO FRQWUROV ZRXOG EH RXW RI

UHDFKWRDQRSHUDWRUVWDQGLQJDWIORRUOHYHODWWKHDFWXDWRURULIUHTXLUHGLQWKH'UDZLQJV

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 13 of 148

% $OODFWXDWRUVVKDOOEHVXSSOLHGZLWKDUHPRWHPRXQWHGVDIHW\GLVFRQQHFWVZLWFKORFN

RXWWDJRXWXVH7KLVGLVFRQQHFWVKDOOSURYLGHDQDX[LOLDU\FRQWDFWUDWHGWREUHDNH[WHUQDO

FRQWUROSRZHUWKDWPD\EHIHGWRWKHDFWXDWRUVPRQLWRULQJOLPLWVZLWFKHV

& $OO DFWXDWRUV VKDOO KDYH D PHFKDQLFDO ORFDO YDOYH SRVLWLRQ LQGLFDWRU WKDW GRHV QRW

GHSHQGXSRQSRZHUEHLQJSUHVHQWWREHYLVLEOHIURPWKHQRUPDORSHUDWLQJSRVLWLRQ

' 9DOYHSRVLWLRQVHQVLQJVKDOOEHE\DQDEVROXWHHQFRGHUWKDWPHDVXUHVYDOYHSRVLWLRQ

LQERWKPRWRUDQGKDQGZKHHORSHUDWLRQ1REDWWHU\RUEDFNXSSRZHUVKDOOEHUHTXLUHG

( $OO DFWXDWRU PRXQWLQJ KDUGZDUH EUDFNHWV DQG DOO DWWDFKLQJ IDVWHQHUV VKDOO EH

VWDLQOHVVVWHHO

) $OO DFWXDWRUV VKDOO SURYLGH D IDLO PRGH SHU WKH YDOYH DFWXDWRUVFKHGXOHVXFKDV)DLO

2SHQ )2 )DLO &ORVHG )& )DLO /DVW 3RVLWLRQ )/3 RU 1RW $SSOLFDEOH 1$ $ IDLO

SRVLWLRQ WKDWLVQRWGHILQHG VKDOOEHFODULILHGWKURXJKWKH SURMHFW5HTXHVWIRU,QIRUPDWLRQ

5),

* $FWXDWRUVKDOOLQFOXGHVWHPSURWHFWLRQIRUULVLQJVWHPW\SHYDOYHV

(/(&75,&02725$&78$7256±7+5((3+$6(32:(523(5$7,21

$ *HQHUDO5HTXLUHPHQWV

7KHDFWXDWRUVKDOOPHHWDSSOLFDEOHUHTXLUHPHQWVRIWKH$::$

0RWRUVWDOOWRUTXHVKDOOQRWH[FHHGWKHWRUTXHZLWKVWDQGFDSDELOLW\RIWKHYDOYH,Q

DGGLWLRQWKHDFWXDWRU¶VWRUTXHRXWSXWVKDOOEHDWDPLQLPXPQROHVVWKDQSHUFHQW

RIWKHWRUTXHUHTXLUHGE\WKHYDOYH¶VRSHUDWLQJFRQGLWLRQVRIIOXLGIORZDQGSUHVVXUH

$FWXDWRU*HDU7UDLQRSHUDWLQJWXUQVVKDOOEHPDWFKHGWRWKHYDOYH8VHWXUQ

DFWXDWRUVRQWXUQYDOYHDQGPXOWLWXUQDFWXDWRUVRQPXOWLWXUQYDOYHV

$FWXDWRU9DOYHDVVHPEO\VKDOOEHILWWHGZLWKDUHOXEULFDWLRQ PHFKDQLVP IRU WKH

VWHPWKUHDGVRQULVLQJVWHPW\SHYDOYHV

$OOYDOYHDFWXDWRUVVKDOOFRPSO\ZLWKWKHPLQLPXPDQGPD[LPXPYDOYHRSHUDWLQJ

WLPHFDSDELOLWLHVOLVWHGLQWKH9DOYH$FWXDWRU6FKHGXOH6OLGHJDWHDFWXDWRUVVKDOOEH

DEOHWRRSHUDWHDWDPLQLPXPUDWHRILQFKHVPLQXWH

8QOHVV RWKHUZLVH VSHFLILHG LQ WKH 9DOYH $FWXDWRU 6FKHGXOH WKH DFWXDWRU VXSSO\

YROWDJHVKDOOEH9SKDVH+]

7KH DFWXDWRU VKDOO EH DEOH WR EHVWRUHG SULRU WR LQVWDOODWLRQ ZLWKRXW WKH QHHG IRU

WHPSRUDU\ HOHFWULFDO SRZHU EHLQJ DSSOLHG IRU WKH ZDUUDQW\WR UHPDLQYDOLGRU IRUDQ\

IDFWRU\SURJUDPPLQJWREHUHWDLQHG

(DFK DFWXDWRU VKDOO EH VXSSOLHG ZLWK D ³VWDUWXS´ NLW FRQVLVWLQJ RI LQVWDOODWLRQ

LQVWUXFWLRQV ZLULQJ GLDJUDPV SURJUDPPLQJ LQIRUPDWLRQ DQG VSDUH FRYHU VFUHZV

XQOHVVKDUGZDUHLVFDSWLYHDQGVHDOVWRDOORZIRUVLWHORVVHVWKDWPD\RFFXUGXULQJ

LQVWDOODWLRQDQGFRPPLVVLRQLQJ

7KH DFWXDWRU FRQWUROV DQG HOHFWURQLFV VKDOO RSHUDWH VDWLVIDFWRULO\ ZLWK SRZHU

GHYLDWLRQV RI SOXV RU PLQXV SHUFHQW RI QRPLQDO UDWHG YROWDJH DQG IUHTXHQFLHV

GHYLDWLRQVEHWZHHQ+]

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 14 of 148

NA

SINGLE PHASE IS REQUIRED FOR

PLASTIC VALVES.

7KHDFWXDWRUDQGFRQWUROV VKDOOEHFDSDEOHRIPRXQWLQJLQDQ\RULHQWDWLRQLQWKH

ILHOGZLWKRXWDQ\DGYHUVHRSHUDWLQJHIIHFWVRUOXEULFDQWOHDNDJH

$ODUPVIURPWKHDFWXDWRUVVKDOOEHSURYLGHGDVVKRZQRQWKHHOHFWULFDOGUDZLQJV

$QDODUPVKDOOQRWEHJHQHUDWHGZKHQWKH/RFDO5HPRWHVHOHFWRUVZLWFKLVSODFHGLQ

WKH/RFDOSRVLWLRQIURPWKH5HPRWHSRVLWLRQQRUVKRXOGWKHDODUPVEHLQKLELWHGZKHQ

WKH/RFDO5HPRWHVHOHFWRUVZLWFKLVSODFHGLQWKH/RFDOSRVLWLRQ

7KHDFWXDWRUVKDOOEHILWWHGZLWKDSKDVHFRUUHFWLRQGHYLFHWRHQVXUHWKHDFWXDWRU

UXQV LQ WKH FRUUHFW GLUHFWLRQ SOXV D GHYLFH WR SURWHFW WKH PRWRU DJDLQVW µVLQJOH

SKDVLQJ´

% *HDUV%XVKLQJVDQG%HDULQJV

7KHDFWXDWRUVKDOO KDYH D UHGXFWLRQ JHDUUDWLRWKDW SUHYHQWVYDOYHVKDIWURWDWLRQ

IURPEDFNGULYLQJWKHRSHUDWLQJPRWRU

7KH JHDU WUDLQ IRU DQ\ DFWXDWRU VKDOO EH VXLWDEOH IRU DQG UDWHG IRU WKDW W\SH

RSHUDWLRQ

1RQPHWDOOLF DOXPLQXP RU FDVW JHDUV DUH QRW DFFHSWDEOH ZLWKRXW 2&6' ZULWWHQ

DFFHSWDQFH ,IWKHVHDUHVXEPLWWHGWKURXJKVXEPLWWDOSURFHVVVSHFLDO DWWHQWLRQ VKDOO

EHGUDZQRIWKHUHYLHZHU

$OO JHDU WUDLQV VKDOO EH JUHDVH RU RLO OXEULFDWHG IURP WKH IDFWRU\ LQ D VHDOHG

KRXVLQJµ'U\¶W\SHOXEULFDQWVPD\EHXVHGRQO\ZLWK2&6'SULRUDFFHSWDQFH

%HDULQJDQGJHDUWHFKQRORJLHVXVHGLQWKHDFWXDWRUKHDGVKDOOEHUDWHGIRUD

\HDUVHUYLFHOLIH

6WHP EXVKLQJ OHQJWK IRU VOLGH DQG VOXLFH JDWH RSHUDWRUV VKDOO EH WLPHV WKH

GULYHVWHPGLDPHWHU

'ULYHQ VWHP QXWV VKDOO EH RI KLJK WHQVLOH VWUHQJWK PDQJDQHVHRUDOXPLQXP

EURQ]HDQGKDYHDPLQLPXPWKUHDGHQJDJHPHQWQRWOHVVWKDQWLPHVWKHVWHP

GLDPHWHU

$FWXDWRUJHDUUDWLRFKDQJHVVKDOOEHDYDLODEOHIURPWKHIDFWRU\

0HFKDQLFDO VDIHW\ GHYLFHV VXFK DV D VKHDUSLQ RU UROORXW FOXWFK VKDOO EH ILHOG

UHVHWWDEOHRUUHSODFHDEOHZLWKRXWUHTXLULQJWRROVIRUGLVDVVHPEO\RIWKHXQLW

& $FWXDWRUVIRU2SHQ&ORVH6HUYLFH

7KHDFWXDWRUVKDOODOORZWKHYDOYHWREHVWRSSHGLQLQWHUPHGLDWHSRVLWLRQV

7KH DFWXDWRU VKDOO LQFOXGH HLJKW LQWHJUDO DGMXVWDEOH OLPLW VZLWFKHV WR LQGLFDWH

YDOYHSRVLWLRQVSHUWKHIROORZLQJWDEOH

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 15 of 148

NA

Switch Usage 0 Percent Open Intermediate

Position 100 Percent Open

6&$'$=6&[[[ &ORVHG 2SHQHG 2SHQHG

6&$'$=62[[[ 2SHQHG 2SHQHG &ORVHG

/RFDOOLJKW=/&[[[ &ORVHG &ORVHG 2SHQHG

/RFDOOLJKW=/2[[[ 2SHQHG &ORVHG &ORVHG

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$FWXDWRUVVKDOOEHFDSDEOHRIF\FOHUDWHVVSHFLILHGLQWKHDFWXDWRUVFKHGXOH

$FWXDWRUVIRU2SHQ&ORVHGXW\VKDOOLQFOXGHDVWDUWLQJDVVLVWIHDWXUHWRIDFLOLWDWH

DQGRYHUFRPHYDOYHVWDUWXSUHVWULFWLRQDQGVHDWEUHDNDZD\RSHUDWLRQDVVSHFLILHGLQ

WKH9DOYH$FWXDWRU6FKHGXOH

' $FWXDWRUVIRU0RGXODWLQJ6HUYLFH0RGXODWLQJDFWXDWRUVVKDOOLQFRUSRUDWHWKH*HQHUDO

5HTXLUHPHQWV RI SDUDJUDSK IRU SKDVH DFWXDWRUV H[FHSW ZKHUH RWKHUZLVH

VWDWHG$GGLWLRQDOO\WKH\VKDOOLQFOXGHWKHIROORZLQJIHDWXUHV

$FWXDWRU VKDOO SURYLGH YDOYH DEVROXWH SRVLWLRQ IHHGEDFN PD GF YLD DQ

LVRODWHGQRQFRQWDFWWUDQVGXFHU7KLVVKDOOLQGLFDWHWUXHYDOYHSRVLWLRQDIWHUUHFRYHU\

IURPDSRZHURXWDJHGXULQJZKLFKWKHYDOYHSRVLWLRQKDVEHHQPDQXDOO\FKDQJHG

7KH DFWXDWRU VKDOO DOORZ IRU DQ (PHUJHQF\ 6KXWGRZQ 6LJQDO WRVHW WKHYDOYH WR

WKH SRVLWLRQ LQGLFDWHG LQ WKH 9DOYH $FWXDWRU 6FKHGXOH RSHQ FORVH RU VWD\ LQ ODVW

SRVLWLRQ

$FWXDWRU VKDOO DFFHSW DQ H[WHUQDO 2SHQ&ORVH VLJQDOV RU PD GF VLJQDO

VRXUFHYROWDJHEHWZHHQWRYGFWRFRQWUROWKHYDOYHSRVLWLRQSHUWKHGUDZLQJV

$FWXDWRUVKDOOEHFDSDEOHRIWKHQXPEHURISRVLWLRQFKDQJHVSHUKRXULQGLFDWHGLQ

WKH 9DOYH $FWXDWRU 6FKHGXOH $FWXDWRUV UHTXLULQJ PRUH WKDQ DQ DYHUDJHVWDUWV

SHU KRXU VKDOO EH ILWWHG ZLWK 6ROLG 6WDWH VWDUWHU FDSDEOH RI VWDUWV SHU KRXU DQG

VKDOO EH ILWWHG ZLWK D &ODVV + LQVXODWLRQ PRWRU UDWHG IRU PLQXWH GXW\ SOXV WKH

VWDUWLQJDVVLVWDQFHKDPPHUDFWLRQVKDOOEHUHSODFHGE\GLUHFWGULYH

7KHDFWXDWRUVKDOOSURYLGHDP$VLJQDOWRLQGLFDWHYDOYHSRVLWLRQ

$FWXDWRUVKDOODFFHSWPDLQWDLQHGGLJLWDORSHQFORVHFRPPDQGVDOVR

$FWXDWRU VKDOO LQFOXGH IRXU LQWHJUDO DGMXVWDEOH OLPLW VZLWFKHV WR LQGLFDWH YDOYH

SRVLWLRQVSHUWKHIROORZLQJWDEOH

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 16 of 148

Switch Usage 0 Percent Open Intermediate

Position 100 Percent Open

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$GMXVWDEOHVSDUH 7%' 7%' 7%'

$GMXVWDEOHVSDUH 7%' 7%' 7%'

( $FWXDWRU&RQWUROV

7KHDFWXDWRUVKDOOKDYHWKHIROORZLQJWRUTXHIHDWXUHV

D ,QFRUSRUDWHDGMXVWDEOHRSHUDWLQJWRUTXHVHQVLQJWRVWRSYDOYHWUDYHOZKHQWKH

VHW WRUTXH OHYHO LV H[FHHGHG ([WUDSRODWLQJ WRUTXH IURP PRWRU VSHHG LV QRW

DFFHSWDEOH

E $FWXDWRUFRQWUROVKDOOSURYLGHWKHRSWLRQRIE\SDVVLQJWKHWRUTXHVHQVLQJLH

127EHDFWLYHGXULQJYDOYHEUHDNDZD\

F &RQWURO)HDWXUHVVKDOOEHDVVSHFLILHGLQWKHYDOYHDFWXDWRUWDEOH

G 7KH DFWXDWRU VKDOO EH FDSDEOH RI 5HPRWH &RQWURO E\ PDLQWDLQHG FRQWDFW

FORVXUHVZKHUHYDOYHRSHQRUFORVHPRYHPHQWRFFXUVZKLOHWKHUHPRWHRSHQRU

FORVHFRQWDFWUHPDLQVFORVHG

H $FWXDWRUV VKDOO KDYH ORFDO VHOHFWRU VZLWFK DQG SXVKEXWWRQV WKDW LQFOXGH

/2&$/2))5(027( 23(16723&/26( WR RSHUDWH WKH YDOYH RU YLD D

KDUGZLUHG ORFDO FRQWURO VWDWLRQ ZKLOH WKLV ORFDO VWDWLRQ LV LQ /2&$/ DQG WKH

DFWXDWRULVLQ5(027(

I 7KH DFWXDWRUVKDOOKDYH LQGLFDWRU OLJKWVDQG DQHOHFWURQLFGLVSOD\WR LQGLFDWH

)8// 23(1 )8// &/26(' ,17(50(',$7( YDOYH SRVLWLRQV VKRZQ DV

SHUFHQWDJHRIRSHQLQLQFUHPHQWVDQG)$,/VWDWXV$OOOLJKWVDQGRUGLVSOD\

VFUHHQVVKDOOEHVXQOLJKWUHDGDEOHDQGEDFNOLWIRUQLJKWWLPHUHDGDELOLW\

J 7KH DFWXDWRU VKDOO LQFRUSRUDWH PRWRU DQWLSOXJJLQJ IXQFWLRQV WR SUHYHQW

GDPDJHWRWKHPRWRUDQGJHDUVLIWKHDFWXDWRULVFRPPDQGHGWRFKDQJHGLUHFWLRQ

LQVWDQWO\

K 7KH LQWHUQDO DFWXDWRU FRQWURO WUDQVIRUPHU VKDOO GHYHORS DOO UHTXLUHG ZRUVW

FDVHLQWHUQDOFRQWUROYROWDJHVSOXVDPLQLPXPRI9$&9$ WREHXWLOL]HG

E\2&6'DVFRQWDFWZHWWLQJYROWDJH,IWKHDFWXDWRU¶VLQWHUQDOFRQWUROWUDQVIRUPHU

FDQQRW VXSSO\ WKH YROWDJH DQGRU SRZHU UHTXLUHG IRU H[WHUQDO VLJQDOLQJ WKH

PDQXIDFWXUHU PD\ SURYLGH DQ H[WHUQDO FRPELQDWLRQ GLVFRQQHFWWUDQVIRUPHU WR

PHHWWKLVUHTXLUHPHQW

L $&&85$&< 5(3($7$%,/,7< +<67(5(6,6 %$&./$6+ $1'

/,1($5,7< IRU PRGXODWLQJ VHUYLFH UHODWLQJ WR WKH DFWXDWRU WUDYHORIWR

SHUFHQWRSHQHGVKDOOEHDVIROORZV

3RVLWLRQLQJ HUURU RI WKH DFWXDWRU¶V DEVROXWH SRVLWLRQ VKDOO EH SOXV RU

PLQXVSHUFHQWRUOHVV

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 17 of 148

3RVLWLRQ IHHGEDFN HUURU RI WKH DFWXDWRU¶V DEVROXWH SRVLWLRQ VKDOOEHSOXV

RUPLQXVSHUFHQWRUOHVV

5HSHDWDELOLW\ HUURU DIWHU D PLQLPXP PRYHPHQW RI SHUFHQW PRYHPHQW

VKDOOEHSOXVRUPLQXVSHUFHQWRUOHVV

+\VWHUHVLVDQGEDFNODVKLQDQ\LQWHUQDOJHDUWUDLQDQGGULYLQJPHFKDQLFV

VKDOOEHOHVVWKDQSOXVRUPLQXVSHUFHQW

) 0RQLWRULQJ6LJQDOV

7KHDFWXDWRUVKDOOLQFOXGHDPLQLPXPRIILYHLVRODWHGUHOD\VWDWXVFRQWDFWVUDWHG

$DW YDF WKDW DUHVXLWDEOHIRULQWHUORFNLQJDQGRU 6&$'$3/&PRQLWRULQJ 7KH

DFWXDWRUVKDOOSURYLGHWKHIROORZLQJVLJQDOVDQGIXQFWLRQV

D $FWXDWRUPRGHVHOHFWRUVZLWFKLQ5(027(

E $FWXDWRUPRWRU21

F 9DOYHIXOO\23(1('

G 9DOYHIXOO\&/26('

H $&78$725)$,/DFRPPRQWURXEOHDODUPWKDWLQFOXGHVLQWHUQDOGLDJQRVWLF

IDLOOREDWWHU\LISUHVHQWLQWKHGHVLJQMDPPHGYDOYHORVVRISKDVHRURYHUORDG

7KLV FRQWDFW VKDOO EH FRQILJXUHG IDLOVDIH FORVHG IRU QRUPDO FRQGLWLRQV DQG

RSHQHGXSRQIDXOWRUWURXEOH7KHFDXVHRIWKH$&78$725)$,/VKDOOEHVKRZQ

RQ WKH DFWXDWRU /&' 'LVSOD\ 7KH DFWXDWRU VKDOO QRW JLYH WURXEOH DODUP LI WKUHH

SKDVHSRZHULVORVWRUWKH/RFDO5HPRWH2IISRVLWLRQVZLWFKLVQRWLQUHPRWH

* (QFORVXUH

7KH DFWXDWRU HQFORVXUH VKDOO KDYH D 1(0$ 7\SH ;1(0$ 7\SH IXOO\

VXEPHUVLEOH WR ,3 PLQLPXP UDWLQJ )RU FODVVLILHG DUHDV WKH DFWXDWRU HQFORVXUH

VKDOOEHUDWHG1(0$

7KH DFWXDWRU VKDOO XWLOL]H DQ LQWHUQDO VSDFH KHDWHU IRU WKH SUHYHQWLRQ RI LQWHUQDO

FRQGHQVDWLRQ

7KH HQFORVXUH VKDOO KDYH D VHSDUDWH VHDOHG DUHD IRU XVHU WHUPLQDWLRQV 7KH

WHUPLQDWLRQVDUHDVKDOOEHIXUWKHUVHSDUDWHGIURPWKHHOHFWULFDOHOHFWURQLFVVHFWLRQE\

DQDGGLWLRQDOVHDO

$OO VOLGLQJ RU URWDWLQJ VKDIWV DQG FRQWUROV WKDW SHQHWUDWH WKH HQFORVXUH VKDOO EH

SURYLGHGZLWK2ULQJVHDOV

7KHHQFORVXUHVKDOODOORZDFFHVVWRWHVWLQWHUQDOYROWDJHVDQG IXQFWLRQV RI WKH

DFWXDWRUZKLOHHQHUJL]HG$QRQLQYDVLYHRUQRQFRQWDFWFRPPXQLFDWLRQVGHYLFHPD\

EHXVHGWRGRZQORDGRUXSORDGDFWXDWRUVHWXSDQGGLDJQRVWLFGDWDDVDQDFFHSWDEOH

DOWHUQDWLYH WR RSHQLQJ WKH FRQWUROVWHUPLQDWLRQV DUHD IRU VHWXS DGMXVWPHQWV DQG

WHVWLQJ$Q\LQIRUPDWLRQXSORDGHGGRZQORDGHGDQGVHWWLQJPDGHWRWKHDFWXDWRUVKDOO

EHDYDLODEOHWREHVDYHGLQHOHFWURQLFIRUPIRUIXWXUHGLDJQRVWLFVUHYLHZDQGXVHG

LQFOXGLQJSULQWLQJZKHQUHTXLUHG

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 18 of 148

7KHWHUPLQDWLRQVDUHDIRU23(1&/26(VHUYLFHDFWXDWRUVVKDOOEHSURYLGHGZLWK

D PLQLPXP RI WZR VWDQGDUG WKUHDGHG FDEOHFRQGXLW HQWUDQFHV 7KH WHUPLQDWLRQV

DUHDIRU02'8/$7,1*VHUYLFHDFWXDWRUVVKDOOEHSURYLGHGZLWKDPLQLPXPRIWKUHH

VWDQGDUGWKUHDGHGFDEOHFRQGXLWHQWUDQFHV7KHFRQGXLWHQWUDQFHWKUHDGV\VWHP

FDEOH JODQGV EODQNRII SOXJV DQG VKDIW VHDOV VKDOO EH JDV DQG OLTXLG WLJKW WR

DWPRVSKHUHV$OOWKHWHUPLQDWLRQVVKDOOEHVFUHZHGFRQQHFWLRQVVKDOOEHDFFHVVLEOH

RQFHFRYHULVRSHQHGDQGVKDOOUHWDLQSRZHUWRDOOFRQWUROFLUFXLWIRUWURXEOHVKRRWLQJ

SXUSRVH

7KH DFWXDWRUVKDOO FRPSO\ ZLWK)&& 3DUW UHTXLUHPHQWV IRU &ODVV$GHYLFHV

7KHDFWXDWRUHOHFWURQLFVVKDOOQRWJHQHUDWH5),(0,OHYHOVEH\RQGWKH3DUWOLPLWV

IRU &ODVV $ LQGXVWULDO GHYLFHV DQG VKDOO QRW PDOIXQFWLRQ LI WKH DFWXDWRU UHFHLYHV

5),(0,IURP2&6'HTXLSPHQWVXFKDV8+)9+)KDQGKHOGUDGLRVRU9)'¶V

+ +DQG:KHHO2SHUDWLRQ

$ SHUPDQHQWO\ DWWDFKHG KDQG ZKHHO RU FUDQN VKDOO EH SURYLGHG IRU HPHUJHQF\

PDQXDORSHUDWLRQ

7KH KDQG ZKHHO RU FUDQN VKDOO QRW URWDWH GXULQJ HOHFWULFDO RSHUDWLRQ 'XULQJ

PDQXDO RSHUDWLRQ WKH KDQG ZKHHO VKDOO EH GHFOXWFKHG IURP WKH DFWXDWRU¶V LQWHUQDO

JHDUWUDLQDQGUHPDLQGHFOXWFKHGXQWLOWKHPRWRULVUHHQHUJL]HG

D 7KHGHFOXWFKLQJPHFKDQLVPVKDOOEHSDGORFNDEOHLQWKHGHFOXWFKHGSRVLWLRQ

DQG VKDOO EH SURYLGHG ZLWK D FKDLQ RSHUDWRU IRU YDOYHV LQVWDOOHG IHHW RUKLJKHU

IURPWKHRSHUDWLQJIORRU7KHFKDLQHQGVKDOOEHIRXUIHHWIURPWKHIORRUOHYHODQG

VKDOO FRQWDLQ D KRRN WR ODWFK LW DZD\ IURP WKH RSHUDWLQJ VSDFH XSRQWKHFKDLQ

LWVHOI

E 6LPXOWDQHRXVPRWRUDQGKDQGZKHHORSHUDWLRQVKDOOQRWEHDOORZHG

7KH PD[LPXP WRUTXH UHTXLUHG RQ WKH KDQG ZKHHO RU FUDQN XQGHUWKHPRVW

DGYHUVHFRQGLWLRQVRIIOXLGIORZDQGSUHVVXUHVKDOOQRWH[FHHGSRXQGVRIULPSXOO

$GLUHFWLRQDODUURZRUWKHZRUGRSHQRUFORVHVKDOOEHFDVWLQWKHKDQGZKHHO

DFWXDWRU KRXVLQJ WR LQGLFDWH WKH GLUHFWLRQ RI RSHUDWLRQ 8QOHVV VSHFLILHG RWKHUZLVH

HOVHZKHUHFORFNZLVHKDQGZKHHORSHUDWLRQVKDOOFORVHWKHYDOYH

9DOYH DFWXDWRUV PRXQWHG KLJKHU WKDQ IHHW DERYH ZRUNLQJ OHYHOVKDOOEH

SURYLGHGZLWKFKDLQRSHUDWRUV&KDLQRSHUDWRUVVKDOOKDYHKRWGLS JDOYDQL]HGFKDLQ

H[WHQGLQJ WR ZLWKLQ IHHW IURP WKH IORRU :KHUH FKDLQ RSHUDWRUV DUH SURYLGHG D

³&KDLQ$ZD\´39&FKDLQVWRUDJHFDQLVWHUVKDOOEHIXUQLVKHG7KHFDQLVWHUVKDOOKDYH

DVFUHHQHGERWWRPIRUGUDLQDJHDQGDKDQGOHWRSXOOWKHFRQWDLQHUGRZQE\H[WHQGLQJ

WKHFKDLQOHQJWKRXWRIWKHFDQLVWHU&DQLVWHUVVKDOOEH0RGHO³&KDLQ$ZD\´E\%DEELWW

67($063(&,$/7<5RWR+DPPHU,QGXVWULHV2U(TXDO

, 0DQXIDFWXUHV2U(TXDOLQDOSKDEHWLFDORUGHURQO\

/LPLWRUTXH$FFXWURQL[0;6HULHV

5RWRUN&RQWUROV,QF,46HULHV

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 19 of 148

LIMITORQUE QX IS

BEING SUPPLED

(/(&75,&02725$&78$7256±6,1*/(3+$6(32:(523(5$7,21

$ *HQHUDO5HTXLUHPHQWV

7KHYDOYHDFWXDWRUVKDOOFRPSO\ZLWKWKHUHFRPPHQGDWLRQVRI$::$&

0RWRUVWDOOWRUTXHVKDOOQRWH[FHHGWKHWRUTXHZLWKVWDQGFDSDELOLW\RIWKHYDOYH,Q

DGGLWLRQWKHDFWXDWRU¶VWRUTXHRXWSXWVKDOOEHDWDPLQLPXPQROHVVWKDQSHUFHQW

RIWKHWRUTXHUHTXLUHGE\WKHYDOYH¶VRSHUDWLQJFRQGLWLRQVRIIOXLGIORZDQGSUHVVXUH

$FWXDWRU*HDU7UDLQRSHUDWLQJWXUQVVKDOOEHPDWFKHGWRWKHYDOYH8VHWXUQ

DFWXDWRUVRQWXUQYDOYHDQGPXOWLWXUQDFWXDWRUVRQPXOWLWXUQYDOYHV

$OOYDOYHDFWXDWRUVVKDOO KRQRUWKHPLQLPXPDQGPD[LPXPYDOYHRSHUDWLQJWLPH

FDSDELOLWLHVOLVWHGLQWKH9DOYH$FWXDWRU6FKHGXOH

$FWXDWRUVXSSO\YROWDJH VKDOO EH 9RU 9SKDVH +] DVVSHFLILHG LQ

WKH9DOYH$FWXDWRU6FKHGXOH

7KH DFWXDWRU FRQWUROV DQG HOHFWURQLFV VKDOO RSHUDWH VDWLVIDFWRULO\ ZLWK SRZHU

GHYLDWLRQV RI SOXV RU PLQXV SHUFHQW RI QRPLQDO UDWHG YROWDJHDQGIUHTXHQFLHV

GHYLDWLRQVEHWZHHQ+]

7KHDFWXDWRUVKDOOEHFDSDEOHRIPRXQWLQJLQDQ\RULHQWDWLRQZLWKRXWDQ\DGYHUVH

RSHUDWLQJHIIHFWVRUOXEULFDQWOHDNDJH

7KH DFWXDWRU PRWRU VKDOO KDYH EXLOWLQ RYHUORDG SURWHFWLRQ RU EH LPSHGDQFH

OLPLWHG

% *HDULQJ

7KHDFWXDWRUVKDOO KDYH D UHGXFWLRQ JHDUUDWLRWKDW SUHYHQWVYDOYHVKDIWURWDWLRQ

IURPEDFNGULYLQJWKHRSHUDWLQJPRWRU

7KH JHDU WUDLQ IRU DQ\ DFWXDWRU VKDOO EH VXLWDEOH IRU DQG UDWHG IRU WKDW W\SH

RSHUDWLRQ

$OO JHDU WUDLQV VKDOO EH JUHDVH RU RLO OXEULFDWHG LQ D VHDOHG KRXVLQJ µ'U\¶ W\SH

OXEULFDQWVPD\EHXVHGRQO\ZLWKSULRU2&6'DFFHSWDQFH

%HDULQJDQGJHDUWHFKQRORJLHVXVHGLQWKHDFWXDWRUKHDGVKDOOEHUDWHGIRUD

\HDUVHUYLFHOLIH

& $FWXDWRUVIRU2SHQ&ORVH6HUYLFH

$FWXDWRUVKDOOLQFOXGHLQWHJUDOHQGRIWUDYHOOLPLWVZLWFKHVWRLQGLFDWHIXOORSHQHG

DQGIXOOFORVHG

' $FWXDWRUVIRU0RGXODWLQJ6HUYLFH

7KH DFWXDWRU PRWRU VKDOO EH UDWHG IRU FRQWLQXRXV PRGXODWLQJ VHUYLFH ZLWKRXW

RYHUKHDWLQJ

7KH DFWXDWRU VKDOO DFFHSW H[WHUQDO 2SHQ&ORVH RU PD GF VLJQDO VRXUFH

YROWDJHEHWZHHQWRYGFWRFRQWUROWKHYDOYHSRVLWLRQSHUWKHGUDZLQJV

SSI #49 15106 MODULATING BALL VALVE IW SERVICE

06/13/2014

Page 20 of 148

Table of contents

Other Spears Control Unit manuals

Popular Control Unit manuals by other brands

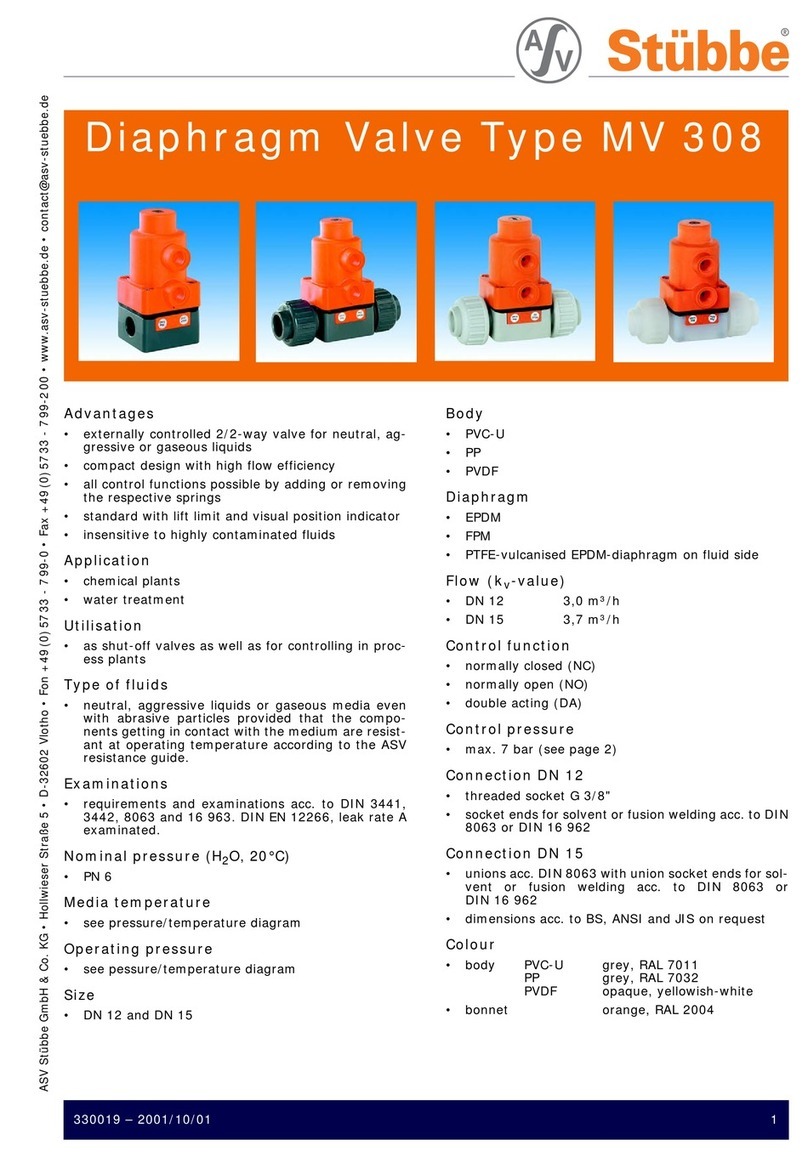

Stübbe

Stübbe MV 308 operating instructions

Hawido

Hawido 1401 Instruction

Sistemes Electrònics Progrés s.a.

Sistemes Electrònics Progrés s.a. AGRONIC 54 instruction manual

Goetze

Goetze 4000 Assembly instructions

Coelbo

Coelbo Speedbox Installation and operating instructions

Jaycar

Jaycar Maycar Electronic Dice Kit quick guide

Moog

Moog D816 Series user manual

Symbol

Symbol MDM 3006 quick reference

Motorline professional

Motorline professional MC61PL installer and user manual

Generac Power Systems

Generac Power Systems SMM Owners & installation manual

Hoffer Flow Controls

Hoffer Flow Controls Integrated Cryogenic Electronics HP-319 quick start guide

Danfoss

Danfoss ASV-P installation guide