2

Contents

VEGASON 61 • Foundation Fieldbus

28790-EN-150603

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 6

2.6 CE conformity................................................................................................................... 6

2.7 FulllmentofNAMURrecommendations ......................................................................... 6

2.8 Environmental instructions ............................................................................................... 6

3 Product description

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Packaging, transport and storage..................................................................................... 9

3.4 Accessories and replacement parts ................................................................................. 9

4 Mounting

4.1 General instructions ....................................................................................................... 11

4.2 Mountinginstructions ..................................................................................................... 12

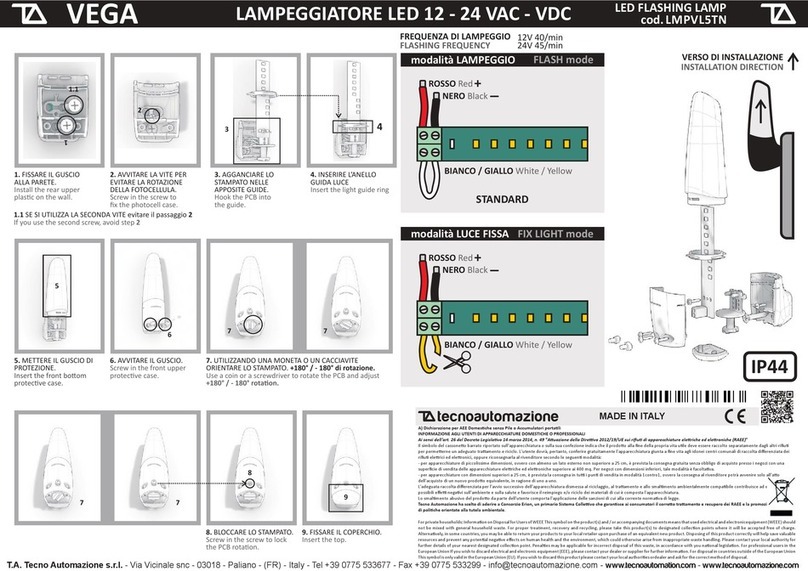

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 19

5.2 Connection procedure.................................................................................................... 20

5.3 Wiring plan, single chamber housing.............................................................................. 21

5.4 Wiring plan, double chamber housing ............................................................................ 22

5.5 Wiring plan - version IP 66/IP 68, 1 bar........................................................................... 24

5.6 Switch-on phase............................................................................................................. 25

6 Set up with the display and adjustment module PLICSCOM

6.1 Insert display and adjustment module............................................................................ 26

6.2 Adjustment system......................................................................................................... 27

6.3 Setup steps .................................................................................................................... 28

6.4 Menuschematic............................................................................................................. 36

6.9 Saving the parameter adjustment data........................................................................... 38

7 Set up with PACTware and other adjustment programs

7.1 Connect the PC via VEGACONNECT ............................................................................ 39

7.2 Parameter adjustment with PACTware............................................................................ 40

7.3 ParameteradjustmentwithAMS™................................................................................. 41

7.4 Saving the parameter adjustment data........................................................................... 41

8 Maintenanceandfaultrectication

8.1 Maintenance .................................................................................................................. 42

8.2 Rectifyfaults................................................................................................................... 42

8.3 Exchanging the electronics module................................................................................ 43

8.4 Software update ............................................................................................................. 44

8.5 How to proceed if a repair is necessary.......................................................................... 44