RF-2000 Round Fire Damper Installation Instructions2

• Wood Stud Wall – Cinch plate required on both

sides of the wall fastened to the wall by

engaging the wood stud a minimum of

1-1/2 in. (38 mm) with a #10 screw.

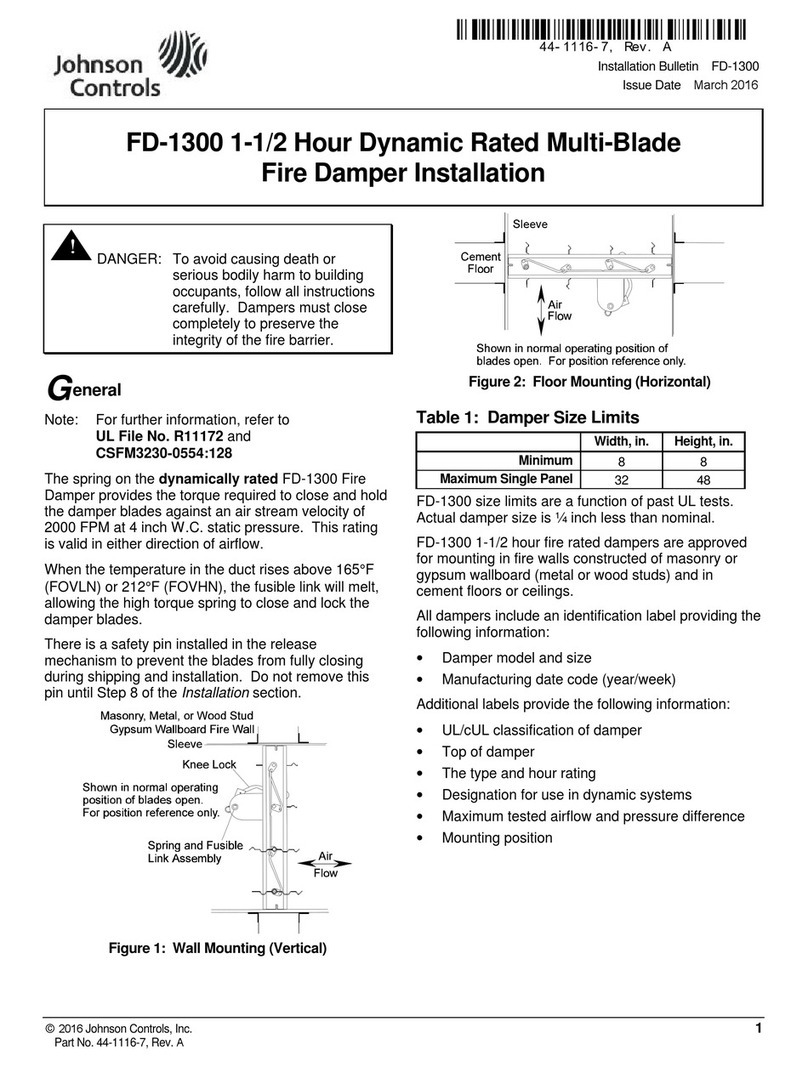

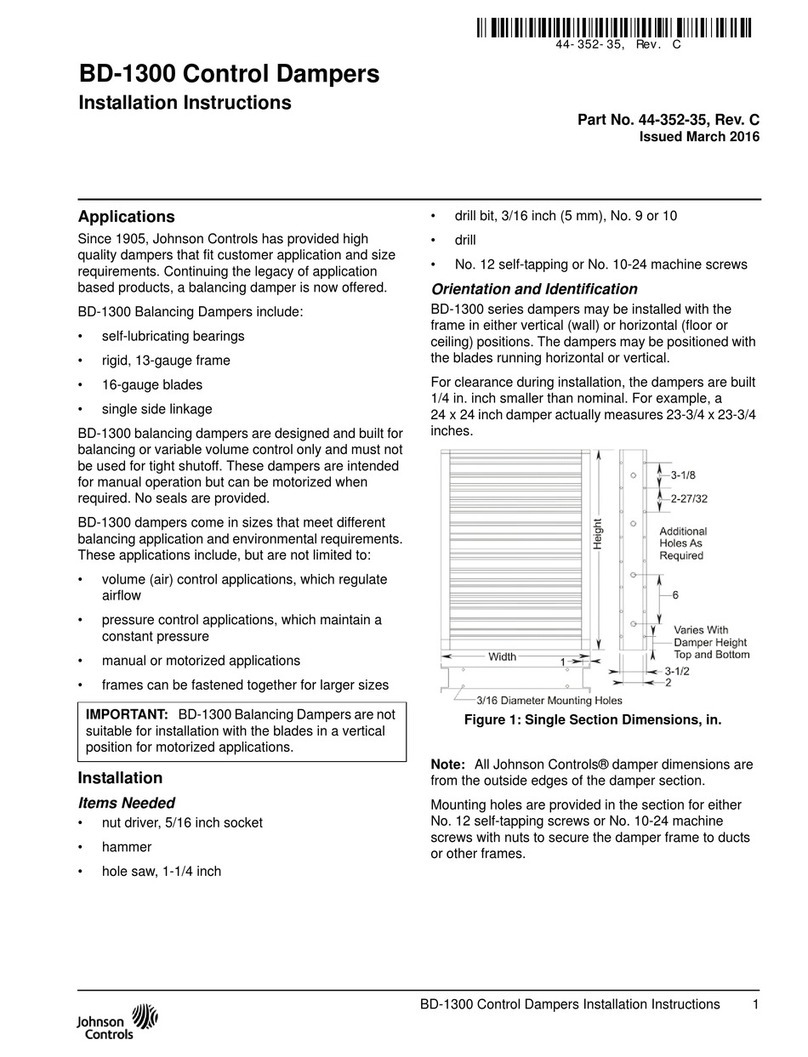

4. Damper Orientation: The leading edge of the

blade in the closed position must be within the

plane of the wall. Vertical installation is illustrated

and horizontal is similar. (See Figure 3 through

Figure 6.) The damper may be installed with up to

a 30 degree variance of the axle being horizontal.

The damper is approved with airflow in any

direction.

5. Duct/Sleeve Connections: Round breakaway

connections must be used. Either a 4 in. (102 mm)

wide draw band or #10 sheet metal screws spaced

equally around the circumference of the ducts as

follows:

• duct diameters of 22 in. (559 mm) and smaller

– three screws

• duct diameters over 22 in. (559 mm) to 24 in.

(610 mm) – five screws

Note: When optional sealing of these joints is

desired, the following sealants may be applied in

accordance with the sealant manufacturer's

instructions:

• Hardcast, Inc. – Iron-Grip™ 601 sealant

• Precision - PA2084T

• ECO Duct Seal 44-52

• Design Polmerics - DP1010

Note: Install the damper so that it is square and free

from raking. Compressing or stretching the damper

frame into the duct or opening may result in failed

operation and will void the warranty.

6. Optional Sealant of Dampers in Fire Rated Wall

or Floor Openings: Following the sealant

manufacturer's directions, remove dirt, grease, and

moisture from the surface to be sealed. Apply a

continuous bead of sealant to the location

applicable to your specific installation.

Approved sealant or fire stop materials:

• Dow Corning® - 999A, Silastic 732RTV

• GE® - RTV 108

• Hilti Corporation - FS-One

• 3M® - #M-CP 25WB+

• Specified Technologies, Inc. - SpecSeal®

Series SSS or LCI

• John Manville International, Inc. - Firetemp™

CI

• Rectorseal - Metacaulk 1000, Metacaulk 350i,

Biostop 500+ or Biostop 350i

Do not apply sealant within the required expansion

gap between the damper and the fire rated wall or

floor.

Press the surface of the sealant in place to dispel

any air. Allow sealant to set up and become tack-

free before operating the damper.

WARNING: Risk of Personal Injury.

Do not place cinch plates in the groove. If

the cinch plates are in the groove, the

damper is not properly secured. An

insecure damper may dislodge and fall,

which may result in severe personal

injury or death.

AVERTISSEMENT : Risque de

blessure.

Ne pas placer les plaques de retenue

dans la rainure. Si les plaques de retenue

se trouvent dans la rainure, le registre

coupe-feu n'est pas correctement fixé.

Il pourrait alors sortir de son logement et

de tomber, ce qui risque de provoquer

des blessures graves, voire mortelles.

Figure 2: Blade Orientation

IMPORTANT: Do not lift the damper using the

blades or actuators. Lift or handle the damper using

the frame or sleeve. Handling or lifting the damper

by the blades or actuator may damage the damper

and will void the warranty. Do not compress or

stretch the damper frame into the duct or opening.

IMPORTANT: Examine each smoke damper on a

regular basis to ensure it is not rusted or blocked. In

addition, test each smoke damper annually or semi-

annually, depending on the application, and

according to the National Fire Protection Association

(NFPA) standards, to ensure it will perform as

intended. Exercise care to ensure that such tests

are performed safely and do not cause system

damage.