Specified Technologies EZ PATH Assembly instructions

GENERAL - READ COMPLETELY BEFORE INSTALLING

This product allows for several optional installation

methods. Available methods for walls are shown here. The

raceway (device) consists of an enclosed heavy gauge

galvanized steel channel with a detachable lid. Depending

on the type ordered, wall plates and gaskets are either

included or may be ordered separately. all plates are

designed to accommodate single, double, or triple device

installations. Component requirements will vary according to

the method of installation chosen. See Table B for

additional information.

NOTE: ALL INSTALLATIONS REQUIRE THIS DEVICE TO BE INSTALLED ITH

THE TOP (LID) FACING UP ARD. The lid may be identified by the BARRIER

GAUGE stamping. ALL PLATES ARE ASYMMETRICAL and are marked with the

word TOP.

CREATING THE OPENING

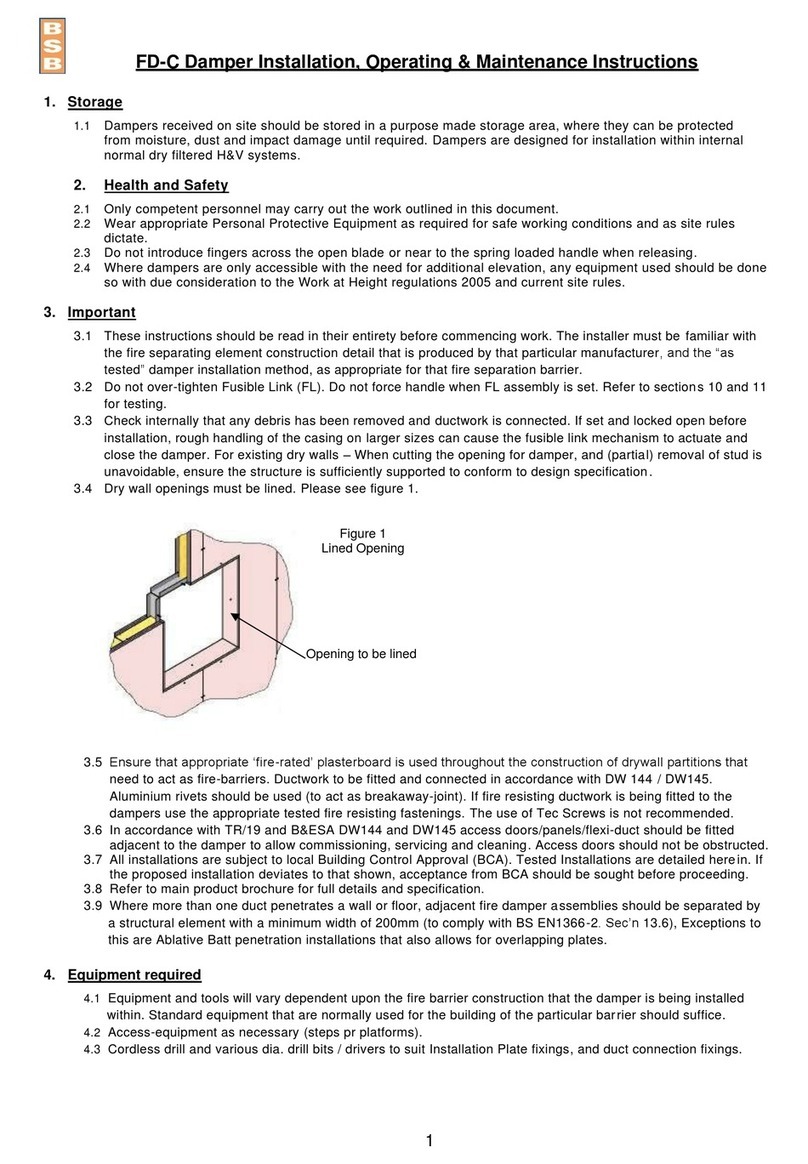

Gypsum Board Walls Square Openings):

1. Locate suitable area of the wall to penetrate making sure that there are no studs, wires, pipes or other obstructions

located within wall.

2. Mark a square or rectangular opening as dimensioned in Table A. Make sure opening is square and plumb. The

inside opening of the wall plates can be used as a template (See Fig. 1).

3. Using a keyhole saw, cut wall board (See Fig. 2). Cutting to the outside of the line will produce a slightly over-sized

opening. Mark and cut opposite side of the wall, exercising care to align both openings. Insert raceway and check

for fit. Remove raceway.

4. Install device per instructions below.

Concrete or Masonry Walls Square or Round Openings):

1. Cut or form a square or rectangular opening or core drill a round opening per dimensions listed in Table A.

INSTALLING WIREWAY USING WALL PLATES

Prior to Pulling Cables

Device is installed through wall and attached using wall plates to sandwich the wall. No mechanical attachment to wall

itself is required.

1. Pre-install required set screws in wall plates using allen wrench (provided).

NOTE: When installing a single wall plate and raceway, two set screws positioned and tightened at 90 degrees to each other in both plates will adequately hold device ( ee

Fig. 4). Multiple devices in a ganged installation using double (Cat No. EZP233W) or triple wall plates (EZP333W) require EVERY set screw to be installed.

2. Install a wall plate around raceway making sure that set screw flanges are facing towards the end of the device.

NOTE: Position plate so that the word TOP stamped on the plate aligns with the lid of the raceway. Use gauge marks located on lid of raceway to adjust plate to thickness

of wall ( ee Fig. 3). This will center raceway within the wall. When properly adjusted, tighten set screws to lock plate onto raceway.

3. Place one of two provided foam gaskets around opposite end of raceway and carefully slide it back to fit snugly

against back side (wall side) of plate.

4. Insert raceway through wall (with TOP facing upwards) using previously installed wall plate and gasket as a stop

(See Fig. 5).

5. Moving to the opposite side of the wall, install remaining foam gasket around raceway and slide toward wall.

Page 1 of 2 Installation Sheet • EZ PATH ZIS1003 01/03

INSTALLATION SHEET

EZ PATH™ Fire Rated Pathway

Fig. 1 Fig. 3

TABLE A: Wall Opening Dimensions

CONFIGURATION SINGLE DOUBLE TRIPLE

Square or Rectangular Using Wall Plates - Gypsum Board or Masonry

Opening Height 3 1/8” 3 1/8” 3 1/8”

Opening idth 3 1/8” 6 1/8” 9 1/8”

Square (Using Sealant - No Wall Plates) - Gypsum Board or Masonry

Opening Height 3 1/8” N/A N/A

Opening idth 3 1/8” N/A N/A

Round (Using Sealant - No Wall Plates) - Masonry

Opening Diameter 4” N/A N/A

Fig. 2

°

Fig. 4 Fig. 5

CITY OF NE YORK MEA 369-02-M

INSTALLING IN WALL OPENINGS USING SEALANT NO WALL PLATES)

IMPORTANT NOTE: This installation applies to the use of SINGLE devices only.

Installing Around Previously Installed Cables

1. Remove lid from raceway by unscrewing the two screws and sliding lid out of channel attachment tabs (on opposite side).

2. Place raceway channel around cables (See Fig. 6).

3. Replace lid and reinstall screws. Continue to install per the following steps for New Cable Installation.

Installing Prior to Installation of Cabling

1. ith fastening screw removed, install optional Positioning Clamp (Cat No. EZP133PC) around cable bundle and slide

over raceway making sure that the flat feet of clamp are facing towards wall surface. Use gauge marks located on raceway

to adjust clamp to thickness of wall. hen properly adjusted, lock clamp in place by installing and tightening fastening screw.

2. Slide device into properly sized opening and center within wall (See Fig. 7).

3. Moving to opposite side of wall, install second clamp around raceway and snug tightly to wall. Tighten clamp securely.

4. Caulk using approved sealant (SpecSeal®SSS, LCI, LC Series sealants, or Pensil®300 Silicone Sealant). Apply

sealant to a depth of 5/8” within annulus on both sides of wall. Apply a 3/8” crown bead at areas of point contact.

INSTALLING or PULLING CABLES

A resilient liner provides an adjustable seal within the raceway. Liner must be protected from damage while adding or removing

cables. rap cable ends with a suitable low friction tape before inserting into the raceway. This device is designed to be fully

functional at all cable loadings from completely empty to visually filled and cables should easily slide through the raceway using

minimal effort. IF RESISTANCE IS ENCOUNTERED, DO NOT FORCE CABLES OR CABLE BUNDLES THROUGH THE

RACE AY. DAMAGE MAY RESULT. Upper curved liner may be depressed if necessary when inserting cables using a flat, smooth

implement and removing after cables are installed.

GROUNDING

At the option of the installer, this device may be grounded. After device(s) has been installed, insert ground

screws where indicated (See Fig. 8). For installations using single, double, or triple wall plates, or optional

positioning clamps, two ground screws are required and are included in these kits.

WALL LABELING

all labels are provided with the wireway as well as wall plate kits. Larger orange colored label is intended to be used to identify

the wireway’s installer as well as to provide applicable UL System information. Smaller secondary labels are included with double

and triple wall plates as an optional method for identifying or marking cable types, uses, or trades. Two sets of labels are provided

for marking both sides of wall.

MAINTENANCE

No maintenance of the raceway is normally required. Interior of device should be inspected before and after any modifications to

cable bundle. If any damage to intumescent pads lining top and bottom of the raceway is found, contact the factory to determine

if replacement is required.

Page 2 of 2 Installation Sheet • EZ PATH ZIS1003 01/03

Important Notice All statements, technical information, and recommendations contained herein are based upon testing believed to be reli

able, but the accuracy and completeness thereof is not guaranteed.

WARRANTY pecified Technologies Inc. manufactures its goods in a manner to be free of defects. hould any defect occur in its goods (within

one year), pecified Technologies Inc., upon prompt notification, will at its option, exchange or repair the goods or refund the purchase price.

Limitations and Exclusions THI WARRANTY I IN LIEU OF ALL OTHER REPRE ENTATION EXPRE ED OR IMPLIED (INCLUDING

THE IMPLIED WARRANTIE OF MERCHANTABILITY OR FITNE FOR U E) AND UNDER NO CIRCUM TANCE HALL PECIFIED

TECHNOLOGIE INC. BE RE PON IBLE FOR ANY INCIDENTAL OR CON EQUENTIAL PROPERTY DAMAGE OR LO E . PRIOR TO

U E, THE U ER HALL DETERMINE THE UITABILITY OF THE PRODUCT FOR IT INTENDED U E, AND THE U ER A UME ALL

RI K AND LIABILITY FOR UB EQUENT U E. No statement or recommendation not contained herein shall have any force or effect unless

in an agreement signed by officers of seller and manufacturer.

MADE IN THE USA – COPYRIGHT © 2002 SPECIFIED TECHNOLOGIES, INC.

TABLE B: Required Components

Fig. 6

Fig. 7

6. Install remaining wall plate around raceway (TOP up) and slide it toward wall surface. hile pulling raceway

toward you, push wall plate and gasket tightly to wall and tighten set screws. Check device for excessive play.

If device appears to be loose or can easily be moved, readjust wall plates as necessary to tighten device

firmly against wall.

New Cable Installations Using

Wall Plates

Single Raceway (Complete Kit) (1) EZDP33F

Single Raceway N/A (1) EZD33F (1) EZP133 N/A

Double Raceway N/A (2) EZD33F (1) EZP233 N/A

Triple Raceway N/A (3) EZD33F (1) EZP333 N/A

New/Existing Cable

Installations Using Sealant

Single Raceway N/A (1) EZD33F N/A (1) EZP133PC

All Components

Included

Raceway Wall Plate Kits Positioning

Clamp Kit

Fig. 8

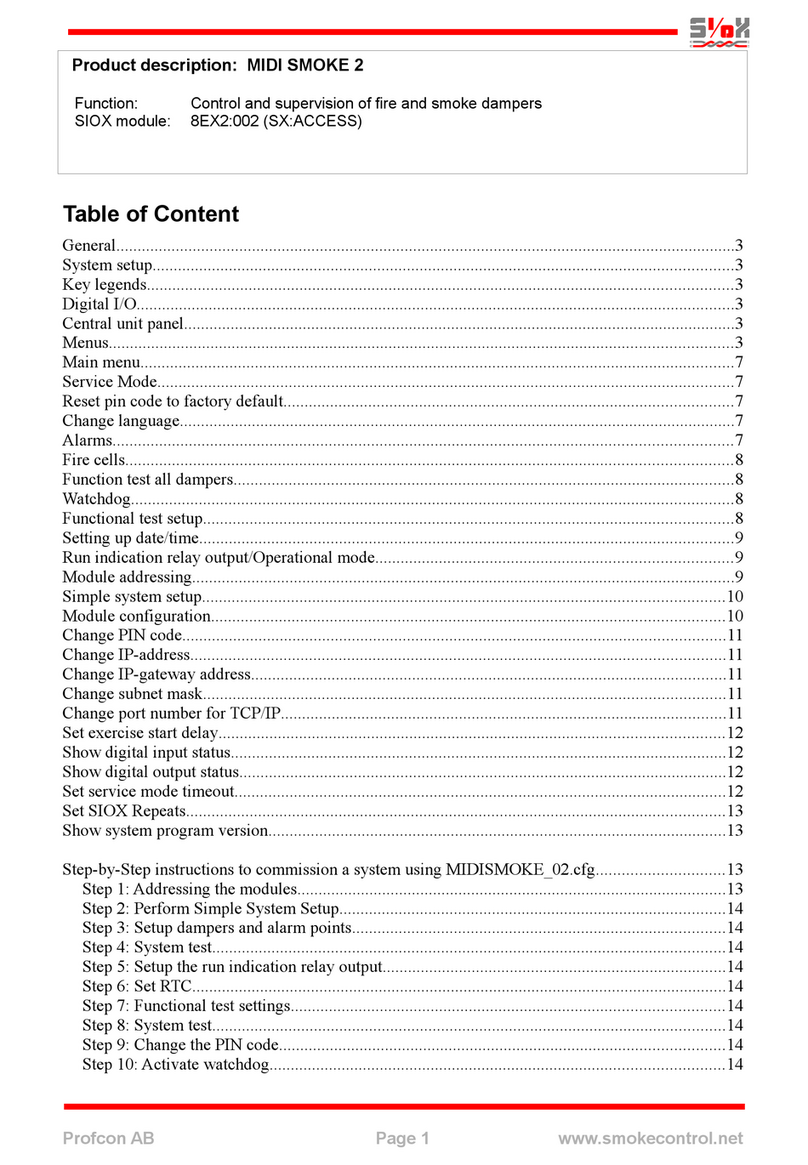

Table of contents

Popular Fire And Smoke Damper manuals by other brands

Mandik

Mandik FDMS manual

Kampmann

Kampmann WKD CM24-SX-L Assembly instructions

Priorit

Priorit PRIODOOR ETX-RDA Assembly and operating manual

Nailor

Nailor 1210 Series OPERATIONS AND MAINTENANCE PROCEDURES

HVC

HVC NCA 100 Series manual

LUCOMA

LUCOMA RGK-10 Series Installation, operation and maintenance instructions