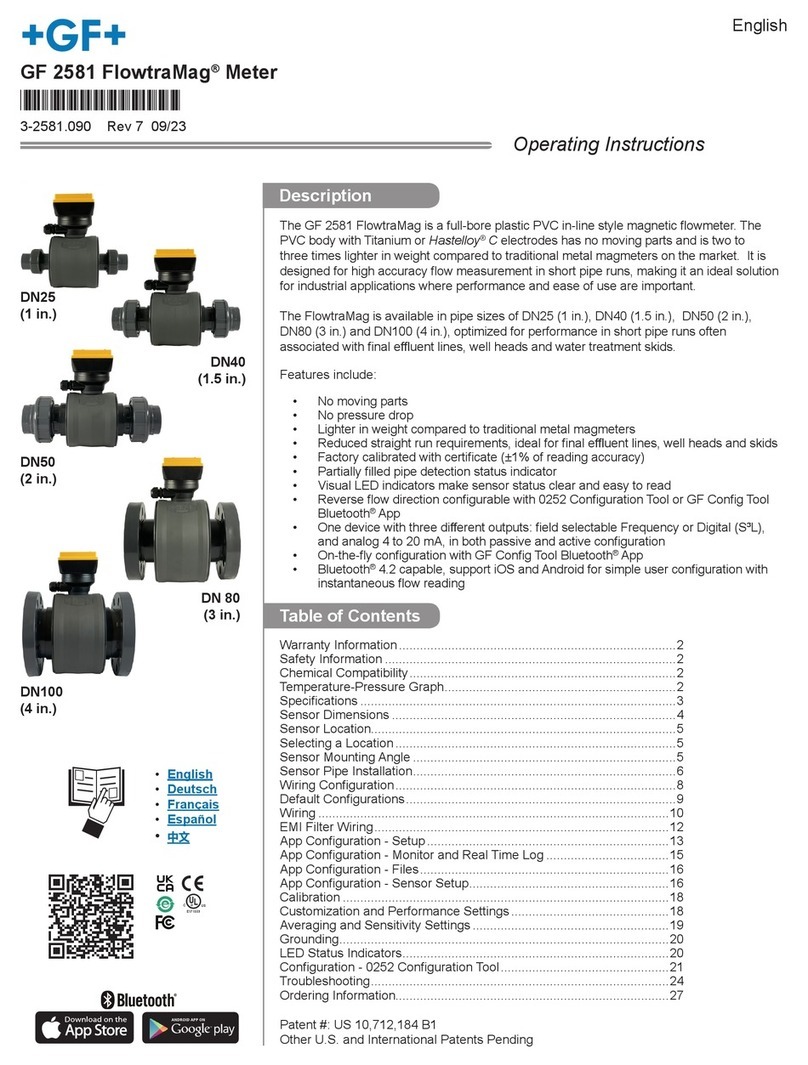

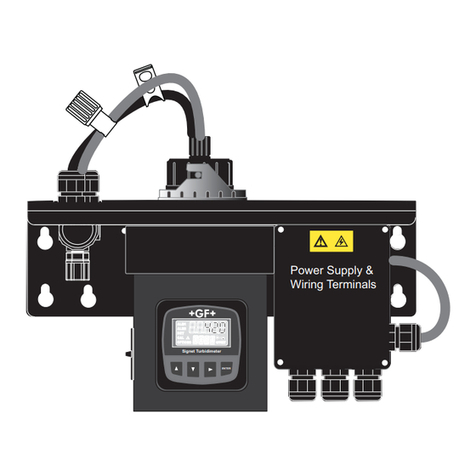

The Signet Chlorine Analyzer System is an integrated, all-in-one chlorine panel system designed to measure free chlorine in

drinking water and clean fresh water treatment applications.

Features:

Complete chlorine analyzer system allows quick setup and easy•

installation. Connect to a water source and plug it in.

Unique integrated clear flow cell combines sensors, flow regulator,•

filter and rotameter in one compact unit.

Built-in rotameter facilitates flow rate confirmation at a glance.•

Integrated flow regulator with removable filter accepts inlet pressures•

of 15 to 150 psi while maintaining constant flow and minimal pressure

to the sensors.

Water flows vertically into sensor tip, eliminating bubble entrapment.•

Raised exit in flow cell sensor chamber ensures sensors stay

submerged even when system and flow is turned off.

System is supplied with pre-wired electronics, power cable, 4 to 20 mA•

current loop and relay output capability.

Flow cell accommodates two sensors; one chlorine and an optional•

pH sensor.

Automatic pH and temperature compensation or manual pH value•

input capability for chlorine reading accuracy.

Easy viewing of the transmitter via the bright backlit LCD display.•

Moisture proof NEMA 4X wiring enclosure.•

Exterior panel enclosure available for outdoor mounting applications.•

Refer to the individual component manuals for detailed component

information.

8630-3 Chlorine Transmitter Manual•

2630-2 Amperometric Chlorine Electrode Manual•

2650 Amperometric Electronics Manual•

2724 pH/ORP Electrode Manual•

2750-7 pH Electronics Manual•

*3-4630.090*

3-4630.090 Rev A 09/10 English

English

CAUTION!

Follow instructions carefully to avoid personal injury.1.

Do not exceed the maximum pressure or temperature specifications.2.

Mounting the Chlorine System in an outdoor box, in areas with elevated temperatures, may3.

cause damage to the system if the enclosure's internal temperature exceeds the temperature

specification of the Chlorine Analyzer.

Do not alter product construction.4.

For use with clean fresh water only.5.

Disconnect AC power before opening wiring enclosure.6.

This panel system uses AC voltages. Wiring should be done by qualified personnel only.7.

1. Description

Signet 4630 Chlorine Analyzer System

1. Description p.1 6. System Setup p.5 11. O-rings p.11

2. Dimensions p.2 7. Wiring p.7 12. Flow Cell Assembly p.12

3. Component Identification p.3 8. Water Flow p.8 13. Troubleshooting p.13

4. Mounting p.4 9. Flow Cell Components p.9 14. Ordering p.14

5. Tubing Connections p.4 10. Cleaning p.10 15. Specifications p.16