Spectrasensors 2000 Series User manual

2001, SpectraSensors, Inc. 1

Model 2000 Series

Operators Manual

Model 2000 Series

2001, SpectraSensors, Inc. 2

Table of Contents

Introduction

Theory of Operation 3

Specifications 4

Installation

Introduction 5

Initial Inspection 6

Location Requirements 6

Mounting Procedure 7

Gas Connections 8

Electrical Connection 9

Output Signal Connection 12

RS-232 Output 15

Calibration 15

Power up Sequence 16

Operation

Specification of Proper Use 17

Keypad Functions 17

Modes (User Password) 19

Power-down Procedure 27

Maintenance

Reducing Contamination of Gas Sampling Lines 28

Cleaning Procedure 28

Troubleshooting

Troubleshooting 33

Warranty Information 35

Service Contact

If the above troubleshooting steps do not result in a resolution of the problem,

you should call the sales representative that sold it to you. Always contact your

sales representative before returning units to factory. The representative can help

with additional troubleshooting procedures and can diagnose whether the unit can

be serviced on-site or should be returned to the factory for repair. Your sales

representative is:

2001, SpectraSensors, Inc. 3

Introduction

About SpectraSensors

SpectraSensors is located in Altadena, California, just a short distance from the

California Institute of Technology's Jet Propulsion Laboratory (JPL) where the

basic technology behind the products offered by SpectraSensors was developed.

This technology was first utilized for accurate measurements of gases in the

Earth's atmosphere in the early 1980s, and recently was incorporated into

miniaturized and space-qualified instruments for Mars research. SpectraSensors

obtained the commercial rights to this NASA technology, and is now offering

state-of-the-art gas sensors.

About the Model 2000 Series Gas Sensor

The 2000 series of gas sensors are Tunable Diode Laser (TDL) absorption

spectrometers operating in the near infrared wavelength region. Each 2000 sensor

contains a TDL light source and detector configured to allow high sensitivity in a

compact package, microprocessor-based electronics, and software incorporating

advanced operational and data processing algorithms. This manual will use the

two-channel system as a reference for description. All comments also apply to

the single channel sensors, except where indicated.

The 2000 Series is designed for use at natural gas sampling stations, extractive

analysis installations, or wherever fast response and high accuracy measurements

are required over a wide measurement range. It is a high performance instrument,

capable of measuring moisture and carbon dioxide in methane and other gases

without regard to corrosive gases and contamination from other gas phase

constituents in the stream.

Several patents protect the TDL absorption technology incorporated in

SpectraSensors' gas analyzers.

Theory of Operation

Both H2O and CO2are measured by monitoring their absorption of laser light at

specific wavelengths in the near-infrared (near-IR) wavelength region near 2µm.

The human eye responds to light in the range of approximately 0.4µm (deep

violet) to 0.8µm (deep red), but most molecules “respond” to light at longer

wavelengths that are invisible to the human eye (the infrared region). By using a

laser that operates precisely at a wavelength where H2O, or CO2, (many other

gases can also be measured using this technique) absorbs, it is possible to

accurately determine the abundance of the gas by measuring the amount of light

that is absorbed by the molecules.

SpectraSensors’ can provide references that describe in detail how our gas

sensors operate. However, a detailed description is beyond the scope of this user

manual.

2001, SpectraSensors, Inc. 4

Specification Sheet for the 2000 Series Analyzer

Table 1 Specification sheet

Measurement Range

Moisture Concentration (H20) 0 to 20 lbs/MMscf

Dew/Frost Point -70 to +-30 °C (-94 to -22°F)

Carbon Dioxide (CO2)0 –10%

Reading Accuracy (H2O) ±2% of reading, or ±4 ppmv,

whichever is greater

Reading Accuracy (CO2)±2% of reading, or ±400 ppmv,

whichever is greater

Response time 1 second continuous updates

(software adjustable)

Normal operating environment range

Temperature -20 to +50°C (-4 to +122°F)

Pressure 0.7 to 1.7 Bar (10.3 to 25.0 PSA)

3 Bar (30 PSIG) absolute maximum

Gas flow rate 0.3 to 10 Liter/minute

Glycol contamination sensitivity None for gas phase glycols

Sample cell construction 300 series polished stainless steel

Input Voltage 100-250 VAC, 50-60 Hz standard

Current draw @ 120 VAC 1 amp maximum

Outputs

Moisture, dew point, CO2%, pressure, and

temperature 4 line LCD display

RS-232 serial port

4-20 ma current loop

(concentration only)

Data Input 16-key keypad

Weight 25 lbs (11.5 kg)

Dimensions (box) Wide: 18.8-in. (478-mm)

Deep: 5.3-in. (135-mm)

Height: 17.5-in. (444-mm)

NOTE: These are typical specifications. Exact performance will vary depending on installation and

operating environment.

2001, SpectraSensors, Inc. 5

Installation

Introduction

The 2000 Series is a compact unit designed to provide years of accurate,

dependable gas monitoring. All of the electronic controls are contained inside a

NEMA 4X stainless steel enclosure.

The 2000 Series contains one or two sensitive measurement heads (depending on

number of target gases analyzed). Each consists of a gas sample cell and an

optical head assembly. Inside the optical head assembly is a tunable diode laser

and optical components that should be handled with extreme care.

CAUTION! –Do not hold or carry the unit by the measurement

heads or sample cells. Doing so may cause optical alignment problems

affecting the performance of your sensor.

Key Hook-up Details

Gas Connection ¼" O.D. Tube

Power Cord Diameter 0.31" to 0.56"

Signal Cable Diameter 0.31" to 0.56"

Conduit Knock Hole ½" K.O.

2001, SpectraSensors, Inc. 6

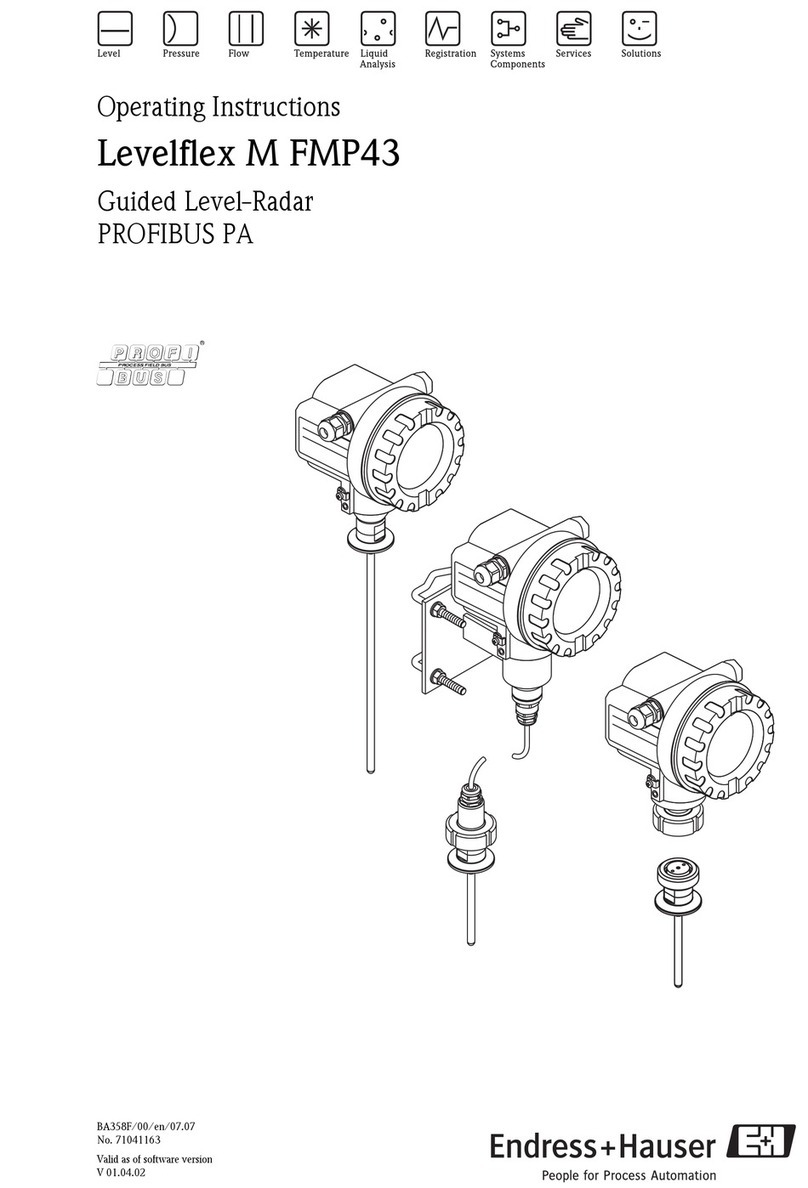

Figure 1 Main external components identified on 2000 Series gas sensor.

Initial Inspection

The 2000 Series should be inspected for damage. The contents of the container

should include:

§The 2000 Series stainless steel enclosure with measurement leads

§Operators Manual

Inspect the unit for dents or dings in the enclosure and keypad. Inspect the inlet

and outlet connections for damage. Report any damage to the shipping agent.

§

Location Requirements

§AC power (100-250VAC, 50/60 Hz). The 2000 Series is equipped with a

universal power supply that will accommodate both US (110 VAC @ 60 Hz)

and European (250 VAC @ 50Hz) AC power configurations

§Mounting surface: wall-mounted, or tabletop mounted.

Sample cell

upper flange

Sample cell

Sample cell

lower flange

Keypad

Optical head

assembly

Left sample

cell gas line

connection

Right sample

cell gas line

connection

Serial and 4-20mA

interface connections

Power connections

2001, SpectraSensors, Inc. 7

§Sampling lines with coalescing and particulate inline filters and shutoff valve

on inlet line

§Ambient temperature: -4°F (-20°C) to 122°F (50°C)

§Ambient pressure: 10 PSIA to 16 PSIA (sample cell pressure: 10 -25 PSIA)

Mounting Procedure

The 2000 Series is designed to be bolted to a wall or other flat surface that is free

of vibrations. Minimizing the gas volume of the sample system and using

stainless steel tubing optimizes performance. The only critical mounting issue is

to mount the unit so that the inlet and outlet line will reach the inlet and outlet

connections on the chassis and still have some flexibility (i.e. the sample lines

will not be under excessive stress).

To wall mount the 2000 Series gas sensor:

1. Unpack the 2000 Series from the shipping container. Be careful not to

shock the instrument by dropping it or banging it against a hard surface

as this could disturb the optical alignment.

2. The 2000 Series has 4 mounting tabs with a 0. 3-in. hole in each tab (see

Figure 2). SpectraSensors recommends using ¼" lag bolts (or ¼-20 machine

screws if through bolted).

3. Position the unit where desired.

4. Mark the hole in one of the top tabs with a pencil.

5. Mark a second top screw location 8" over from the first.

6. Mark the lower screw locations 12-3/4" below the top holes.

7. Drill the appropriate size hole for the screws being used.

8. Hold the unit in place and insert the top screws.

9. Insert the bottom screws and tighten all four screws. The unit should be very

secure.

10. The unit is now ready to receive the inlet and outlet sampling gas lines.

Figure 2 Main external components identified on 2000 Series gas sensor.

Foot of mounting

bracket (identical on

each rear corner of

enclosure)

2001, SpectraSensors, Inc. 8

Gas Line Connection Procedure

The 2000 Series is configured to accept ¼" O.D. sampling lines (inlet and outlet)

via compression fittings mounted on the chassis.

CAUTION! –The inlet line should be equipped with a membrane or

coalescing filter to prevent liquid from entering the sample cell and possibly

accumulating on the internal optics.

It is important that the internal optical elements remain clean for proper readings.

The inlet line should also have a shutoff valve to prevent gas flow into the

analyzer when it is not in use. The outlet line of the 2000 Series is connected to a

¼-in. O.D. stainless steel line that vents the sampled gas to ambient air outside

the sampling station. After the inlet and outlet lines have been connected, the

connections should be checked for leaks. The minimum flow rate through the

analyzer should be 0.3 liters per minute (L/min). Optimum sample cell pressure

is just above ambient pressure for the installation location. Sample cell pressure

is displayed on the front panel LCD.

CAUTION! –The pressure in the sample cell must not exceed 30

PSIG (3 Bar A). Higher pressures will cause catastrophic damage to the

instrument. We recommend that there be no restrictions in the output vent

line of the sample cell and that a pressure relief valve be used on the input

line in case of regulator failure.

To make the gas line connections:

1. To avoid initial contamination entering the analyzer, establish the gas flow

and blow any contamination from the line before connecting.

2. Align the inlet and outlet tubing to gas sensor inlet and outlet connections.

3. Be sure that there is no stress on the tubing when it is aligned to the gas

sensor.

4. Install union type swage fittings to connect the inlet and outlet tubes to the

gas sensor.

5. Follow manufacturer's recommended procedure for tightening the fittings.

6. Open the shutoff valve on inlet line.

7. Check the connections for gas leaks.

2001, SpectraSensors, Inc. 9

Electrical Power Connection Procedure

Electrical power can be connected to the unit with either a power cord or through a

conduit. A ½" knockout is provided at the lower right of the unit to accomplish this. The 2000

Series is equipped with either a universal power supply that will accommodate both US (115

VAC @ 60 Hz) and European (240 VAC @ 50Hz) AC power configurations or a DC input

power supply.

CAUTION! –Before attempting to attach the power wiring to the

gas sensor, be sure that there is no power present on the wires.

To connect an electrical power cord to the unit:

1. Open the enclosure door, being careful not to disturb the electrical assembly

inside.

2. Thread a 120VAC power cord through the strain relief fitting supplied with

the unit. See figure 3. The power cord must be the three wire grounding

type. The power cable should have at least 16 gauge conductors. The strain

relief fitting is designed to accommodate cords with outside diameters from

0.31" to 0.56".

Figure 3 Thread power supply through the right side access point at the bottom of the enclosure.

Power supply

access point

2001, SpectraSensors, Inc. 10

Figure 4 Connect neutral line to terminal marked “NEU”, and hot line to terminal marked “LINE”.

3. Remove at least 8" of the jacket to expose the three conductors within.

4. Cut the black wire (line or hot) and the white wire (neutral) about 2" from the

jacket and strip off 3/8" of insulation from the ends.

5. Loosen the terminal screw marked LINE, insert the black wire, and tighten

the terminal screw. Be sure that the terminal is contacting the conductor and

not clamped onto the insulation. See figure 4.

6. Loosen the terminal screw marked NEU, insert the white wire, and tighten

the terminal screw. Be sure that the terminal is contacting the conductor and

not clamped onto the insulation.

7. Crimp a #10 ring terminal to the green (ground) wire in the cord. Be sure

that the terminal is the correct size for the gauge of wire being used and the

crimp holds both the insulation and the wire. Follow the terminal

manufacturer's instructions for preparing and crimping the terminal.

8. Remove the grounding screw at the bottom right of the electrical panel. See

figure 5. Insert the screw through the ring terminal on the green wire of the

power cord, through the ring terminal of the internal grounding wire, and

tighten it into the panel.

CAUTION! –Failure to properly ground the gas sensor can create a

high voltage shock hazard. Follow the instructions carefully.

“Neutral” terminal

connection

“Hot” or “Line”

terminal connection

2001, SpectraSensors, Inc. 11

Figure 5 Connect the green wire to the ground contact in the lower left corner of the enclosure.

9. Tighten the strain relief mechanism so that it is grips the power cord.

10. Close and lock the enclosure door.

11. Plug the power cord into an AC socket. The socket should be fused for 15A

or less. Because the plug on the power cord is the primary power disconnect

means, the AC socket must be located within 10 ft of the gas sensor.

To hardwire power to the unit through a conduit:

CAUTION! –Before attempting to attach the power wiring to the

gas sensor, be sure that there is no power present on the wires.

1. Open the enclosure door, being careful not to disturb the electrical assembly

inside.

2. Remove the cord strain relief fitting from the power knockout.

3. Replace the strain relief with a NEMA 4X rated conduct hub.

4. Run conduit from the AC panel to the conduit hub. Since the breaker or switch

in the AC panel will be the primary disconnect means for the gas sensor, the AC

Ground Contact

2001, SpectraSensors, Inc. 12

panel must be located within 10 ft. of the gas sensor. The gas sensor should be

on a circuit that is protected at 15A or less.

5. Pull Ground, Neutral, and Hot wires into the electrical enclosure.

6. Attach the Neutral and Hot wires to the power terminal strip as shown in figure 3.

7. Crimp a #10 ring terminal to the green (ground) wire. Be sure that the terminal is

the correct size for the gauge of wire being used. Follow the terminal

manufacturer's instructions for preparing and crimping the terminal.

CAUTION! –Failure to properly ground the gas sensor can create a

high voltage shock hazard. Follow the instructions carefully.

8. Turn on power to the gas sensor circuit.

Output Signal Connection Procedure

The 4-20mA and serial outputs are supplied from a mating terminal block inside

the unit. Connections can be made with a customer supplied cable through the

strain relief fitting supplied with the gas sensor or by running the signal wires

into the enclosure through a ½" conduit.

CAUTION! –Be sure the power to the unit is turned off before

opening the gas sensor enclosure and making any connections.

Note that the 4-20mA outputs are factory set to source current. If a passive current

loop is required, the jumper on the current loop board may be moved from the “A”

(active) position to the “P” (passive) position.

To connect the 4-20mA and serial outputs through a cable:

1. Disconnect power from the unit.

2. Open the enclosure cover, being careful not to disturb the electrical assembly

inside.

3. Thread the signal cable through the strain relief fitting into the enclosure.

The strain relief fitting is sized to accommodate cables with outer diameters

from 0.31" to 0.56". SpectraSensors recommends that a cable with an

individually shielded pair for each signal be used for the signal connections.

4. Strip back the jacket and insulation of the signal cable enough that it can be

connected to the mating terminal block.

5. The mating terminal block can be pulled up from its base to make cable

connection easier. See figure 6.

2001, SpectraSensors, Inc. 13

6. Table 2 shows the pin number for each of the output signals. Note that there

is a single ground connection shared by all of the signals.

Pin #

Signal Description

1CH1 Serial RX

2CH1 Serial TX

3COM Serial Gnd

4CH2 Serial RX

5CH2 Serial TX

6CH1 Current Loop +

7CH1 Current Loop -

8CH2 Current Loop +

9CH2 Current Loop -

Table 2 Output Signal Connections

7. Connect the output wires to the desired terminals. See figure 7.

8. Reinsert the matting terminal block into the base and verify that the terminals

are tight. See figure 8.

9. Cinch the strain relief mechanisms so that they are snug with the outside of

the enclosure.

10. Close and lock the enclosure cover.

Figure 6 Remove the mating terminal block from base by hand.

4-20 mA and serial

output block

Power supply

block

4-20 mA and serial

output block base

2001, SpectraSensors, Inc. 14

Figure 7 Insert signal wires into terminals as shown in Table 2

Figure 8 Replace block on base and check all terminals are tight.

2001, SpectraSensors, Inc. 15

To connect the 4-20mA and serial outputs through a cable:

1. Disconnect power from the unit.

2. Open the enclosure cover, being careful not to disturb the electrical assembly

inside.

3. Remove the cable strain relief fitting and replace it with a NEMA 4Xrated

conduit hub.

4. Run conduit to the gas sensor and pull signal wires through the conduit.

SpectraSensors recommends the use of shielded wire to prevent signal

interferences.

5. Follow steps 4 through 10 above for connecting the signal wires to the

terminal block.

RS-232 Output

The RS-232 presents a string of data to a serial device. The serial device is

typically a computer terminal running HypeTerminal or other serial port

software. The serial port should be set for 9600 baud, 1 stop bit, no parity, and

no handshake. The RX output is connected to pin 3 on the computer's serial

input. The TX output is connected to pin 2 on the computer, and the GND is

connected to pin 5.

The data string is space delimited with a carriage return at the end of each line.

The data are output in the following order:

Water vapor concentration (if a water channel)

Dewpoint (if a water channel)

CO2 concentration (zero unless a CO2 channel is present)

Pressure

Temperature

2F signal

DC signal

Peak Position (Index)

Null

Calibration

The instrument is calibrated at SpectraSensors against standard (assayed) gas

mixtures, and should not be adjusted in the field. Unlike aluminum oxide or

electrolytic sensors that are in contact with the sample gas, the laser used to make

the measurement in the 2000 Series simply passes through the sample cell and

there are no sensors in contact with the gas. So drift or contamination from

contaminants (such as glycols or amines in the gas phase) is not possible.

If, however, there is any question or doubt about the 2000 Series readings, a

calibration using a Certified Master Class Calibration Standard, or a chilled

2001, SpectraSensors, Inc. 16

mirror hygrometer, may be used to verify measurement accuracy. Note that any

H2O calibrations must be performed with the same type of background gas

that is used in normal operation.

Power Up Sequence

When the 2000 Series gas sensor has been mounted, the gas sampling lines

connected and checked for leaks, and the (optional) output signal wires

connected, the unit is ready to apply AC power. It is possible to apply AC power

before the gas lines are connected to ensure the unit is functional, but ambient air

contains levels of water vapor that are much higher than the instrument is

designed to measure. Therefore, valid H2O readings cannot be obtained until

sample gas is flowing through the sample cell.

To power up the 2000 Series:

Apply AC power by plugging in the gas sensor (if cord connected) or by

energizing the circuit if the gas sensor is hard wired. Note that there is a 500

mA slow-blow fuse located on the bottom right hand side of the chassis.

When AC power is applied to the 2000 Series, the system will go through a 15

second initialization period. The LCD on the keypad will display the word

INTIALIZING… and then start counting down from 15. The keypad will not

respond to key presses during this time period. Allow 3 additional minutes for the

2000 Series to stabilize before recording measurements.

Normal operation is indicated by continuous updates of the measurement

parameters on the LCD. See Figure 9. The LCD displays four lines of

alphanumeric data.

In the normal operational mode ("Normal Mode"), the LCD readout displays:

Figure 9 2000 Series LCD on the keypad

<NORMAL MODE>

H2O: 120.62pmv

CO2: 2.33% DP: -41.00C

P: 1011.8mb T: 23.20C

2001, SpectraSensors, Inc. 17

Operation

Specifications for Proper Use

The 2000 Series is designed specifically to measure levels of moisture, and

carbon dioxide in a gas stream. It also reports dew point, temperature and

pressure of the sampled gas.

Although the unit can easily be dismounted and moved from one sampling

station to another, it is designed to be a stationary measuring device. It should be

securely mounted during normal operation.

Opening of the main enclosure cover is required for installation only. Thereafter,

you will rarely need to open the cover of the main enclosure for inspection or

maintenance. Subsequent to installation, do not open the enclosure for this

purpose unless directed to do so by a service representative.

The measurement heads may be disassembled for cleaning purposes (see the

Maintenance Section of this manual). The two main parts of the measurement

head are the gas sampling cell and the optical head assembly. The gas sampling

cell may be separated from the optical head assembly, and can be further

disassembled for mirror cleaning purposes from time to time. In no case,

however, will the operator need to disassemble the optical head assembly.

CAUTION! –Note the enclosure seal, used to prevent inadvertent

tampering with the device. It is imperative that the operator not attempt to

compromise the seal of the optical head assembly enclosure. Doing so will

result in loss of device sensitivity and inaccurate measurement data. Repair

of this situation must be handled by the factory and is not covered by

warranty.

Keypad Functions

The keypad allows the operator to modify certain parameters that control the

2000 Series. However, once the unit has been properly installed and normal

operation has been established, there should be no need to alter the operational

parameters. Measurements of H2O, CO2, Dew Point, Temperature and sample

cell Pressure are continuously displayed on the LCD display. For single channel

H2O-only systems, the CO2value will always display as zero.

NOTE: To activate any functions on the keypad, press the “#” key and then

press a number to select “Mode” or the TEST key. If the “#” key is not

pressed before pressing a Mode or function key, there will be no response.

When the “#” key is pressed, the word “MODE” will be displayed on the

LCD. At this point the unit will wait for a second key to be pressed before

responding.

2001, SpectraSensors, Inc. 18

Figure 10 2000 Series Keypad

2001, SpectraSensors, Inc. 19

Modes The following modes can be accessed from the keypad by pressing the “#” key

and then entering 1, 2, 3, 4 or “Test”.

§Mode 1 is Normal Display Mode.

§Mode 2 provides change of parameters for H2O measurement.

§Mode 3 provides change of parameters for CO2 measurement

§Mode 4 displays System Diagnostic Parameters for H2O

§Mode 5 displays System Diagnostic Parameters for CO2

§Mode 6 outputs spectra and calculations to serial port

§Mode “Test” displays H2O System Test parameters

Mode 1 (Normal Display Mode)

Mode 1 continuously displays updated measurements.

Mode 2 (H2O Measurement Parameter Change)

After pressing the “#” key and then “2” key, the LCD will prompt the user to

enter a numeric password.

#

1

+

#

2

+

<NORMAL MODE>

H2O: 120.62pmv

CO2: 2.33% DP: -

41.00C

P: 1011.8mb T: 23.20C

<SET PARAMETER MODE>

Password

Enter password

2001, SpectraSensors, Inc. 20

Enter the user password on the keypad, then press the “*” key.

NOTE: The user password is 3142, the first four digits of the value of ππ.

Mode 2 allows the operator to view and change the values of the following H2O

measurement parameters:

Note that prior to setting the zero offset or RCalb parameters, suitable calibration

gases must be available, along with the tools necessary to hook them up to the

analyzer.

Function Setting Function

Spectrum Average 1 –16

default = 4

Sets the number of scans

that are averaged for each

2F spectrum.

RCalb 1000 –3000 Sets gain calibration for

H2O or CO2measurements.

Alarm Action 0 or 1 Determines if the

concentration values goes to

full scale or zero on an

alarm condition.

Zero Offset

0 –100 ppmv for

H2O, 0-1% for

CO2

Sets the zero offset for H2O

or CO2measurements.

Logger Rate 1 –300 seconds

for both H2O and

CO2

Sets the gas concentration

integration time.

Temperature unit 0 or 1 Sets the display unit for

Temperature.

Pressure unit 0,1 or 2 Sets the display unit for

Pressure.

Concentration unit 0 or 1 Sets the display unit for the

water concentration.

Table 3 2000 Series Keypad

Table of contents

Other Spectrasensors Measuring Instrument manuals