Spectronix 100529A User manual

Optical Signal Test Set

User’s Manual 2023-02-17

100529A. 100560A

Page 1 of 6 www.spectronixinc.com

Description:

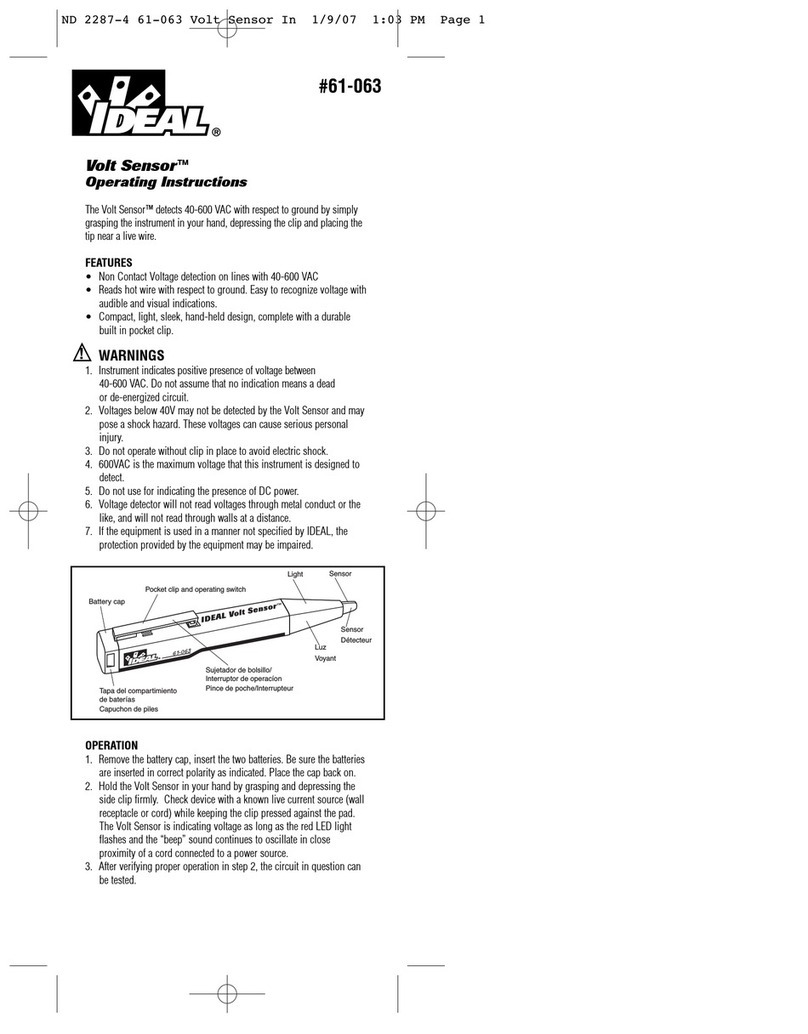

The Optical Signal Test Set (OSTS) is a low power miniature instrument intended for general purpose

optical testing. The 100529A consists of a high performance optical power meter, stable CW laser

source, and variable optical attenuator. All functions are controlled and monitored via Windows

software and a USB port which also provides power to the unit.

Optical System Test Set, PN 100529A

An OEM CCA version of the OSTS is also offered (PN 100560A). The OEM version adds a second

optical power meter and Ethernet port which can be used instead of the USB.

Optical System Test Set Dual OEM version, PN 100560A

Operation:

All optical connections are brought out on single mode LC connectors allowing each subsystem to be

used independently or together. Connecting the laser output, variable attenuator, and power meter

together allows for self calibration. The supplied Windows software allows the user to read and log

optical power levels, adjusts the laser power, and set the VOA attenuation, as well as some advanced

features described below.

Optical Signal Test Set

User’s Manual 2023-02-17

100529A. 100560A

Page 2 of 6 www.spectronixinc.com

Connection

In order for the unit to communicate via USB, some operating systems require a driver to be installed;

see the USB driver section at the end of this document. Upon startup the application will search for

OSTS devices connected via USB and display them in the dropdown list next to the button with the

USB icon. Selecting a device and pressing the USB connect button will allow the device to

communicate with the host computer over the USB port.

The Dual OEM version also features an Ethernet port. Entering the device’s IP address in the “IP

Address” box and pressing the “Connect” button will allow the device to communicate with the host

computer via the Ethernet port. For discovering and managing network settings see the Ethernet

section at the end of this document.

Operation

The power meter features a numeric read-out as well as a strip chart for displaying power readings.

Data can optionally be saved to a .CSV file for later analysis by clicking on the disk icon. The strip

chart can be taxing on computer resources and is dependent on the sample rate and data set size; if

performance issues are noticed, reducing these parameters can help. The 100529A provides an LED

next to the USB port which flashes blue at the sample rate; if the laser is on, the LED will flash

blue/red. Several controls on the main panel are used for manipulating the strip chart appearance

and are described below.

•Run toggle button: Enables / disables displaying new power readings on the strip chart.

•Clear button: Removes all data points from the strip chart.

•Disk icon: Saves all strip chart data to a user specified .CSV file.

Optical Signal Test Set

User’s Manual 2023-02-17

100529A. 100560A

Page 3 of 6 www.spectronixinc.com

•Auto toggle button: When enabled the chart auto-scales to the chart data; the chart

continues to expand accordingly as new data points are added.

•Zoom All button: Expands the chart to its extremes (-120dBm to +10dBm).

•Seconds spin box: Sets the X axis range of the strip chart. As samples older than the

specified range expire, they are automatically removed from the chart.

•Using the check boxes above power meter readings, averaged data and raw data can

optionally be displayed in the plot window.

In addition to using the controls above, the plot range can be controlled manually using the mouse.

To zoom in, hold the left mouse button and drag inside the plot area. While the chart is running, this

will adjust the Y axis only, when stopped both X and Y axis will be adjusted. To zoom out, simply

right-click anywhere in the chart area.

The laser power can be varied between 0 and -10dBm by adjusting the laser dial. When the dial has

focus the mouse wheel can be used to change the power by +/-3dB and the up/down keys by +/-1dB.

The button in the center of the dial displays the current power; toggling this button turns the laser

on/off. The laser settings are saved in the application and restored at start-up.

The VOA knob is used to set the attenuator loss. The knob can be varied between the calibrated

insertion loss and the VOA’s maximum useable range. When the dial has focus the mouse wheel and

up/down keys can be used to change the attenuation by +/-0.3dB, the page up/down keys by 1.0dB,

and the arrow keys by 0.1dB. The attenuation is saved in the application and restored at start-up.

Advanced Features

Several advanced features are exposed when the down arrow button is selected. The power meter

features an advanced digital filter implemented in hardware; different filter settings are can be

selected using the “Fast Sampling” checkbox. When this box is checked, the sample rate increases

to 50 samples per second but the filter’s effectiveness is decreased. In normal mode, the sample rate

is 10 samples per second. Additionally, the user can select a variable number of samples to average

for display and logging purposes (1 for no averaging). The averaged data is plotted with colored lines

and when the “Plot Raw Data” box is checked the un-averaged data is displayed in grey. Un-

checking the “Calibrated” box, will cause the application to ignore the calibration and display the un-

calibrated data.

Optical Signal Test Set

User’s Manual 2023-02-17

100529A. 100560A

Page 4 of 6 www.spectronixinc.com

Calibration and Zeroing

The Optical Signal Test Set is designed to be self calibrating using a few simple steps listed below.

Calibration is performed at the factory and all parameters are stored in the unit, therefore calibration

only needs to be performed periodically or if the measurement accuracy is in question. Each step is

dependent on the previous and should be executed in the order shown below. The calibration

controls are displayed in the correct order from left to right in the application. The optical components

are wavelength sensitive; therefore the calibration will only be accurate for the wavelength used

during calibration.

Calibrate OPM1/2

The power meters(s) are calibrated against a known power level

1. Connect a stable source of known power to the power meter 1/2 input.

2. Enter the known optical power level in the “Actual Cal Power” box.

3. Press the “Calibrate OPM1/2” button. The power meter should now read the same value

entered in the box.

Laser Zero

The laser is automatically adjusted for a maximum output power of 0dBm.

1. Connect the laser output to the OPM1 input using a 0dB loopback cable.

2. Execute the “Zero Laser” command from the advanced screen. This takes only several

seconds to complete.

Optical Signal Test Set

User’s Manual 2023-02-17

100529A. 100560A

Page 5 of 6 www.spectronixinc.com

Calibrate VOA

This procedure measures the minimum insertion loss and calibrates the VOA in 0.1dB steps. The

entire procedure takes less then ten minutes to complete. When finished the VOA dial will reflect the

minimum VOA insertion loss and maximum usable range. The laser must already be zeroed.

1. Connect the laser output to the VOA input and the VOA output to OPM1 using cables with

minimal loss.

2. Press the “Calibrate VOA” button on the advanced screen. A “Calibration” message and

status will appear on the screen during calibration. This can take up to 30 minutes to

complete.

Low Power OPM Calibration

The power meter exhibits very accurate law conformance to about -85dBm; below this level

calibration is used to correct errors in law conformance. During calibration the VOA attenuation is

automatically varied from minimum insertion loss through its useable range in 1dB steps. At each

step, the measured value along with the actual power level is recorded and stored. This table is then

used to correct all subsequent measurements within this power range. Calibration accuracy is

dependent on the accuracy of the VOA calibration.

1. Set the VOA for minimum loss.

2. Connect a stable optical source (laser output) to the VOA input and the VOA output to the

power meter input using external attenuators so that the power meter reads between -80 and -

75dBm. Due to the large amount of attenuation and the low power levels, it’s suggested to

split the attenuation equally between the four ports.

3. Due to the high sensitivity of the OPM, the OSTS and all optical connections should be placed

in a dark box or low ambient light environment to ensure stray light does not effect the

calibration.

4. Execute the “Calibrate OPM” command from the advanced screen. A “Calibration” message

and status will appear on the screen during calibration. Calibration typically takes about 60

seconds to complete. The OSTS should be power cycled after calibration.

An automated VOA sweep utility and calibration read function can be found under the factory controls

section by pressing the gear wheel when the advanced controls are exposed. These utilities can be

useful for characterizing performance and calibration.

Ethernet (Dual OEM version)

The dual OEM CCA comes supplied with a Lantronix XPort Pro Ethernet interface which can be used

for communication instead of the USB port. The device IP and MAC address can be read from the

USB port using the “Read IP” button. This command takes about 5 seconds to execute, after which

the XPort interface is automatically rebooted.

The IP address can be changed over USB or Ethernet by entering the desired IP address in the dialog

box under “IP Address” and pressing the “Set” button. This command takes about 10 seconds to

execute, after which the XPort interface is automatically rebooted. After reboot is complete (~15

seconds), the device should be power cycled for the changes to take effect.

Alternatively the XPort interface can be configured using the embedded web page. The default login

credentials are: user name: “admin”, password: “PASSWORD”. Care should be taken when

modifying settings other than the IP address.

Optical Signal Test Set

User’s Manual 2023-02-17

100529A. 100560A

Page 6 of 6 www.spectronixinc.com

Should the configuration options become corrupt the factory default configuration can be recovered by

executing the “Factory Reset XPort” button. The button can be found by first exposing the advanced

options screen (down button), then pressing the gear button. The factory default IP address is

192.168.1.160 port 2101. Alternatively the Lantronix provisioning manager can be used to discover

connected devices. Vendor documentation can be found at https://docs.lantronix.com/products/xport-

edge/ug/5.1/

USB Driver:

In order for some versions of Windows to recognize the device the USB driver must first be installed,

after which the unit appears as an additional COM port on the computer. Currently Windows XP,

Vista, and 7, 8, and 10 are supported.

1. Copy the file “cdc_NTXPV764.inf” from the supplied CD to the hard drive.

2. Plug the device into a free USB port. When the hardware installation wizard asks for the driver

location, browse to the “cdc_NTXPVista.inf” file on the hard drive.

3. After the driver has been installed right click “my computer” and select “properties”. In the

properties window select the “hardware” tab. Click on “device manager” and expand the

“Ports (COM & LPT)” item. Locate the “Spectronix, Inc.” entry and note the assigned COM

number, (ie “COM4”). This is the COM port that the software will use to communicate with the

device.

Note, on some operating systems such as Window 7, manual USB driver installation may be

necessary. If the hardware installation wizard fails, go to “My Computer” > “Properties” > “Hardware”

> “Device Manager”, and find the “Spectronix” or “SERIAL DEMO” entry under “Other Devices” and

select “Update Driver”. At this point you will be able to browse to the location of the driver.

Notes and Precautions

•The maximum input power on any port is +10dBm. Levels above this value may damage

the device.

•Due to the very low leakage of the photodetector, when powering up the device with little

or no power on the power meter port, the device may initially take several seconds to

register an accurate reading while the circuitry stabilizes. Applying a signal above -70dBm

will immediately stabilize the readings.

•Small amounts of light can leak through fiber jackets and into connectors and components

affecting power readings at very low power levels. Care should be taken to minimize

leakage by utilizing light shielding when possible.

•For the dual OEM CCA version, see data sheet for notes on shielding.

LOV and Clearing Procedure

The OSTS contains both volatile and nonvolatile memory. The application processor only stores

calibration data generated internally, therefore there is no clearing procedure for this.

The Lantronix XPort Edge used in the OEM version is capable of storing user files and network

configuration data. Executing the “Factory Reset XPort” command will reset the configuration back to

the factory default and will also format the XPort flash file system. Additional Information regarding

memory and formatting can be found on the Lantronix website.

This manual suits for next models

1

Table of contents

Other Spectronix Test Equipment manuals