Contents

Chapter 1 About this guide........................................................................................................................5

1.1 Release history.............................................................................................................................5

1.2 Glossary and abbreviations........................................................................................................6

1.3 Notifications................................................................................................................................. 7

Chapter 2 Product overview...................................................................................................................... 9

Chapter 3 Technical description..............................................................................................................11

3.1 Features......................................................................................................................................11

3.2 Applications................................................................................................................................11

3.3 Principles of operation..............................................................................................................12

3.4 Product certification..................................................................................................................14

3.5 Models and types...................................................................................................................... 16

3.6 Description................................................................................................................................. 16

Chapter 4 Operating modes.................................................................................................................... 19

4.1 Operational modes................................................................................................................... 19

4.2 Visual indicators........................................................................................................................ 20

4.3 Output signals........................................................................................................................... 20

4.4 System setup..............................................................................................................................21

Chapter 5 Technical specifications......................................................................................................... 25

5.1 General specifications...............................................................................................................25

5.2 Electrical specifications.............................................................................................................26

5.3 Electrical outputs.......................................................................................................................26

5.4 Mechanical specifications.........................................................................................................27

5.5 Environmental specifications...................................................................................................27

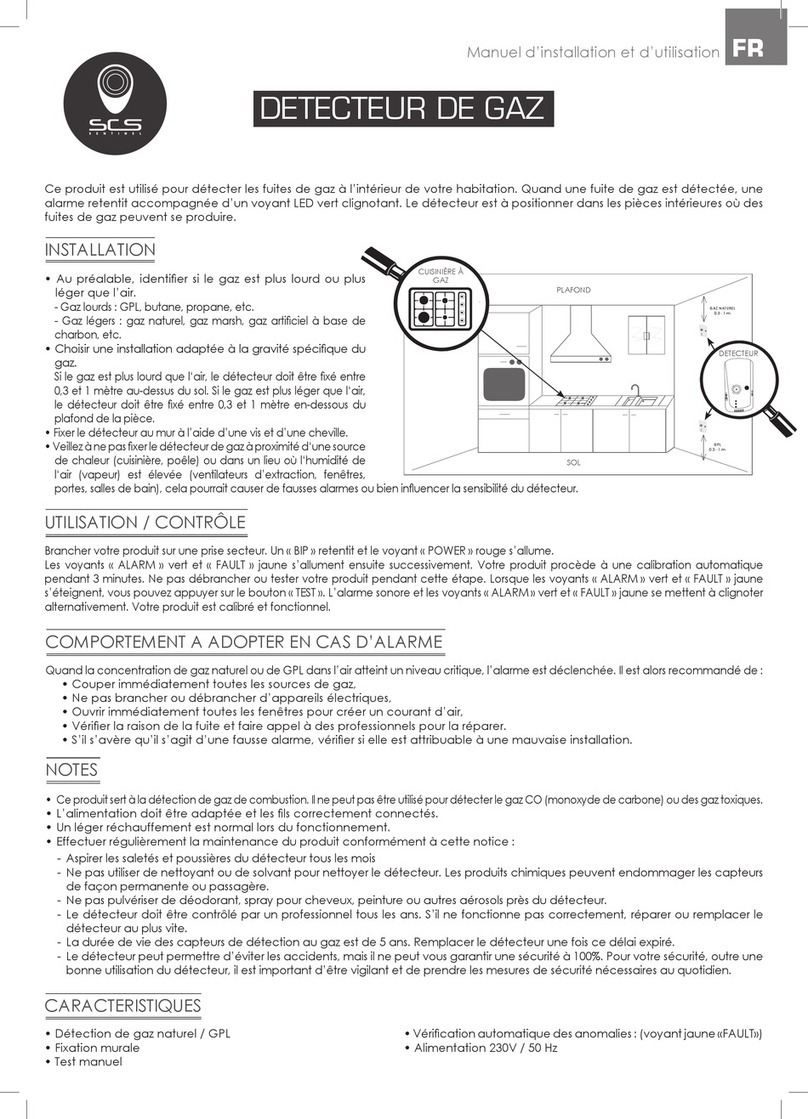

Chapter 6 Installation instructions........................................................................................................ 29

6.1 Introduction............................................................................................................................... 29

6.2 General considerations.............................................................................................................29

6.3 Preparations for installation.................................................................................................... 31

6.4 Certification instructions.......................................................................................................... 32

6.5 Conduit/cable installation........................................................................................................ 33

6.6 Receiver/transmitter mounting...............................................................................................34

6.7 Receiver wiring.......................................................................................................................... 34

6.8 Receiver terminal wiring...........................................................................................................37

6.9 Transmitter wiring.....................................................................................................................38

Chapter 7 Operating instructions........................................................................................................... 41

7.1 Safety operation........................................................................................................................ 41

7.2 Alignment of unit.......................................................................................................................41

7.3 Powering up the system...........................................................................................................42

7.4 Safety precautions.....................................................................................................................42

7.5 Signal verification...................................................................................................................... 43

7.6 Zero calibration..........................................................................................................................43

Manual Contents

TM888200 May2023

SafEye™ Quasar 900 3