Speck Badu Stream II SwimJet User manual

IMPORTANT

SAFETY

INSTRUCTIONS

INSTALLATION.

OPERATINGAND

SERVICEMANUAL

- READ

ANDFOLLOW

ALL

INSTRUCTIONS

BaoU-SiTtrIEAM II

Counterstream

Swimming

Unit

U.S.

Patent

No.

3.977.O27

OWNER'SMANUAL

This is the Baou Sirne prvr

II

Allparts

aremanufactured

ofcorrosion-resistant

material

andcombinedin

onesingle

housing

(or

two

singlehousings

for

two

jet

systems)which

can

be

installed

inpools

of

any

sizeand

shape.

Key

toillustration:

A. Flush

mounted

Jet

Housing. E.

Control

Box

with

GFCI

with

pneumatic

button

B.

Square,Anti-Entrapment

Cove

r(B 114"xB 114"\ and

tubing'

undetectable

pump

suction.

(Optional

Round) F. Speck

4 HP or 3.5 HP self-priming,

plastic

c Adjustabre

waterFrowJet

Nozzre frtri:i:flIi,.?H:i,"U.Jli'#:l

il:Ji"Xlj::

D. AirRegulator

adjusts

amount

ofairbubbles

in motor and control

available

(Normalpriming

waterflow. pump

availableforinstallation

belowwaterlevel).

G.

Optional

Massage

Hose

with

pulsator

maybe

attachedto

jetnozzle.

The

Speck

(\

D/J

BADUSTReAM ll ffi :;Tnil;::ri;h::'

\AMETL Listinq#F-rrr8

ts

*-

*

^/

tf

TABLE

OFCONTENTS

1. lmportant

Safety

lnstructions Page

3

2. Introduction

andPlanning .Page

3

3. Plumbing

forEladu'stnearrt II . . Page4

4. Concrete

or Gunite

Installation Page

5

5. Liner

and/orFiberglass

PoolInstallation Page

6

5a.

Removal

of Liner. Page7

6. Plumbing

Suggestions

. . Page

8-9

7. lnstallation

of the Pump

andthe Control

Box Page

9

8. OperationInstructions . Page10

L Winterizing Page10

10.Frequently

Asked

Questions Page

10

11.Parts

Listfor

Eladu'stnearn II . . . Page11

12.Limited

Warranty Page12

IMPORTANT

INSTALLATION

TIPSINBOLD

PRINT

v

2

1.

Important

Safetylnstructions

When installing

and using this electrical

equipment,

basicsafety

precautions

should

alway

be

followed,

including

thefollowing:

A.READANDFOLLOW

ALLINSTRUCTIONS.

B.IAwARntrJGl

:Toreduce

the

risk

of

injury,

do

not

permit

childrento

usethis

equipment

unlessthey

are closelysupervised

at all times.

Failure

to

adheretothis

andall

otherwarnings

could

result

in

seriousinjury

ordeath.

C.

A licensed

electricianisrequired

for

all

wiring

connections.

D TO REDUCE

RISK OF ELECTRICAL

SHOCK,connect

all

ground

wires

to

grounding

terminal

located

in

the

control

box.

Use

no

smaller

than

a No.12

AWG

(3.3

mm')

wire.

E.TO REDUCE

RISK OF ELECTRICAL

SHOCK,abonding

connector

is

provided

onthe

moto

rJorbo

ndingof

local

g

rou

ndpoi

ntssuchaswate

r

pipes,

metalladders/handrails,

orothermetal

within

5

feet

of

the

pool.

Alllocal

ground

points

shouldbe

bondedwith

a

No.

SAWG

(8.4

mm'?)

wire.Never

use

gas

piping

asanelectrical

ground.

F.

Allelectrical

equipment

should

beinstalled

in

accordance

with

localcodes.

G.DONOTstore

oruse

gasoline

orotherflammable

vapors

or

liquids

inthevicinity

of

this

equipment.DO

NOTstore

pool

chemicalsnearthe

equipment.

H.DONOT

remove

anysafety

alert

labels

suchas

DANGER,

WARNING,

orCAUTION.Keep

safety

alertlabelsin

good

conditionandreplace

missing

ordamagedlabels.

l.Keep

andread

allequipmentmanuals.

Adhere

to

alloftheirinstructions.

J.

IAWARNINGI:Stayalert,watch

what

you

aredoing

anduse

common

sense.DONOT

useunitif

you

aretired

and/orexhausted.

DONOT

useunitwhile

underthe influence

of drugs,

alcohol,

or any

medications.

X.

lnwnnttttlcl:

Consult

your physician

before

exercisingwith

theEraEtusTFreaw-

II orusingthe

massage

nose.

L.EwARNINCI:

DO NOT use or operatethe

ErADUsiTFtealvl.

II ifthesquare,

anti-entrapment

coverismissing,

broken

orloose.

M.

SAVETHESE

INSTRUCTIONS!

Refer

tothem

frequently

and use them to instruct

third party

users.

2.Introduction

andPlanning

The eaousTREAM 11is normally

incorporated

into

the

original

pool

design.However,

itcan

be

added

toany

pool

ata later

date.

The eaousTFrEAM

11has no protruding

parts,

ensuring

the

pool

user's

safety.

ltisvery

compact

andinstalls

atminimal

cost.

The eaousTREAM II can

be installed

in any

size

pool.

We

suggest

a minimum

pool

size

of

7 ft. wide,

14 tt. long

and 3 1/2 ft. deep in

orderto swim.

Most

prefer

16ft. in length

or

longer.

The

extra

length

allows

the

swimmer

to

comfortably

driftback

and

swim

upstream.The

EfAous;TReaw.

II is

complete

with

jethousing,

4HP

or

3.5HP

pump,

control

box,

andoptional

massage

hose.

The

only

additionalrequirement

isthe

plumbing.

(4"

pipe

for4 HP

and3"

pipe

for

3 HP

units.)

Consult

localcodes

forminimum

distance

between

pump

and

pool.

Locate

pump

as closeto the

EtAEtusTFrearvl

11

as practical.

Use

at

least

4"pipe

when

distance

between

jet

housing

and

pump

is

30ft.orless

and6"

pipe

for

runslongerthan

30ft.

The4

HP,self-priming,

plastic

pump

hasa

single

phase

motorwith

thermal

overload

(no

motor

starterrequired).

The4HP

single

phase

motor

draws

amaximum

of1

9.4amps

@

230V.

The

unit

requires

aminimum

circuitof

30amps.Install

a

40

ampbreaker

toavoidnuisance

tripping

when

thepump

isturned

onand

offfrequently.

The

starting

current

of

the

4HPmotor

canreach

up

to 6times

therunning

currents.

(Threephase

motor

drawsamaximum

of

12.8

amps

@230V

and

6.4amps

@

460

V.)The

3.5HP

single

phase

motordraws

13.6amps

@

230V.

-

3.Plumbing

for eaoufSrREAM 11

PLUMBING

REOUIREMENTS

Number

of

Badu

Streams Number

of Pumps Pump

Model Water

Flow

per Nozzle

*Tota

I

Perf

ormance Power

Requirement

2221l80-325G 11OO

LPM 22OO

LPM 24av15

Ampeach

2221

/80-335G 12OO

LPM I

24OO

LPM 415v

10

Amp

each

. 6" pipe will allow distances of well over

50 ft. However, control box needsto be

within 50 ft. tor thepneumatic on/off

button to function properly.

Air

Regulator

BaduStream

/1

Fig.1

ThesaousTFtEAM ll assembly

package

contains

all necessary

parts

for the installation

of the unit

into

concrete,

gunite,

liner

orfiberglass

pools.

trcAUTloNl: All necessary

screws

and boltsincluded

with the EtAEUsiTFrea,ru

11

are stainless

steel or

plastic.

ALL screwthreads

andthreaded

inserts

are

METRIC!

ONLYMETRIC

bolts

and

nuts

may

beused!

The two exceptions

are the connectingthread

for

the intake and delivery connections

on the

EtAclusTFlen

ru11

and

pump

housing

andthe

hardware

forthe

airregulator

assembly.Theintake

anddelivery

connections

on the pump

model

21-80

are

3" NPT

threads

and

4" slip

(3 on pump

model

98).Theair

regulator

assembly

hardware

is US standard

thread.

tAcAurtoN]:

The

centerofthehousing(the

nozzle)

should

be 10"BELOWwater levelfor maximum

efficiency. The air regulator should be

approximately

4"ABOVE

thewaterlevel.

(See

fig.

3.)

4

Valves rOpl ona

Check Va ue (Opt ona )

(Below Water Level)

Vedical Slct on Llne

NOTE:Vavesarerecommendedwhen

pump

s nstal

edbelowwaterevel.

I

AcAUTtoN

l:

When

connectingthe

pressure

lineto

the

pressure

connectionontop

of

the4 HPPumpModel

21-80,firstinstall

a 15cm (6")

riser

(fig.

1) before

installing

an elbow

and leading

the pressure

line

downwardto the pressure

connection

at the jet

housing.Thiswill

guarantee

trouble-free

priming

of

the

pump.

(Not

requiredfor

the

3.5

HPModel.)

EcAUTtoN]:

The

suctionline

shouldrunbelowwater

levelright

up

to

the

pump

location.

EcAUTtoNl:

In

areaswith

softsoilconditionsorwith

frequent

earthmovement,

a flexible

section

of hose

should

be attachedto the backof the

jet housingto

prevent

housing

breakage.

EcAUTtoNl:

Throughout

theentireinstallation,make

sure plumbing connectedto the e^aousrnearvl ll

housingis wellsupported.

Unsupported

plumbing

willcrackthee^aousTFtEAM

11housing.

Conro Box

l-/-1

-l 4 t

Lr

T-

Seruce

Disconnect

t7r

-t L7 | -

l, I

E

E

E

.E

5<.

Hor zontal Suclion Line

max. 30 leet w[h 4 " pipe

4.

ConcreteorGunite

Installation

A. Preplumb

EtAousiTFrea,rvl11

Housings

1.Install

plumbing

manifold

orapproximately

12"of4"

SCH

40pipe

toboth

suctionanddischarge

fittings

on

the jet(s)housing.NOTE:lf plumbing

exceeds

30'

between

jet housing

and

pump,

increase

pipe

sizeto

6". Install

a 6x4" reducing

bushing

as closeto jet

housing

as

possible.

2. Install

aircontrol

PVChoseto hose

socket

insert

fittings

(paft

# 6).Usehose

clampstosecure

hose

to

insertfitting.

B. Tape

jet housing.

Keep

concrete

outof threaded

inserts

andoutoftheinside

ofthehousing.

C. Place

jethousing

intoreinforced

steel.Jethousing

location

isveryimportant.

1. Locate

aircontrol

hoseconnector

(part

#6)at the

top and centerof jet housing.

Air controlhose

connectorsmust

be vertical

or the squarecoverwill

beunevenin

appearance.

2. The center

of the housing

(the

nozzle)

shouldbe

10"BELOW

waterlevel

formaximum

efficiency.

3. Front

edgeof jet housing

shouldfinish

even

with

inside

gunite

wall.Make

surea V shaped

groove

is

scraped

outaroundthehousing

approximately

1 112"

deeptoallowmarcite

toseal

againstthehousing.

Air

Regulator

4. Rechecklocation

ofthe

jet housingwhen

gunite

is

beingapplied.

Theforce

of thegunite

maymovethe

jetlocation.

5.To avoidstress

onthe

jethousing,we recommend

thattheEta'BusiTReavl

ll housing

beencasedwith

gunite

andat least2 to3 inchesoftheplumbing

stub

out is covered

with gunite.

NOTE:Stress on the

plumbing may crack the EIADUSITnEAM II

housing.

D. Air regulator

installation

should

be approximately

4 ABOVE

thewaterlevel.

1. Air regulator

holder

and hose

socketinsertfitting

connectto PVChose.

Makesureairregulator

holder

face is tapped

overto prevent

gunite

fromentering

holder.

2. Air regulator

can be locatedin thetileline

above

waterline

orinthe

deck.

E. Keep

allparts

notbeingusednowinoriginalbox.

Store

in

asafe

place

untilneeded.

An extensionringis available

(upon

request)for an

application

thathasspecialneeds.

Fig.

3

Baou'srnea,ru 11inConcreteorGunite

Pool.

Fig.2

Template

forInstallation

in

Gunite

orConcrete

5

Pools.

5.

Liner

and/or

FiberglassPoolInstallation

trCAUT|ON]: Locate

theaircontrol

hose

connector

(part

#6) at the top and centerof the jet housing.

Connectors

mustbe exactlyverticalor the square

cover

will

beuneven

inappearance.

IACAUTION-I

:Centerof

Housingshouldbe1

O"

BELOW

water

levelformaximum

eff

iciency.

trcAurtoNl: Clampingring

gasket(part

# 12)

goes

inFRONT

of pool

wall.A good

RTV

silicone

may

be

used

with

gasket

whenmounting

jethousing,

but

in

mostcasesisnotnecessary.Installershoulddecide

whetherornot

silicone

isnecessary.

ForFiberglass

poolsonly,theclamping

ring

(part

#

3) canbe used

to mark

anddrilltheholes

as shown

in Fig.4. Fortheair regulator,ofle1/2"

holemust

be

provided, preferably along the vertical axis,

approximately

4' ABOVEthe

waterline.

For Liner pools only, two holes

at the horizontal

axisof thejet housingandthetwo holes

on the air

regulator

will

allowboth

housingandairregulatorto

be mounted

to the oool wall beforethe liner is

installed.

Use

thetwo plastic

M6 countersunkbolt

(part

#18)and

twoMOnuts

(part

#19)

(bolt

headson

poolside

and nutson backside)

to mountthe air

regulatorand two screws(part#27) to mountthe

housing.

Thiswillkeepthe holderandjet housing

attachedto the oool wall durino installationor

reolacementof

liner.

Air

Regulator

--

2"Minimum

Fitting4"

45 ETOOW

-

_

Liner

or

FiberglassPool

-----T-----

I

I

I

10"

I

I

t_

Housing

Fitting4"

Pipe

Fig.4

Cutout

PoolWallforEtaou'EirRenrvr 11

Housing

6

Fig.

5

Elaou'STFTEAM 11in

t

c

f

E

.E

5

N

iI

I

I

1

I

.Fdd'u

I

u"n'ou

For LinerPoolONLY

-y

rv

5a.

Removal

ofLiner

When replacingliner

or removinglinerfor repairs;

remove4 bolts

(part

#9/1)whichholdsquare

cover

(part

#8)tojethousing.Removeallbolts

(part

#9/2

&

9/3) excepttop two, which hold the clamping

ring

(part#

3 and gasket(part

#12)to jet housing.

Back

out the two remainingboltsapproximatelyhalfway

andcheck

foranymovement

ofjet housing

fromthe

wall.

(NOTE:

lf thetwocountersunk

bolts

(part#

27)

whichholdthe

jethousing

tothewallwereinstalled,

the jet housingshould not move, and the two

remainino

boltscan

beremoved.)

Removeone of the remaining

two boltsand slide

clamping

ring(part

#3) to the side.Replaceall the

bolts before removingthe last bolt. Removeor

replaceliner.Reverse

process

toinstallliner.

NOTE:When replacingclamping

ring and bolts:

locatebolt

heads

under

liner,makesmallcuton

liner

at

the

bolt

headsand

push

liner

overbolt

head.

Fig.

6

Ele,ou-STFTEAM11

dimensionaldrawing

7

y

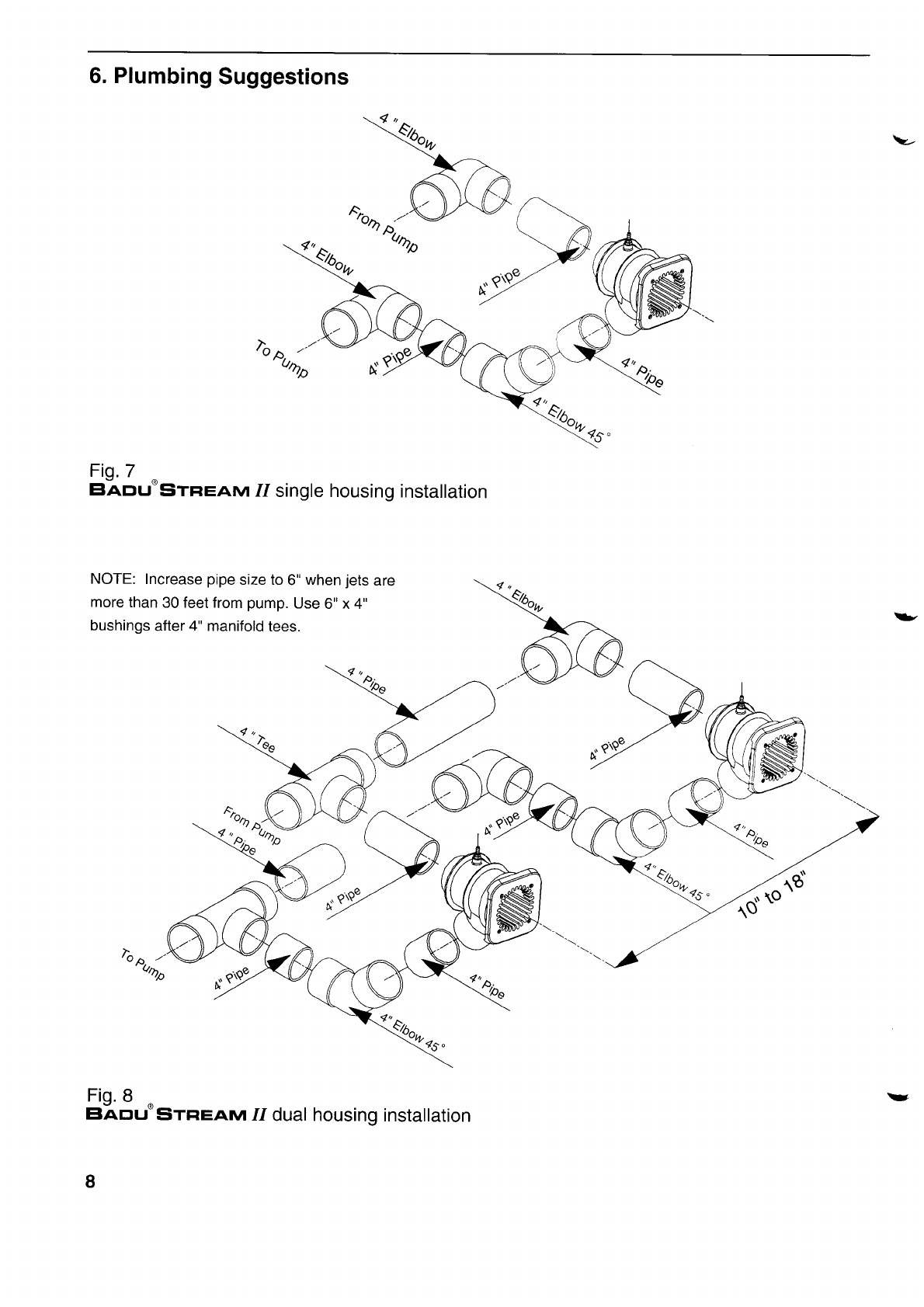

6.

Plumbing

Suggestions

Fig.7

Elaou-STFTEAM 11

singlehousing

installation

NOTE:

Increase

pipe

sizeto

6"

when

jets

are

morethan

30feetfrom

pump.

Use

6"x4"

bushings

aller

4"manifold

tees.

Fig.

B

EIADU"

SrRee,rvl 11

dualhousing

installation

8

\z-

-,

-

v

>

NOTE:Increase

pipe

sizeto6' when

jets

are

more

than30

feetfrom

pump.

Use6"x4"

bushings

after

4' manifoid

tees.

Fig.

9

Baou"SrFrEAM 11triplehousing

installation

NOTE:

Checkvalvesmust

beusedonthe

discharge

side

of

each

pump.

N4inimum4"

pipe

between

pump

andBaduStream

plumbing

manifold.

94^

-{Qk'"-{rqi'

7.Installation

ofthePump

andthe

ControlBox

lAcAUTloNl:

Beforeinstalling

the

SpeckPump,

read

theentire

pump

owner'smanual

found

in thepump

oox.

Consultlocal

codesfor minimum

distance

between

pump

and

pool.

Locate

pump

asclosetothe

pool

as

practical.

Theairbutton

works

upto 50 ft.Thereis50ft.of air

tubingin

BaouSrFrEAM 1/box.

trWARNtNGl:

Toreduce

therisk

ofinjury,

donot

permit

children

to use

this

product

unlessthey

areclosely

supervisedat

alltimes.

Thewiring

of the pool

motor

andcontrol

boxshould

bedoneby a licensed

electrician

inaccordancewith

localcodes.

Be certain

thatthe motorframe

and

control

box are grounded.

Motorname platehas

voltage, phase, amp draw, and other motor

information

as

well

aswiring

connection

instructions.

BONDING:

As required

by NationalElectrical

Code

Article

680-22,the pump motormustbe electrically

bondedtothepool

structure

(reinforced

bars,etc.)

by

a solid

copperconductornot

smallerthanNo.

8 AWG

via the external

copperbondinglug on the pump

moIor.

GROUNDING:Permanently

ground

thepump

motor

andcontrol

boxusing

a conductorofappropriate

size.

Connectto the No.10 green

headed

ground

screw

provided

inside

themotor

terminal

box.

NOTE:

Do notconnectto electric

power

supply

until

unitis

permanently

grounded.

Section

6 concernsthe

electricmotor

andcontrolbox

onlysince

allother

parts,

the

pump,

the

jetunit,etc.

have

complete

andabsolute

separationfromthepool

water.

I

8.Operation

lnstructions

Remove

redfiller

plug

or strainer

tank

lidon pump

andfill

pump

with

water.

Replace

red

filler

ptug

orlid.

Push

pneumatic

button

on.For

thefirst

start-up

allow

approximately

5 minutes

forthepump

to prime.

lfthe

pump has not stafted

priming

after5 minutes,

the

amount

of water

inthepump

was not

sufficient.

Add

more

water.

To start

swimming,

jogging

or running

itissuggested

that

the two nozzles

are pointed

slighfly

inward

and

slightly upward so that the water "breaks"

approximately

3ft.in front

of the Baousrneavr 11

Startswimming

with

onlyminimal

force

in armsand

legsuntil

you feel yourself

drifting

backwards,

then

addforce

andswim

upstream

until

a proper

balance

isfound

betweenforce

andendurance.

Keep

in

mind

thatthis

unitis

designed

for

a balanced

workout.

Find

a pace

that

you

cankeep

upfor

atleast

20 minutes.

Out

pacing

isalways

possible.

Theidea

is

tocontinue

exercisefor

anextended

period

of

time.

Consult your physician before attemptingany

strenuous exercise.This product may not be

challenging

or satistying

for all levels

of exercise.

The air regulator

permits

a controlled

mixture

of air

intothe

water

flow

and

creates

a unique,

invigorating,

bubble bath effect. lt wili also add additional

resistance

toswim

against.

Et^aousiTRearu

11's

adjustableflownozzle

enables

swimmerto regulate

the volume

of water released

through

the jet(s).

Turning

the nozzle

clockwise

reduces

theflow.

The swivelnozzle(s)

of the EtaclusiTFlea,u 11

can

be positioned in various directions,allowing

swimmerstousevarious

swim

styles.

OPTION:A pulsating

massage

hose

canbeattached

to oneofthenozzlesformassages.

(Askyour

dealer

for availability.)

Use massage

hose as advised

by

yourphysician.

Directions

for use: Consult

your physician

before

usingthemassage

hose.

To reduce

therisk

ofinjury,

do notpermit

children

to use

themassage

hosewith

pulsator

unless

they are closely

supervised

at all

times.

Close

air regulator.

Reduce

the volume

of

water by turning the adjustable

flow nozzle(s)

clockwise.

Undercertain

conditions

itispossible

that

thecurrent

"drifts

off"the

theleft

ortheright

fromthemiddle

due

towater

bouncing

off

the

backwall.

Inthe

eventthatit

interferes

with

your

swimming

action,

turnunit

off

for

afew

minutes

andrestart.

EWAiNlltclDo

notuseoroperatetheE4ousrneau 1I

if

thesquare,

anti-entrapment

coverismissing,

broken,

or loose.

v

v

9.Winterizing

In areassubject

to freezing

water

temperatures,

protect

pump

byremoving

drain

plug

andred

filler

ptug

(or

lid). Drain

pool

untilwater

levelhas

dropped

belowthesquare,

anti-entrapment

cover.Alternatively

purchase

a winter

coverkit

part

#2308752006K.

10.

Frequently

Asked

Questions

Whatsize pool do I need?Thes^aousTREAM 11

can be installed

in any size pool. However,

we

recommend

a minimum

length

of 14'and

a minimum

width

ofaswimming

lane.

What

size

plumbing

is

necessary?

How

far

awayfrom

theBaousrnea,vlllcan the

pump

beinstalled?

Use

a4"

plumbing

upto

30'.

For

runs

longer

than

30'

use6"

plumbing.

The pump can be placed

as closeto

EtADUsTFrel.w-

II aslocal

codeswill

allow.

Howmany

ampsdoes

the pumpoperate

at?

4 HP:

Maximum

19.4

amps

@230V

3.5HP:

Maximum

13.6

amps

@230V

What size breaker

do I need?You mustusea 40

amp

breaker

forthe

4 HP

pump

or30amp

breaker

for

the

3 HP

pump

toavoidnuisance

tripping.

10

Does

it matter

ifthehousing

is installed

higher

or

lower than the manual states? Yes,

the center

of

the

jet

must

be10 BELOW

estimated

waterlevel

for

properperformance

ofunit.

Can the air regulator be placedelsewhere?

Yes,

as

long

asitisnot

continuouslyflooded

withwater.

Canthe pump be placed belowwater level?

Yes.

However,

for best performance

we recommend

ordering

pump

forflooded

suction

(Model

21-80i33G)

instead

of self-priming(Model

21-80133

GS). We

recommend

installing

valves

for

ease

ofmaintenance.

How far away can the air button function

properly?A maximum

of 5O'.

Consultfactory

for

distances

over

50'.

Do I need to install a motor starter? No the pump

has

a built-inthermaloverload.

\t

-

11.Partslistfor EIAclU'STFTEAnvl.II

f,

f

V

---E

Y

18

IJ

to

6

v

\t

Part# Qty

'II

26

JI

f,l

ol

71

B1

911 4

912 B

9/3 8

914 8

9/5 4

'10 1

11/1 1

11t2 2

tz I

13 1

(14-21) 1

vt+1

15 1

162

Description

FaceRing

-Nozzle

Screw

-

Tapping

5.5x 19

ClampingRing

Nozzle

(adjustable

flow)

Bushing

Hose

Connector1/4"

Housing

SquareCover

Bolt-M6x25

Bolt-M6x20

Bolt-M6x25

Bolt-M6x40

Bolt-M6x45

Seat

-Nozzle

SpacerRing

-

6.2

Spacer

Ring

-

4

Gasket

-

ClampingRing

Gasket

-Face

Ring

HolderW/hose

Subassembly

Hose

Fitting

- 1/4"

Hose-8x3

Hose

Clamp14l9

Part# Qty

17 1

18 2

192

202

21 1

(22-26) 1

zal

zJl

24 1

25 1

26 1

272

'1

9t1

Optional

WinterCover Kit:

Part# Qty Description

1

12 1

9/1 4

- Extensionring

Description

Holder

-AirRegulator

BolI

- 1/4-20x 1-1

12"

Nut

- 1/4-20

Washer

- 1/4"

Gasket

60

x11x2

SubassemblyComplete

TopPart

-AirRegulator

Bottom

Part

-AirRegulator

Bolt

-Air

RegulatorM10xB0

Hose

Ring

-AirRegulator16x30

x80

Gasket

-Air

Control

42x 11

x2

Screw

-

Jet

Housing14x 1"

ExtensionRing

(pre-glued)(not

shown)

WinterPlate

(not

shown)

Gasket

-ClampingRing

Bolt-M6x25

An

extension

ring

(not

shown)isavailable

(upon

request)

11

12.

Limited

Warranty

Themanufacturer

supplies

a limited

warranty

to the

original

consumer

purchaser

ofthe

gaousrnearvl 11

onthefollowing

terms

andconditions:

1.

TheEtAclusTFlea,rvl

11iswarranted

tobefreefrom

defectsin material

andworkmanship

for a period

of

twelve (12) months from the date that the

EtAousTRea,ru

11is

originallyinstalled.

2.Notwithstanding

any

provision

herein

to

thecontrary,

thewarranties

andobligations

hereunder

shallnotin

any event

extend

for more

than2 years

beyondthe

date of shipment of the EtAclusTFtea,vr 11 from

Speck Pumps-Pool

Products,

Inc. in Jacksonville,

Florida.

3. Warranty

is voidin the following

cases:

damages

which

result

in whole

or in parl

from:

(a)careless

or

improper

installation

of the EtAclusTFr=arvr

II; (b)

improper

or negligent

use and maintenance

of the

BacIUSITFTEAM II; (c) tampering with the

EtaousiTFrea,rvl

11

byunauthorized

repair

personnel;

(d)ground

movement;(e)

substitution

of parts

and/or

components.

4.The

manufacturer's

sole

obligationhereunder

shall

be

toreplace

orrepair

any

defectiveEtAousTneana ^1L

The manufacturer

reserves

the absolute

rightto

determine

whether

anydefective

EIAclUsTne^aru

11

should

bereplaced

or

repaired.

5. Anycustomer

whowishes

to make

a claimunder

this Limited

Warranty

shallnotify

SpeckPumps,

of

such claim by telephone

or by mail. After the

customer

has beenauthorizedto return

a defective

BAousTneevr II, the customermust return

the

EtADUsTRea,rvl

11toSpeckPumps.

Any goods

returned

to Speck

Pumps

without

prior

authorization

will

be

returned

tothe

shipper

unopened.

Speck Pumpsshall not bear any costs or risks

incurred

inshipping

a defective

BAousTFrearvr Id

toSpeckPumps

orin

shippinga repaired

orreplaced

BArlusTne.aru 11toacustomer.

6. SpeckPumps

will

charge

customersfor all non

warranty

work

whichit mayperform.

Warranty

work

will not be performed

until the customerhas

acceptedthe

pricequoted.

7.Except

as specifically

setforth above,no other

warranties,

whether

express

or implied,including

without limitation, the implied warranties of

merchantability and fitness for a particular

purpose, are made by the manufacturer.

In no

eventwill the manufacturer

beliablefor any loss,

includingtime, money,goodwill, lost profits and

consequentialdamages based on contrast, tort

or other legal

theory,

which mayarise hereunder

or from the use,operationor modification

of the

pump, motor or associated

parts.The maximum

liability of the manufacturer

hereunder

shall not

exceedthe amountactually

paidby the customer

for the Fump,

motorandassociated

parts.

8.Somestates

donot

permit

limitations

onthe

terms

of implied

warranties

orontherecovery

of incidental

or consequentialdamages. Accordingly, the

limitations

contained

in paragraph

7, maynotapply

tocertain

customers.

9.Thiswarrantygives

customers

specificlegal

rights

which may vary from state to state. The

EIAEUsTFrea,ru

11is manufactured

underlicense

from

Speck

Pumpen,

GERMANY.

v.

v

Date

ofInstallation:

Installed

By:

For

Service

Call:

SAVETHESE

INSTRUCTIONS!

5PSI(_tr

PUmPScffi

q)

J

0.)

F

frl

F

a

ct)

F

o

v

U

fTl

(n

LH-F

i.l c E^

6--X

&d6d6=

q)

q)

-/A

Aotrdd

.IdHH

H EIeq

rvvv

'a (nQd/

X

a

+F

o ----___1}'

N

l.

-T-

I

I

I

I

I

3

I

Y

q)

\)>

\v

H

C)

!

C)

d

@aa)

0N!!E

AFFFg

a

: r/)F-o\ ^

ll19

F ca ..,f- .b

v9

E TfF:

5 6EEE

U >>>

E

Hx 9996

IHH>

;i ''f i'-'i /a

HHHV

a

+

X

\

\

\

\

\

\

\<\

\

\

\

\

rFl

z

^

O

\

\

\

\

i1

\

\

\

Table of contents

Other Speck Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

TECHTOP

TECHTOP URANUS 18 WW 25 user manual

National Specialty Lighting

National Specialty Lighting LED Brick Star Gen I installation instructions

JARDINICO

JARDINICO LUNA LED LIGHT Assembly and operation guide

LED World

LED World FA36M57-2M-12V-X Important instructions

GE

GE Arize Element Series installation guide

BeLuce

BeLuce MAXIMA TSL instructions