Rapid Oil Test Gauge

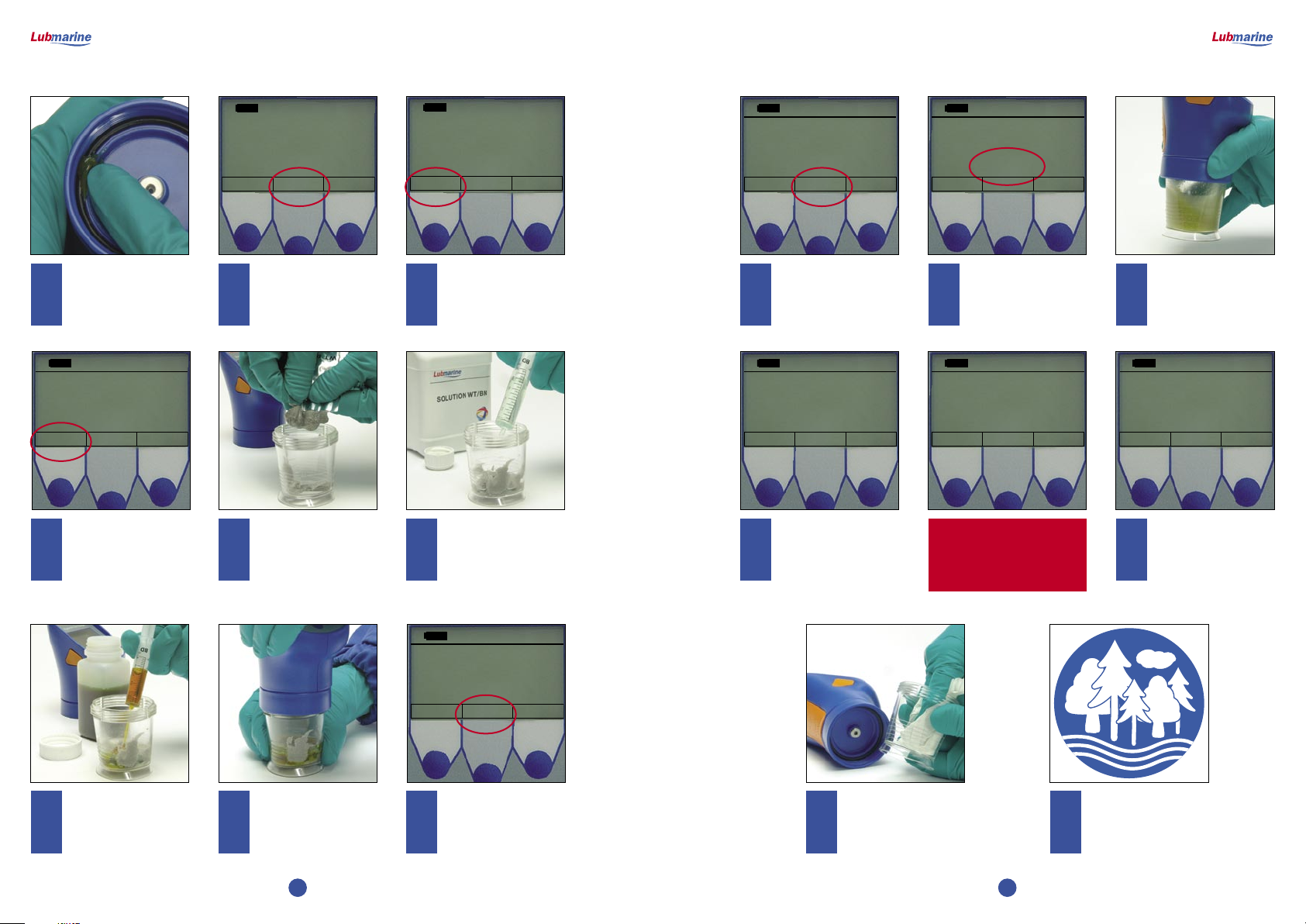

Operating the Rapid Oil Test Gauge

12

It is recommended to grease from time to

time the internal O’ring using silicon free

grease p/n DP6108.

In order to ensure the accuracy of subsequent tests and to preserve the instrument over time, the Rapid Oil Test Gauge shall always be kept

clean and dry :

The battery compartment cap and USB

port cap shall be kept in place at all

times in order to protect the internal

electronics of the instrument.

Any trace of oil, solutions or reagents

shall be removed from the gauge and

reaction flask after each use. Special

attention shall be paid to the measuring

port which must be kept perfectly free,

and to the internal O’ring.

Use dedicated cleaning fabric or

absorbing paper for cleaning purpose.

Proper cleaning solvents include White

Spirit or Petroleum Distillates p/n DP9206.

Never use toluene or other benzene

derivatives.

7. Preserving the Rapid Oil Test Gauge

The Lubmarine Rapid Oil Test Gauge was designed for maintenance free operation.

No maintenance is required apart from:

• Keeping the instrument clean with its O’ring greased as described in §7.

• Replacing the battery when necessary.

• If required by your quality assurance system: recalibrating the instrument at regular intervals.

8. Maintenance

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

13

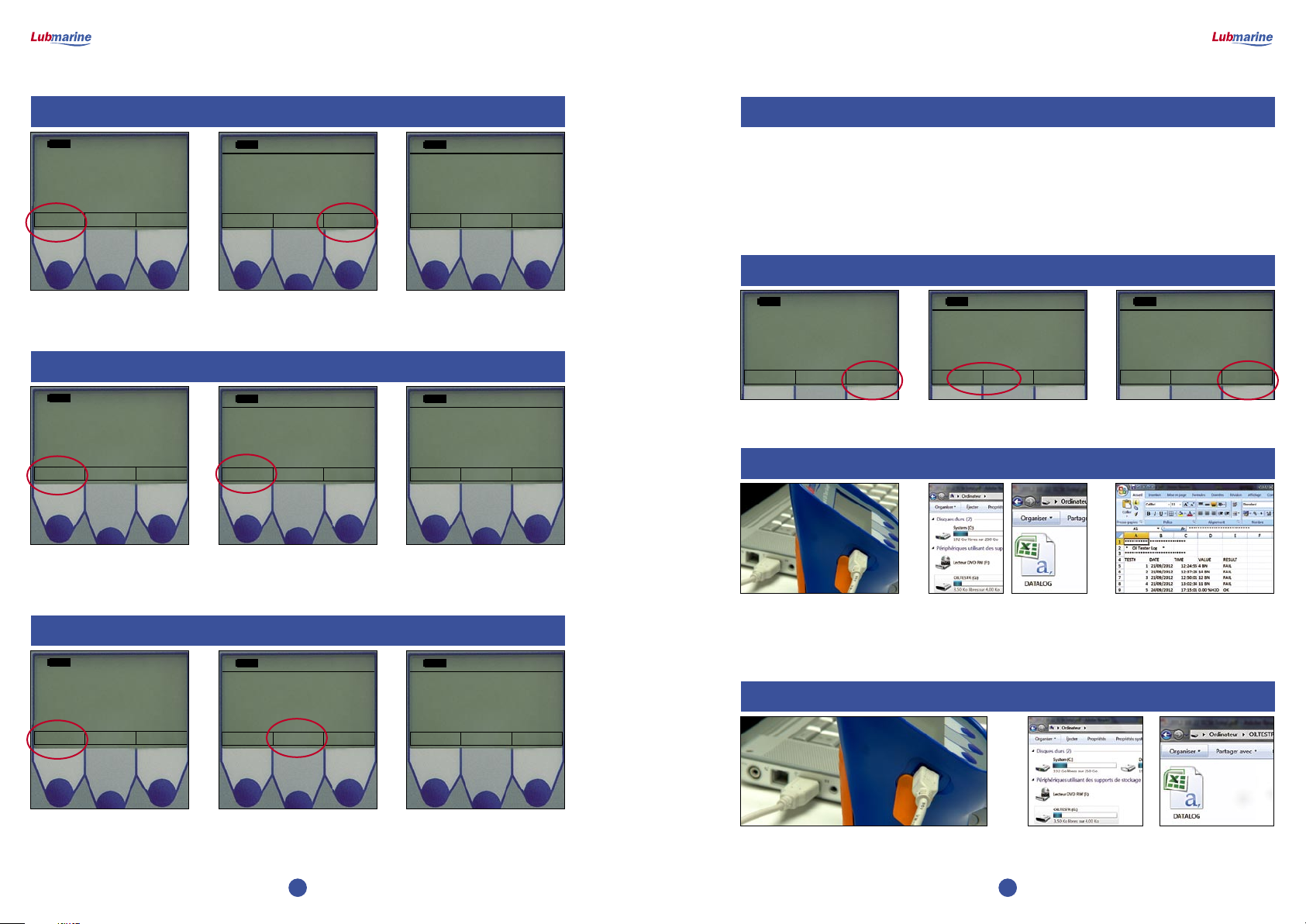

5 - The year is displayed.

Press the [▲] key to increment the year.

Press the [▼] key to decrement the year.

Press [Next] when done.

Press any of the 3 front panel keys to turn

the Rapid Oil Test Gauge on.

The instrument initializes and displays its

serial number and embedded software

version for a few seconds.

The instrument then displays the Main

Run Screen which offers three functions:

[Conf], [Test] and [Hist]

Press the key corresponding to the

function you want to run:

Select [Conf] to adjust the internal clock

and the oil monitoring function of your

instrument

Select [Test] to run a water test or a BN

test (optional)

Select [Hist] to view the test history

Refer to the appropriate section of this

manual for details on each function.

The instrument turns off automatically

if not used for 60 seconds in order to

preserve battery life.

Note: When first powered on after

the battery has been replaced, the

instrument accesses automatically

the clock adjustment function.

The Rapid Oil Test Gauge has an internal clock which is used to time stamp test results when they are stored in the instrument memory.

To adjust the internal clock:

6 - Adjust the month and press [Next]

when done.

7 - Adjust the day and press [Next] when

done.

8 - Adjust the hour and press [Next]

when done.

9 - Adjust the minutes and press [Save]

to store the data and return to the main

run screen.

1 - Press any of the 3 front panel keys to

turn the Rapid Oil Test Gauge on.

2 - Press the [Conf] key.

3 - Press the [Other] key.

4 - Press the [Time] key.

2 Adjusting the internal clock

1 Power on / Main run screen / Power off

The Lubmarine Rapid Oil Test Gauge has an oil monitoring function which can warn the operator in case of:

- Excessive water in oil content

- Insufficient oil alkaline reserve (low BN)*

If the function is On, the water in oil content or the BN value* is evaluated at the end of each test and the instrument shows if the test result is

acceptable or not. The information is also stored in the instrument memory with the test result.

The default settings of the function are:

- Function status: Off

- Water content alarm set to 1.5 %H2O

- BN alarm* set to 1 BN

(* The BN monitoring function is available only for Lubmarine

Rapid Oil Test Gauges having the BN Test option).

3 Oil Monitoring Function

Note:

When first powered on after the battery has been replaced, the instrument accesses automatically the clock adjustment function.