Spectra Precision Trimble UL 633N User manual

GL400 Series

www.trimble.com

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424

USA

+1-937-245-5600 Phone

www.trimble.com

User Guide

Bedienungsanleitung

Manuel de l´utilisateur

Guida per l´uso

Gúia del usuario

Gebruikershandleiding

Operatörshandbok

Brugermanual

Guia do Usuário

Bruksanvisning

Käyttäjän opas

取扱説明書

© 2007, Trimble Navigation Limited. All rights reserved.

GL400 Series

www.trimble.com

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424

USA

+1-937-245-5600 Phone

www.trimble.com

User Guide

Bedienungsanleitung

Manuel de l´utilisateur

Guida per l´uso

Gúia del usuario

Gebruikershandleiding

Operatörshandbok

Brugermanual

Guia do Usuário

Bruksanvisning

Käyttäjän opas

取扱説明書

© 2007, Trimble Navigation Limited. All rights reserved.

UL 633N

GL400 Series

www.trimble.com

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424

USA

+1-937-245-5600 Phone

www.trimble.com

User Guide

Bedienungsanleitung

Manuel de l´utilisateur

Guida per l´uso

Gúia del usuario

Gebruikershandleiding

Operatörshandbok

Brugermanual

Guia do Usuário

Bruksanvisning

Käyttäjän opas

取扱説明書

© 2007, Trimble Navigation Limited. All rights reserved.

Руководство пользователя

Russ_Titel.indd 1 06.05.2008 08:38:53

© 2017 , Trimble Inc.. All rights reserved.

PN 112644-00 Rev. B (07/17)

Trimble - Spectra Precision Division

5475 Kellenburger Road

Dayton, Ohio 45424 U.S.A.

+1-937-245-5600 Phone

Instrukcja obsługi

UL 633N

112644-00 Rev. B (07/17)

df

h

g

i

k

i

c

e

b

a

j

l

Service and Customer Advice

North America

Trimble - Spectra Precision Division

5475 Kellenburger Road

Dayton, Ohio 45424 U.S.A.

888-527-3771 (Toll Free)

+1-937-245-5600 Phone

+1-937-482-0030 Fax

www.trimble.com

www.spectralasers.com

www.spectraprecision.com

Europe

Trimble Kaiserslautern GmbH

Am Sportplatz 5

67661 Kaiserslautern

GERMANY

+49-6301-711414 Phone

+49-6301-32213 Fax

Latin America

Trimble Navigation Limited

6505 Blue Lagoon Drive

Suite 120

Miami, FL 33126

U.S.A.

+1-305-263-9033 Phone

+1-305-263-8975 Fax

Africa & Middle East

Trimble Export Middle-East

P.O. Box 17760

Jebel Ali Free Zone, Dubai

UAE

+971-4-881-3005 Phone

+971-4-881-3007 Fax

Asia-Pacic

Trimble Navigation

Australia PTY Limited

Level 1/120 Wickham Street

Fortitude Valley, QLD 4006

AUSTRALIA

+61-7-3216-0044 Phone

+61-7-3216-0088 Fax

China

Trimble Beijing

Room 2805-07, Tengda Plaza,

No. 168 Xiwai Street

Haidian District

Beijing, China 100044

+86 10 8857 7575 Phone

+86 10 8857 7161 Fax

www.trimble.com.cn

1

TABLE OF CONTENTS

1 INTRODUCTION 3

2 FOR YOUR SAFETY 3

3 COMPONENTS 3

4 HOW TO USE THE LASER SYSTEM 4

4.1 Powering the Laser 4

4.1.1 Batteries 4

4.1.2 Recharging the batteries 4

4.2 RC603N Radio/IR Remote Control 4

4.2.1 Powering the RC603N 4

4.2.2 Turning On/Off the RC603N 4

4.3 ST802/ST805 Signal Transporter 5

4.3.1 Powering the ST802/ST805 5

4.3.2 Turning On/Off the ST802/ST805 5

5 LASER SETUP 5

5.1 Turning On/Off the Laser 5

5.2 Features and functions 6

5.2.1 Standard Display 6

5.3 Standard Features 6

5.3.1 X-Y-Z-grade entering - Digit Select mode (Default) 6

5.3.2 X-Y-Z-grade - Step and Go mode 7

5.3.3 Rotation Mode 7

5.3.4 Pointing Mode 7

5.3.5 Scan Mode 8

5.3.6 Manual Mode 8

6 SPECIAL MENU FEATURES 8

6.1 Menu Functions (radio controlled) 8

6.2 Menu Functions (IR controlled) 8

6.3 Automatic PlaneLok Mode 9

6.4 Automatic Grade Match 10

6.5 Manual Grade Match 11

6.6 Automatic Axis Alignment 11

6.6.1 Automatic Axis Alignment 11

6.6.2 View Align Angles 12

6.6.3 Edit Align Angles 12

6.7 Mask Mode 12

6.8 Spot Search 12

6.9 Activating/Deactivating Standby mode 13

6.10 Start Reference Check 13

GB

2

6.11 Setting Menu 13

6.12 Info 13

6.13 Service 14

6.14 RC603N Service Menu 14

6.14.1 RF IR Options 14

6.14.2 RF Connectivity 14

7 SPECIAL FEATURES - VERTICAL SETUP 15

7.1 Z-Axis Automatic Spot Align 15

7.2 Z-axis Automatic Spot Lok 15

7.3 Z-axis Automatic Spot Match 16

7.4 Line Scan 16

7.5 Beam Plunge 16

8 SETTING 17

8.1 Pairing 17

8.2 Pairing the laser with remote control 17

8.3 Pairing the laser with receiver HL760 17

8.4 Pairing the laser with the Signal Transporter (ST802/ST805) 18

8.5 Grade Entry 18

8.6 Grade Display 18

8.7 Sensitivity Selection 19

8.8 HI-alert selection 19

8.9 User Name 19

8.10 Set Password 19

8.11 Password On/Off 20

8.12 Radio (RF-Channel) 20

8.13 Select Language 20

8.14 Position Info 20

9 CALIBRATION 21

9.1 Checking Calibration of the Y- and X-Axes 21

9.2 Checking Calibration of the Z-(vertical) Axis 21

10 TROUBLESHOOTING 22

11 SF601 SPOT FINDER USER GUIDE 23

12 PROTECTING THE UNIT 26

13 CLEANING AND MAINTENANCE 26

14 PROTECTING THE ENVIRONMENT 26

15 WARRANTY 26

16 TECHNICAL DATA 27

16.1 UL633N 27

16.2 RC603N 27

16.3 SF601 27

17 DECLARATION OF CONFORMATY 27

18 ELECTROMAGNETICAL COMPATIBILITY 28

3

1 INTRODUCTION

Thank you for choosing one of the Spectra Precision Lasers from the Trimble family of precision lasers.

The universal laser is an easy-to-use tool that offers accurate horizontal, vertical and sloped laser reference

up to 1300 ft (400 m) away using a receiver. The plumb beam can be detected automatically and manually

using the additional SpotFinder.

2 FOR YOUR SAFETY

For hazardless and safe operation, read all the user guide instructions.

• Useofthisproductbypeopleotherthanthosetrainedonthisproductmayresultinexposuretohazardous

laser light.

• Donotremovewarninglabelsfromtheunit.

• TheUL633NisClass3A/3R(IEC60825-1:2014).

• Neverlookintothelaserbeamordirectittotheeyesofotherpeople.

• Alwaysoperatetheunitinawaythatpreventsthebeamfromgettingintopeople‘seyes.

• Ifinitialserviceisrequired,whichresultsintheremovaloftheouterprotectivecover,removalmustonlybe

performed by factory-trained personnel.

Caution:Useofotherthanthedescribeduserandcalibrationtoolsorotherproceduresmayresult

inexposuretohazardouslaserlight.

Caution:UsingdifferentthandescribedattheUL633Nuserguide,mayresultinunsafeoperation.

3 COMPONENTS

a Keypad/LCD-Display

b Handle

c Rotor with fan beam lens

d Sunshade

e Axes-Alignment-Marks

f Sighting Guides/Scope Mounts

g Battery door

h Rubber Cover/Recharge Jack

i 5/8” x 11 Tripod Mounts

j Rubber Feet

k Turnable Legs

l Plus and Minus Battery Diagrams

4

4 HOW TO USE THE LASER SYSTEM

4.1 POWERING THE LASER

4.1.1 Batteries

WARNING

Ni-MHbatteriesmaycontainsmallamountsofharmfulsubstances.Besuretochargethebatterybeforeusing

itforthersttime,andafternotusingitforanextendedlengthoftime.Chargeonlywithspeciedchargers

accordingtodevicemanufacturer‘sinstructions.Donotopenthebattery,disposeofinreorshortcircuit;it

mayignite,explode,leakorgethotcausingpersonalinjury.Disposeinaccordancewithallapplicablefederal,

state,andlocalregulations.Keepthebatteryawayfromchildren.Ifswallowed,donotinducevomiting.Seek

medical attention immediately

4.1.2 Recharging the Batteries

ThelasermightbeshippedwitharechargeableNi-MHbatterypack.

Note: TheapproximatechargeofthebatteriesisshownatthelefttopsideoftheLCD.

Thechargerrequiresapprox.10hourstochargeemptyrechargeablebatteries.

Forcharging,connecttheplugofthechargertotherechargejackofthebatterypack.

Neworlong-timeout-of-userechargeablebatteriesreachtheirbestperformance

afterbeingchargedandrechargedvetimes.ForIndoorapplicationsthecharger

can be used as a power supply for the laser.

Alkalinebatteriescanbeusedasabackup.Insert4D-cellbatteriesnotingtheplus(+)andminus(-)diagrams

inside the battery housing.

The batteries should only be charged when the laser is between 50° F and 104° F (10°C to

40°C). Charging at a higher temperature may damage the batteries. Charging at a lower

temperature may increase the charge time and decrease the charge capacity, resulting in

loss of performance and shortened life expectancy.

4.2 RC603N Radio/IR Remote Control

4.2.1 Powering the RC603N

1. Open the battery door using a coin or similar pry device to release

thebatterydoortab onthe RC603N.RC603N willbe shippedwith

alkalinebatteries.Rechargeablebatteriescanbeusedoptionalbut

needtobechargedexternally

2.InserttwoAAbatteriesnotingtheplus(+)andminus(-)diagrams

inside the battery housing.

3.Close the battery door. Push down until it “clicks” into the locked

position.

4.2.2 Turning On/Off the RC603N

Theradio/IRremotecontrolisahand-helddevicethatallowsyoutosendoperationalcommandstothelaser

from a remote location.

Pressthepowerbuttontoturnontheradioremotecontrol.Thesymbol“ ”andadditionalverticalbarsappear

in the right corner of the remote’s top display line indicating the radio connection status between the laser and

theremotecontrol.IftheRC603Nisoutsidetheradiooperatingrangetheremoteswitchesautomaticallyinto

theIRconnectioncapability.

Note:Whentheremotecontrolisinitiallyturnedon,thestandarddisplay(modelnumberandsoftwareversion)

appearfortherst3seconds,thentheaxessymbolsandlast-enteredgradeforeachaxisappearintheLCD.

Witheverybuttonpress,theLCDbacklightisactivatedandturnsoffautomaticallyifnobuttonispressedfor

8seconds.

To turn off the radio remote control, press the power button for two secounds.

Note:5minutesafterthelastbuttonpress,theremotecontrolturnsoffautomatically.

5

4.3 ST802/ST805 SIGNAL TRANSPORTER

4.3.1 POWERING THE ST802/ST805

1.Open the battery door using a coin or similar pry device to release the battery door tab on the

ST802/ST805.ST802/ST805willbeshippedwithalkalinebatteries.Rechargeablebatteriescan

beusedoptionalbutneedtobechargedexternally.

2.InserttwoAAbatteriesnotingtheplus(+)andminus(-)diagramsinsidethebatteryhousing.

3.Closethebatterydoor.Pushdownuntilit“clicks”intothelockedposition.

4.3.2 Turning On/Off the ST802/ST805

Thesignaltransporter(ST)isahand-helddevicethatextendstheradiorangeofalaserwhichispairedwith

theST.Pressthepowerbuttontopoweronthesignaltransporter.AllLEDsturnonforthreeseconds.Finally

aashingyellowstatusLEDshowsthesignaltransporterhasbeenpairedwithalaserbutthislaserisnot

available.AsolidblinkingyellowstatusLEDisshowingthattheradioconnectionbetweenthesignaltransporter

and the paired laser has been established.

5 LASER SETUP

Position the laser horizontally (tripod mount and rubber feet downward!) on a stable platform, wall mount or

tripod at the desired elevation.

The laser recognizes automatically whether it is used horizontally or vertically when switched on.

5.1 Turning On/Off the laser

Press the power button for one second to turn On the laser.

Press the power button for two seconds to turn Off the laser.

Note:Whenagradevaluehasbeenenteredandaftertemperaturechangeofmorethan9°F(5°C),theunit

startsthetemperature/referencecheckwhilethethermometersymbolisashing(Pic1).

Anothertemperaturechecktakesplaceafter20min.andnallyevery60min.Whenthetemperature/reference

checkhasbeennished,thestandarddisplayappearsandthebubblesymbolsashuntilself-levelinghas

beencompleted(Pic2).

Iftheself-levelingcan’tbenishedbasedontheselectedsensitivity,anerrormessageappears.

AbubblesymbolhelpstoadjusttheunitatthecrossaxiswhensetupverticalforautomaticSpotAlignorin

vertical manual mode.

Pic 1 Reference check Pic 2 Standard display horizontal

Pic 3 Standard display vertical

6

5.2 Features and Functions

5.2.1 Standard Display

The remote control mirrors the functionality of the laser keypad

Button 1: Quicklypressandreleasestartsthe

MENU entry.

Button 2: Quicklypressandreleasestartsthe

grade entering mode.

Button 3: Quicklypressandreleaseactivates/

deactivates the manual mode.

Button 4: Quicklypressandreleasetotoggle

through the pre-selected rotation speeds.

Press and hold for three seconds

changestheunitintoscanmode.When

inscanmode,quicklypressandrelease

button 4 toggles through the pre-selected

scan sizes.

Button 5, 8:up/downarrowbuttons.

Button 6, 7:left/rightarrowbuttons.

Button 9: ON/OFFbutton-pressfor1secondto

turnontheunit;pressandholdfor2

seconds to turn off the unit.

Leveling/Standby – LED (green/red)

Batterystatuslaser HIalertfunctionisactivated

Maskselection BatteryStatusRemoteControl

StatusRadioConnectivity

Rotationspeed/Scanangle

FanBeamisactivated

5.3 Standard Features

5.3.1 X-Y-Z-grade entering – Digit Select mode (Default)

Quicklypressandreleasebutton2 (Pic5)startsthegradeenteringmode.

Bothgradevalueswillbeshown.

Acursor(Pic6)blinksatthecurrentpositionwhichcanbechanged.

Press/releasebutton1aquicksetto0%

Press/releasebutton2achange the sign in front of the grade value

Press/releasebutton3areturn to the standard display.

Quicklypressandreleasebutton4toconrmtheselectedgradevalueandreturntothestandarddisplay.

Press and release button 5or 8(downorup)tomovethecursortotheX-orY-axis(notusedinZ-mode).

Pressing and releasing button 6or 7(rightorleft)movesthecursortotheright/left.

Usebutton 1 or 2(PlusorMinus)tosetthedesireddigit(Pic9).

Thelaserwillself-leveltotherequiredgradepositionafterconrmingthegradechangewithbutton4.

Pic 5 Standard Display Pic 6 Grade Entry Mode

7

Note: ThebubblesymbolsatthelaserandremotecontrolLCDwillashuntilthelaserhasbeenself-leveled

totherequestedgradeposition.

5.3.2 X-Y-Z-grade entering – Step and Go mode

Howtochangeto‚StepandGo‘modeseechapter8.5

Quicklypressandreleasebutton2(Pic10)startsthegradeenteringmode.Bothgradevalueswillbeshown.

Press/releasebutton1agrade reverse Y (Pic 11)

Press/releasebutton2agrade reverse X (Pic 11)

Press/releasebutton3areturn to the standard display

Quicklypressandreleasebutton4toconrmtheselectedgradevalueand

return to the standard display

Press and hold button 6or 7(left/right)tochangeX-axisgradevalueafterthecomma;pressandholdbuttons

6+7simultaneouslystartsX-axisquickchangemodewherethegradevalueinfrontofthecommawillbeset

to0%andthenstartschangingin1%increments.

Press and hold button 5or 8 (up/down) for changing Y-axis grade value; press and hold buttons 5 + 8

simultaneouslystartsY-axisquickchangemodewherethegradevalueinfrontofthecommawillbesetto

0%andthenstartschangingin1%increments.

Note: The speed of the grade value change increases with the amount of time the button is held down.

Note: Thegradevalueforbothaxesincreasesin1.00%increments.Whenthegradevalueforeitheraxis

reachesitshighestamount,thegradevalueswitchestothelowestvalueforthataxis.Forexample,thevalue

switchesfrom+25%to-25%.

Thelaserwillself-leveltotherequiredgradepositionafterconrmingthegradechangewithbutton4.

Note:Thebubblesymbolsatthelaser’sLCDwillashuntilthelaserhasbeenself-leveledtotherequested

grade position.

5.3.3 Rotation Mode

Repeatedlypressingthebutton4togglesthrough0,80,200,600,750rpmregardlessiftheunit

is in automatic or manual mode.

At0rpm,thebeamstopsautomaticallyclosetothe+Y-axiscenterposition.

Whensetupinautomaticorgrademode,usingbuttons5/8increases/decreasesrotorspeed

from0to80andthenupto750rpmcontinuouslyin10rpmincrements.

5.3.4 Pointing Mode

At0rpm,buttons6/7movethebeamtotheleft/rightside.Whensetupverticallyat0rpm,button5/8 move

thebeamclockwise/counterclockwise.

Note:Pressandholdbutton4for three seconds to change the unit from rotation mode (default) into scan mode.

Pic 9 Set Digit

Pic 10 Standard Display Pic 11 Grade Reverse

8

5.3.5 Scan Mode

Press and hold button 4attheStandardDisplayforthreesecondstochangetheunitintoscan

mode.

Quicklypressandreleasebutton4totogglebetweenthepre-selectedscansizes5,15,45,90,

180degreesand0;regardlessiftheunitisinautomaticormanualmode.

Whenworkinginhorizontalautomaticmode,pressandholdbutton5/8toincrease/decreasethe

linesizein5degreesincrements.Pressandholdbutton 6/7movesthescanlinetotheright/leftdirection.

Whenusedinautomaticverticalmode,pressingandholdingbutton5/8movesthescanlinecounterclockwise/

clockwise.Whensetupvertical,pressingandholdingbutton6/7movesthescanlineintotheright/leftdirection

regardless if in automatic or manual mode.

Note:Pressandholdbutton4for three seconds to change the unit back to rotation mode (default) mode.

5.3.6 Manual Mode

Pressing and releasing button 3attheStandardDisplayactivates/deactivates

the manual mode regardless if set up horizontal or vertical.

Manualmodeisindicatedbyhorizontallinesnexttotheaxessymbols(Pic12).

An additional bubble helps to adjust the laser on the cross axis when set up

vertical (Pic 13).

Inmanualmode(horizontal),theY-axiscanbeslopedbypressingtheUp-(5)andDown-Arrow-(8) buttons on

thelaser‘skeypadortheremotecontrol.Additionally,theX-axiscanbeslopedbypressingtheLeft-(6) and

Right-(7)Arrow-buttonsonthelaserorremotecontrol.

Inmanualverticalmode,theupanddownarrowbuttonsadjusttheZ-axisslope,andtheleftandrightarrow

buttonsalignthelaserbeamtotheright/leftside.

To resume automatic self-leveling mode, press the manual button again.

6 SPECIAL MENU FEATURES

6.1 Menu Functions (Radio controlled)

Press and release button 1attheStandardDisplaytoentertheMENU.

The menu offers always only the features which can be selected depending on the setup (horizontal

or vertical).

The icon of the selected function will be highlighted.

A down arrow at the the right site indicates that the user can scroll down through the menu using the

button 8(down arrow).

Aftergoingtothenextmenurow,anup/downarrowatthetherightsiteindicatesthattheusercanscrollup/

down through the menu (4 different screens) using the buttons 5/8(up/downarrows).

Pressing and releasing button 3changes the unit always back to the standard or previous display.

Press and release the buttons 6/7 until the desired icon at the selected menu row is highlighted.

Press and release button 4toopenthesubmenuORstarttheselectedfunction.

6.2 Menu Functions (IR controlled)

IftheRC603Nispairedwithatransmitterandtheradioconnectionisnotavailable,e.g.,throughapipe,the

IRconnectionoffersreducedfunctionssuchasSpotAlign,SpotMatchandPairing.

Pic 12 Horizontal manual Pic 13 Vertical manual

9

PressandreleasetheMENUbuttonattheStandardDisplay.

Pressing and releasing button 3changes the unit always back to the standard or previous display.

Press and release the buttons 5to 8until the desired icon is highlighted.

Press and release button 4toopenthesubmenuORstarttheselectedfunction.

Note: Pairing function is needed to pair an already paired remote with a new transmitter.

The new transmitter has to be set to the pairing dialog for this operation. Otherwise the pairing can not be

successful processed.

The pairing information of the previous pairing is still stored in the previous paired transmitter and should be

deleted in the pairing dialog of this transmitter

Note:If aremoteis pairedwitha transmittertheIRsignalsof theremote(in caseofan interruptedradio

connection) will transmitted in a private mode so that only the paired transmitter can received these IR

commands.

6.3 Automatic PlaneLok Mode

The PlaneLok mode can be activated in horizontal and vertical

automatic and manual mode.

InPlaneLokmodewhensetuphorizontal,thebeamwillbelocked

toaxedelevationpoint(upto150m(490ft)locatedononeaxis

at each side of the laser.

Forkeepingverticalalignmentsxedtoadirectionpoint,PlaneLok

canbeusedinbothdirectionsontheY-axisand/orontheX-axis.

Note:IneveryPlaneLokmodethelasercontinuestoservotothe

receiver’ssignals.Anylossofsignaloveranextendedperiodoftime(1minute)causesthelasertogointo

theHI-alertcondition(beamturnsoff,rotorstopsandawarningmessageoccursattheLCD.PlaneLokmode

canbereactivatedaftertheerrormessagehasbeendeletedwithbutton4.ExitingofPlaneLokmodecanbe

donebypressingbutton3(ESC)oranyHL760button.

HorizontalSetUp:

1. Set up the laser over the reference point.

2.AttachtheHL760receivertoagraderod.PlacethereceiveratthesecondpointandadjustittotheOn-

grade position. The receiver should be permanently mounted at this location and at the desired elevation.

3.Usethesightingguidesonthetopofthelasertoalignthelasertothereceiver.Turnthelaseronthetripod

untilitisroughlyalignedtothereceiver’sposition(thealignmentrangeforbothaxesis+/-40°).

4.PressandreleasetheMENUbuttonattheStandardDisplayandselectPlaneLok(Pic14).

Pic 14 PlaneLok

horizontal

Pic15PlaneLok

vertical

5.Whensetuphorizontally,pressandreleasebutton4toopenthePlaneLoksubmenu;selectthedesired

PlaneLokaxisY(Pic16)orX(Pic17)orYandX-axis(Pic18)thenpressbutton4to start PlaneLok.

Pic16PlaneLok

Y-Axis

Pic17PlaneLok

X-Axis

Pic18PlaneLokY-

andX-Axis

10

Note:Thelaserstartstosearchforthereceiver.AashingReceiverandLocksymbolappearsattheselected

axisandbecomessolidwhenPlaneLokhasbeencompleted.

Pic19PlaneLok

symbol

The HL760 display shows a ashing –PL– during the time the

laserissearchingandadjustingthebeamtotheon-gradeposition.

When PlaneLok is complete, –PL– stops ashing at the HL760

display.

6.ExitingofPlaneLokcanbedonebypressingbutton3(ESC).

VerticalSetUp:

1. Set up the laser over the reference point

2.AttachtheHL760receiver(withtheverticaladapter)tothenext

reference point

3.PressandreleasetheMENUbuttonattheStandardDisplayandselectPlaneLok(Pic15).Pressandrelease

button4toopenthePlaneLoksubmenu;selecttheYaxis(Pic16)orX-axis(Pic17)orY-andX-axis(Pic18)

and press and release button 4 to start PlaneLok.

Note:Whenusedinverticalmode,thereceiverhastobeplacedwiththephotocellonthebottomside;for

Y-PlaneLok,alignthetopofthereceivertothetopofthelaser.TheHL760displayshowsaashing–PL

–duringthetimethelaserissearchingandadjustingthebeamtotheongradeposition.WhenPlanLokis

complete,-PL–stopsashingattheHL760display.

4.ExitingofPlaneLokcanbedonebypressingbutton3(ESC).

6.4 Automatic Grade Match

TheGradeMatchmodecanbeactivatedinhorizontalautomaticand

manual mode.

InGradeMatchmode,thelasercanbeusedtomeasuretheexisting

gradevaluebetweentwoknownelevationpoints(upto150m(490ft)

locatedononeaxisateachsideofthelaser

1. Set up the laser over the reference point.

2.AttachtheHL760receivertoagraderod.Checkthelaser’selevation

next to the laser then position the receiver at the second point

WITHOUTchangingthereceiver’selevationontherod.

3.Usethesightingguidesonthetopofthelasertoalignthelasertothereceiver.Turnthelaseronthetripod

untilitisroughlyalignedtothereceiver’sposition(thealignmentrangeforbothaxesis+/-40°).

4.PressandreleasetheMENUbuttonattheStandardDisplayandselectGradeMatch.(Pic20)

5.SelectthedesiredGradeMatchaxisY(Pic21)orX(Pic22)orYandX(Pic23)thenpressbutton 4 to

startGradeMatch.

Pic22GradeMatch

X-Axis

Pic23GradeMatch

Y-/X-Axis

Pic21GradeMatch

Y-Axis

Note:Thelaserstartstosearchforthereceiver.AashingReceiverandanglesymbolappearsattheselected

axisanddisappearswhenGradeMatchhasbeencompleted.

mm

Pic20GradeMatch

11

Whilethelaserissearchingandadjustingthebeamtotheon-gradeposition,

theHL760displayshowsaashing–GM–.

WhenGradeMatchhasbeencompleted,theHL760goesbacktothestandard

elevationdisplay.Theremotecontrolaswellasthelaserwilldisplaythenal

measured grade value.

Note:IfGradematchcan’tbecompletedbycheckingthelimits,thelasercomes

withanErrormessage(GradeMatchhasFailed)whichcanbedeletedwith

button 4(OK).TheHL760goesbacktostandardelevationindication.

6.5 Manual Grade Match

NavigatetothemenuGradeMatch(Pic20).ChoosethesubmenuGradeMatchMan.(Pic25)

Pic25

GradeMatchmanual

InManualGradeMatch,thebeamonbothaxescanbeadjustedtothereceiver‘son-gradeposition,e.g,when

otherreceiversastheHL760areused.ThegradefortheY-axiscanbeadjustedwithbutton5/8 while button

6/7adjusttheX-axis.DuringManualGradeMatchacrossedvialandangle(Pic26)symbolappearnextto

thecontinuouslychangingY-andX-axisgradevalue.Afteradjustingtothereceiver’son-gradeposition,press

button 2(OK)togobacktoautomaticmodewherethenalgradevaluewillbeshownforbothaxes.

Pic26

Note:Pressingbutton3(ESC)exitsManualGradeMatchandchangestheunittomanualmode..

6.6 Axis Alignment

6.6.1 Automatic Axis Alignment

AutomaticAxis Alignment mode adjusts automatically the direction

thegradeaxisispointingtothereceiver’slocationbyanelectronically

simulationofrotatingtheunitonitsbasetomatchthehub.UsingAxis

Alignment,thelaseraxiscanbealignedtoonedirectionhub(upto150

m(490ft)locatedononeaxisateachsideofthelaser.

1. Set up the laser over the reference point.

2.PlacethegraderodwiththeattachedHL760receiveratthedesired

direction hub.

3.Usethesighting guidesonthe topofthelaser toalignthe laserto

the receiver. Turn the laser on the tripod until it is roughly aligned to the receiver’s position (the alignment

rangeforbothaxesis+/-40°).

4.PressandreleasetheMENUbuttonattheStandardDisplayandselectAxisAlign.(Pic27)

5.SelectthedesiredaxisY(Pic28)orX(Pic29)orYandX(Pic30)thenpressbutton4tostartAxisAlign.

Pic28Axis

AlignmentYAxis

Pic29Axis

AlignmentX-Axis

Pic30AxisAlignment

YandX-Axis

Note:Adjustingthereceiverintothebeambefore starting the automaticAxisAlignment reduces the time

neededfornishingthealignment.

mm

Pic27Axis

Alignmenthorizontal

12

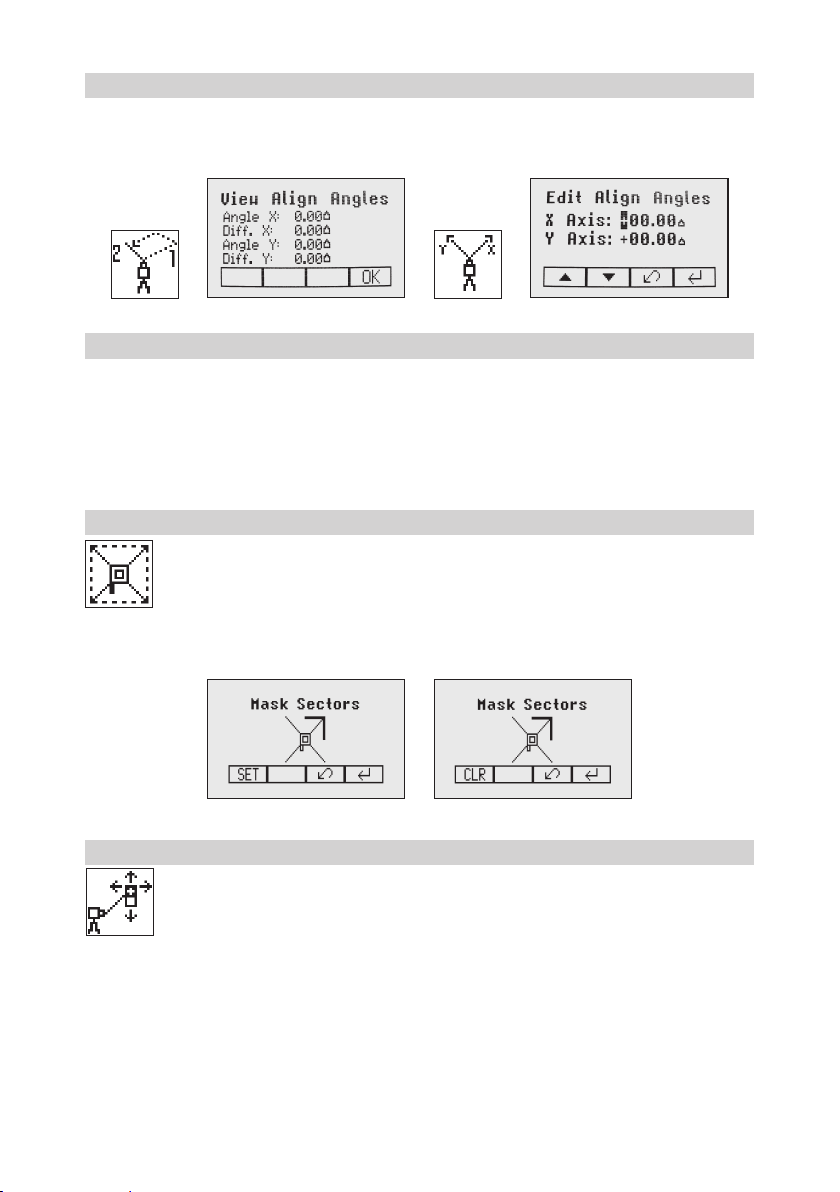

6.6.2 View Align Angles

Selecting the submenu „View Align Angles“showsthealignmentangleafteranaxisalignmenthasbeen

completed. This function can be used to measure an angle difference between two direction hubs in a range

uptomax.80°byperformingtwoaxisalignmentsinsequence.

6.6.3 Edit Align Angles

The submenu „Edit Align Angles“selectionallowstodialinanaxisanglewheretheaxisdirectionwillbe

alignedtooafterarstaxisalignmenthasbeendone.Tworowsareavailablefortypinginaxisanglevalues.

Button5and 8canbeusedtotogglebetweenbothrows.Changingthesignandnumberscanbedoneusing

the buttons 1and 2.

Press and release button 4toconrmtheselectedaxisangles.Theaxeswillbeadjustedwhilethedisplay

fallsbacktothemainMenu.

Press and release button 3(ESC)toexittheAnglefunctions.

6.7 Mask mode

SelecttheMaskicon(Pic32)andpressandreleasebutton4toopentheMasksettingmenu.

Dependingonwhichsideorcornerthebeamshouldbeturnedoff,therequiredsectorcanbe

selected. Press and release the buttons 5to 8formovingashortashinglinearoundthemask

modesymbol.Forselectingthesectorwherethebarisashing,pressandreleasebutton1(SET).

Aftersettingtherstsector,button1changestoshowCLRwhichofferesthecapabilityofdeleting

theselectedmasksectoragain.Usebutton5to 8tomovetheashingbartootherrequiredareas

andrepeatthesettingprocess.Whenallareashavebeenset,pressbutton 4 to store the mask

sector selection until the unit will be turned off.

Note:Theunitalwayspowersupwiththemaskmodedeactivated(default).

6.8 Manual Spot Search mode

The Spot Search mode is used for detecting the plumb beam manually using the Spot Finder

SF601andcanbeactivatedinhorizontalandverticalautomaticandmanualmode.

PressandreleasetheMENUbuttonattheStandardDisplayandselectSpotSearch(Pic33).

Pressing button 4activatesthefanbeamwhiletherotationspeedchangesto750rpmand

the unit goes back to the standard display.

The4redLEDsaroundthecenterholeguidetheusertotheplumbbeam‘scenterposition-all4LEDson=>

conrmationtheSF601hasbeensettothecorrectcenterposition.

ToswitchofftheSportSearchmodepressandreleasetheMENUbuttonandselectSpotSearch(Pic33);

pressing button 4 switches off the Spot Search mode. The regular plumb beam is visible again and the unit

goes back to previous rotation speed.

Note:ManualSpotSearchcanalsobeactivatedanytimebyturningontheSpotFinderSF601.

TurningOfftheSF601deactivatestheSpotSearchmodeimmediatelybydeactivatingthefanbeam.

Pic32

MaskMode

Pic 33

Spot Search

13

6.9 Activating/Deactivating Standby mode

PressandreleasetheMENUbuttonattheStandardDisplayandselectStandby(Pic31).

Pressing and releasing button 4activates the Standby mode.

Theself-levelingwillbestoppedandthebeamwillbeturnedoffwhiletheHIalertisstillactive.

ThedisplayshowsthestandbysymbolandtheLevel/StandbyLEDashesredevery5seconds.

To deactivate Standby mode and restore full operation of the laser, press and release button 4.

6.10 Start Reference Check

Whenworkingduringtemperaturechangesandoverlongdistancestheproductrequiresafrequent

reference check to maintain accuracy and avoid errors caused by drift. The transmitter will do an

automaticuponstartupandafter20minutesofoperation.Itwillrepeatthereferencecheckevery

60minutesandwhenthereisa5°C(9°F)changewithintheproduct.Whencarryingoutworkwhere

accuracy is paramount it is advised to manually prompt a reference check at regular intervals.

PressandreleasetheMENUbuttonattheStandardDisplayandselectReferenceCheck

(Pic35).

Pressing and releasing button 4startstheReferenceCheckconsideringthecurrenttemperatureinside the

housing.Whiletherotorchecksthecorrectpositiontherotationwillbestopped.

Note:Agradevaluehastobeenteredbeforetheunitstartsthereferencecheck.

6.11 Setting Menu

PressandreleasetheMENUbuttonattheStandardDisplayandselectSettings(Pic36).

Press and release button 4toopentheSettingMenu;selectthedesiredfunctionthenpressbutton

4toopentheselectedsubmenufunctionORstarttheselectedfunction.

PleaseseetheSettingMenudetailsattheendoftheuserguide.

6.12 Info

PressandreleasetheMENUbuttonattheStandardDisplayandselectInfo(Pic37).

Buttons6/7canbeusedtotogglebetweenUL,RCandRuntime.

Press and release button 4toconrmtheselection.

TheUL/RCinformation(softwareversion,ID,etc.)ortheruntimeoftheULwillbedisplayed.

Pic 34

Standby

Pic35

Reference

Check

Pic36Settings

Pic37Info

Pic38InfoUL Pic39InfoRC Pic40Runtimes

14

6.13 Service

PressandreleasetheMENUbuttonattheStandardDisplayandselectService(Pic41).Buttons

6/7 can be used to toggle between Calibration Y and Calibration XOR Calibration Z when

set up vertically.

Press and release button 4toconrmtheselection.Thecalibrationattheselectedaxisstartstheeldcalibration

procedure.

6.14 RC603N Service menu:

ThismenuisavailableonlyviatheRC603N.

6.14.1 RF IR options

Choosemenu‚RFIROptions‘(Pic45).Pressandreleasebutton4toconrmtheselectionand

selectoneofthefollowingoptions:

RFOn;IRauto=>Radioonalltimes;IRwillbeactivatedautomaticallyafterradioconnection

has been lost.

RFOff;IROn=>RadioturnedOff;IRalwaysactivated

RFOn;IROff=>RadioturnedOn;IRalwaysOff

Pic46RFOn;

IRAuto

Pic47RFOff;

IROn

Pic48RFOn;

IROff

6.14.2 RF Connectivity

Press and release button 4togetastatusofthecurrentRadioconnectivity(Pic49).

Pic 41

Service

Pic42

CalibrationY

Pic 43

CalibrationX

Pic 44

CalibrationZ

Pic45RFIR

Options

Pic49Radio

Connectivity

15

7 SPECIAL FEATURES - VERTICAL SETUP

7.1 Z-Axis Automatic Spot Align

TheSpotFinderSF601guidestheplumbbeamtothetargetpointinthehorizontalaxis,while

theZ-axisgradevaluewillbemaintained.UsingSpotAlignment,theplumbbeamcanbealigned

automaticallytoonedirectionhub(upto80m(260ft)locatedinfrontoftheplumbbeam.

1. Set up the laser over the start point.

2.Adjustthedisplaybubbletothecenteredposition.

3.TurnonandattachtheSF601SpotFinderatthedesireddirectionhub.

4.PressandreleasetheMENUbuttonattheStandardDisplay;selectSpotAlign(Pic50)andstartthefunction

using button 4(fan beam will be activated).

Note:SpotAligncanalsobestartedusingtheRC603Nviainfrared.

Note:ThedisplayfallsbacktothestandarddisplaywhileaSpotFindersymbol(Pic51)isashing.

Pic51

SpotFinder

TheplumbbeamwillbeautomaticallyalignedtothecenteroftheSF601.

5.Afteralingmentiscomplete(all4redLEDsattheSF601areon),theplumbbeamwillmoveverticallytothe

previousdialedinZ-axisgradevalue.

Note:AutomaticSpotAligncanbeexitedanytimebypressingandreleasingbutton3(ESC).

7.2 Z-axis Automatic Spot Lok

Automatic SpotLok (likePlaneLok)canbeusedtoalignandholdtheplumbbeamautomaticallytotheSF601’s

centerpointandcontinuouslyadjustingtheZ-andX-axisuntilexitingthismode.TheULlooksalwaystothe

centerpositionoftheSF601andre-adjuststhebeamimmediatelytothecentertoavoidanysetup/alignment

driftcausedbyvibrationsortemperatureinuences(e.g.whenworkingonconcretepads,facadeapplications).

UsingSpotLok,theplumbbeamcanbealignedautomaticallytoonedirectionhub(upto80m(260ft)located

in front of the plumb beam.

1. Set up the laser over the start point.

2.PlacetheSF601SpotFinderatthesecondreferencepoint.

3.Press and release the MENU button at the Standard

Display, select SpotLok(Pic52) and start thefunction

using button 4(fan beam will be activated).

Note:SpotLok canalsobe startedviainfrared usingthe

RC603N.

Note:ThedisplayfallsbacktothestandarddisplaywhileaSpotFinderandlockicon(Pic53)isashing.The

plumbbeamwillbeautomaticallyalignedtothecenteroftheSF601.

Pic53

LockMode

4.AfterSpotLokiscompleteall4redLEDsattheSF601areonandtheiconsstopashing.Thetransmitter‘s

plumbbeamisalwayscheckingforperfectalignmenttothecenteroftheSF601.All4LEDsashevery5

secondstoconrmthecorrectalignment.

Note:AutomaticSpotLokcanbeexitedanytimebypressingandreleasingbutton3(ESC).

Pic50

SpotAlign

16

7.3 Z-axis Automatic Spot Match

Automatic-Spot-Match canbeusedformeasuringanunknowngradevaluebetweentwoexistingelevations

e.g.,inanexistingpipewhichneedstobereplacedoranopentrenchwithanunknowngradevalue.

TheplumbbeamwillbeautomaticallyalignedtotheSF601centerpoint(Z-andX-axis)andswitchesback

toautomaticZ-axisgrademodewhiledisplayingthemeasuredZ-gradevalue.

UsingSpotMatch,theplumbbeamcanbealignedautomaticallytoonedirectionhub(upto80m(260ft)

located in front of the plumb beam..

1. Set up the laser over the start point.

2.Place the SF601 Spot Finder at the second reference

point.

3.Press and release the MENU button at the Standard

Display,selectSpotMatch(Pic54)andstartthefunction

using button 4(fan beam will be activated).

Note:SpotMatchcanalsobestartedviainfraredusingtheRC603N.

Note:ThedisplayfallsbacktothestandarddisplaywhileaSpotFinderandanglesymbol(Pic55)isashing.

TheplumbbeamwillbeautomaticallyalignedtothecenteroftheSF601.

Pic55

AngleSymbol

4.WhenSpotMatchhasbeencompleted,thefanbeamwillbeturnedoffandtheULcalculatesthegrade

valuebetweenbothelevationpoints.ThecalculatedgradevaluewillbedisplayedattheUL‘sandRC‘sdisplay.

Note:AutomaticSpotMatchcanbeexitedanytimebypressingandreleasingbutton3(ESC).

7.4 Line Scan

LineScan(Pic56)centerstherotorhorizontallyandcanbeusedtoaligntheplumbbeamto

adesiredhorizontalposition.PressandreleasetheMENUbuttonattheStandardDisplayand

select Line Scan. Pressing and releasing button 4activates the Line Scan mode while the rotor

checksthelimitsoftheX-axisandstopsatthecenterposition.

Pressing button 3(ESC)stopsthemovementandchangestheunitintomanualmode.

Correctionsupanddowncanbedoneusingbutton5/8;forleft/rightcorrectionsusebutton6/7.

Press and release the manual button to change the unit back to full automatic mode.

DuringtheLineScanprocessthecentermovesymbol(Pic57)isashing.

7.5 Beam Plunge

BeamPlungecenterstherotorverticallyandcanbeusedtoaligntheplumbbeamtoadesired

verticalposition,e.g.,whendoingInteriorlayout.

PressandreleasetheMENUbuttonattheStandardDisplayandselectBeamPlunge(Pic58).

Pressing and releasing button 4activatestheBeamPlungemodewhiletherotorchecksthelimits

oftheY-axisandstopsatthecenterposition.

Pressing button 3(ESC)stopsthemovementandchangestheunitintomanualmode.

Correctionsupanddowncanbedoneusingbutton5/8;forleft/rightcorrectionsusebutton6/7.

Press and release the manual button to change the unit back to full automatic mode.

Pic56

Line Scan

Pic57

CenterMove

Pic58

BeamPlunge

17

8 Settings

PressandreleasetheMENUbuttonattheStandardDisplayandselectSettings(Pic59).

Press and release button 4toopentheSettingMenu;selectthedesiredfunctionthenpressbutton

4toopentheselectedsubmenufunctionORstarttheselectedfunction.

TheSettingMenuoffersthefollowingfunctions:

Pairing Grade Entry Grade Display Sensitivity

HI-Alert

User Name Set Password Password On/Off RF-Channel

Select

Language

Position Info

8.1 Pairing

Pairing is needed to couple different devices with the laser. The laser is able to communicate with

several numbers of other radio network participants and pairing is the process to link these to each

other.Buyingthelaseralldevicesshouldbepairedbutforsomereasonsthismaynotbetrue

or the pairing has been lost. So you can pair the devices as described in the following sections.

Note:Makesurethatpairingmodeisselectedonlyatonelaserwhichiswithintheradiorangeoftheremote

duringapairingrequest.Otherwisepairingprocedurecanbeconfused.

8.2 Pairing the laser with remote control

Startwiththelaser.WheninmenuSettings(Pic59),pressandreleasebutton4toopenthepairingmenu

(Pic71).Thedisplayshowsthecurrentlypairedunits(uptotworemotes).MakesureatleastoneRCslotis

freefortheremotetobepaired.IfnofreeRCslotisavailable,chooseoneofthemanddeleteitusingbutton

1(CLR).Pressbutton2tostartthepairingprocess.Continuewiththeremotechoosingthesymbolpairing

(Pic71);thepairingstartsautomatically.Aftersuccessfulpairing,thelaserdisplayshowstheIDoftheremote

in the pairing list.

8.3 Pairing the laser with receiver HL760

To pair the laser and the receiver select Settings and press and release button 4to open the Pairing menu (Pic

71).Thedisplayshowsthecurrentlypairedunits(upto2receivers).Ifalready2receivershavebeenpaired,

one or both of them have to be deleted using button 1(CLR).

Pic59

Settings

Pic71Pairing

18

A

B

C

Next,turnonthereceiverthenpressandholdtheDeadband(A)andtheAudio(B)buttonsfortwoseconds.

AftertwosecondsthedisplayshowsMENUrst,thenRDIO.

PressandreleasetheUnits(C)button–displayshowsthecurrentradiomode.

IfnotalreadysettoLS,pressUnitsbuttonandthenpressDeadbandorAudiobuttonuntilLS is displayed.

PressUnitsbuttonagaintoenterselection.PressandreleasetheAudiobutton–displayshowsPAIR.Press

theUnitsbuttonagain–thedisplayshowsPAIRandarotatingbar.AftercompletingPAIR,OKwillbedisplayed.

TheUL633Npairsnowautomaticallywiththenewreceiver.PressandreleasethePowerbuttontwotimesto

exitthemenu.Alasersymbolislittoconrmthereceivercancommunicatewiththelaser.

8.4 Pairing the laser with the signal transporter (ST802/ST805)

MakesuretheST802/ST805isswitchedoff.StartwiththeLaser.WheninmenuSettings(Pic59),pressand

releasebutton4toopenthepairingmenu(Pic71).Thedisplayshowsthecurrentlypairedunits(onesignal

transportermax).MakesuretheSTslotisfreeforthesignaltransportertobepaired.Iftheslotisnotfree,

choosetheSTslotanddeleteitusingbutton1(CLR).Pressbutton2tostartthepairingprocess.Switchon

thesignaltransporter.Thesignaltransporterpairsautomaticallywiththelaser.Ifthepairingwassuccessful

theaddressorIDofthepairedSTisshowninthepairinglist;alsothesignaltransportershowsasolidblinking

yellowstatusLED.

8.5 Grade Entry

SelecttheGradeEntryicon(Pic73)andpressandreleasebutton4toopentheGradeEntrymenu.

Buttons6/7canbeusedtotogglebetweenStepandGo(Pic74)andDigitSelect(Pic75).

Press and release button 4toconrmtheselection.

Pic 74

Step and Go

Pic 75

Digit Select

8.6 Grade Display

SelecttheGradeDisplayicon(Pic76)andpressandreleasebutton4toopentheGradeDisplay

menu.

ThedesiredGradeDisplayMode(Percent(Pic77)/Permille(Pic78)/Degree(Pic79))canbe

selected using the buttons 6/7. Press and release button 4toconrmtheselecteddisplaymode.

Pic73

GradeEntry

Pic76

GradeDisplay

Pic78

Per mill

Pic77

Percent

Pic79

Degree

Other manuals for Trimble UL 633N

1

Table of contents

Other Spectra Precision Laser Level manuals

Spectra Precision

Spectra Precision LL300S Instruction manual

Spectra Precision

Spectra Precision LL300S User manual

Spectra Precision

Spectra Precision GL6X2N Installation guide

Spectra Precision

Spectra Precision LL300S User manual

Spectra Precision

Spectra Precision GL412N User manual

Spectra Precision

Spectra Precision LL100N Assembly instructions

Spectra Precision

Spectra Precision AL28M User manual

Spectra Precision

Spectra Precision HV302 User manual

Spectra Precision

Spectra Precision HV302 User manual

Spectra Precision

Spectra Precision Trimble UL 633N Installation guide