Stübbe MV 308 User manual

1

ASV Stübbe GmbH & Co. KG • Hollwieser Straße 5 • D-32602 Vlotho • Fon +49(0)5733 - 799-0 • Fax +49(0)5733 - 799-200 • www.asv-stuebbe.de • [email protected]

330019 – 2001/10/01

Advantages

• externally controlled 2/2-way valve for neutral, ag-

gressive or gaseous liquids

• compact design with high flow efficiency

• all control functions possible by adding or removing

the respective springs

• standard with lift limit and visual position indicator

• insensitive to highly contaminated fluids

Application

•chemicalplants

• water treatment

Utilisation

• as shut-off valves as well as for controlling in proc-

ess plants

Type of fluids

• neutral, aggressive liquids or gaseous media even

with abrasive particles provided that the compo-

nents getting in contact with the medium are resist-

ant at operating temperature according to the ASV

resistance guide.

Examinations

• requirements and examinations acc. to DIN 3441,

3442, 8063 and 16 963. DIN EN 12266, leak rate A

examinated.

Nominal pressure (H2O, 20°C)

•PN6

Media temperature

• see pressure/temperature diagram

Operating pressure

• see pessure/temperature diagram

Size

• DN 12 and DN 15

Body

•PVC-U

•PP

•PVDF

Diaphragm

•EPDM

•FPM

• PTFE-vulcanised EPDM-diaphragm on fluid side

Flow (kv-value)

• DN 12 3,0 m³/h

• DN 15 3,7 m³/h

Control function

• normally closed (NC)

• normally open (NO)

•doubleacting(DA)

Control pressure

• max. 7 bar (see page 2)

Connection DN 12

• threaded socket G 3/8"

• socket ends for solvent or fusion welding acc. to DIN

8063 or DIN 16 962

Connection DN 15

• unions acc. DIN 8063 with union socket ends for sol-

vent or fusion welding acc. to DIN 8063 or

DIN 16 962

• dimensions acc. to BS, ANSI and JIS on request

Colour

• body PVC-U grey, RAL 7011

PP grey, RAL 7032

PVDF opaque, yellowish-white

• bonnet orange, RAL 2004

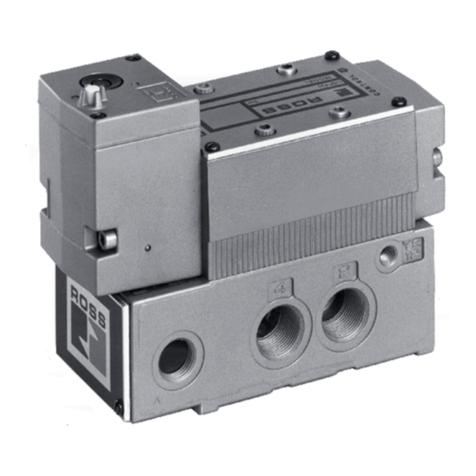

Diaphragm Valve Type MV 308

2

ASV Stübbe GmbH & Co. KG • Hollwieser Straße 5 • D-32602 Vlotho • Fon +49(0)5733 - 799-0 • Fax +49(0)5733 - 799-200 • www.asv-stuebbe.de • [email protected]

Pressure/temperature diagram

The pressure/temperature limits are applicable for the

stated nominal pressures and a computed operating life

factor of 25 years.

The values are a guide for harmless media (DIN 2403),

to which the material of the valve is resistant.

For other media see the ASV resistance guide.

Control curve

Durability of valve depends on the operating conditions

of the application.

For temperatures below 0 °C (PP < +10 °C) please

sepcify the precise operating conditions of the applica-

tion.

Ident number PVC-U

Ident number PP

Ident number PVDF

Diaphragm Valve MV 308

temperature (°C)

pressure (bar)

operating pressure (bar)

control pressure (bar)

body PVC-U normally closed NC normally open NO double acting DA

diaphragm EPDM FPM EPDM/

PTFE EPDM FPM EPDM/

PTFE EPDM FPM EPDM/

PTFE

connection G 3/8"-socket

d (mm) DN (mm) DN (inch)

16 12 3/8 120186 120187 120188 120195 120196 120197 120204 120205 120206

connection union socket ends for solvent welding

d (mm) DN (mm) DN (inch)

16 12 3/8 120213 120214 120215 120222 120223 120224 120231 120232 120233

20 15 1/2 120240 120241 120242 120249 120250 120251 120258 120259 120260

body PP normally closed NC normally open NO double acting DA

diaphragm EPDM FPM EPDM/

PTFE EPDM FPM EPDM/

PTFE EPDM FPM EPDM/

PTFE

connection G 3/8"-socket

d (mm) DN (mm) DN (Zoll)

16 12 3/8 120189 120190 120191 120198 120199 120200 120207 120208 120209

connection union socket ends for fusion welding

d (mm) DN (mm) DN (inch)

16 12 3/8 120216 120217 120218 120225 120226 120227 120234 120235 120236

20 15 1/2 120243 120244 120245 120252 120253 120254 120261 120262 120263

body PVDF normally closed NC normally open NO double acting DA

diaphragm EPDM FPM EPDM/

PTFE EPDM FPM EPDM/

PTFE EPDM FPM EPDM/

PTFE

connection G 3/8"-socket

d (mm) DN (mm) DN (inch)

16 12 3/8 120192 120193 120194 120201 120202 120203 120210 120211 120212

connection union socket ends for fusion welding

d (mm) DN (mm) DN (inch)

16 12 3/8 120219 120220 120221 120228 120229 120230 120237 120238 120239

20 15 1/2 120246 120247 120248 120255 120256 120257 120264 120265 120266

330019 – 2001/10/01

3

ASV Stübbe GmbH & Co. KG • Hollwieser Straße 5 • D-32602 Vlotho • Fon +49(0)5733 - 799-0 • Fax +49(0)5733 - 799-200 • www.asv-stuebbe.de • [email protected]

Dimension and spare parts list

Diaphragm Valve MV 308

socket d 16

view A view A

female threaded

socket G 3/8"

item designation

1body

2bonnet

3insert

4pressure piece

5spindle

6indicator pin

7 diaphragm

8washer

9 pressure spring

10 pressure spring

11 nut

item designation

12 piston

13 O-ring

14 O-ring

15 O-ring

16 identification plate

17 hexagonal socket screw

18 nut

19 insert

20 O-ring

21 union nut

330019 – 2001/10/01

4

ASV Stübbe GmbH & Co. KG • Hollwieser Straße 5 • D-32602 Vlotho • Fon +49(0)5733 - 799-0 • Fax +49(0)5733 - 799-200 • www.asv-stuebbe.de • [email protected]

Operating instructions:

ATTENTION

Safe operation of the valve can only be ensured if it is

properly installed, operated, serviced or repaired by

qualified personnel according to its intended use while

observing the accident prevention regulations, safety

regulations, relevant standards and technical regula-

tions or data sheets such as e.g. DIN, DIN EN, DIN ISO

and DVS* for example. 9

*DVS = German Welding Society

The intended use includes adhering to the specified li-

mit values for pressure and temperature as well as che-

cking the chemical resistance with regard to the

operating conditions.

For this purpose, ensure that all components coming

into contact with the media are "resistant" in accor-

dance with the ASV resistance guide.

The owner/user must inform the authorized qualified

personnel instructed to perform the assembly, inspec-

tion and/or maintenance work of any potential danger

emanating from the machine line/medium, and ensure

that suitable safety measures are observed. This also

includes the consideration of local regulations and laws

of the territories of use.

The connection of electric or pneumatic actuators and/

or accessories to the power/compressed air supply re-

quires special knowledge. Ensure that this work is per-

formed only by authorized qualified personnel

according to the operating instruction of the manufac-

turer.

If no operating and maintenance manual is available to

the authorized qualified personnel, please request a

manual prior to installation, maintenance or repair.

Non-observance of the specified instructions and safety

regulations may cause damage to health and/or dama-

ge to assets. 9

Adjustment of lift limit

• Turn indicator pin (6) with appropriate screw driver

counter-clockwise.

• The maximal lift limit is appr. 2/3 of valve lift.

1. Disassembly

• The pipe section is to be shut off upstream and

downstream and to be emptied properly.

• Any fluid rest is to be disposed properly (see above).

• Adhere to the workers protection rules - if required

protection clothes must be worn.

2. Exchange of diaphragm

• Shut off compressed air towards diaphragm valve.

• Release compressed air connections of diaphragm

valve and remove them.

• Release hexagonal socket screws (17) with appro-

priate tool and remove them.

• Pull off bonnet (2) from body (1).

• Turn out diaphragm (7) from spindle (5).

• Pull off pressure piece (4) from diaphragm, assem-

bly see point 4.

3. Exchange of O-rings or piston

• Disassembly as described under point 2.

• Unscrew the insert (3) out of the bonnet (2) with an

appropriate spanner.

ATTENTION

The insert is under tension of spring. 9

• Unscrew indicator pin (6) from the spindle (5).

• Lever the O-ring (13) out of the O-ring groove with

a blunt tool and replace it.

• Pull out the spindle (5) out of the insert with rotating

movements.

• Release nut (11) and remove it together with wash-

er (8) from the shaft.

• Pull off piston (12) from the spindle and replace it.

• Carefully remove O-ring (14) from the insert and re-

place it.

• Dismount O-ring (15) from insert and replace it.

4. Assembly

• In the reverse order to disassembly.

Take care of correct installation of each component

according to sectional drawing.

• Always use new sealing elements when refitting.

• Neutral gliding agents (e.g. soap and water) eases

assembly.

• After each disassembly all connections are to be

checked for leakages prior using.

NOTE

Elastomeres, especially the EPDM sealing elements,

should not be touched or cleaned with synthetic oils,

mineral oils, fats or cleaning agents. 9

Danger of swelling. Only appropriate fats should be

used, e.g. silicone greases.

Subject to technical modifications

Diaphragm Valve MV 308

330019 – 2001/10/01

This manual suits for next models

3

Other Stübbe Control Unit manuals

Popular Control Unit manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC EXS0000 instruction manual

Telit Wireless Solutions

Telit Wireless Solutions LE910 reference guide

Rtelligent

Rtelligent R110PLUS user manual

Texas Instruments

Texas Instruments AWR1443 user guide

schmersal

schmersal SRB 320XV3 V.2 operating instructions

Siemens

Siemens 3AD8 instruction manual