3.7.3 RS-485 Interface ...........................................................................25

3.8 Terminals............................................................................................26

3.8.1 Detector Terminal..........................................................................26

3.8.2 Light Source Terminals...................................................................28

3.9 System Setup ...................................................................................... 29

3.9.1 Detection Function Programming .....................................................29

3.9.2 Detection Setup Function................................................................ 29

3.9.3 Detector Default Setup................................................................... 31

4Technical Specifications ...................................................................... 33

4.1 General Specifications...........................................................................33

4.2 Electrical Specifications .........................................................................34

4.2.1 4–20mA Current Output .................................................................34

4.2.2 Communications Network ...............................................................34

4.2.3 Relay Output: ...............................................................................35

4.2.4 HART Protocol ...............................................................................35

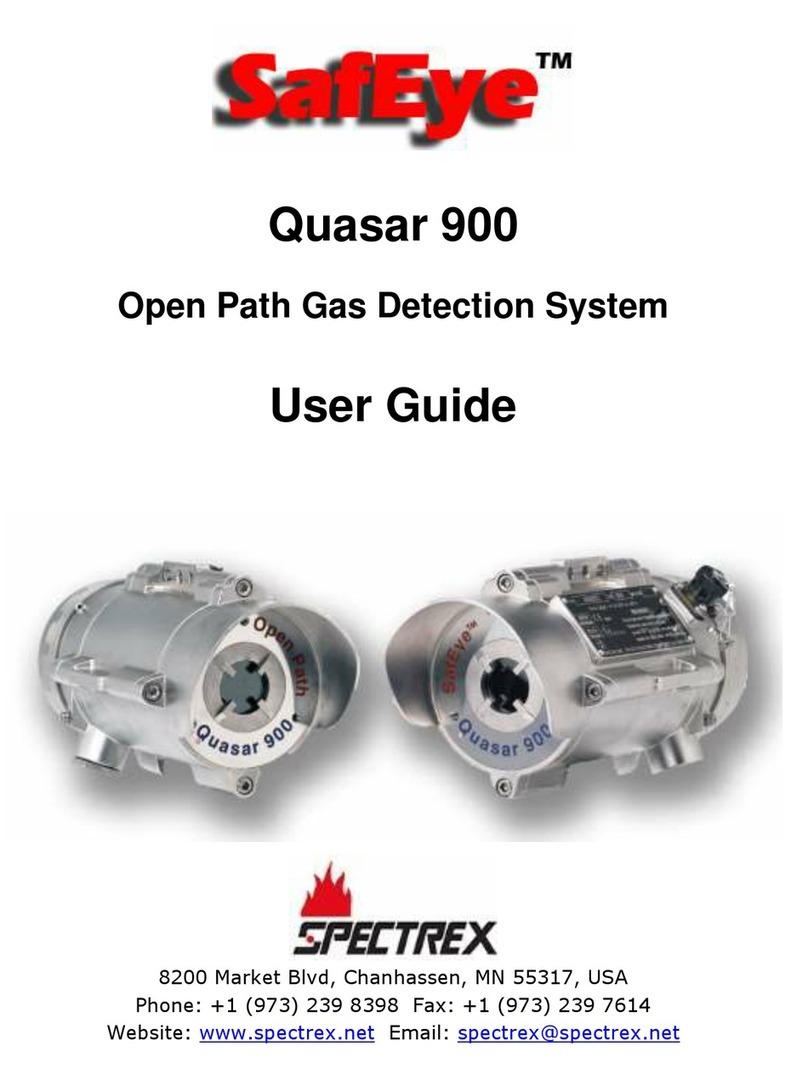

4.3 Mechanical Specifications ......................................................................36

4.4 Environmental Specifications .................................................................37

5Installation Instructions...................................................................... 39

5.1 Introduction ........................................................................................39

5.2 General Considerations .........................................................................39

5.2.1 Personnel .....................................................................................39

5.2.2 Tools Required ..............................................................................39

5.2.3 Site Requirements .........................................................................39

5.2.4 The Source and Detector ................................................................40

5.2.5 Guidance Tips for Gas Detector Locations .........................................40

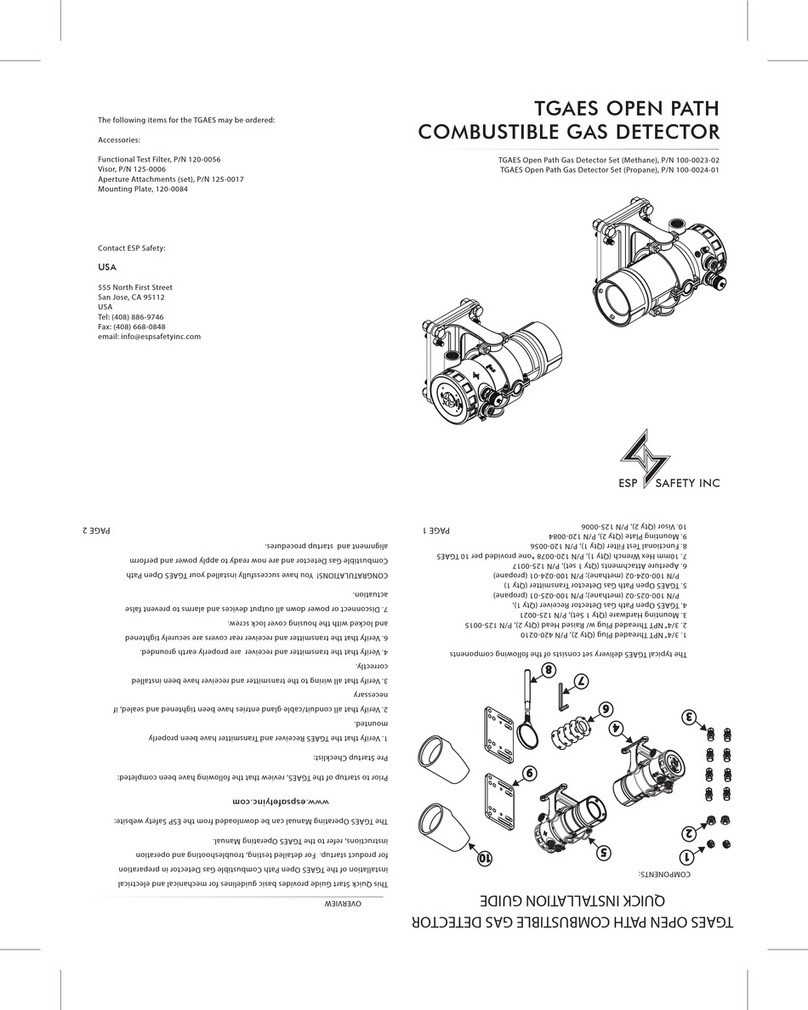

5.3 Preparations for Installation...................................................................40

5.4 Mounting for Duct Installation................................................................41

5.4.1 Duct Mount Set ............................................................................. 41

5.4.2 Duct Alignment Set and Accessories ................................................41

5.4.3 Duct Installation: Surface Preparation ..............................................42

5.4.4 Duct Mount Installation .................................................................. 44

5.4.5 Duct Mount Alignment....................................................................47

5.4.6 Conduit/Cable Installation...............................................................49

5.4.7 Harness Connection .......................................................................49

5.4.8 Detector Terminal Wiring................................................................52

5.5 Light Source Wiring .............................................................................. 53