3

PME-MP60/MP07

A0616-13.4 en HBM

Contents Page

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of supply and accessories 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 General 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Selecting amplifier settings with DIP switches 11. . . . . . . . . . . . . . . . .

3 Mounting/dismounting the MP60/MP07 15. . . . . . . . . . . . . . . . . . . . . . . .

3.1 Connecting several modules 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Connections 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

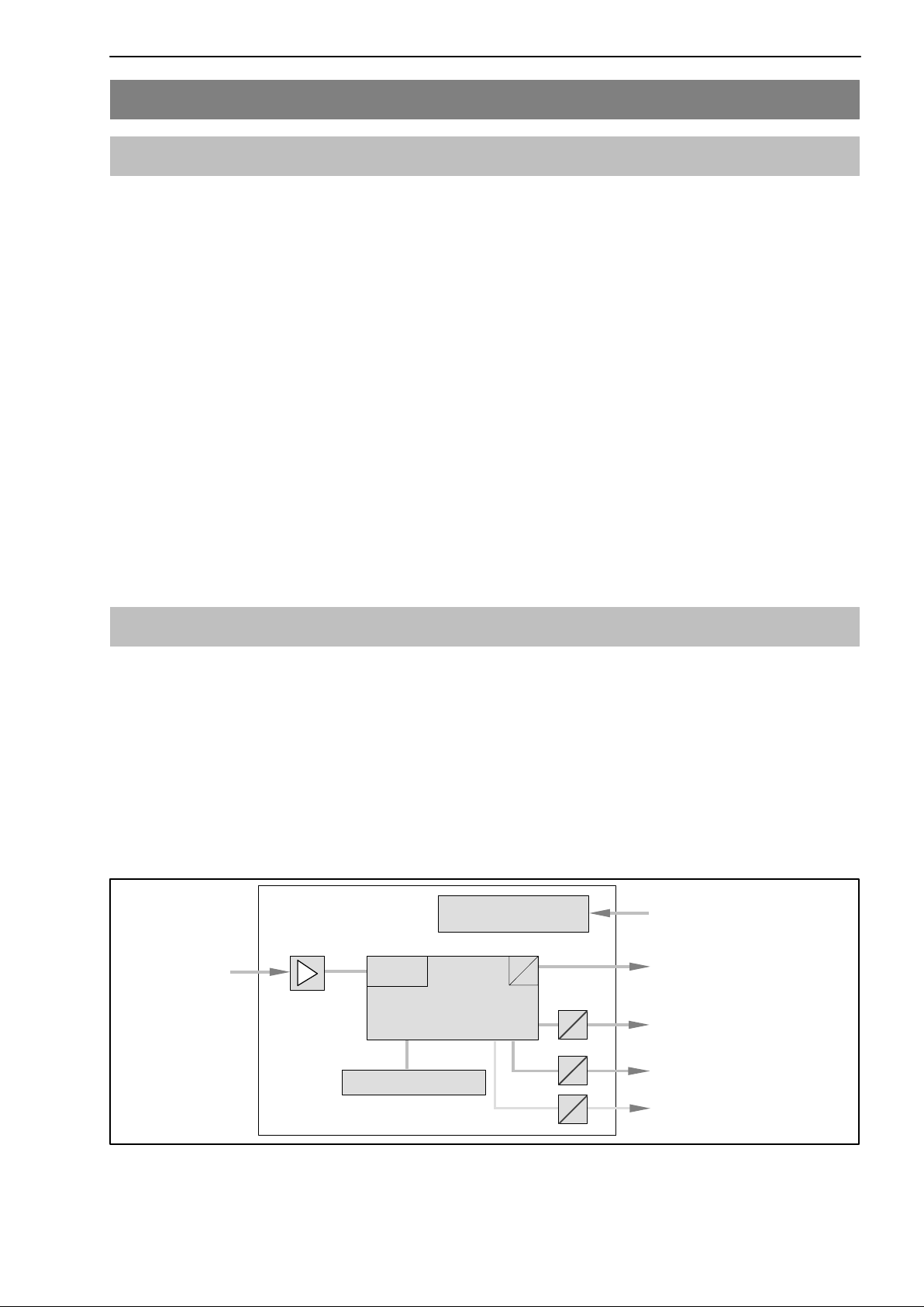

4.1 Functional overview of MP60/MP07 18. . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Supply voltage and control inputs/outputs MP60 19. . . . . . . . . . . . . .

4.2.1 External supply voltage for control outputs (MP60) 20. . . . . . .

4.3 Supply voltage MP07 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Connecting a transducer 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 CAN interface 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Synchronization (MP60) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Setting up and operation (MP60) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Operating principles 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Commissioning 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Guide to all groups and parameters 31. . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Set up all parameters 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Example: measuring Md and N with torque

transducer T10F (24 V supply) 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Declaring the significant parameters 39. . . . . . . . . . . . . . . . . . . . . . . . . .

7 CAN interface description (MP60 only) 47. . . . . . . . . . . . . . . . . . . . . . . .

7.1 General 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Cyclical data transmission 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Parameter assignment 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Object directory (communications profile section) 50. . . . . . . . . . . . .

7.5 Emergency objects 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Object directory: manufacturer-specific objects 54. . . . . . . . . . . . . . .

7.7 Manufacturer-specific objects in floating data format 64. . . . . . . . . .

7.8 Examples 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Error messages/operating status (LED) 67. . . . . . . . . . . . . . . . . . . . . . .

9 Keyword index 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .