Spectris Particle Measuring Systems Ultra DI 50 User manual

Ultra DI®50

Liquid Particle Counter

P/N 1000001689

OPERATIONS MANUAL

Without measurement there is no control

HEADQUARTERS

5475 Airport Blvd

Boulder, Colorado 80301 USA

T: +1 303 443 7100, +1 800 238 1801

Instrument Service & Support

E: +1 800 557 6363

Customer Response Center

T: +1 877 475 3317

E: Info@pmeasuring.com

GLOBAL OFFICES

AUSTRIA

T: +43 1 71 728 285

E: [email protected]om

BENELUX

T: +32 10 23 71 56

E: [email protected]om

BRAZIL

T: +55 11 5188 8227

E: pmsbrazil@pmeasuring.com

CHINA

T: +86 21 6113 3600

E: [email protected]om

FRANCE

T: +33 (0)1 60 10 32 96

E: pmsfranc[email protected]om

GERMANY

T: +49 6151 6671 632

E: pmsgermany@pmeasuring.com

ITALY

T: +39 06 9053 0130

E: [email protected]om

JAPAN

T: +81 3 5298 8175

E: pmsjapan@pmeasuring.com

KOREA

T: +82 31 286 5790

E: pmskore[email protected]om

MEXICO

T: +52 55 2271 5106

E: pmsmexico@pmeasuring.com

NORDIC

T: +45 707 028 55

E: pmsnordic@pmeasuring.com

PUERTO RICO

T: +1 787 718 9096

E: pmspuertoric[email protected]

SINGAPORE

T: +65 6496 0330

E: pmssingapore@pmeasuring.com

SWITZERLAND

T: +41 71 987 01 01

E: pmsswitzerland@pmeasuring.com

TAIWAN

T: +886-3-5525300 Ext: 301

E: pmstaiwan@pmeasuring.com

Ultra DI® 50

Liquid Particle Counter

Operations Manual

P/N 1000001689 Rev R

ii Ultra DI 50 Particle Counter Operations Manual

Ultra DI 50 Liquid Particle Counter Operations Manual

P/N 1000001689 Rev R

© 2019 by Particle Measuring Systems, Inc.

All Rights Reserved

Ultra DI® is a registered trademark of Particle Measuring Systems, Inc.

All other trademarks appearing in this manual are the property of their respective

owners.

DO NOT REPRODUCE OR DISTRIBUTE CONFIDENTIAL DOCUMENT

This confidential document contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this document may be reproduced,

distributed, or transmitted in any form without the prior written consent of Particle

Measuring Systems. The information contained in this document is subject to change

without notice.

Quality Statement

The Quality Policy of Particle Measuring Systems is to strive to meet or exceed the

needs and expectations of our customers, and to align the activities of all employees

with the common focus of customer satisfaction through continuous improvement in

the quality of our products and services.

Environmental Information

This equipment must be properly disposed of at end-of-life by means of an authorized

waste management system. Contact our Customer Response Center at (877) 475-3317

or (303) 443-7100 (International Telephone +1 3034437100) for dismantling and

disposal information.

Ultra DI 50 Particle Counter Operations Manual iii

Manual Conventions

A warning in the text is used to notify the user of the potential for bodily injury or death.

CAUTION

A caution in the text is used to highlight an item that if not done, or incorrectly done, could

damage the instrument and/or any materials or devices affected by the instrument.

A notice in the text is an instructional communication regarding requirements or policies

issued by Particle Measuring Systems.

NOTE: A note in the text is used to highlight an item that is of operational importance

to the user.

It is important that you observe cautions and warnings while performing the

procedures described in this manual. Caution and warning labels are located on and

inside the instrument to alert you to potentially hazardous conditions. Please

familiarize yourself with this information.

WARNING

– — NOTICE — –

iv Ultra DI 50 Particle Counter Operations Manual

CE – Declaration of Conformity

- Declaration of Conformity

Application of Council Directive(s): 2014/30/EU, 2014/35/EU, RoHS 2011/65/EU

Standard(s) to which Conformity is Declared: EMC EN 61326-1: 2013

Safety EN 61010-1: 2010, 3rd Ed.

EN 60825-1: 2007

Manufacturer’s Name: Particle Measuring Systems, Inc.

Manufacturer’s Address: 5475 Airport Boulevard

Boulder, CO 80301 USA

Manufacturer’s Telephone/FAX: +01 3034437100 / +01 3034496870

Distributor’s Name: Particle Measuring Systems, S.R.L.

Distributor’s Address Via di Grotte Portella 34

00044 Frascati (Roma) ITALY

Distributor’s Telephone/FAX: + 39 06 90530130 / + 39 06 9051315

Type of Equipment: Particle Monitoring

Model No: Ultra DI®50

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive(s) and

Standard(s).

Signature: Signature:

Full Name: Scott MacLaughlin Full Name: Giovanni Scialo

Position: Director of Engineering Position: Vice President Life Sciences

Place: Boulder Date: June 13, 2019 Place: Rome Date: June 13, 2019

CAUTION

All I/O cables and accessories must meet current factory specifications in order for this unit to

remain in compliance with CE marking requirements. Consult the factory for details.

If the equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

Ultra DI 50 Particle Counter Operations Manual v

Table of Contents

Chapter 1: Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Chassis - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Internal Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Front Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Back Panel Features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Chapter 2: Unpacking and Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Selecting a Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Completing Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Minimum Required Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

Other Components- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

Connecting the Tubing and Flow Controller - - - - - - - - - - - - - - - - - - - 2-5

Chapter 3: TCP/IP Set Up (Configuration) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Connecting the RS-232 Cable- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Terminal Emulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

HyperTerminal Status Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

TCP/IP Addresses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Connecting the Ethernet Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

Chapter 4: 4-20 mA Output and Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4-20 mA Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Factory-set Status Message Levels- - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4-20 mA Channels- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4-20 mA Output Configuration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Connecting the Computer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Setting Up a Terminal Emulation Session with HyperTerminal - - - - - - - 4-3

4-20 mA Parameter Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Connecting Ultra DI 50 Particle Counter to your SCADA or PLC - - - - - - - 4-4

4-20 mA Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

Chapter 5: Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Sample Interval - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Start the HyperTerminal Program - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

vi Ultra DI 50 Particle Counter Operations Manual

Define the Sample Interval- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Permanence of the Sample Interval Setting - - - - - - - - - - - - - - - - - - - 5-3

Facility Net Software - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Status LED Function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

LED Function at Startup- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

LED Function During Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Chapter 6: Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Cleaning Instructions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Air Filter Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Frequency of Air Filter Cleaning and Replacement - - - - - - - - - - - - - - 6-2

Cleaning the External Air Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Replacing the External Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

Replacing the Internal Filters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

Replacing the PFA Tubing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

Replacing Fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-5

High Counts in Channel 1 and/or 4 and/or a DC Value > 2 V - - - - - - - - - - 6-6

Cleaning the Laser window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-6

Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-6

Chapter 7: Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Appendix A: International Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

WARNING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

AVERTISSEMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

WARNUNG - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

ATTENZIONE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

ADVERTENCIA- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

Hazard Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

Symboles de risque - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

Warnschilder - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

Simboli di pericolo- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

Simbolos de peligro - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

Appendix B: Cable Pinouts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

RS-232 Cable Pinouts- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

Straight-Through Ethernet Cable Pinouts- - - - - - - - - - - - - - - - - - - - - - - - B-1

Crossover Ethernet Cable Pinouts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-2

4-20 mA Cable and Connector Pinouts - - - - - - - - - - - - - - - - - - - - - - - - - - B-2

Appendix C: Modbus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-1

Modbus Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-1

Input Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-3

Configuration Section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-3

Data Section- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-5

Holding Registers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-9

Ultra DI 50 Particle Counter Operations Manual vii

Coils - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-10

Data Packet Processing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-12

Associated Values for Specific Registry Entries - - - - - - - - - - - - - - - - - - - - C-13

Modbus Processing Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-14

Appendix D: 㦘㹡㒥㦘⹂䤓䓸德✛⏒侯- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-1

viii Ultra DI 50 Particle Counter Operations Manual

This page intentionally left blank.

Ultra DI 50 Particle Counter Operations Manual ix

List of Figures

Chapter 1: Introduction- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Figure 1-1 Front view of the Ultra DI 50 liquid optical particle counter - - - - - - - - - - - - - - - - - - - - - 1-2

Figure 1-2 Ultra DI 50 liquid optical particle counter back panel - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Chapter 2: Unpacking and Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Figure 2-1 Side view of Ultra DI 50 particle counter with the external air filter in place - - - - - - - - 2-3

Chapter 3: TCP/IP Set Up (Configuration)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Figure 3-1 First HyperTerminal window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Figure 3-2 HyperTerminal Connection Description window- - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Figure 3-3 HyperTerminal Phone Number window- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Figure 3-4 HyperTerminal COM1 Properties window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Figure 3-5 HyperTerminal error message if COM1 is not functional- - - - - - - - - - - - - - - - - - - - - - - - 3-4

Figure 3-6 HyperTerminal status display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

Figure 3-7 HyperTerminal Session window- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Chapter 4: 4-20 mA Output and Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Chapter 5: Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Figure 5-1 HyperTerminal window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Chapter 6: Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Figure 6-1 Ultra DI 50 particle counter external air filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Figure 6-2 Ultra DI 50 particle counter power entry module with fuse drawer - - - - - - - - - - - - - - - 6-5

Chapter 7: Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Appendix A: International Precautions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

Appendix B: Cable Pinouts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B-1

Appendix C: Modbus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-1

Figure C-1 Modbus flowchart - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C-14

Appendix D: 㦘㹡㒥㦘⹂䤓䓸德✛⏒侯 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D-1

x Ultra DI 50 Particle Counter Operations Manual

This page is intentionally left blank.

Ultra DI 50 Particle Counter Operations Manual Page 1-1

Chapter 1

Introduction

This manual gives you the information necessary to successfully unpack, install,

operate, and maintain the Ultra DI 50 liquid optical particle counter.

The Ultra DI 50 particle counter samples deionized water to monitor the presence of

particles. Laser illumination with a high-resolution optical system, collects particle-

scattered light. Determination of particle size is accomplished with pulse height

analysis (PHA) of the scattered light. The Ultra DI 50 particle counter detects particles

0.05 µm and larger. See Specifications on page 1-4 for more details.

Water passes through the instrument's sample cell at a flow rate set by an attached

flow controller. The particle counter is designed for a flow rate of 1000 ml/minute and

a sample rate of 3.75 ml/minute.

Sample data is transferred to a user interface for analysis and accumulation. The user

interface most frequently used is Facility Net software and a PC display. Facility Net is

a Particle Measuring Systems software application that controls the Ultra DI 50 particle

counter and other Particle Measuring Systems instruments, collects the sample data

of interest to the user, manages alarm settings, and displays the data in a manner set

by the user.

The Ultra DI 50 particle counter also generates 4-20 mA output for input to other

control systems.

Description

See Specifications on page 1-4, for more detailed information.

Chassis

Stainless steel.

Internal Components

Laser

Laser diode.

Optical System

All glass optical elements have an anti-reflective coating to minimize light loss.

Cooling Fans

Two internal fans pull ambient air through a cleanable or replaceable external air filter,

through two internal high-performance air filters, and then over internal components

that require cooling.

Page 1-2 Ultra DI 50 Particle Counter Operations Manual

Chapter 1 Introduction Description

Front Panel Features

The front panel of the Ultra DI 50 liquid optical particle counter is shown in Figure 1-1.

Figure 1-1 Front view of the Ultra DI 50 liquid optical particle counter

Outlet

A Flaretek®fitting that connects the particle counter to a flow controller.

When the particle counter is idle, cap this fitting to retain water within the sample cell.

Inlet

A Flaretek fitting that connects the DI water source to the particle counter.

When the particle counter is idle, cap this fitting to retain water within the sample cell.

Status LED

Displays red or green to indicate the instrument’s operational status.

When the particle counter receives power, its status light illuminates red while laser

diagnostics are performed. After 5–10 minutes, the laser will stabilize, and the status

light will turn green. If the status light flashes red, the sensor has failed to initialize

correctly.

Facility Net’s alarm settings control this light. The status light will turn red if the laser

is not operating correctly.

For more information about the status LED, see Chapter 7, Troubleshooting.

Description Chapter 1 Introduction

Ultra DI 50 Particle Counter Operations Manual Page 1-3

Back Panel Features

The communication ports and the power entry module are on the back panel of the

Ultra DI Particle Counter (see Figure 1-2). The power entry module is comprised of the

power source connection and the fuse drawer.

Fuse drawer

Figure 1-2 Ultra DI 50 liquid optical particle counter back panel

4-20 mA connector

This connector is used to connect to a Programmable Logic Controller (PLC) or SCADA

system. A 9-pin connector and hood is included with the unit. See Chapter 4, 4-20 mA

Output and Configuration.

RS-232 connector

This connector is used to configure the UDI. Configuration requires the RS-232 cable

assembly provided with the instrument and a PC with a terminal emulation program.

For more information, see Connecting the RS-232 Cable on page 3-1.

Ethernet connector

Connects to a stand-alone PC running Facility Net software or to an Ethernet hub.

Power entry module

Connects to an appropriate power source with the provided power cord. There is no

ON/OFF switch. The AC Mains disconnect is the power cord.

Page 1-4 Ultra DI 50 Particle Counter Operations Manual

Chapter 1 Introduction Specifications

Specifications

Channels 4

Channel sizes 0.05, 0.10, 0.15, 0.20 µm

Flow rate 1,000 ml/minute

Counting efficiency (0.117 µm) 100% of sampling volume

Sample volume > 3.75 ml/minute ± 10%

Maximum concentrationa

a. Greater than 90% accuracy (less than 10% coincidence loss) at the maximum recommended

concentration.

10,000 counts/ml

Sample temperature 59 – 122 °F (15 – 50 °C) b

b. For temperatures greater than 122 °F (50 °C), use of a chiller is recommended.

Maximum pressure 100 psi

Zero count level 50 counts per literc

c. Requires optimization by local Particle Measuring Systems service representative.

Exterior surface Stainless steel

Wetted materials Teflon®, Kel-F®, Fused Silica, Sapphire, 96% alumina Ceramic

Dimensions (d w h) 17 17 10.5 in (43 43 27 cm)

Weight 45 lb (20.4 kg)

Communications Ethernet

4-20 mA: Four particle channels and one instrument status)

RS-232 (set up and diagnostics; no data)

Status indicator Laser, power and activity: one 3-color LED

Calibration Calibration materials used are traceable to the USA National

Institute of Standards and Technology (NIST)

Environment Temperature: 59 – 86 °F (15– 30 °C)

Humidity: Non-condensing

Maximum altitude: 6,562 ft (2,000 m)

Electrical rating 100 - 240V, 50 - 60 Hz, 1.25 A

Fuses 250 V, 5x20 mm, T, 1.25 Amp

Voltage fluctuation AC input voltage fluctuation shall not exceed + 10%

Laser classification Class 1, complies with US 21 CFR 1040.10 and EN60825-1.

Internally an enclosed Class 4 laser is used per EN60825-1.

Installation requirements Indoor use only

Pollution degree 2

Over-voltage Category II

Ordinary protection (Not protected against harmful ingress of

moisture.)

Class I Equipment (Electrical earth ground from the mains

power source to the product input is required for safety.)

Storage and transportation

environment

-40 – +158 °F (-40 – +70 C)

5 – 90% Humidity

Particle Measuring Systems reserves the right to change specifications without notice.

Ultra DI 50 Liquid Particle Counter

Ultra DI 50 Particle Counter Operations Manual Page 2-1

Chapter 2

Unpacking and Installation

Unpacking

Inspect the shipping container for any damage. If the container appears damaged,

contact the shipper immediately.

Ensure that the contents of the shipping container include the following items:

• Ultra DI 50 particle counter unit

• RS-232 configuration cable with RJ-11 male connectors on each end and a

DB-9-to-RJ-11 adapter

• Ethernet crossover cable

• DS 9-pin connector for the 4-20 mA option (P/N CO165-1)

• 9-pin hood for the 4-20 mA option (P/N CO266-1)

• Power cord

• Operations manual (this document)

If anything is missing, contact Particle Measuring Systems Customer Response Center

at 1-877-475-3317, or support@pmeasuring.com.

If all of the materials are included and undamaged, store the packing materials. It is

important to keep these materials because warranties may not apply if return

shipping containers are inadequate.

CAUTION

The Ultra DI 50 particle counter is filled with filtered propylene glycol before shipping.

The propylene glycol must be removed immediately and replaced with deionized water.

Failure to remove the shipping fluid can result in contamination of the sample cell.

If the particle counter is not in use, ensure that it is always filled with deionized water.

Never allow it to go dry.

NOTE: The provided handles are to be used only for lifting and moving the

instrument by one or two persons.

Page 2-2 Ultra DI 50 Particle Counter Operations Manual

Chapter 2 Unpacking and Installation Installation

Installation

Selecting a Location

>> To choose an effective location for the particle counter, consider the following

issues:

Accessibility

The particle counter should be readily accessible for connecting and

disconnecting cables, etc.

Visibility

The front panel should be visible from a reasonable position.

Plumbing

The particle counter should be located near the deionized water source so that

the tubing has no sagging or dead spots where particles might accumulate.

Cables

The unit should be located near a source of grounded electrical power, whatever

communication ports you wish to use, and any other devices with which it must

communicate. Cables should not be strained or constricted.

Chassis clearance

The external air filter and the cooling air discharge (on the sides of the chassis)

should not be obstructed.

Drainage

When completely installed, the particle counter will have a flow controller

connected to the DI water outlet tube. Water passing through the flow controller,

will drain to waste. The drainage site should be close enough that displacement

of the tubing and subsequent spillage does not occur.

Installation Chapter 2 Unpacking and Installation

Ultra DI 50 Particle Counter Operations Manual Page 2-3

Completing Installation

>> To complete the installation of the particle counter, the following operations

must be performed:

• Ensure that you have all the additional components (other than those shipped) to

install, initialize, and operate the monitor.

See Minimum Required Components, below and Other Components on page 2-4.

• Connect the tubing.

See Connecting the Tubing and Flow Controller on page 2-5.

• Connect the cabling required for your installation.

See Chapter 4 4-20 mA Output and Configuration

• Connect your cabling to the device that will receive the data output, usually an

Ethernet hub.

See Chapter 3 TCP/IP Set Up (Configuration)

• Ensure that the external air filter is still positioned correctly — in its channels and

pushed fully in.

Figure 2-1 Side view of Ultra DI 50 particle counter with the external air filter in place

Page 2-4 Ultra DI 50 Particle Counter Operations Manual

Chapter 2 Unpacking and Installation Installation

Minimum Required Components

To install and operate your particle counter, you will need components in addition to

those included with the purchase of your Ultra DI 50 particle counter. The following

items are not included in the shipment unless you have specifically purchased them as

accessories.

• flow controller

• sample tubing with 1/4-inch Flaretek end-fittings

• a PC

See Table 2-1 Accessories and supplies available from Particle Measuring Systems on

page 2-4.

Other Components

Depending on your installation of the Ultra DI 50 particle counter, you may also need

some or all of the items listed in Table 2-1 and the following items:

• 4-20 mA cable (9-pin connector and hood included)

• Programmable Logic Controller

• Facility Net software

• a straight-through Ethernet cable

• heating gun

• Flaretek fittings

Ultra DI 50 particle counter initialization requires a PC and an RS-232 connection.

Table 2-1 Accessories and supplies available from Particle Measuring Systems

Item Part Number

Flow controller (FC-100-2) 90351015

Tubing installation kit 90351040

PFA tubing WR103

Flaring tool TL062

1.5 ft RS-232 extension cable AE2070

RS-232 (DB-95)/phone jack cable PMS-CD1995

USB to RS-232 adaptor 1000016655

10 ft Ethernet straight-through cable CD22

3 ft Ethernet crossover cable 1000011477

External air filters 1000001997

Internal air filter (2 per unit) FL08

Installation Chapter 2 Unpacking and Installation

Ultra DI 50 Particle Counter Operations Manual Page 2-5

Connecting the Tubing and Flow Controller

You will need three segments of Teflon tubing at lengths suitable for your operation.

You will be connecting between the following items:

•from the DI water source to the particle counter inlet

•from the particle counter outlet to the flow controller inlet

•from the flow controller outlet to drain

Prepare Tubing

Your tubing must have 1/4-inch Flaretek fittings where it connects to the inlets and

outlets of the particle counter and the flow controller.

>> To install Flaretek fittings using the flaring tool:

1. Cut three pieces of tubing for the three connections listed above, making the pieces

a little longer than you think they must be. It is easier to adjust the finished tubing

by cutting a little off rather than having to cut an entirely new piece of tubing.

2. Place the flaring tool on a solid surface.

3. Select the piece of tubing that will connect from your DI water source to the particle

counter inlet fitting.

4. Place a Flaretek screw-down cap over the end of the tubing you will be flaring. The

threaded part of the cap should face the end you will be flaring.

5. Heat the tubing end with a heating gun until the tube is transparent but still holding

its shape.

6. Push the tubing over the flare molding part of the flaring tool.

7. Allow the tube to cool. The flared end will lose its transparent look.

8. Repeat steps 4through 7for the other two pieces of tubing.

NOTE: Only one end of the flow controller’s discharge tube may require

flaring.

9. Now you are ready to connect the tubing (see Connect Tubing on page 2-6).

NOTE: If the flow controller is not the FC-100, ensure that it can be set to a

flow rate of 1000 ml/minute.

Table of contents

Popular Cash Counter manuals by other brands

HEIDENHAIN

HEIDENHAIN VRZ 450 operating instructions

Milesight

Milesight VS350 user guide

Heath Company

Heath Company RC-1 Assembly and operation

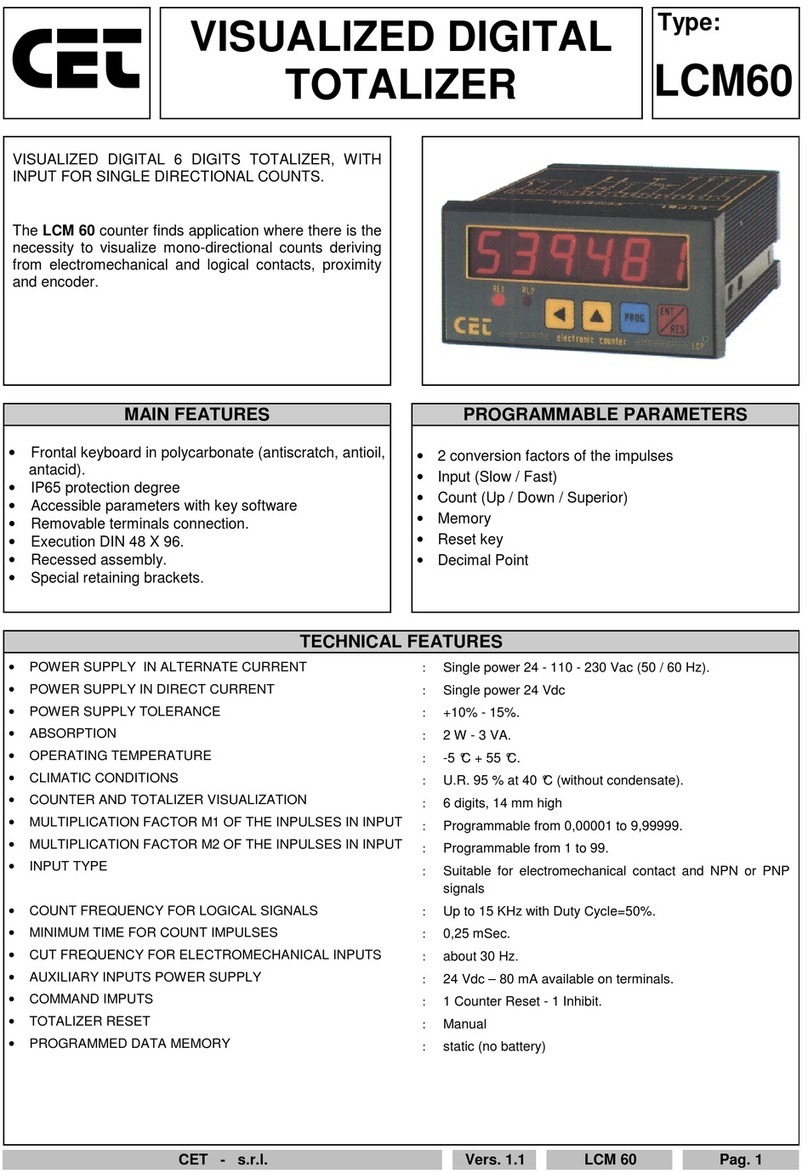

CET

CET LCM60 manual

Precision Digital Corporation

Precision Digital Corporation PD6363 Series instruction manual

Polar Electro

Polar Electro GD882 instruction manual